Hydraulic unit, castor assembly and container moving device and method

A hydraulic unit and container technology, applied in fluid pressure actuating devices, servo motor components, packaging, etc., can solve the problems of unsuitable container moving devices, occupancy of yoke frame 3 and frame 7, potential safety hazards, etc., and achieve space improvement The effect of utilization rate, compact structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

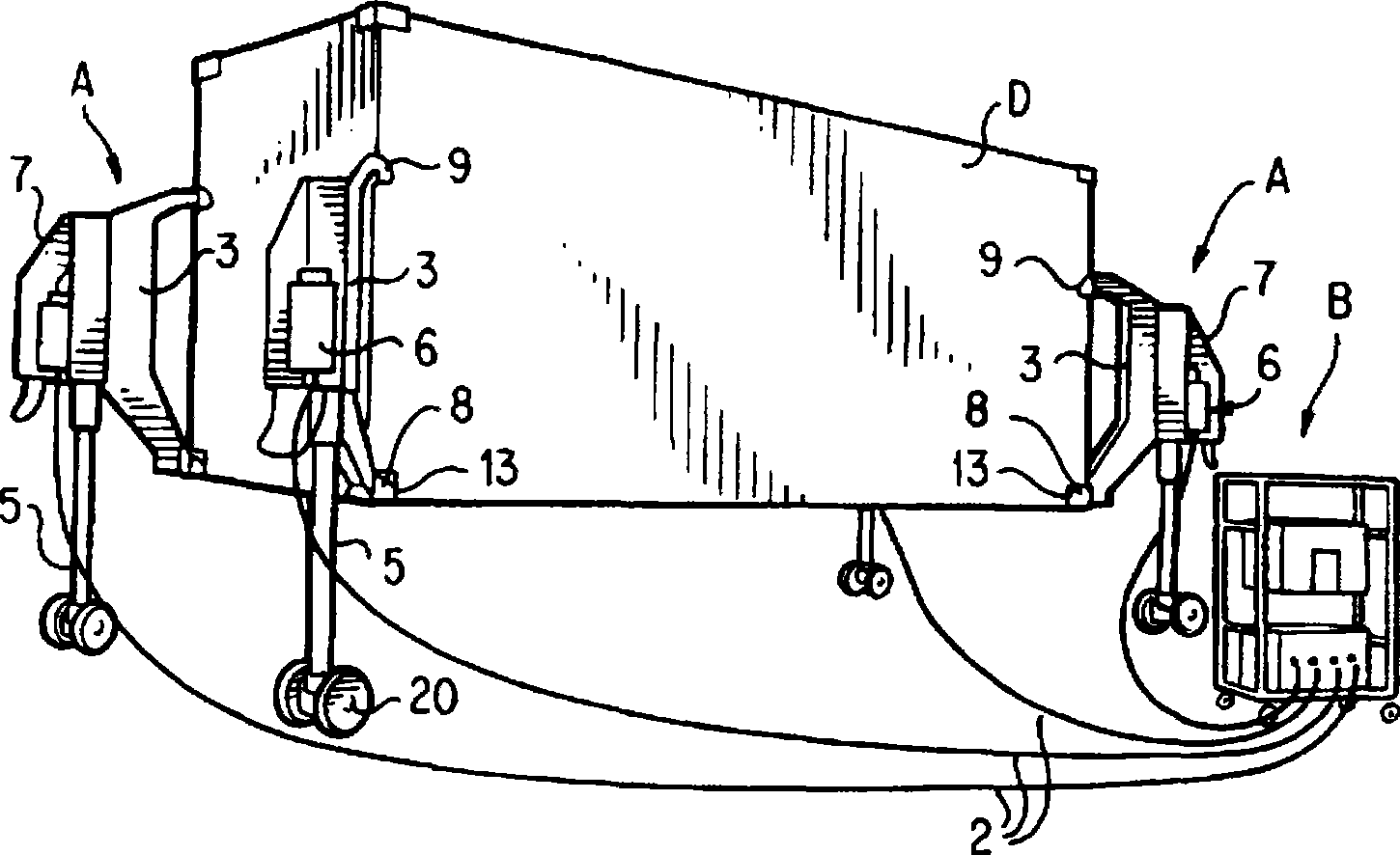

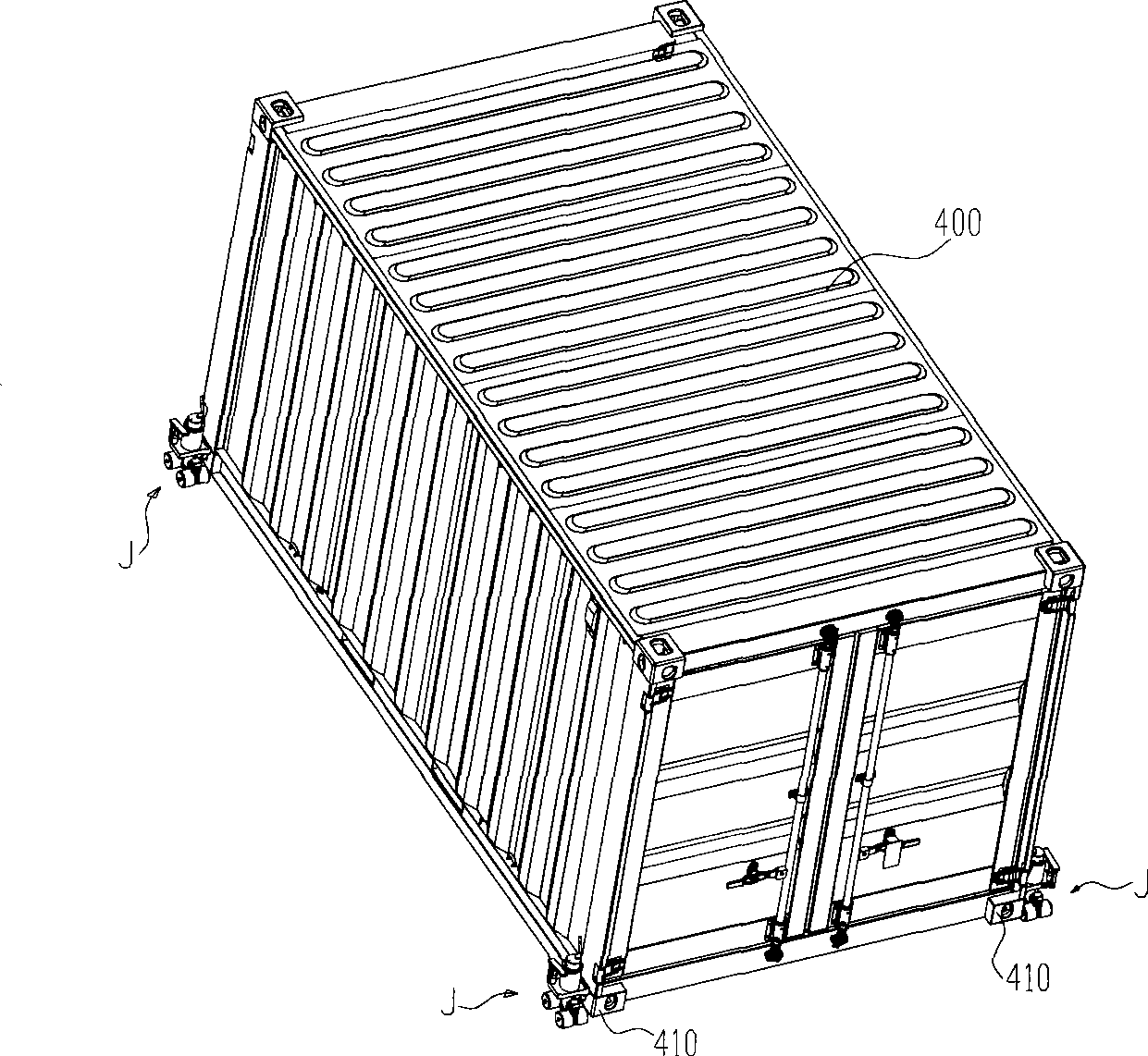

