Patents

Literature

31results about How to "Remarkable cost reduction and efficiency increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

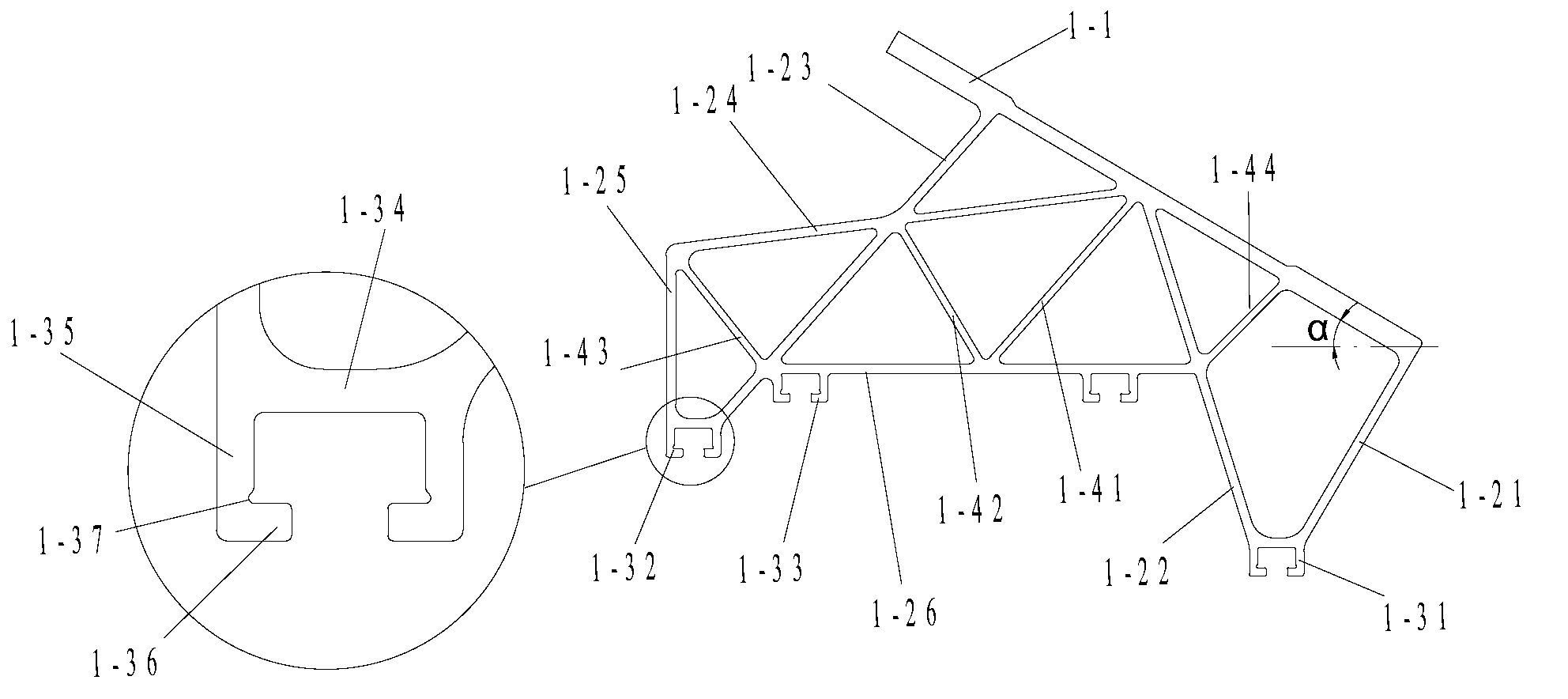

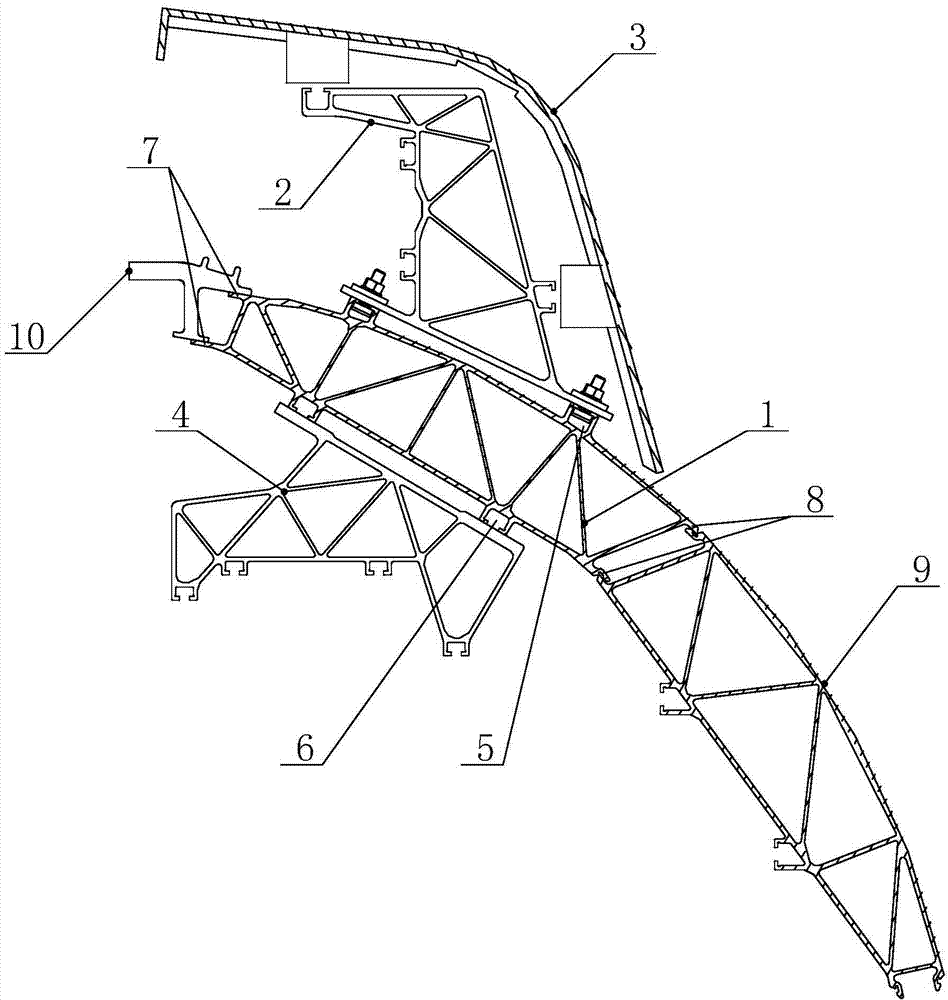

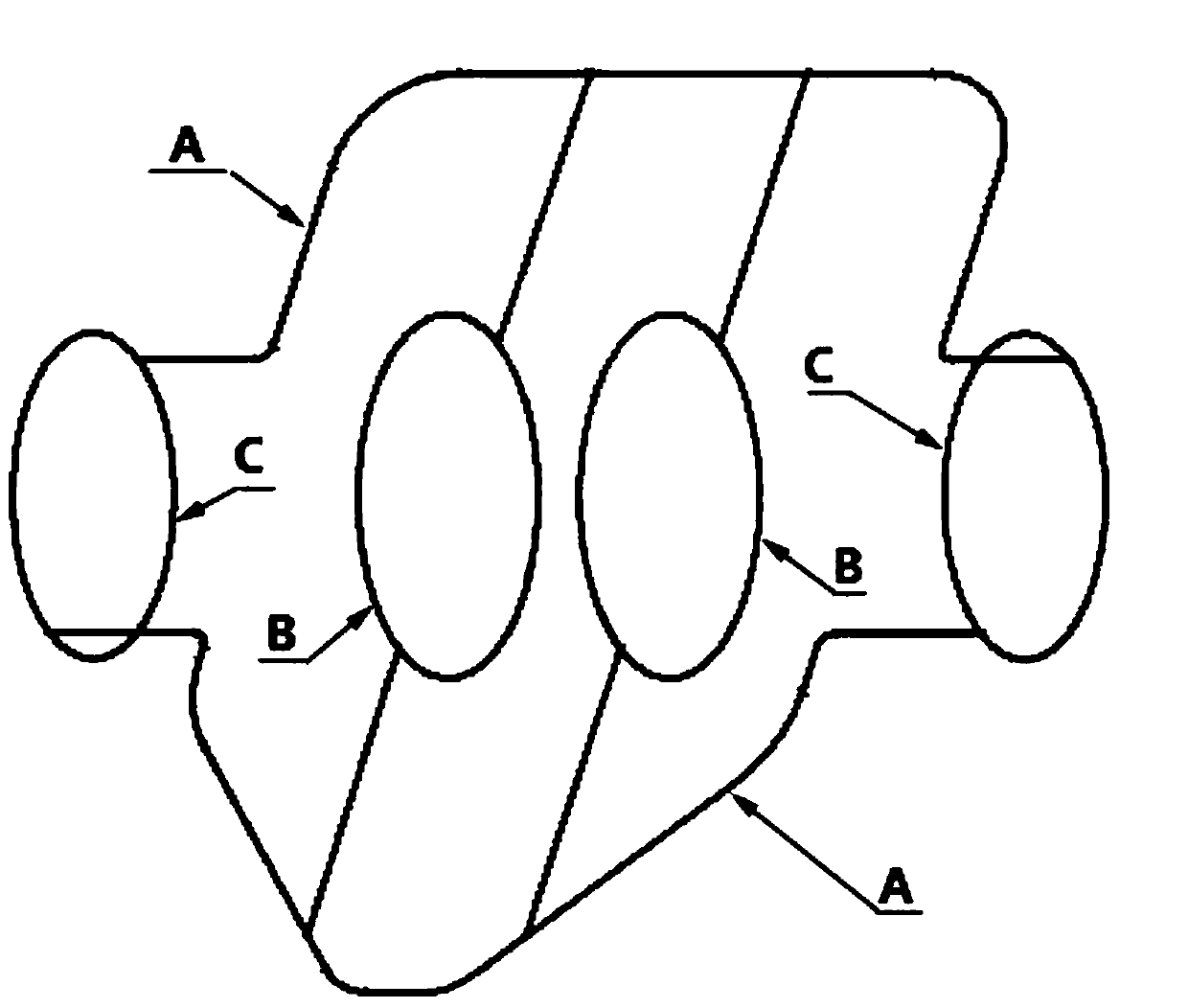

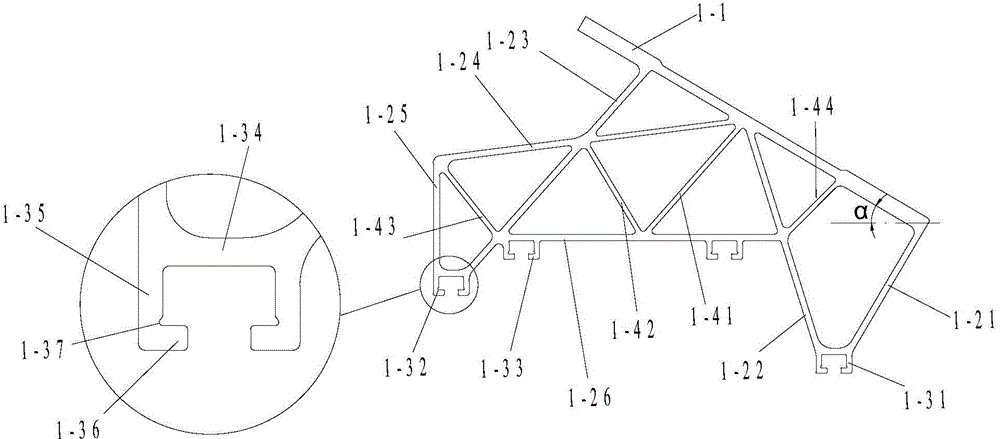

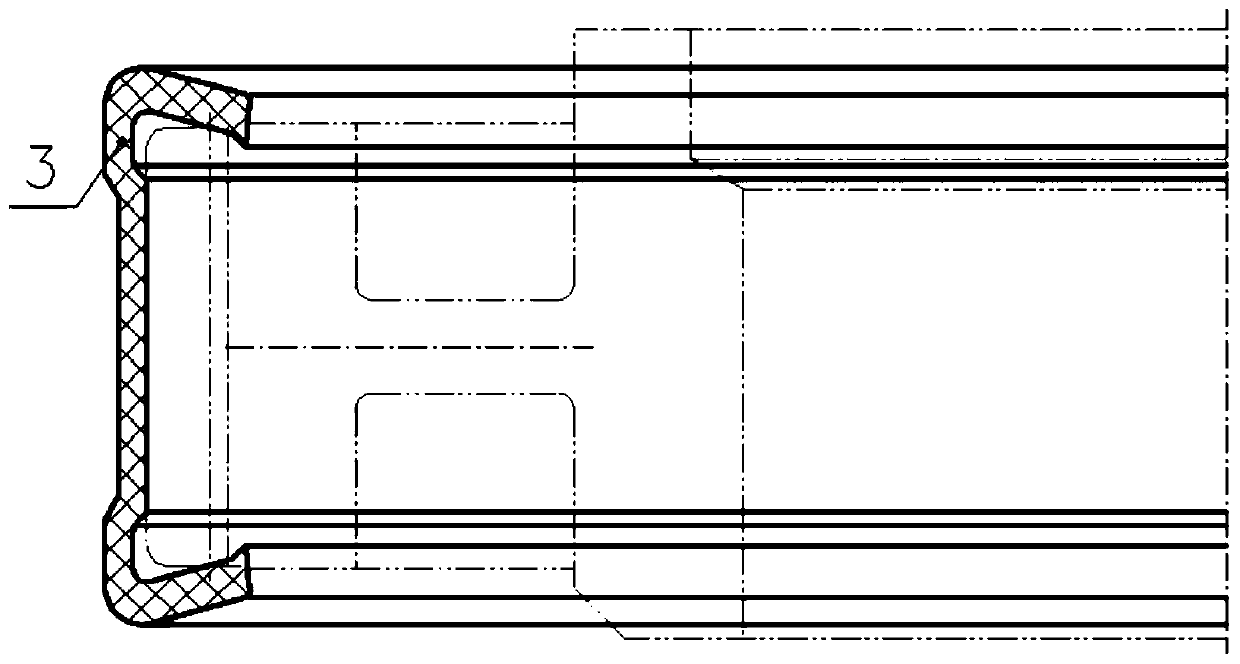

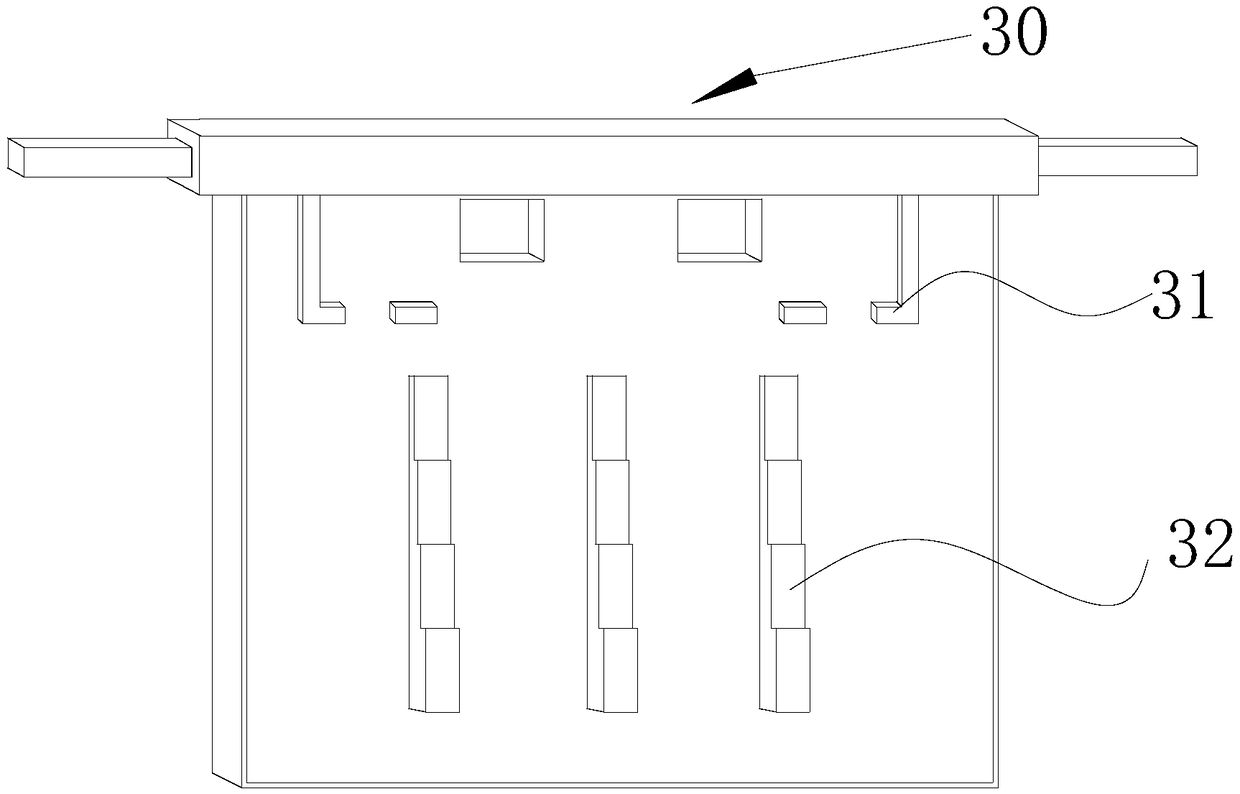

Multifunctional built-in hanging arm

The invention relates to a multifunctional built-in hanging arm which is a strip profile, wherein a bevel edge is arranged on the section of the profile; a first flange extends out of the low end of the bevel edge; a second flange extends out of the middle part of the bevel edge; the tail end of the first flange is fixedly connected with the tail end of the second flange by a first C-shaped groove; a third flange extends out, close to the high end, of the bevel edge; a fourth flange extends out of a connecting part between the middle part of the bevel edge and the second flange; the middle upper part of the third flange is intersected with the middle part of the fourth flange; a fifth flange extends out of the tail end of the fourth flange; the tail end of the third flange is fixedly connected with the tail end of the fifth flange by a second C-shaped groove; the hanging arm further comprises a horizontal sixth flange; at least two third C-shaped grooves are formed on the lower side of the sixth flange; openings of the first C-shaped groove, the second C-shaped groove and the third C-shaped grooves are vertically downward; the third C-shaped grooves are higher than the second C-shaped groove; and the second C-shaped groove is higher than the first C-shaped groove. The hanging arm can mount various built-in components at the top of a coach simultaneously, is high in integration level, improves the mounting efficiency and reduces the weight of the coach.

