Nuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method

A disassembly method and technology for nuclear power plants, which are applied to hand-held tools, manufacturing tools, non-variable-capacity pumps, etc., can solve the problems of re-disassembly workload and manpower waste, inconvenient horizontal disassembly and hoisting, and difficult to control. , to achieve the effect of reducing the risk of repeated maintenance, simplifying the measurement of rotor channeling, and reducing the risk of equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

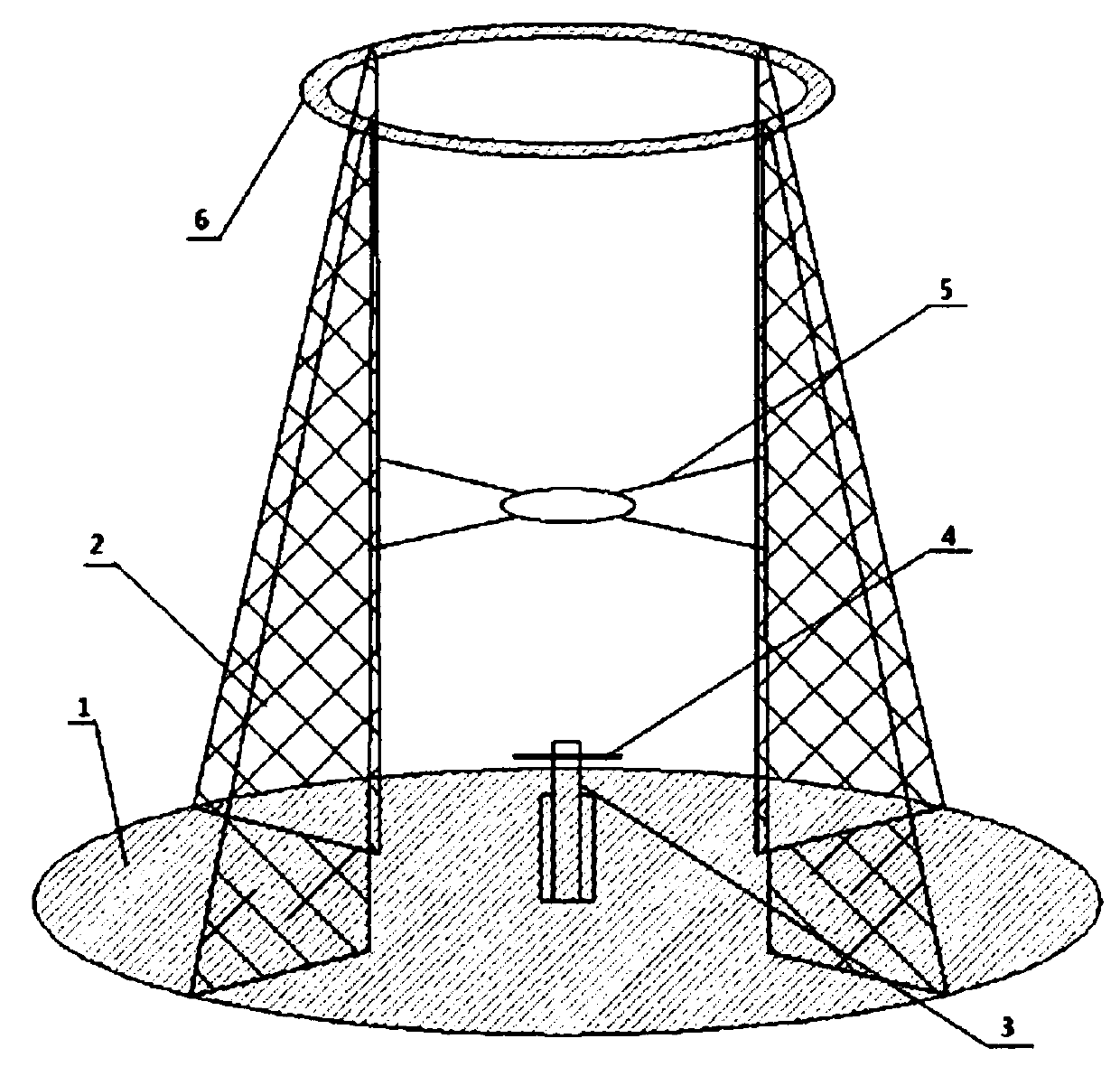

[0064] Such as figure 1 A nuclear power plant horizontal multi-stage centrifugal pump core package removal tool shown includes a bottom plate 1, a support rib plate 2, a top nail 3, a handle 4, a middle support seat 5, and an upper support ring 6.

[0065] The bottom plate 1 is a circular plate, a cylinder is welded at its center, and an internal thread is processed on the inner wall of the cylinder. The top nail 3 is screwed into the cylinder on the base plate 1, and the handle 4 is welded on the top of the top nail 3, and the lifting of the top nail 3 is adjusted by rotating the handle 4, thereby adjusting the height of the rotor of the pump.

[0066] There are four supporting ribs 2, all of which are right-angled trapezoidal plates, and are fixed on the base plate 1 at intervals of 90°.

[0067] The middle supporting seat 5 is a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com