Vertical injection molding device

An injection molding device and injection device technology, applied in the field of vertical injection molding devices, can solve problems such as extended delivery time, increased handling costs, and increased adjustment costs, and achieve simple reassembly, reduced handling costs, and elimination of height restrictions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Embodiments of the present invention will be described below based on the drawings.

[0080] 【Example】

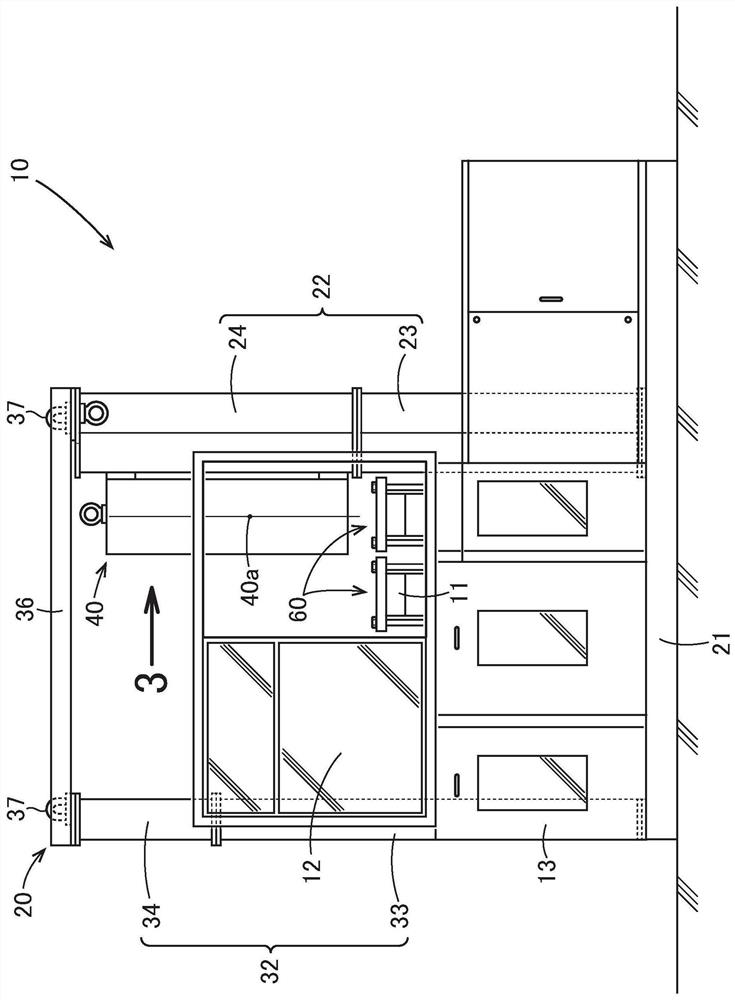

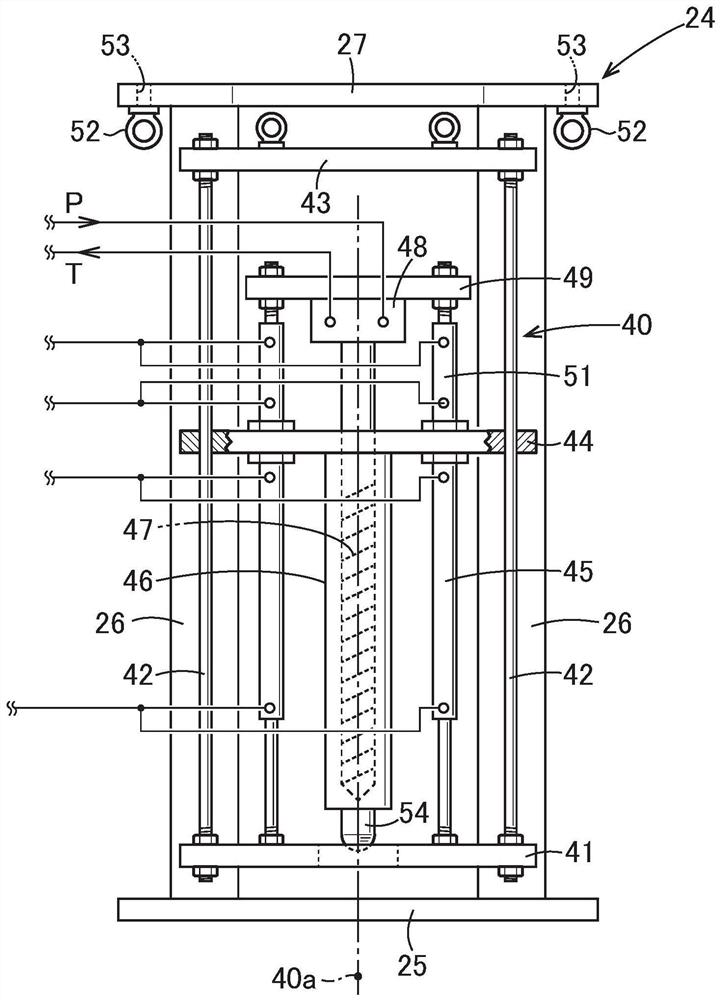

[0081] Such as figure 1 As shown, the vertical injection molding device 10 includes a mold 11, a mold clamping device 60 for opening and closing the mold 11, and an injection device 