Owner:CHINA RAILWAYS CORPORATION +1

Digital antiskid inkjet ink, preparation method thereof, and preparation method of digital antiskid ceramic tile

ActiveCN111362728AEasy to implementAnti-slip coefficient controllableClaywaresActive agentSURFACTANT BLEND

The invention relates to a digital antiskid inkjet ink, a preparation method thereof, and a preparation method of a digital antiskid ceramic tile. The digital antiskid inkjet ink comprises a digital antiskid inkjet ink A and a digital antiskid inkjet ink B. The digital antiskid inkjet ink A comprises the following raw materials in parts by weight: 40-48 parts of antiskid glaze; 0-25 parts of calcined alumina; 62 to 70 parts of a solvent; 6-9 parts of a dispersant; 16 to 22 parts of a surfactant; 1-4 parts of a defoaming agent; and 3-7 parts of an acidity regulator; and the digital antiskid inkjet ink B comprises the following raw materials in parts by weight: 5-20 parts of calcined alumina; 62 to 70 parts of a solvent; 6-9 parts of a dispersant; 16 to 22 parts of a surfactant; 1-4 parts ofa defoaming agent; and 3-7 parts of an acidity regulator.

Owner:GUANGDONG JIA MEI CERAMIC +4

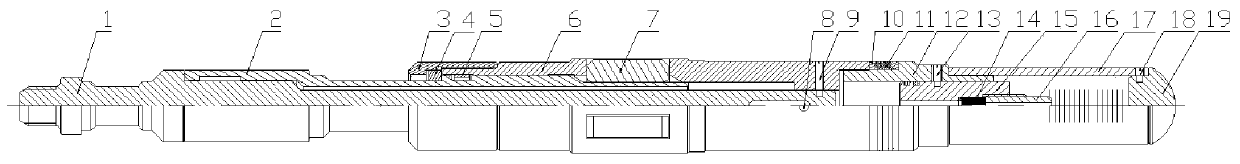

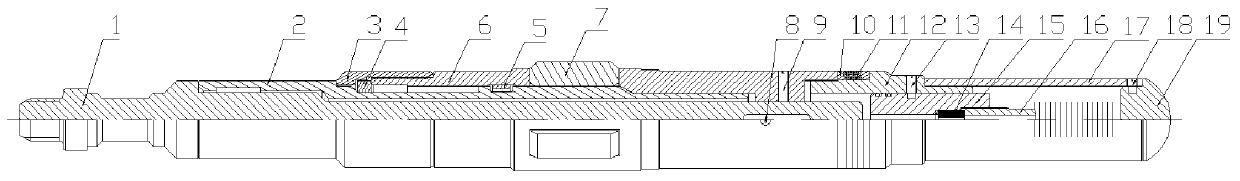

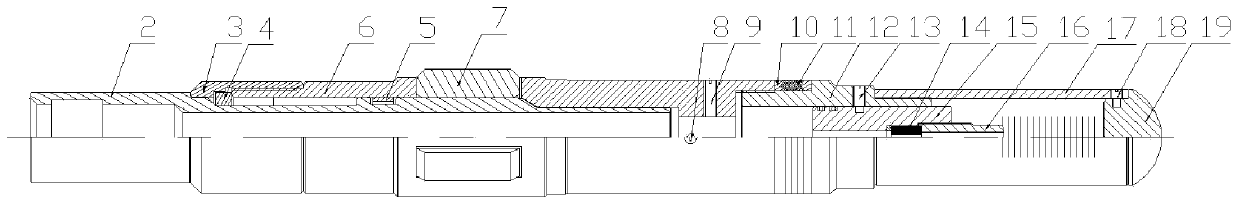

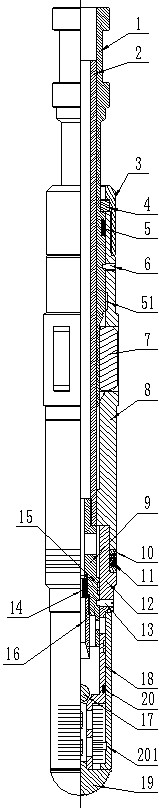

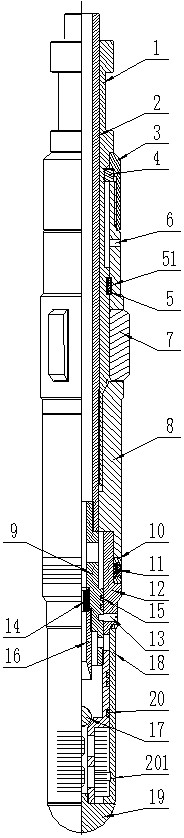

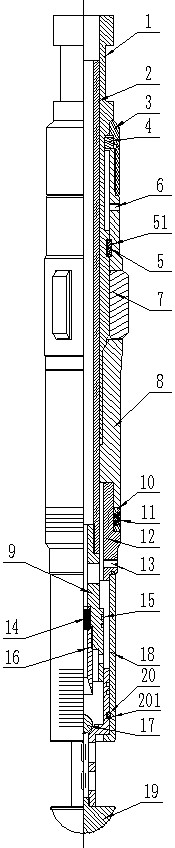

Gas well full-life-cycle downhole throttling production device and using method thereof

PendingCN111075407AImprove delivery success rateHigh hardnessFluid removalProcess engineeringEnvironmental geology

The invention discloses a gas well full-life-cycle downhole throttling production device and a using method thereof. The gas well full-life-cycle downhole throttling production device comprises a dispenser and a downhole throttle; the lower end of the dispenser is provided with two symmetric strip-shaped grooves, and the dispenser and the downhole throttle are fixedly connected together through apin. The gas well full-life-cycle downhole throttling production device adopts a special material V-shaped sealing ring to form self-sealing seal, and the dispensing success rate is high; the sealingsurface is short and high in hardness, releasing force is small during salvaging, and the salvage success rate is high; and meanwhile, the gas well full-life-cycle downhole throttling production device has the effects that during salvage failure, a large channel is formed by knocking off a gas nozzle, and smooth implementation of a drainage gas extraction process of a gas well in the middle and later periods is not affected, the gas well full-life-cycle downhole throttling production device is simple in structure, on-site operation is convenient, and cost reduction and efficiency increasing are significant.

Owner:PETROCHINA CO LTD

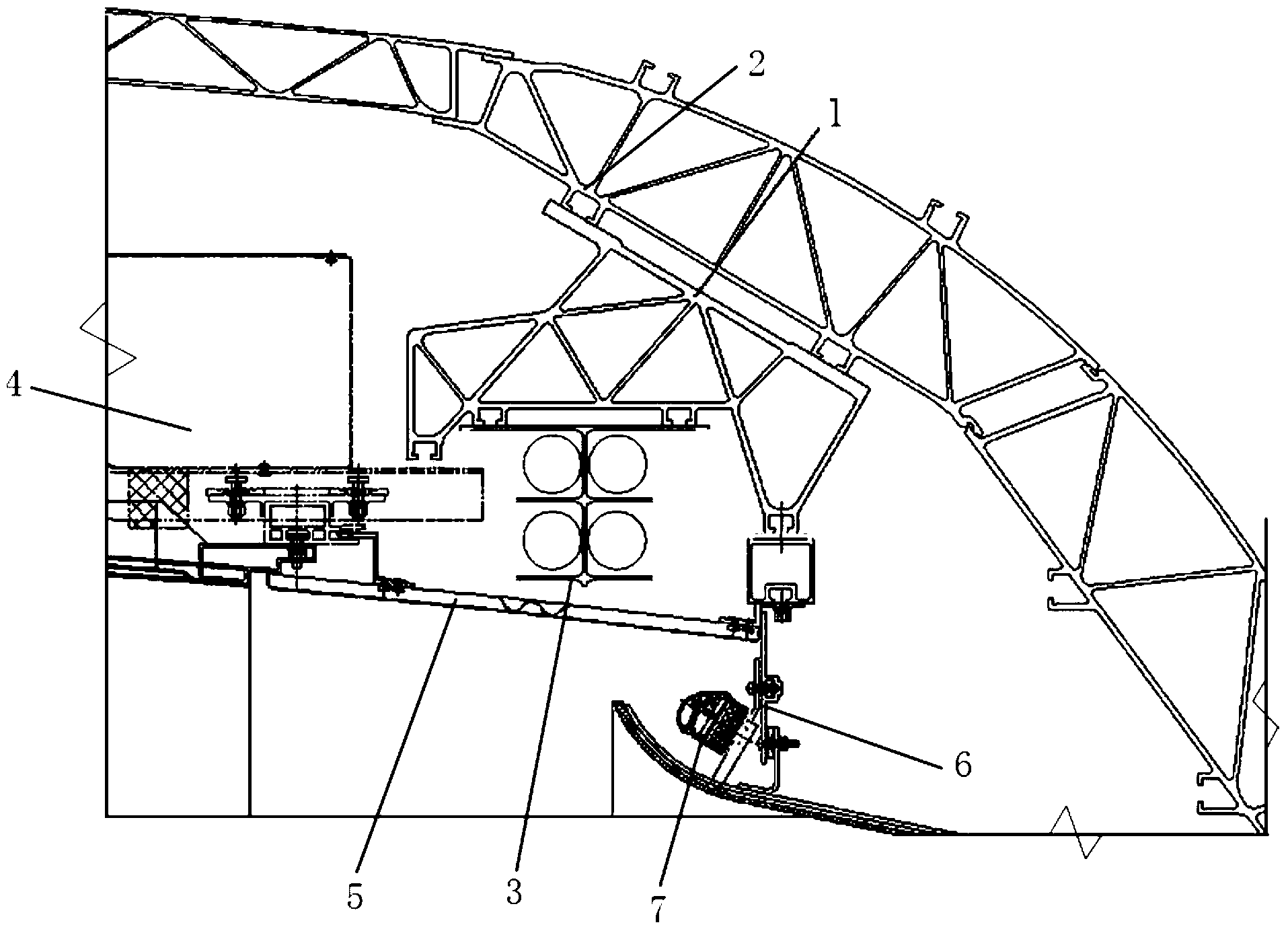

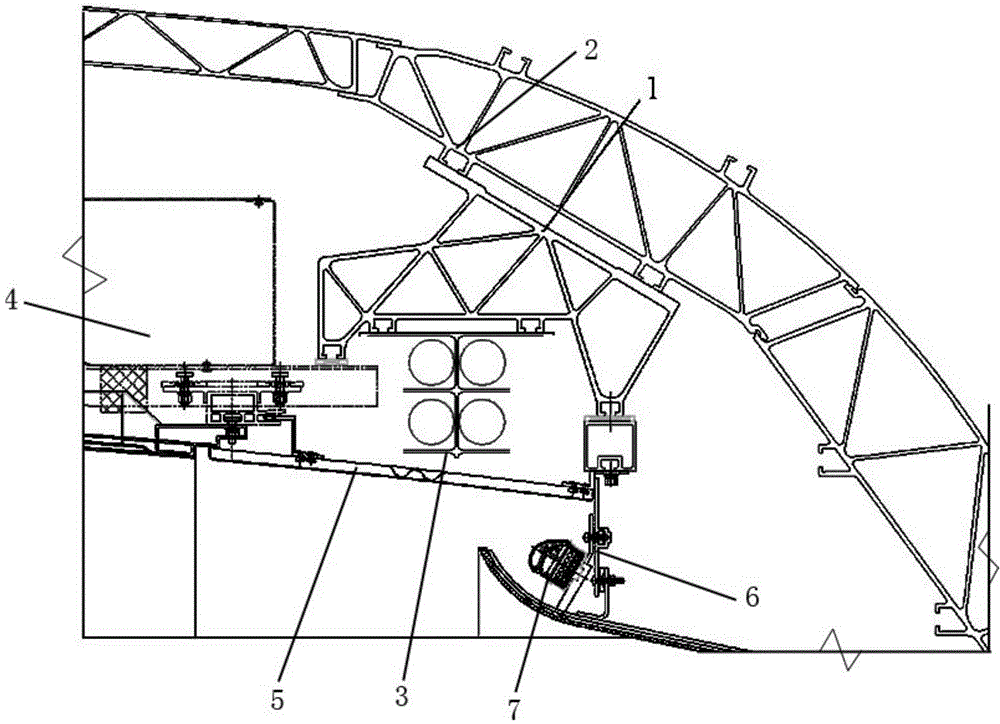

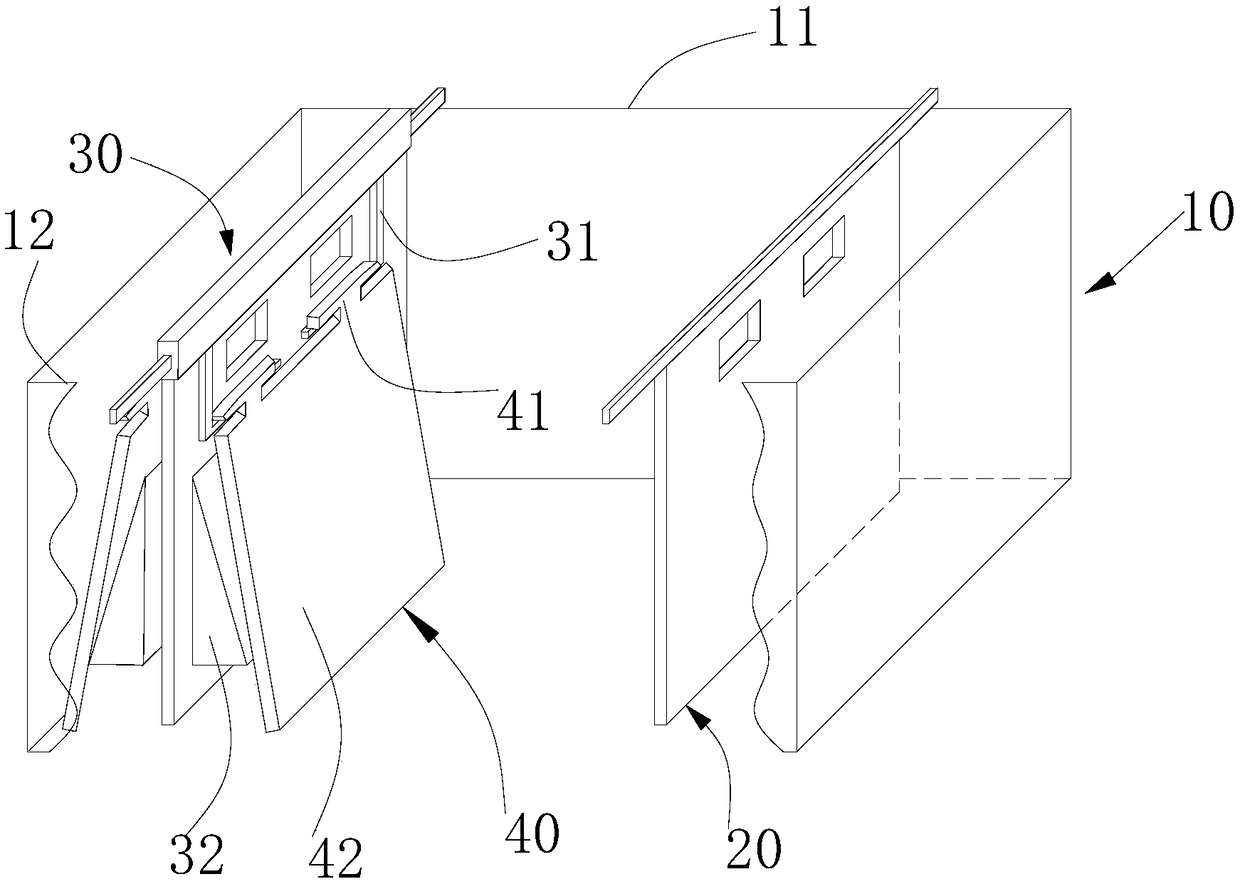

Multifunctional vehicle roof edge beam for railway vehicle

InactiveCN104709302AInstallation Size AdjustmentImprove installation efficiencyRailway roofsRailway heating/coolingModular designModularity

