Novel large-lifted-weight high-safety tower crane for counterweight balance mechanism and reforming and upgrading of tower crane

A technology of counterweight balance and tower crane, which is applied in the direction of cranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] make the object of the present invention and the new type The advantages of the tower crane and the technical solution for upgrading the tower crane are simpler and more obvious. The following will be further described in detail in combination with specific examples:

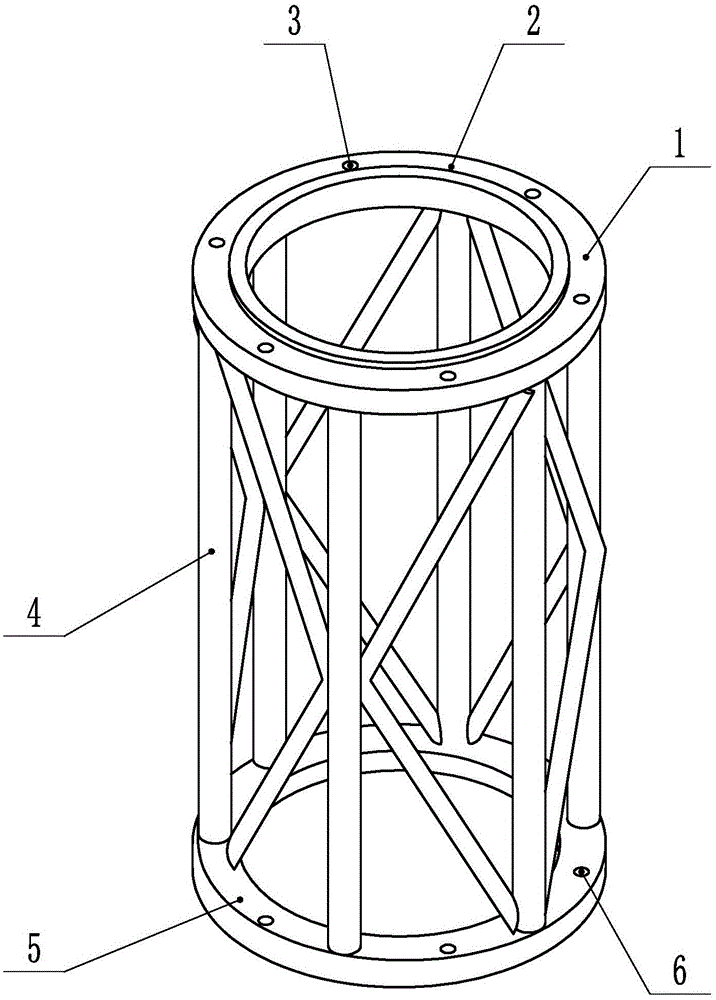

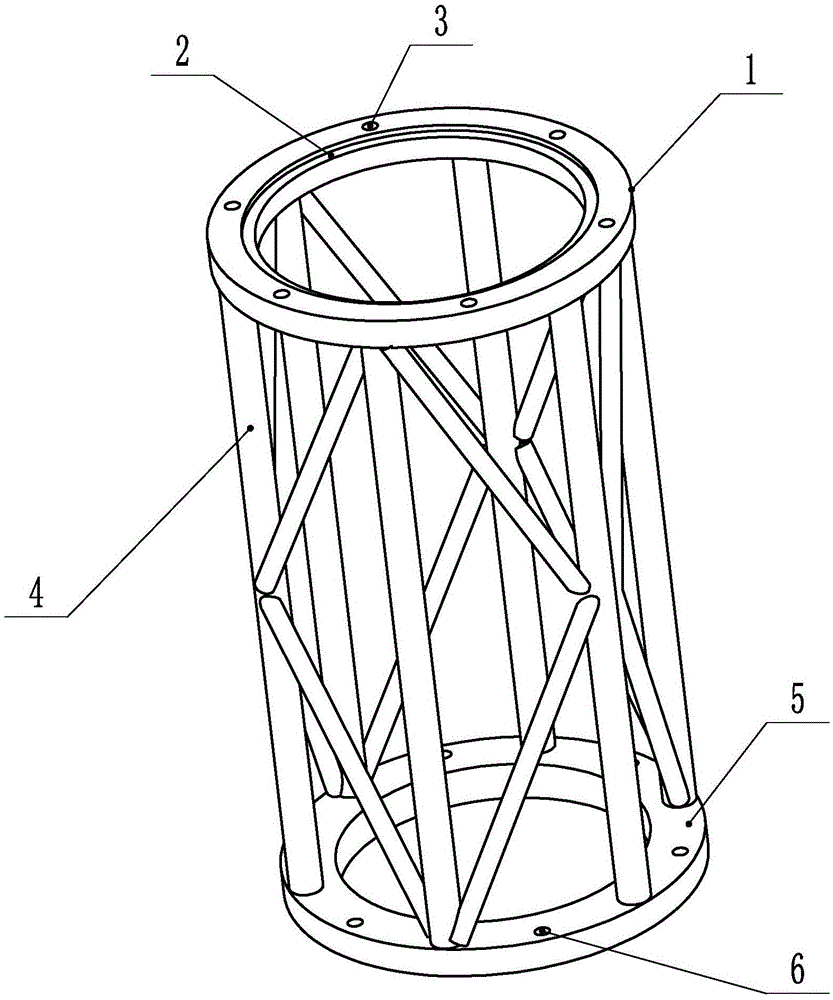

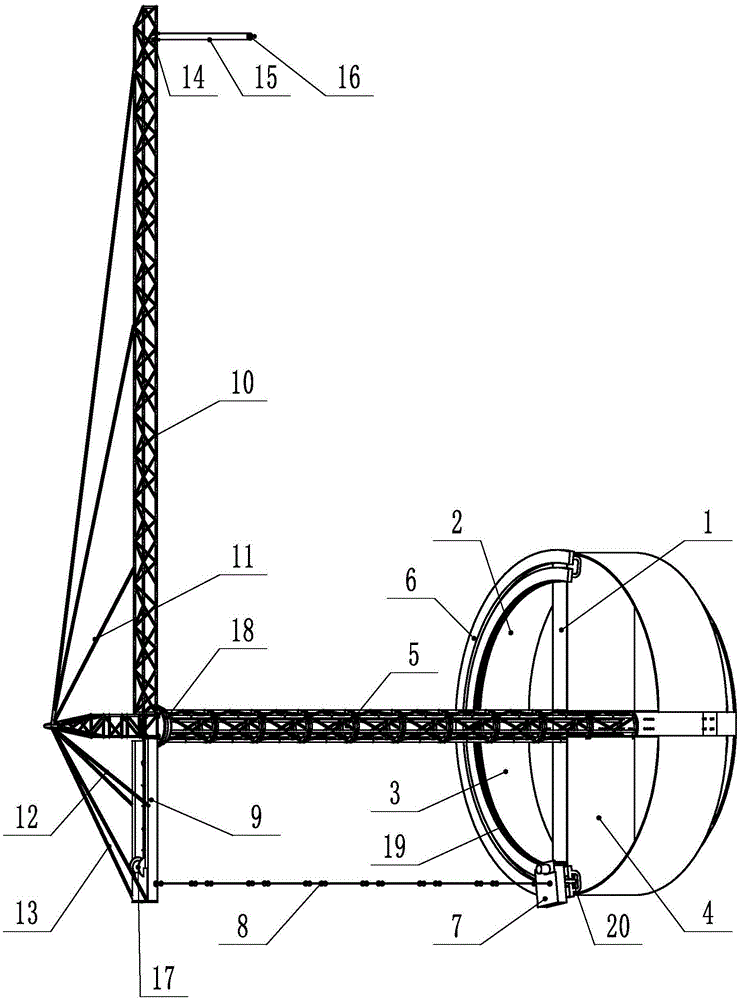

[0024] Such as figure 1 Examples Figure Institute Show: it is the present invention new type The upper flange of one of the tower body frames of the tower crane body (such as figure 1 Mark 1 in ), convex outer straight mouth ( Such as figure 1 Mark 2) in the flange bolt holes ( Such as figure 1 Mark 3 in ), the seamless steel pipe support column ( Such as figure 1 Mark 4 in ), the lower end method (such as the mark 5 in 1), the bolt hole of the lower end method ( Such as figure 1 The identity in 6) is composed.

[0025] Such as figure 1 Examples Figure Institute Show: yes new type The lower end of one section of the tower body of the cylindrical tower crane is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com