40 arranged on (above) the mold clamping device 60 with the injection axis 40a vertical. as the main element. In this example, there are a plurality of mold clamping devices 60 , but one mold clamping device 60 may be used.

[0082] The vertical injection molding device 10 is appropriately covered by a safety door 12 and a safety cover 13 .

[0083] The mold clamping device 60 and the injection device 40 are surrounded by the device frame 20 and supported by the device frame 20 .

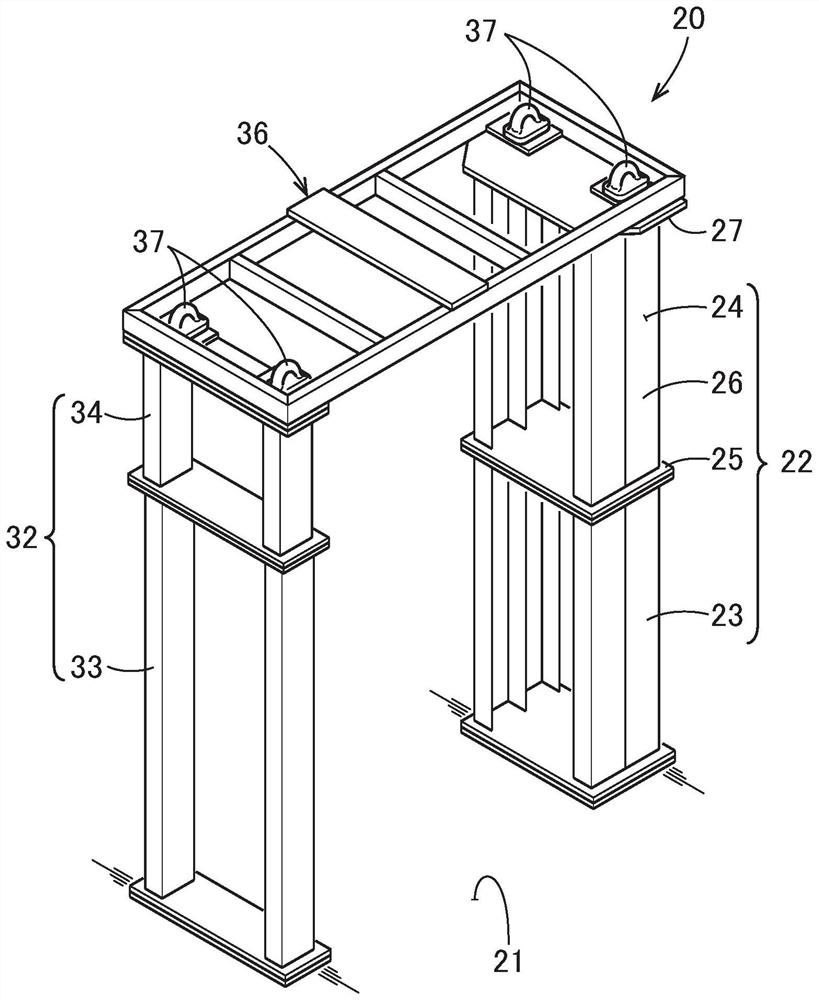

[0084] The device frame 20 includes a base frame 21 , a first support 22 and a second support 32 standing from the base frame 21 , and a top beam 36 connecting the upper end of the first support 22 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com