A multifunctional vehicle roof edge beam for a railway vehicle comprises a long-strip-shaped body with radian. The multifunctional vehicle roof edge beam is characterized in that a connector suitable for being connected with an air conditioner frame in a lapped mode is formed in the upper end of the body, and two long-strip-shaped C-shaped grooves are formed in the back of the body and used for installing an air conditioner diversion cover installation base through bolts; two C-shaped grooves are formed in the inner side of the body and used for hoisting built-in lazy arms through bolts; a connector suitable for being connected with the side wall of a vehicle body in a lapped and welded mode is formed in the lower end of the body. According to the multifunctional vehicle roof edge beam, the two C-shaped groove structures are integrated on the back, the diversion cover installation base is made of extrusion sections and is connected with the C-shaped grooves through the bolts, zero welding is achieved, and it is not required to polishing welding seams. The installation base is provided with a transverse long circular hole, and the installation size of a diversion cover can be adjusted conveniently. The multifunctional edge beam has the advantages that modular design of vehicle roof equipment can be achieved easily, the installation efficiency is high, the appearance of the diversion cover can be guaranteed easily, cost is reduced obviously, and benefits are increased obviously.

Owner:CRRC NANJING PUZHEN CO LTD

Mixed electrolysis system for producing cathode copper

ActiveCN106835196ARealize comprehensive utilizationElimination of remelting processPhotography auxillary processesProcess efficiency improvementElectricityHigh energy

The invention belongs to the technical field of smelting, and particularly relates to a mixed electrolysis system for producing a cathode copper; the mixed electrolysis system comprises an electrolytic bath and electrolyte in an electrolytic bath cavity; two bath openings in parallel of the electrolytic bath are paved with cathode and anode conducting busbars along the length direction; the mixed electrolysis system for producing the cathode copper further comprises a cathode and a mixed electrolytic process special anode which are arranged in parallel along the length direction of the electrolytic bath; the cathode and the mixed electrolytic process special anode are electrically connected with the cathode and anode conducting busbars; the plate body of the mixed electrolytic process special anode is obliquely hung with a coarse copper / residual electrode plate. The mixed electrolysis system for producing the cathode copper can direct recycle the residual polar plate, or completely apply the course copper to produce the high purity cathode copper; thus the mixed electrolysis system can eliminate the re-melting procedure of the residual polar plate, shorten the copper smelting technical flow, and save huge cost and high energy consumption for re-melting the residual polar plate.