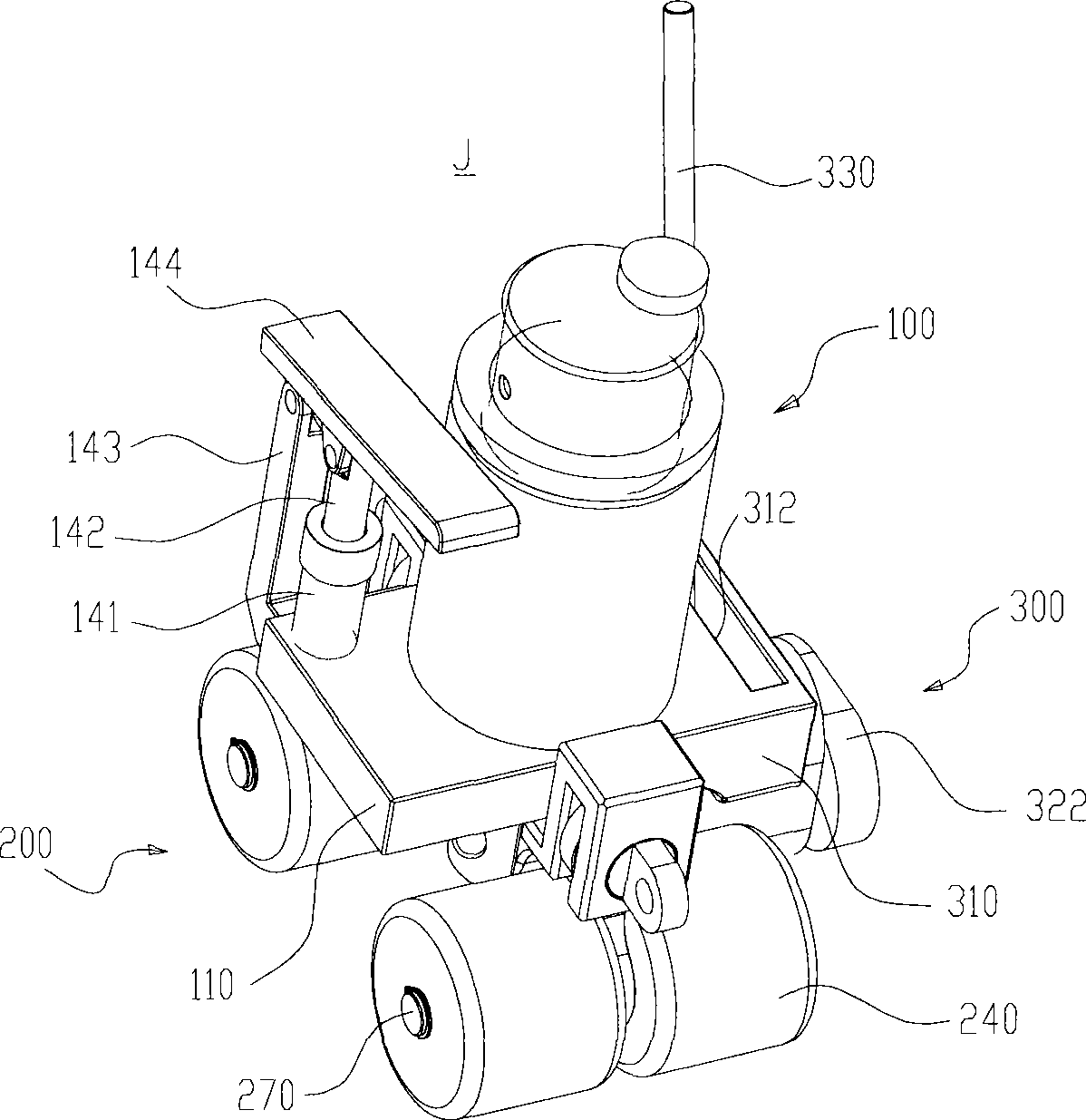

[0032] like figure 2 As shown, the container moving device of the present invention includes four caster assemblies J. Each caster assembly J can be connected to a bottom corner piece 410 of the container 400 respectively. like image 3 As shown, each caster assembly J includes a hydraulic unit 100, a traveling unit 200 for moving, and a positioning tightening mechanism 300 for cooperating with the bottom corner fittings of the container.

[0033] like Figure 3-11 As shown, the hydraulic unit 100 includes a hydraulic mechanism 120 , an oil tank 130 and a foot pump 140 respectively disposed on the support base 110 . Wherein, the pump body 141 of the pedal pump 140 communicates with the oil cylinder 121 of the hydraulic mechanism through the oil supply circuit, and the oil supply check valve 50 is arranged in the oil supply circuit, so that the hydraulic oil can only flow from the pump body one-way. 141 flows to the oil cylinder 121; the oil tank 130 communicates with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com