Owner:铜陵有色金属集团股份有限公司

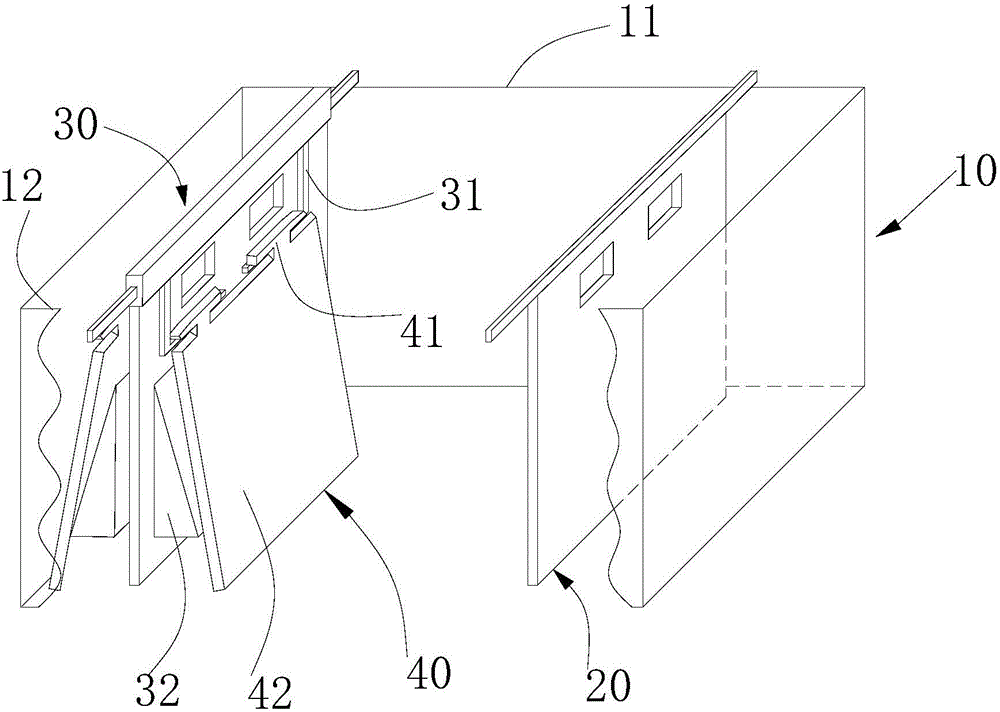

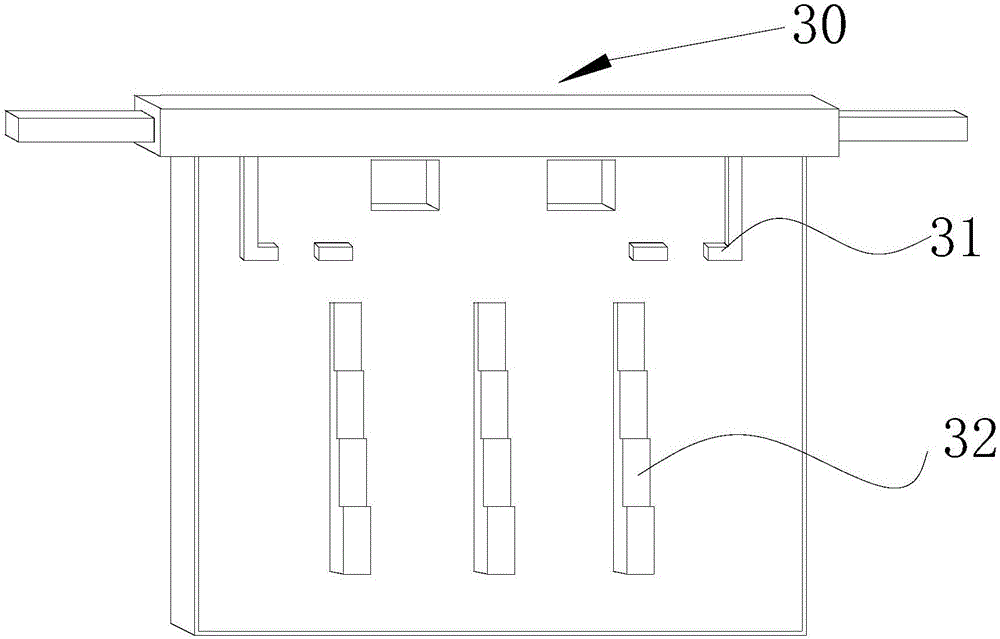

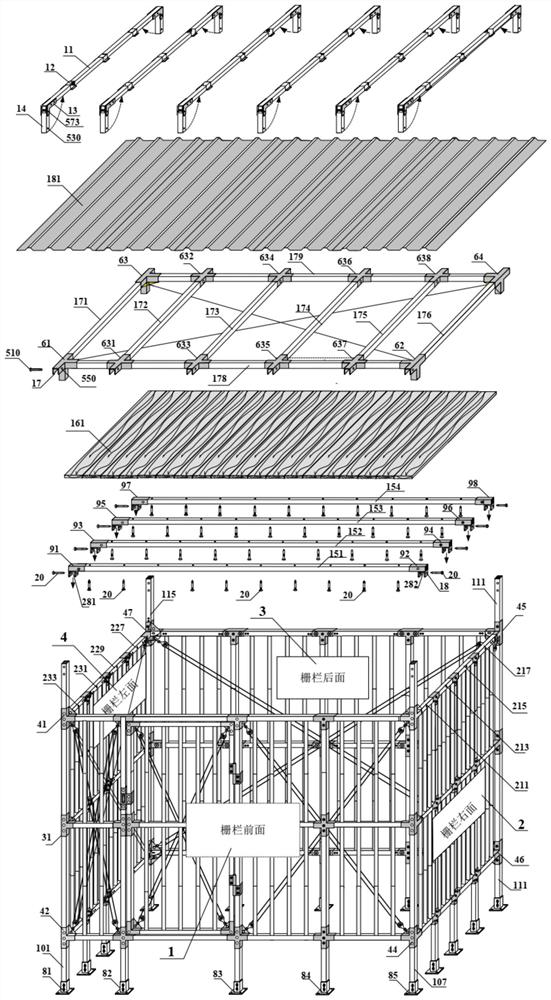

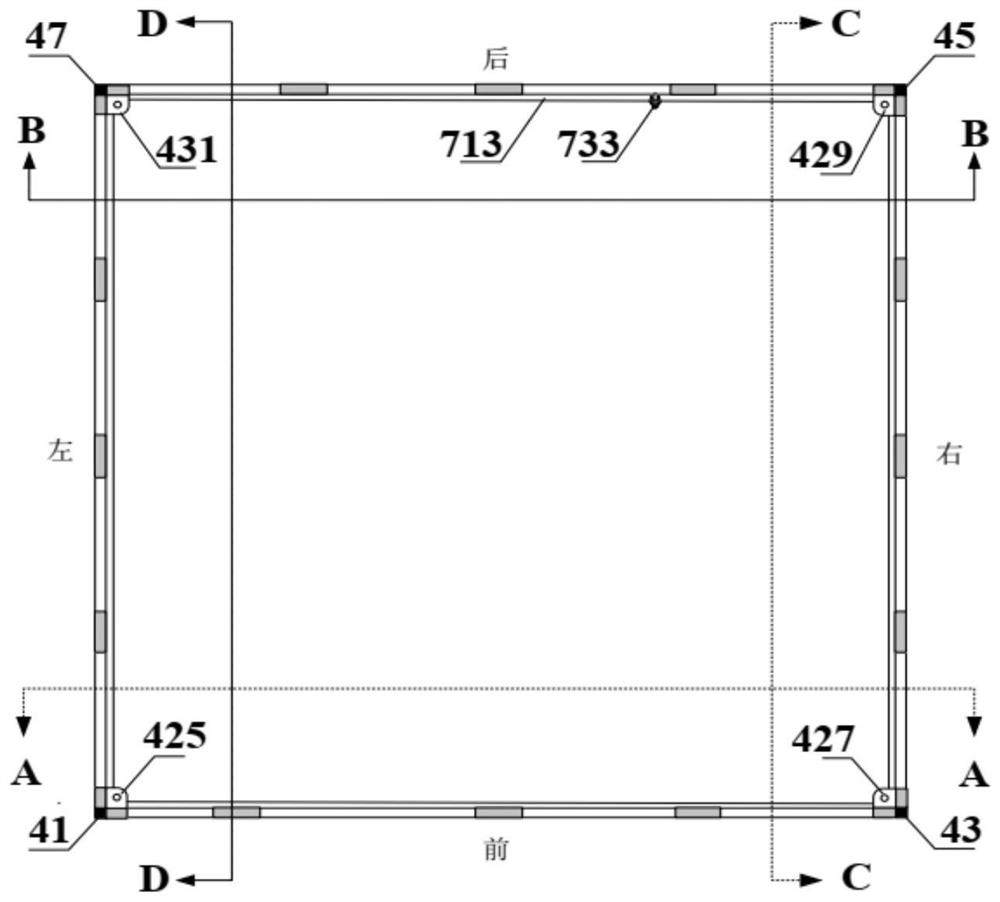

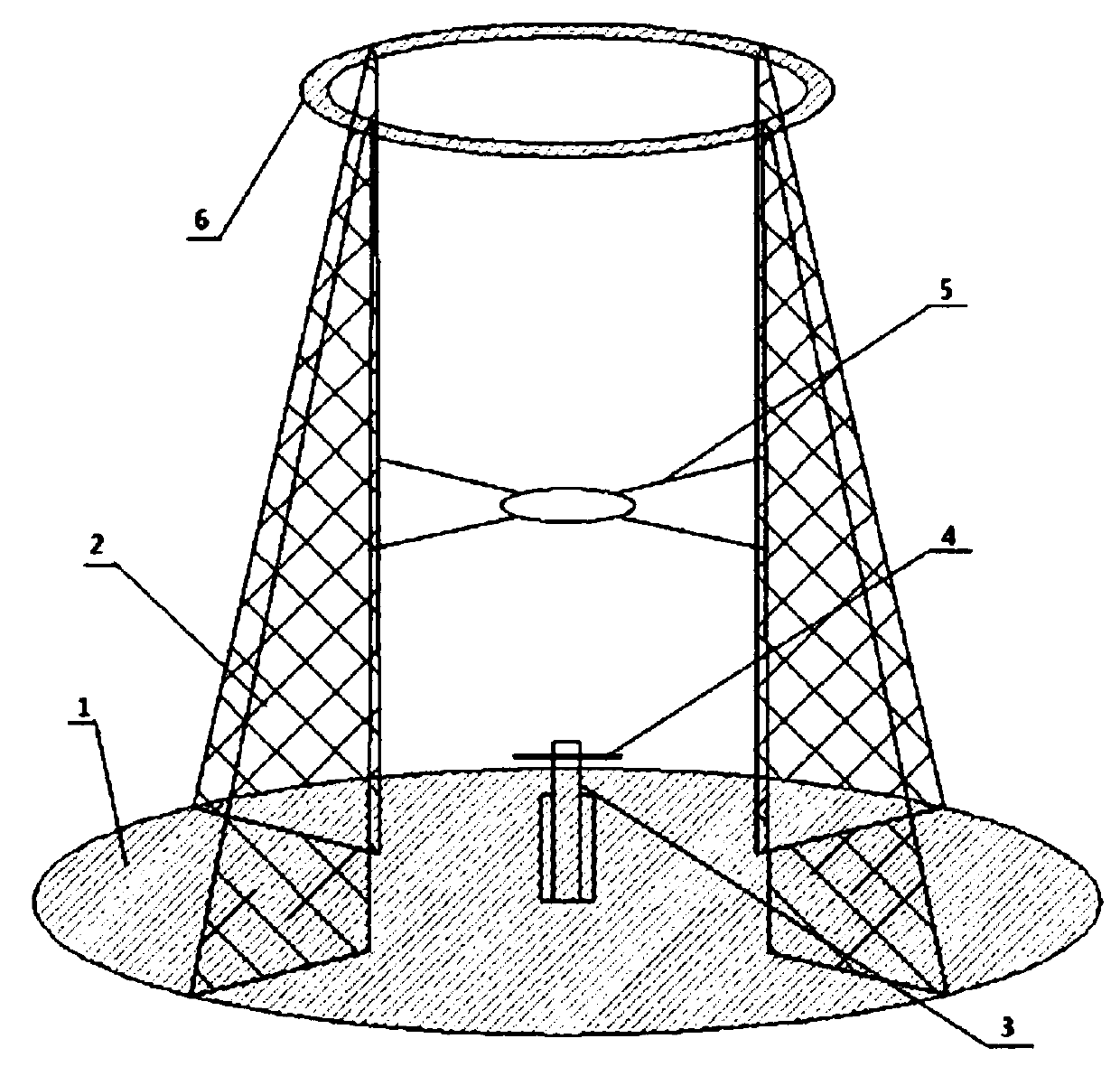

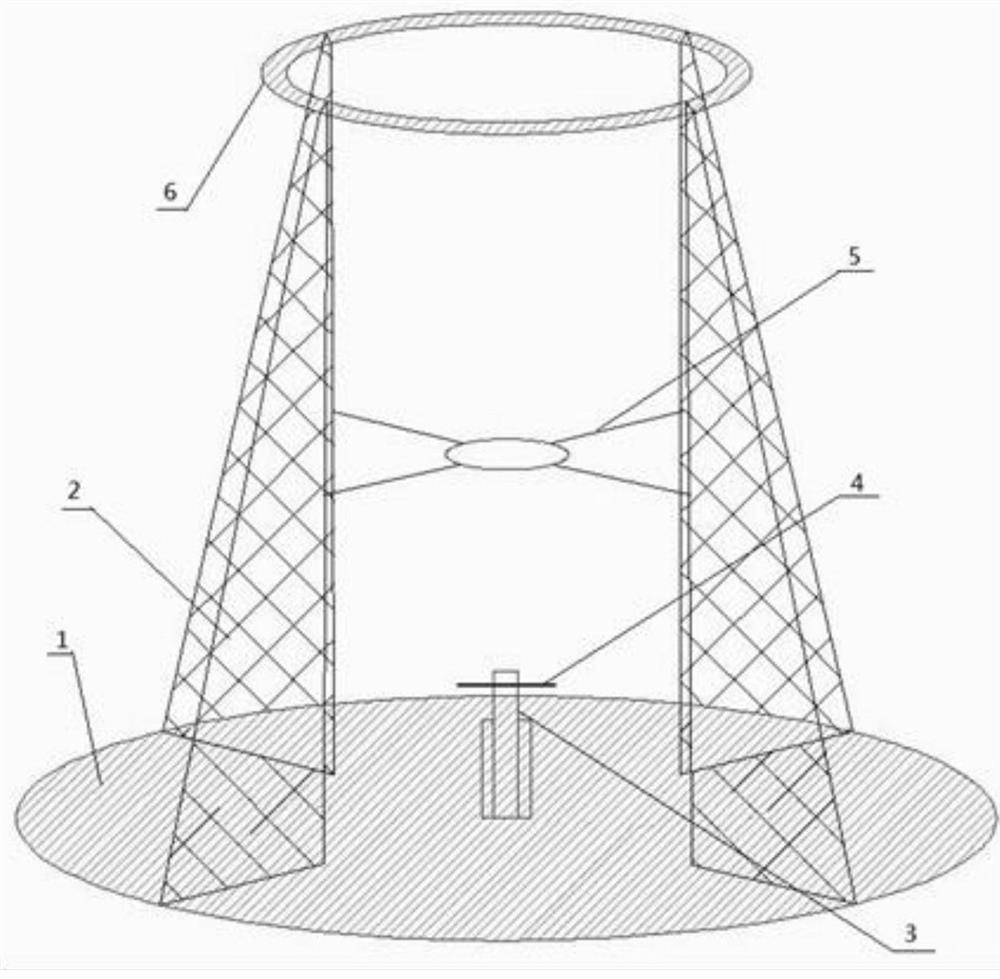

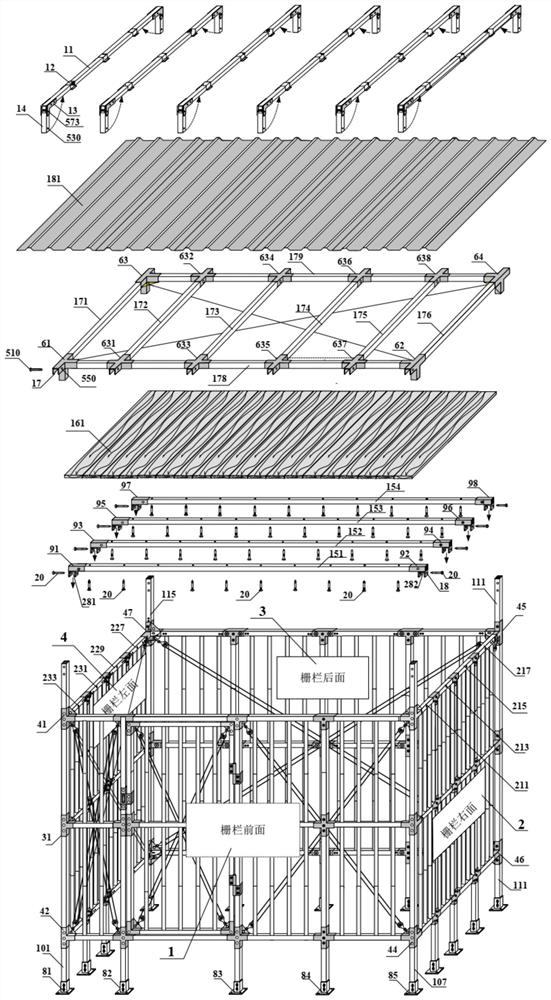

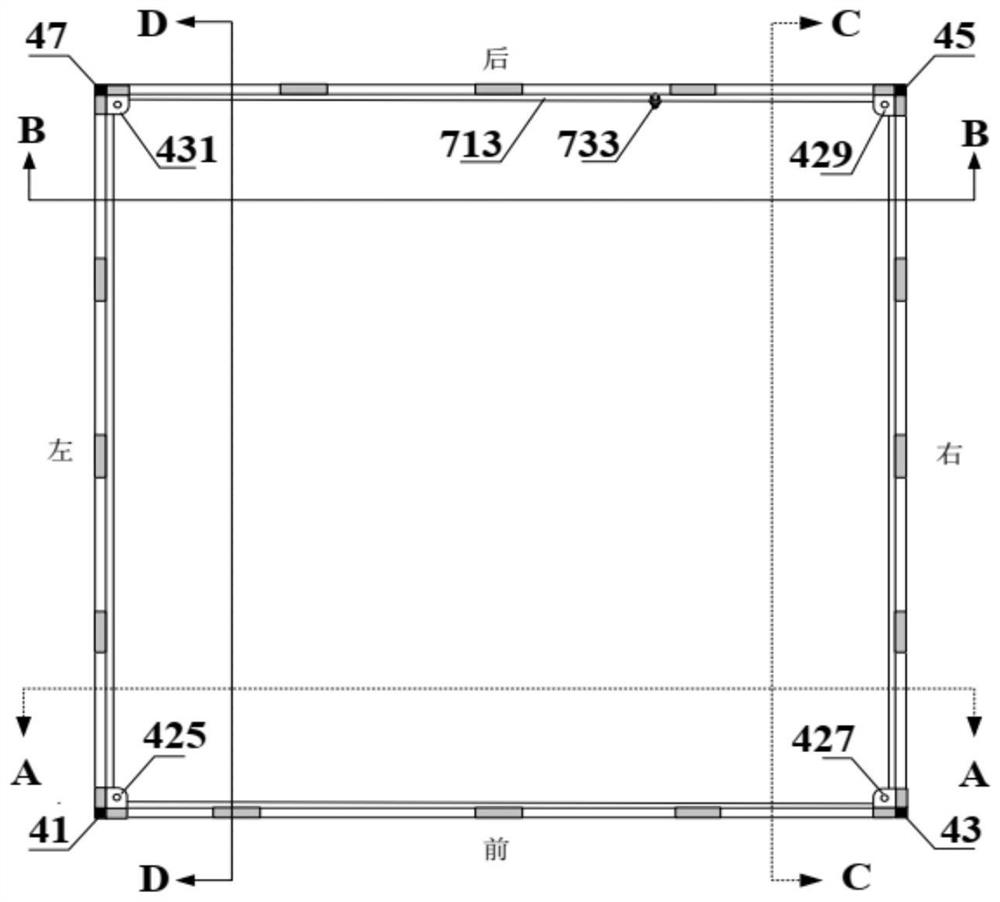

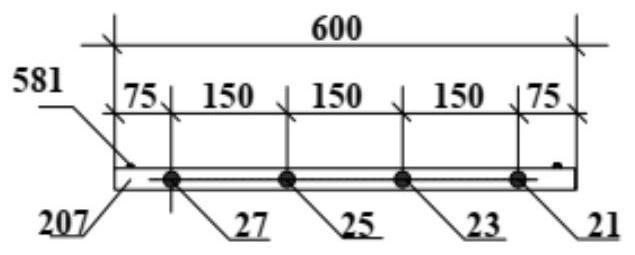

Tool type safety protective fence structure

ActiveCN112227826AReduce volumeNo secondary pollutionFencingArchitectural engineeringStructural engineering

The invention relates to the field of protective fences, and discloses a tool type safety protective fence structure. The tool type safety protective fence structure comprises a fence defining a circumferential closed structure, the fence comprises a plurality of fence units and stand columns, the fence units are detachably connected through the stand columns, oblique tensioning ropes are connected between opposite angles of a local reinforcing structure formed by the fence units and the stand columns, and the oblique tensioning ropes between the two opposite angles of the local reinforcing structure intersect with each other; and the fence is further provided with horizontal tensioning ropes, and the horizontal tensioning ropes are arranged in the circumferential direction of the fence toform a closed loop. According to the tool type safety protective fence structure, the inclined and horizontal flexible tensioning ropes are adopted for reinforcement, the reinforcing effect of a three-dimensional symmetrical geometrical shape is generated, and the mechanical strength and safety of a protective fence are improved while convenient disassembly and assembly are guaranteed; and colorsteel tiles are installed through a tile pressing device, the requirement that the whole use process of the color steel tiles is complete and lossless can be met, and the requirements of zero pollution and environmental protection of construction waste in a standard construction site are met.

Owner:CHINA 19TH METALLURGICAL CORP

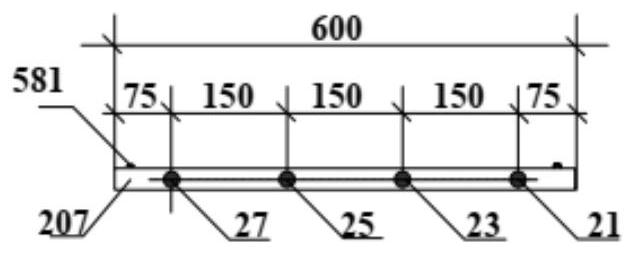

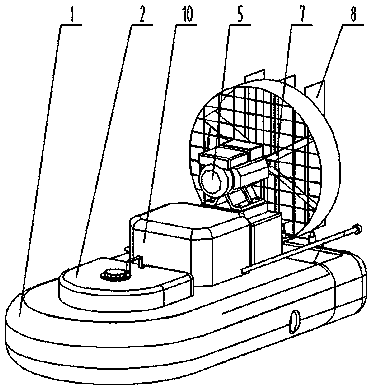

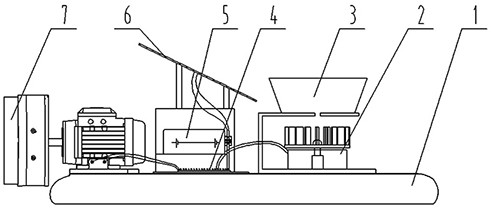

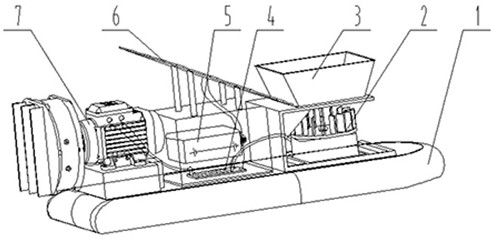

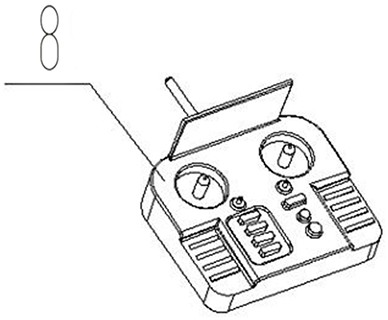

Closed weeding remote control pesticide delivery boat for paddy field

PendingCN109673605AGuaranteed uniformityGuaranteed continuityUnmanned surface vesselsAir acting propulsive elementsSurface layerRemote control

The invention discloses a closed weeding remote-control pesticide delivery boat for a paddy field, belonging to the agricultural machinery field. According to the closed weeding remote-control pesticide delivery boat, the production problems that the water blending quantity is low, the pesticide is not uniformly delivered, the working efficiency is low, the labor intensity is high, and the large-area chemical injury is easily caused in the existing closed weeding process of the paddy field. The pesticide delivery boat comprises a boat body, a primary pesticide mixing tank, a mixer, a water pump, a small-sized gasoline engine, a remote control device, an air propeller, a guiding control board, a pesticide spray head, a protecting cover and a monitoring remote controller. The water pump is mounted in the boat body and is used for introducing water into the mixer, a pesticide diluting solution in the primary pesticide mixing tank and filtered field water are mixed and diluted again into drops, and the drops are sprayed to a surface layer of the paddy field, and the field pesticide spraying operation is finished. According to the closed weeding remote-control pesticide delivery boat, the uniformity and continuity of the field pesticide spraying can be guaranteed, the working efficiency is high, the labor intensity is decreased, the cost decreasing and benefit increasing effects areobvious, and the closed weeding remote-control pesticide delivery boat is particularly suitable for the high-speed pesticide spraying operations of large-area linked paddy fields.

Owner:JIAMUSI UNIVERSITY

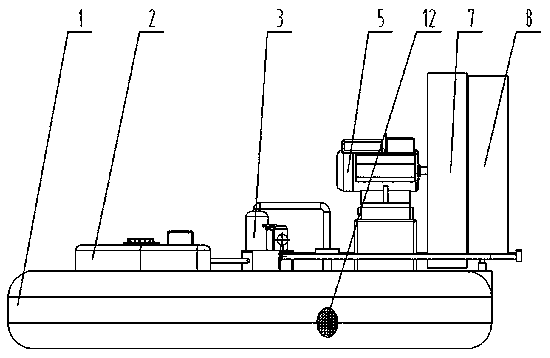

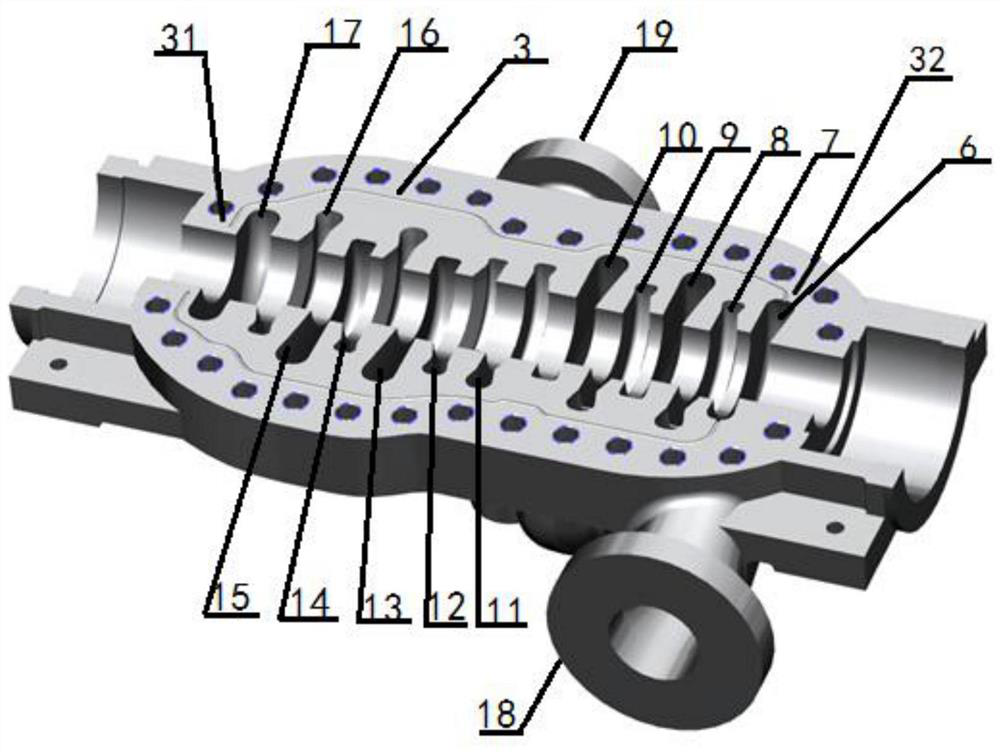

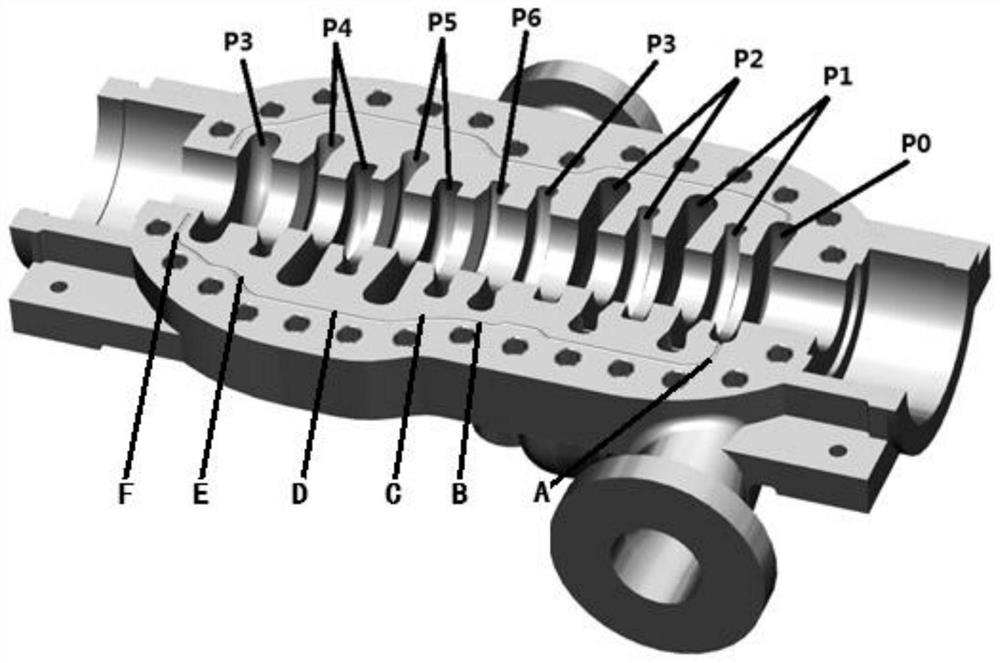

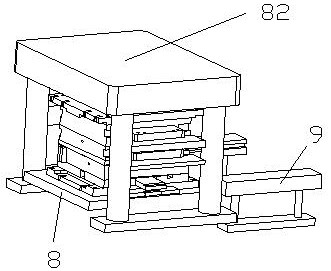

Nuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method

ActiveCN111055233AEasy measurement of channelingEfficient measurement of channelingPump componentsPumpsNuclear plantNuclear power

The invention relates to the technical field of nuclear power maintenance, and particularly discloses a nuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method. The disassembling and assembling tool and method is characterized in that an upper supporting ring, a middle supporting seat and a bottom plate are fixed through supporting ribplates, and the upper supporting ring, the middle supporting seat and the bottom plate are parallel to one another; when a core package is disassembling, the pump core package is slowly lifted and stably placed on a disassembling tool, so that the outer edge of the pump core package is clamped on the upper supporting ring, and then subsequent disassembling operation is completed. According to thenuclear power plant horizontal multi-stage centrifugal pump core package disassembling and assembling tool and method, manpower is greatly liberated, on-site core package disassembling and rotor channeling amount measurement operation becomes simple and efficient, and equipment damage risks as well as safety risks can be reduced.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

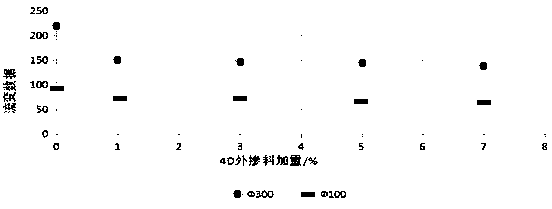

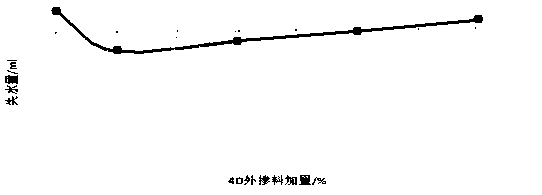

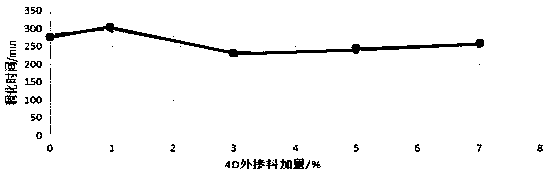

4D admixture for well cementation

Disclosed is a 4D admixture for well cementation. The 4D admixture for well cementation is characterized in that (1) the 4D admixture for well cementation is prepared from 70% of special low-density materials (floating beads and pulverized fuel ash), 10% of stabilizer (micro-silicon), 10% of reinforcing agent (slag) and 10% of modifier (CaO); (2) the 4D admixture for well cementation and cement can be well mixed to form a system, and the temperature resistance, acid resistance and corrosion resistance performance of the formed system can well meet various requirements of well cementation; (3)the 4D admixture for well cementation and the well cementation cement are mixed according to a certain ratio to form the new cement slurry system, the system is stable and is applied to low-pressure wells where seepage and leakage occur easily, and prepared cement slurry has the advantages of channeling prevention, high toughness and the like; (4) through the application of the 4D admixture for well cementation, on the basis of ensuring well cementation quality, the use quantity of various well cementation admixtures and the well cementation cost can be reduced.

Owner:潜江市联瑞石油机械有限公司

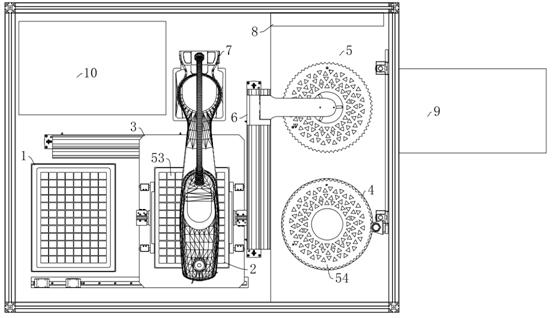

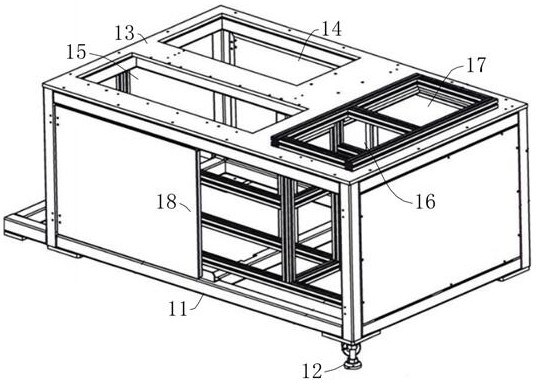

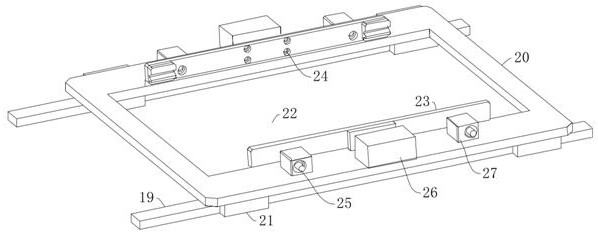

An automatic loading and unloading device and method applied to cemented carbide tool grabbing

ActiveCN113501311BReduce labor intensityEliminate the effects ofControl devices for conveyorsGrinding work supportsCemented carbideVisual positioning

Owner:CHINA POWER IND INTERNET CO LTD

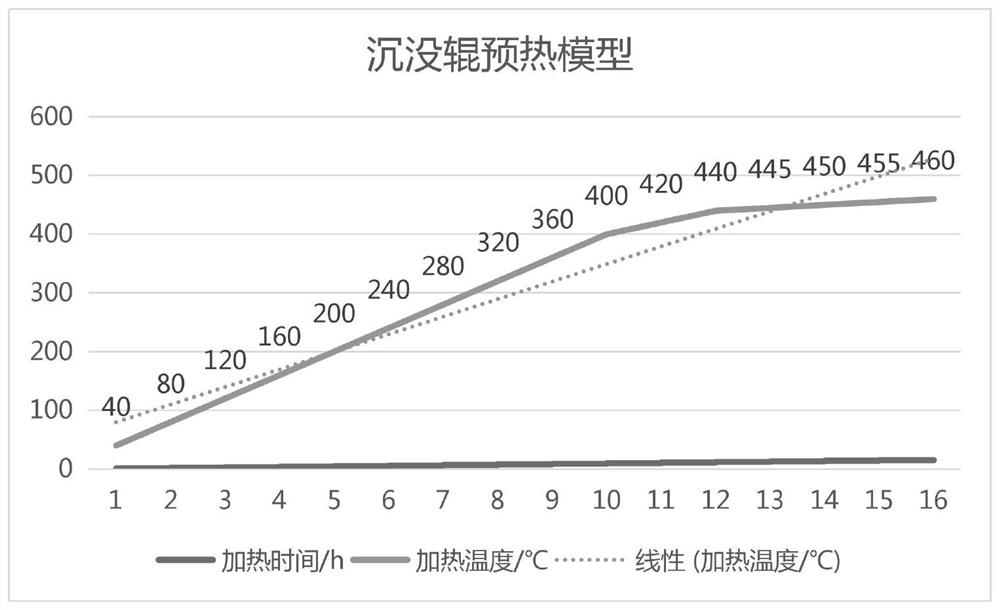

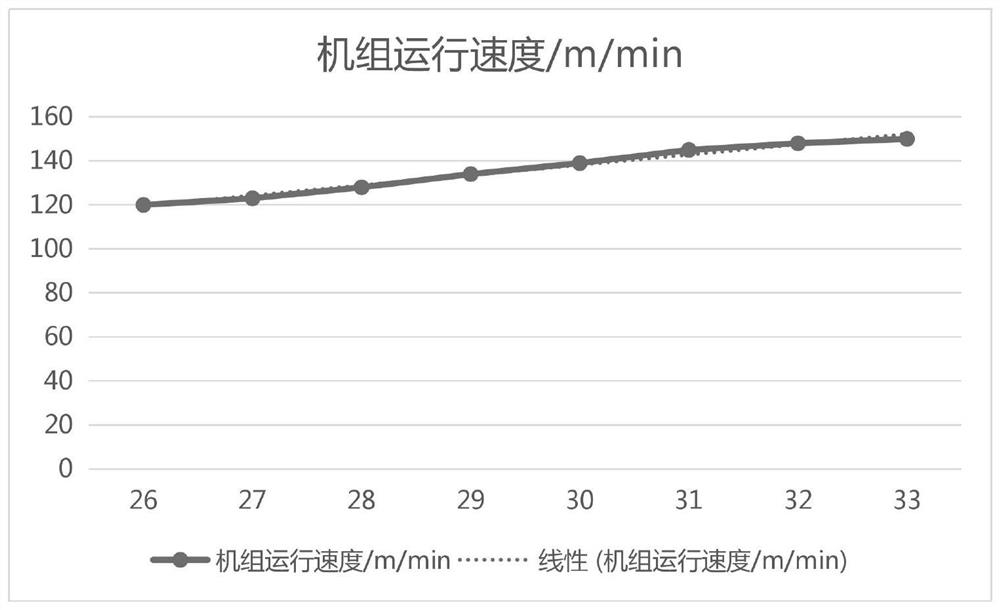

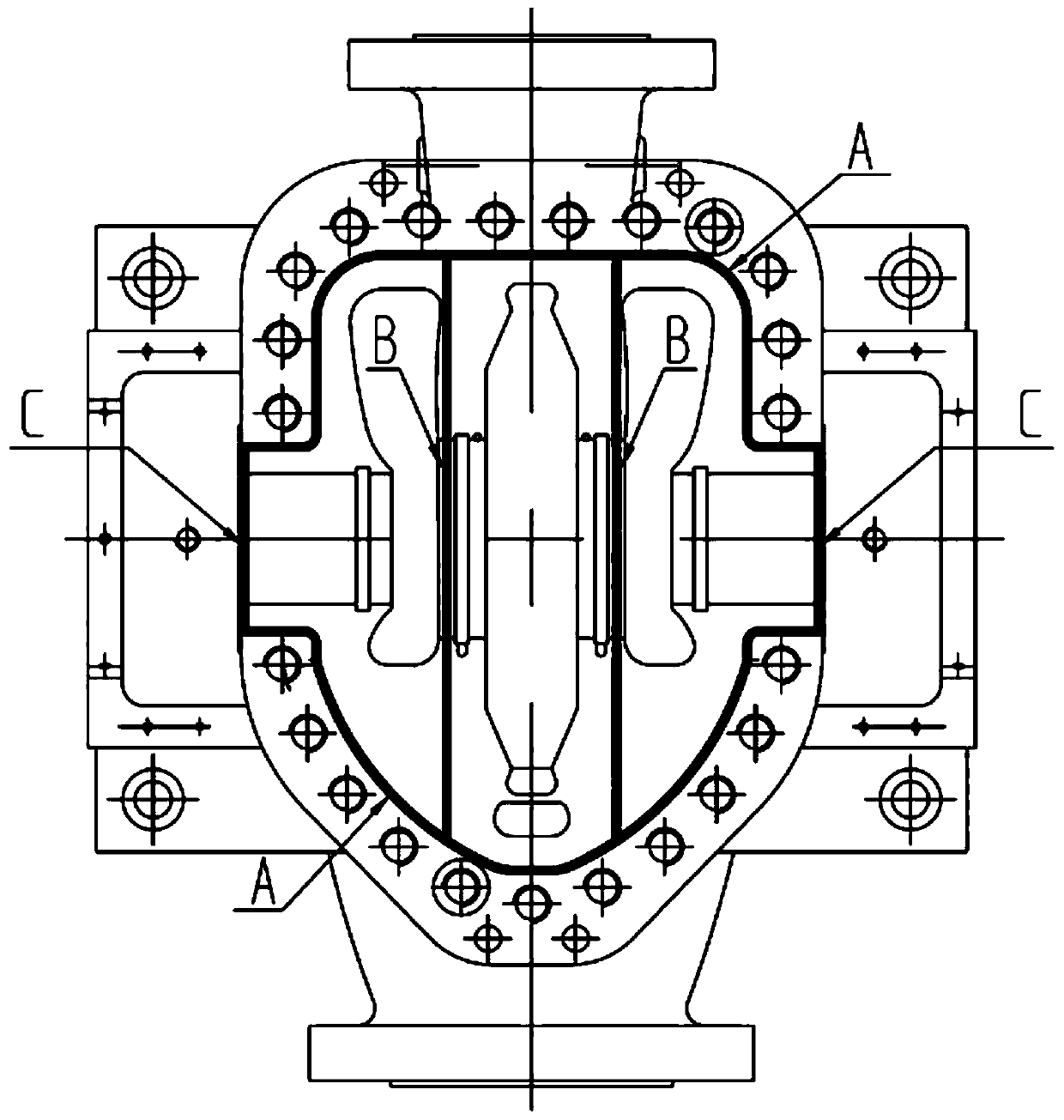

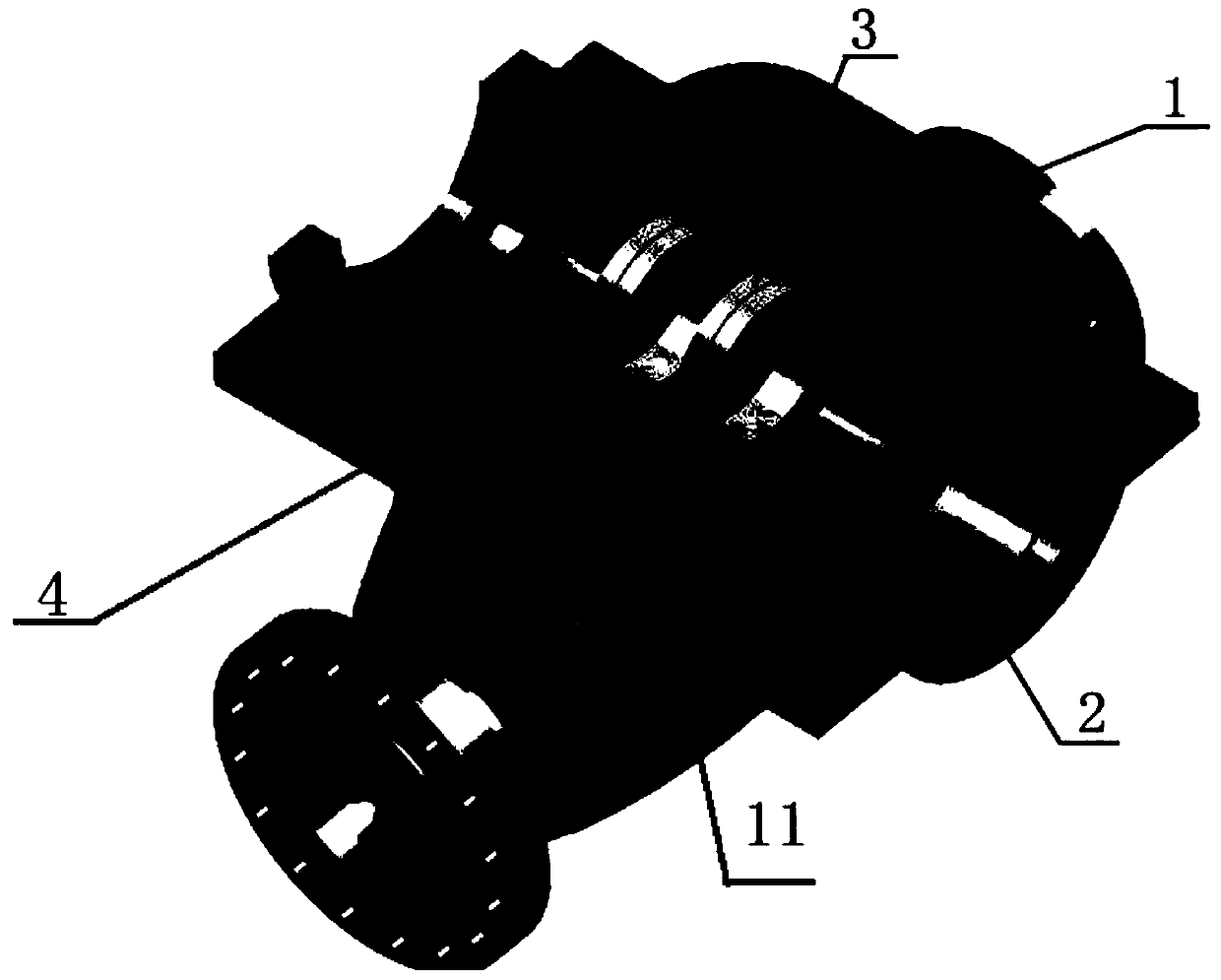

High-speed stable production method of CQ-grade thin-gauge galvanized sheet

PendingCN113088855AImprove overall running speedIncrease production capacityHot-dipping/immersion processesFurnace typesFurnace temperatureManufacturing line

The invention relates to a high-speed stable production method of a CQ-grade thin-gauge galvanized sheet. According to the method, a continuous hot galvanizing unit sink roll preheating model, the purity of zinc liquid, a plan schedule, secondary crescent shearing, the temperature of an annealing furnace, a sink roll scraper and the tension of a zinc pot are comprehensively controlled, the average running speed of a CQ-grade thin-specification galvanized sheet is improved from 90m / min to 140m / min, the capacity is fully released, and the production efficiency is improved; the in-furnace wrinkle judgment change rate is reduced from 8.11% to below 1%, the scratch and wrinkle degradation judgment change rate is greatly reduced, and the cost is reduced; and the yield is greatly improved, cost reduction and efficiency increase are obvious, order delivery is effectively guaranteed, the productivity is greatly released, and the method can be applied to a continuous hot galvanizing production line.

Owner:SD STEEL RIZHAO CO LTD

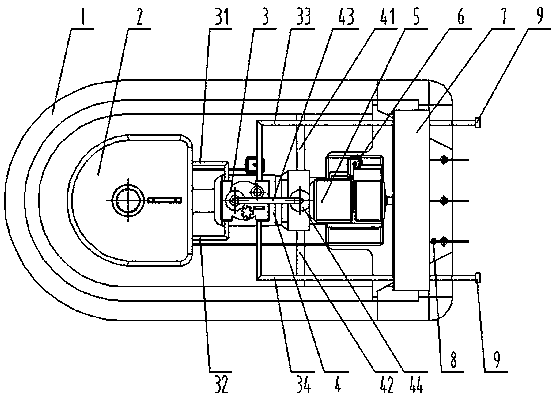

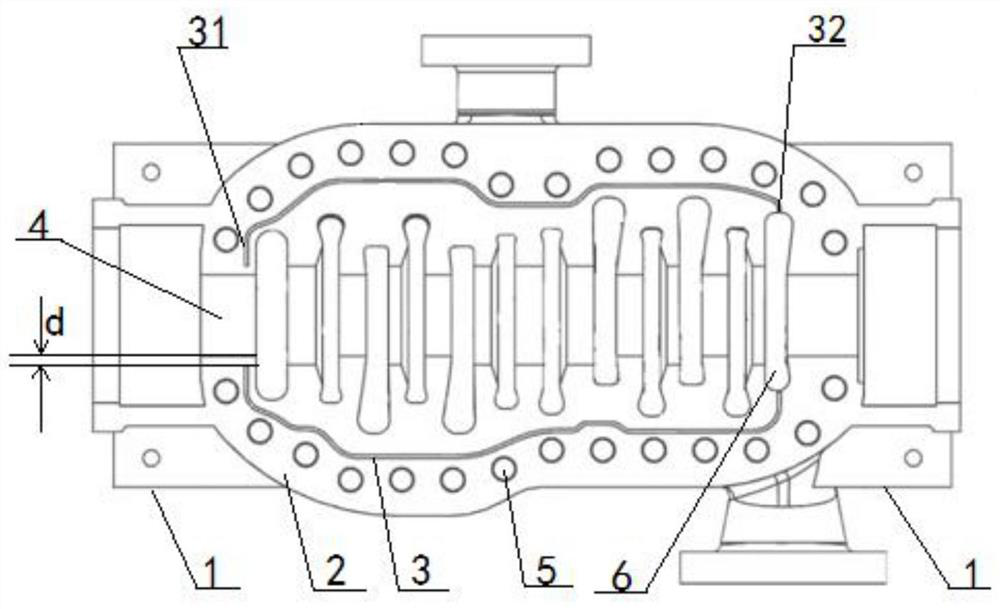

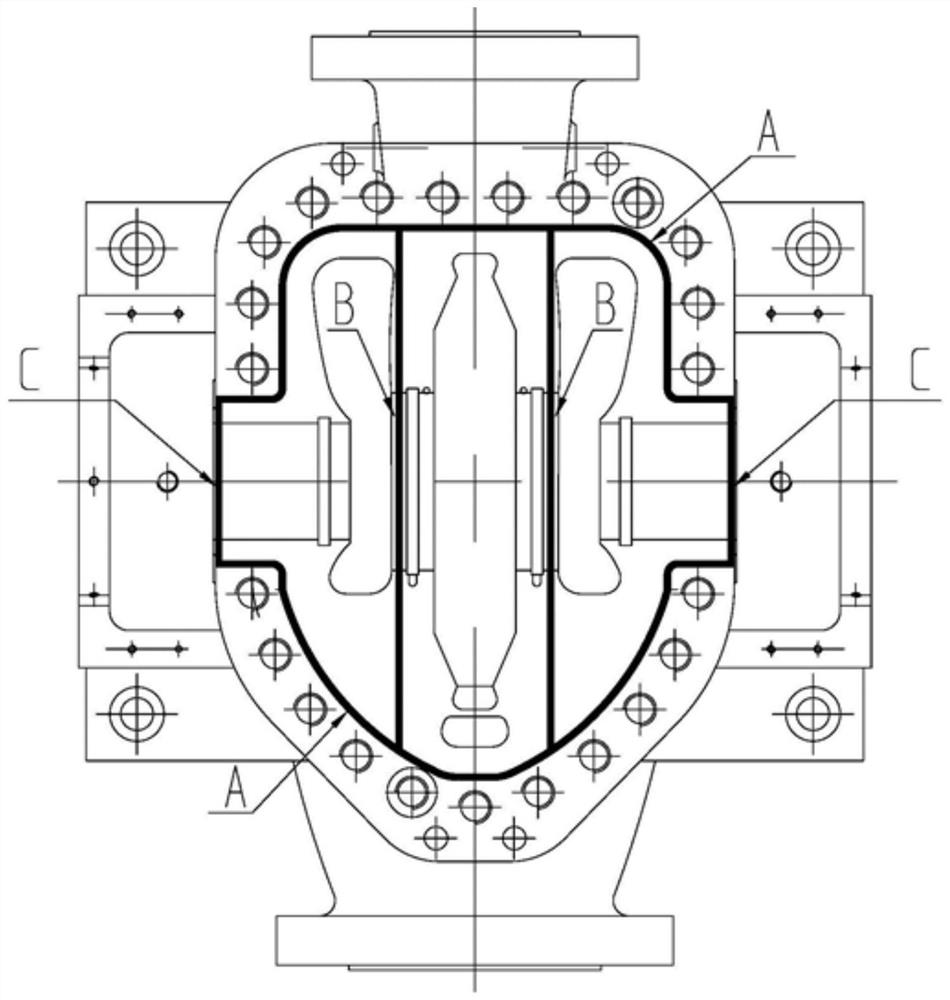

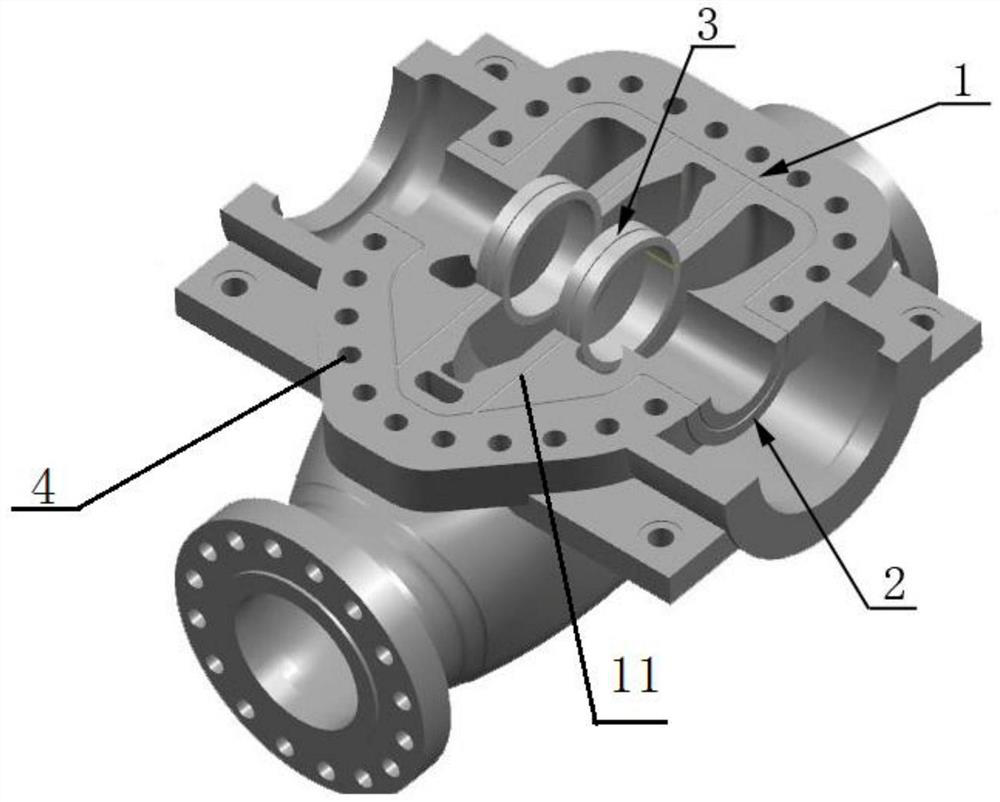

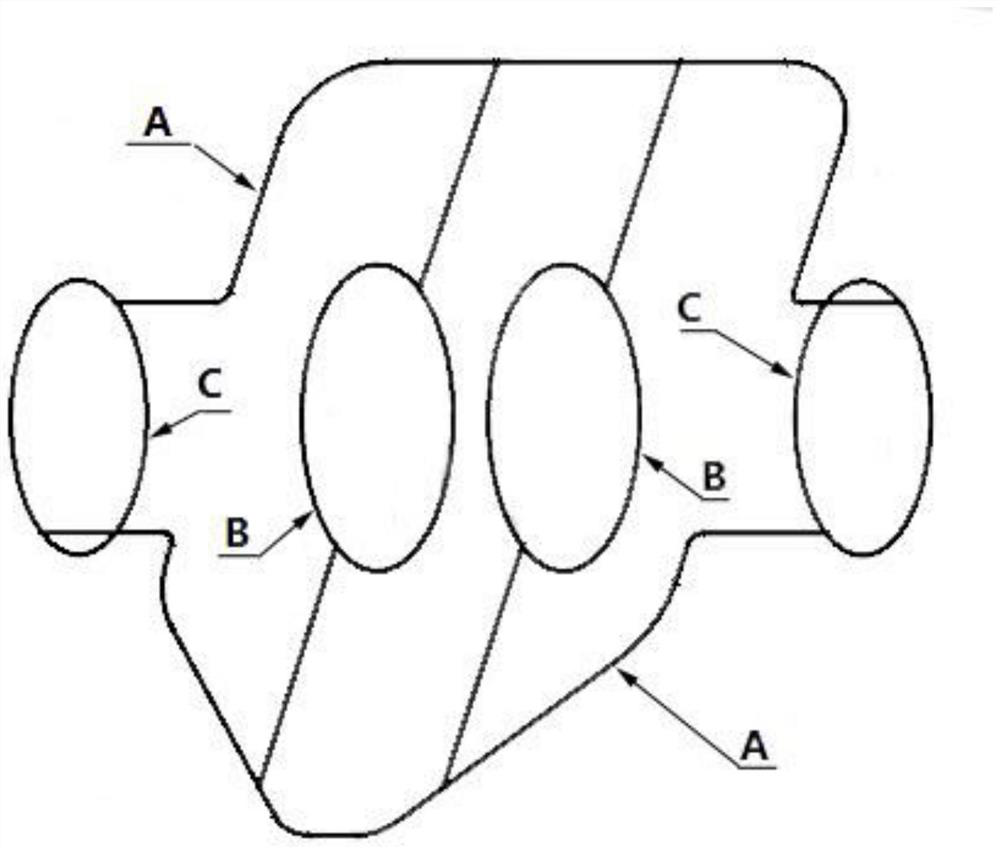

Sealing structure of horizontal axially split pump and mounting method of sealing structure

ActiveCN110671356AReduce in quantityReduced processing performancePump componentsPumpsImpellerEngineering

The invention provides a sealing structure of a horizontal axially split pump and a mounting method of the sealing structure. The problems that the process requirement of head-to-head metal sealing adopted for an existing horizontal axially split pump is high, the cost of flat gasket sealing is high, the reliability of gumming sealing is poor, and interstage sealing is lacked are solved. The sealing structure comprises a stereoscopic sealing groove and an integrated sealing element matched with the stereoscopic sealing groove. The stereoscopic sealing groove is formed by sealing ring sealing grooves located in the peripheries of N shell body sealing rings separately and a sealing groove in an upper pump body and a lower pump body. The sealing groove in the upper pump body and the lower pump body comprises two pump body sealing grooves in the axially split surface of the lower pump body and two pump shaft end sealing grooves. The two ends of the two pump body sealing grooves are connected with the two pump shaft end sealing grooves separately, and each sealing ring sealing groove is connected with the two pump body sealing grooves. N is determined by the stage number of the horizontal axially split pump, the impeller form and the impeller arrangement position.

Owner:西安航天泵业有限公司

Solar remote control small fertilization boat

PendingCN113973557AFertilize evenlyImprove work efficiencyWaterborne vesselsUnmanned surface vesselsAgricultural scienceRemote control

The invention discloses a solar remote control small fertilization boat, and belongs to the field of agricultural mechanical equipment. The solar remote control small-sized fertilization boat comprises a hovercraft body assembly, an electric fertilizer applicator, a fertilizer box, a multi-channel remote control panel, a solar storage battery, a solar power generation panel, an electric air propeller and a fertilization boat remote controller, the solar remote-control small fertilization boat can provide energy power in a paddy field by utilizing solar energy, realizes remote-control uniform fertilization, is high in working efficiency, replaces a traditional manual operation mode, reduces cost and improves efficiency, and is particularly suitable for fertilization operation of large-area continuous paddy fields.

Owner:JIAMUSI UNIVERSITY

A nuclear power plant horizontal multistage centrifugal pump core package disassembly tool and method

ActiveCN111055233BEasy measurement of channelingEfficient measurement of channelingPump componentsPumpsNuclear plantNuclear power

The invention relates to the technical field of nuclear power maintenance, and specifically discloses a nuclear power plant horizontal multi-stage centrifugal pump core package disassembly tool and method. The support base and the bottom plate are parallel to each other; when disassembling the core package, slowly lift the pump core package and place it on the disassembly tool stably, so that the outer edge of the pump core package is clamped on the upper support ring, and then the subsequent disassembly operation is completed . The invention greatly liberates manpower, makes on-site core package disassembly and rotor displacement measurement work simple and efficient, reduces the risk of equipment damage, and reduces the safety risk.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

Film-mulching planting method without seedling transplanting for graminaceous food crops in dry farming area

InactiveCN107439182AReduce production linksRemarkable cost reduction and efficiency increaseClimate change adaptationCultivating equipmentsDrought resistanceTransplanting

The invention discloses a film-mulching planting method without seedling transplanting for graminaceous food crops in a dry farming area. The method comprises the steps that ridging is conducted, trenches are ditched closely to the two sides of the ridges, the trench depth is 3-4 cm, and artificial sowing in drill and artificial spaced sowing or mechanical sowing are conducted in the trenches; after sowing is completed, the trenches are filled with soil, the soil surface is as high as the trench surfaces, then the soil is patted or repressed, and the sowing trenches are tamped, so that no cracks, mud cakes and soil blocks exist in sowing rows, the soil and seeds are tightly pasted, the moisture loss in soil pores is reduced, and the seedling emergence is facilitated; after repression is finished, film mulching is conducted on the ridge surfaces, the film edges are pressed and tightly sealed with soil, and meanwhile, the mulching film above the sowing trenches is covered with soil with the thickness of 1-1.5 cm, and the thickness needs to be uniform and consistent, and the mulching film above the sowing trenches is prevented from being exposed. According to the method, the seedling transplanting is avoided, the production links are reduced, cost decrease and effect improvement are obvious, and the seedling emergence rate is extremely high; meanwhile, mulching film integrity, ground temperature regulation, drought resistance, soil moisture preservation, evaporation suppression and grass control are ensured.

Owner:平凉市农业科学院

Horizontal axially split pump for guiding leaked liquid

PendingCN112922903AReduce processing difficultyReduce processing costsPump componentsPump controlEngineeringMechanical engineering

The invention relates to a horizontal axially split pump, in particular to a horizontal axially split pump for guiding leaked liquid, and solves the problem that the sealing mode of an existing horizontal axially split pump cannot give consideration to simple process, low cost and good reliability. At least one flow guide groove is formed in each of two sides of a volute chamber flow channel on the axially split surface of a pump body; or at least one flow guide groove is formed in each of two sides of the volute chamber flow channel on the axially split surface of a pump cover; or at least one flow guide groove is formed in one side of the volute chamber flow channel on the axially split surface of the pump body, and at least one flow guide groove is formed in the other side of the volute chamber flow channel on the axially split surface of the pump cover. The number of the flow guide grooves in the two sides of the volute chamber flow channel is equal, and the flow guide grooves in each side are formed between bolt holes in the side and the volute chamber flow channel. The starting end of the flow guide groove on each side is close to a mechanical sealing cavity, and the leading-out end of the flow guide groove is communicated with a suction cavity. By means of the mode that dredging replaces blocking, leaked liquid is guided to the suction cavity through the flow guide grooves, and the sealing difficulty of the axially split surface of the horizontal axially split pump is reduced.

Owner:西安航天泵业有限公司

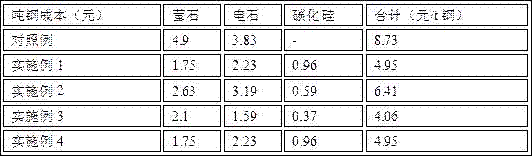

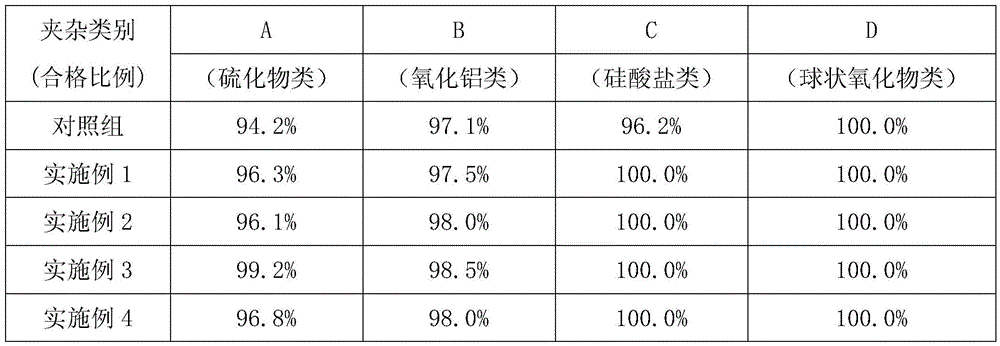

A kind of killed steel deoxidation method

The invention discloses a killed steel deoxygenation method and belongs to the technical field of ladle refining. The killed steel deoxygenation method is characterized by comprising the following steps of slag washing, refining, slag electrification, deoxygenation, acceleration of steel slag interface reactions and soft blowing. According to the deoxygenation step, a deoxidizing agent comprises silicon carbide and calcium carbide, 70% of silicon carbide is added firstly, then calcium carbide is added, and then 30% of silicon carbide is added. Compared with the prior art, the killed steel deoxygenation method has the characteristics of being good in product deoxygenation effect, greatly reducing the deoxygenation cost and being stable in product quality.

Owner:RIZHAO STEEL HLDG GROUP

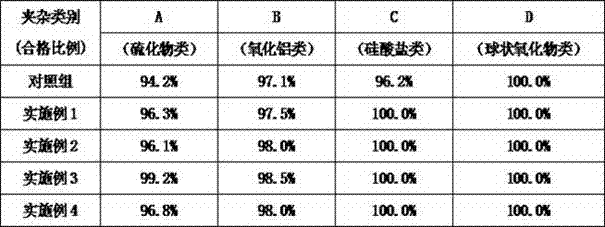

Steam-assisted gravity channel oil extraction method

The invention relates to the technical field of thickened oil recovery, in particular to a steam-assisted gravity channel oil recovery method. According to the channel thermal recovery method, a horizontal section of a horizontal well is drilled into an inclined horizontal section, a tiptoe (the front end of the horizontal section of the horizontal well) penetrates through a vertical well, good communication is formed, steam injection is conducted through the inclined horizontal well, and oil extraction is conducted through the vertical well. The practical problems that in the heavy oil thermal recovery process, steam injection heating is uneven, heat is wasted, the recovery rate is reduced, the flow resistance of a horizontal well steam injection tubular column in the horizontal section is increased, crude oil is difficult to discharge, and the operation pressure is increased can be solved, and the device can be independently used, can also be combined with a traditional steam injection mode for use, can be applied to newly developed oil fields and has a wide application prospect. The device can be applied to an old oil field, can be used for drilling a new well, can also be realized by sidetrack drilling of an old well, can be used for injecting steam by using an electric heating steam generator and can also be used for injecting steam by using a ground steam injection boiler, and is one of the optimal modes for saving energy, reducing consumption, improving the recovery rate of thickened oil and converting a development mode in an old thermal recovery area.

Owner:嘉仕嘉德(盘锦)石油技术研究院有限公司

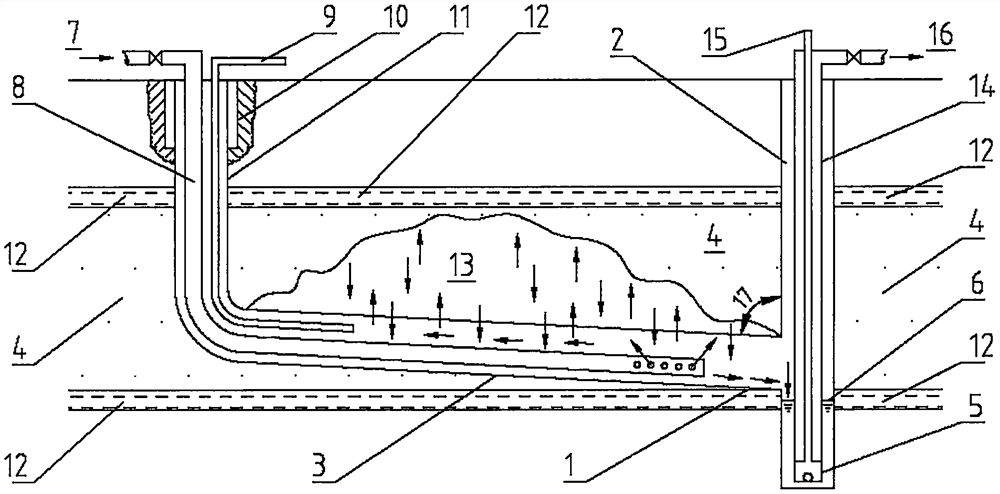

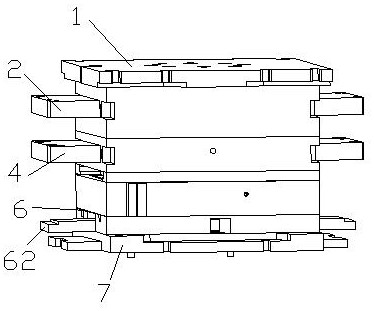

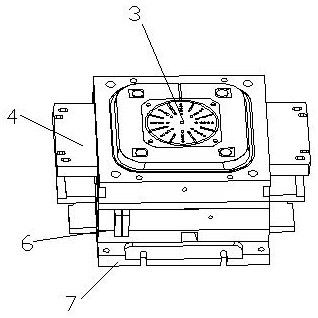

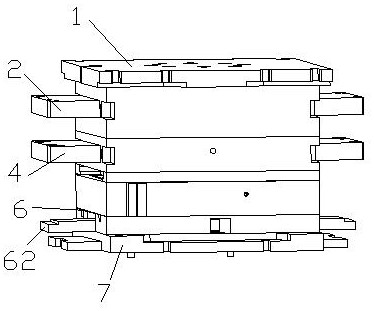

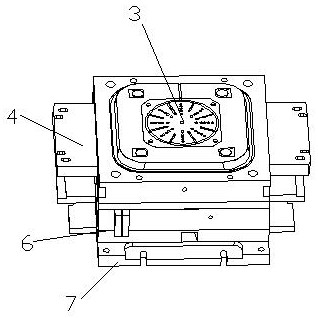

A kind of automatic mold opening method and mold structure of conical rubber spring vulcanization mold

ActiveCN112428490BRealize fully automated production operationsImprove working conditionsDomestic articlesVulcanizationSemi automatic

A fully automatic mold opening method and mold structure for a conical rubber spring vulcanization mold. The rubber injection insert of the vulcanization mold is fixed on the middle mold of the mold and moves up and down together with the middle mold to complete the connection between the mold rubber injection cylinder and the vulcanized product. The automatic separation between the molds realizes the automatic operation of the injection inserts; the guide mechanism is set between the middle mold, the valve mold and the lower mold of the vulcanization mold so that the valve mold moves up and down with the middle mold to complete the gap between the two valve molds. The separation and closing of the vulcanization mold can realize the automatic separation between the valve mold and the vulcanized product; the vulcanized product is automatically ejected by setting an ejection mechanism on the lower mold of the vulcanization mold; the bottom mold of the vulcanization mold and the lower plate of the curing equipment The fast positioning between the vulcanization mold and the vulcanization equipment is realized by setting a positioning mechanism between them. The invention realizes the automatic separation between the mold parts and between the mold parts and the vulcanized product, and avoids the highly difficult semi-automatic operation and structure of using the mobile crane back and forth.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Multifunctional built-in hanging arm

The invention relates to a multifunctional built-in hanging arm which is a strip profile, wherein a bevel edge is arranged on the section of the profile; a first flange extends out of the low end of the bevel edge; a second flange extends out of the middle part of the bevel edge; the tail end of the first flange is fixedly connected with the tail end of the second flange by a first C-shaped groove; a third flange extends out, close to the high end, of the bevel edge; a fourth flange extends out of a connecting part between the middle part of the bevel edge and the second flange; the middle upper part of the third flange is intersected with the middle part of the fourth flange; a fifth flange extends out of the tail end of the fourth flange; the tail end of the third flange is fixedly connected with the tail end of the fifth flange by a second C-shaped groove; the hanging arm further comprises a horizontal sixth flange; at least two third C-shaped grooves are formed on the lower side of the sixth flange; openings of the first C-shaped groove, the second C-shaped groove and the third C-shaped grooves are vertically downward; the third C-shaped grooves are higher than the second C-shaped groove; and the second C-shaped groove is higher than the first C-shaped groove. The hanging arm can mount various built-in components at the top of a coach simultaneously, is high in integration level, improves the mounting efficiency and reduces the weight of the coach.

Owner:CHINA RAILWAYS CORPORATION +1

Tool type safety fence structure

ActiveCN112227826BReduce volumeNo secondary pollutionFencingArchitectural engineeringStructural engineering

The invention relates to the field of guardrails, and discloses a tool-type safety guardrail structure. The tool-type safety fence structure disclosed by the present invention includes a fence surrounding a circumferentially closed structure, the fence includes several fence units and uprights, and the fence units are connected in a detachable manner through the uprights, and the fence units and Diagonal tension ropes are connected between the diagonal corners of the local reinforcement structure formed by the columns, and the oblique tension ropes between two pairs of diagonal corners of the local reinforcement structure cross each other, and the fence is also provided with horizontal tension ropes. The horizontal tension ropes are arranged along the perimeter of the fence to form a closed loop. The invention adopts oblique and horizontal flexible tensioning ropes for reinforcement, which produces a reinforcement effect of three-dimensional symmetrical geometry. While ensuring the convenience of disassembly and assembly, the mechanical strength and safety of the guardrail are improved. The invention adopts a tile press to install color steel tiles The method can meet the complete and undamaged use of color steel tiles in the whole process, and meet the requirements of zero pollution of construction waste and green environmental protection in standard industrial sites.

Owner:CHINA 19TH METALLURGICAL CORP

A kind of reinforced and stable yttrium oxide slurry and its preparation method

ActiveCN112170776BReduce solubilityReduce hydrolysisFoundry mouldsFoundry coresInvestment castingLatex rubber

Owner:章元材料科技(沈阳)有限公司

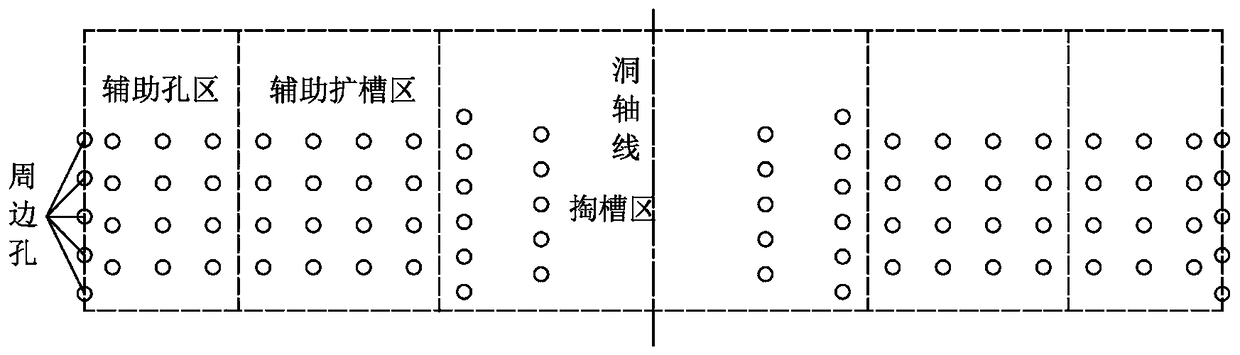

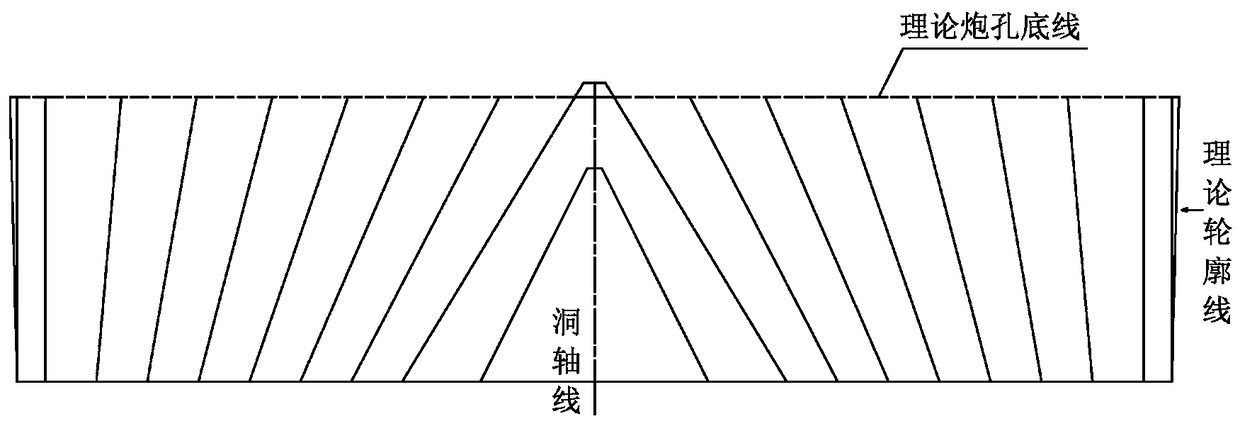

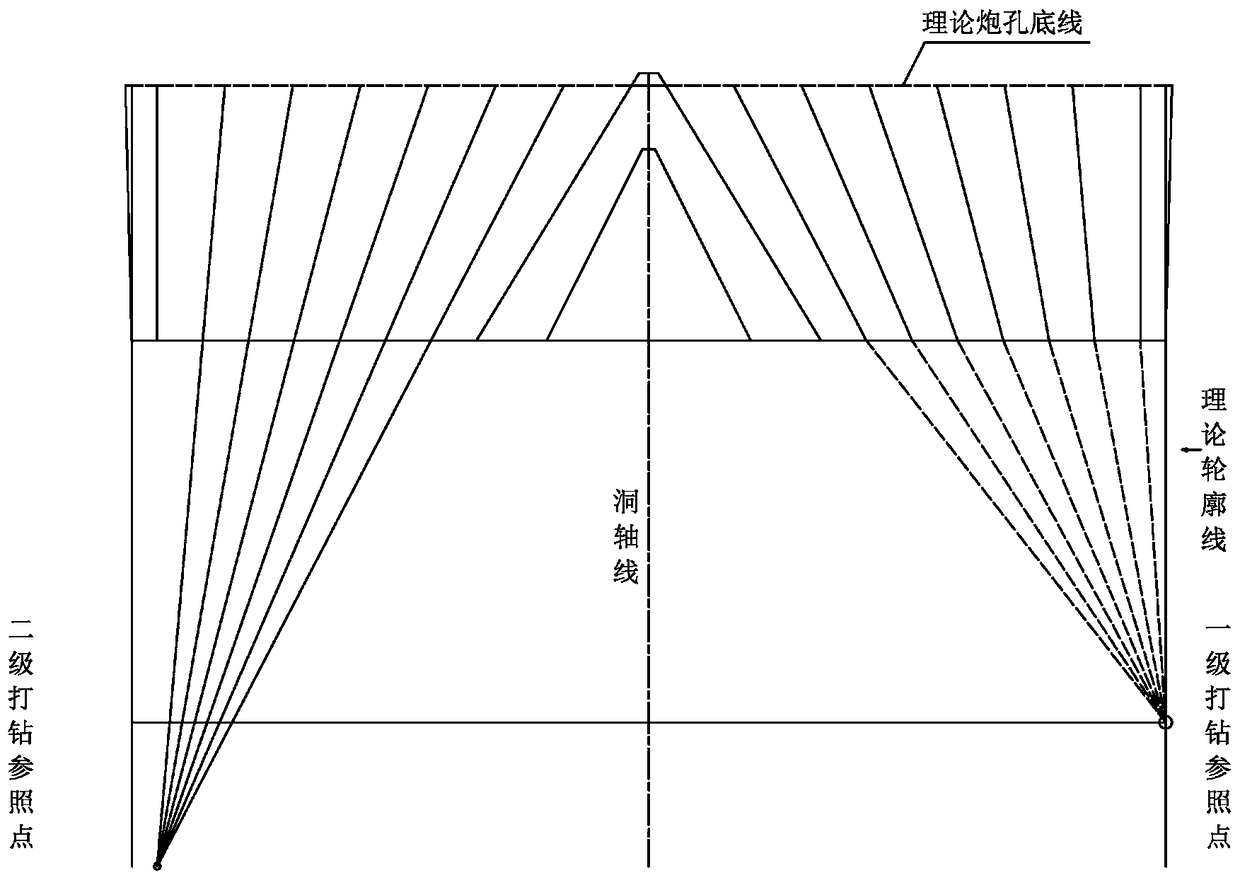

A Blasting Construction Method of Equidistant Fan-shaped Holes in Tunnel Excavation and Expansion Area

The invention discloses a tunnel mine drawing groove area equidistant sectoral hole arrangement blast construction method. The method comprises the steps of 1, designing a drawing, wherein blast holes are reasonably arranged according to the tunnel lithology grade and the tunnel blast design requirement, and an equidistant sectoral hole arrangement method is utilized to conduct CAD software drawing; 2, erecting an instrument and conducting surveying and lofting, wherein the drawing in the first step is utilized, a vertical line is made in the profile plane of the joint of the blast holes, a lofting rod or a ready-made anchor rod is arranged and fixed on the vertical line, and a nylon rope is hung and serves as a drill lofting line; 3, conducting drilling, wherein the drawing in the first step is utilized, and a drill reference point construction method is adopted to conduct construction; 4, conducting charge blast, wherein powder charging, blocking, blast network connection, alerting and blast initiating are conducted according to the designed detailed requirement for segmentation of the powder charge volume of each blast hole, and the powder charging structure. The tunnel mine drawing groove area equidistant sectoral hole arrangement blast construction method is easy to learn and operate, and hole arrangement and lofting on a palm mine drawing groove area are precisely conducted.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG +1

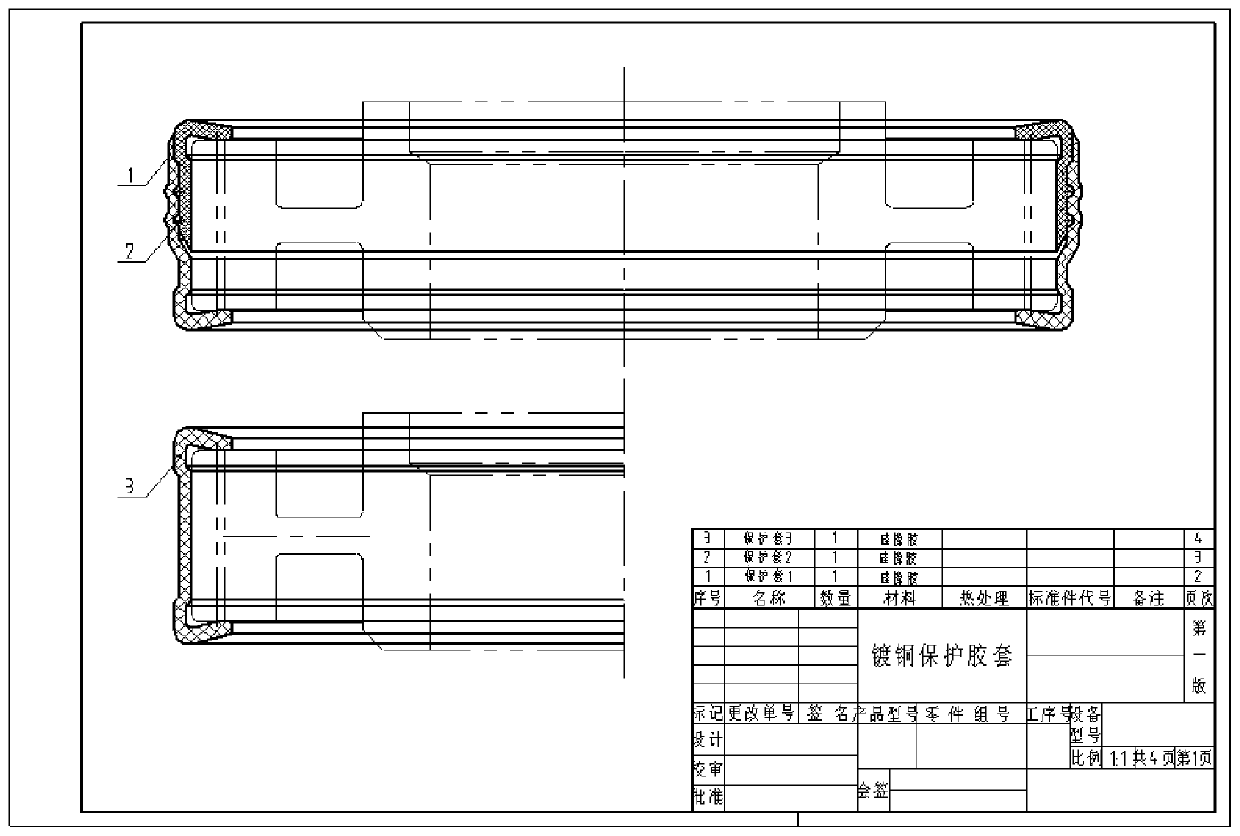

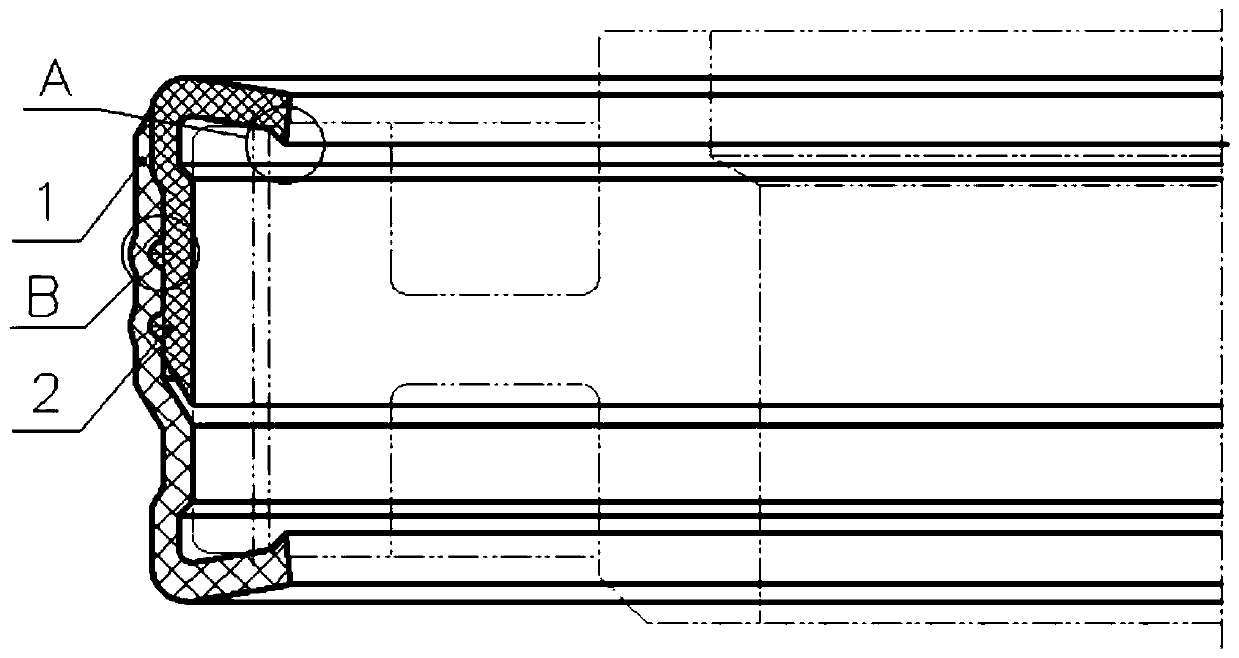

Protection method with sealing structure and sealing protection tool

PendingCN111501028AUniform qualityImprove the protective effectLiquid/solution decomposition chemical coatingAdhesiveProcess engineering

The invention belongs to the technical field of local protection of metal surface treatment, and relates to a protection method with a sealing structure and a sealing protection tool. The tool comprises protection covers and sealing lip structures, the protection covers seal protection parts, and the sealing lip structures seal the transition areas of the protection parts. The tool replaces an original tradition protection mode, the original mode for local protection through manual bonding and adhesive hanging is changed, the protection quality is improved, the efficiency is promoted, environmental protection and energy conservation are realized, and cost decreasing and benefit increasing are achieved.

Owner:HARBIN DONGAN ENGINE GRP

Digital anti-slip inkjet ink and preparation method, preparation method of digital anti-slip ceramic tiles

ActiveCN111362728BEasy to implementAnti-slip coefficient controllableClaywaresSURFACTANT BLENDAcidity regulator

The invention relates to a digital anti-slip inkjet ink and a preparation method thereof, and a preparation method of a digital anti-slip ceramic tile. Digital anti-slip inkjet ink, including digital anti-slip inkjet ink A and digital anti-slip inkjet ink B, digital anti-slip inkjet ink A includes parts by weight raw materials: 40-48 parts of anti-slip glaze; 0-25 parts of calcined alumina; 62 parts of solvent ~70 parts; 6~9 parts of dispersant; 16~22 parts of surfactant; 1~4 parts of defoamer; ~20 parts; 62~70 parts of solvent; 6~9 parts of dispersant; 16~22 parts of surfactant; 1~4 parts of defoamer; 3~7 parts of acidity regulator.

Owner:GUANGDONG JIA MEI CERAMIC +4

Hybrid electrolysis system for the production of copper cathodes

ActiveCN106835196BRealize comprehensive utilizationElimination of remelting processPhotography auxillary processesProcess efficiency improvementElectricityBusbar

The invention belongs to the technical field of smelting, and particularly relates to a mixed electrolysis system for producing a cathode copper; the mixed electrolysis system comprises an electrolytic bath and electrolyte in an electrolytic bath cavity; two bath openings in parallel of the electrolytic bath are paved with cathode and anode conducting busbars along the length direction; the mixed electrolysis system for producing the cathode copper further comprises a cathode and a mixed electrolytic process special anode which are arranged in parallel along the length direction of the electrolytic bath; the cathode and the mixed electrolytic process special anode are electrically connected with the cathode and anode conducting busbars; the plate body of the mixed electrolytic process special anode is obliquely hung with a coarse copper / residual electrode plate. The mixed electrolysis system for producing the cathode copper can direct recycle the residual polar plate, or completely apply the course copper to produce the high purity cathode copper; thus the mixed electrolysis system can eliminate the re-melting procedure of the residual polar plate, shorten the copper smelting technical flow, and save huge cost and high energy consumption for re-melting the residual polar plate.

Owner:铜陵有色金属集团股份有限公司

Rope-dropping-fishing-free multifunctional downhole throttler

InactiveCN111691862ARemarkable cost reduction and efficiency increasePrevent slippingFluid removalWell/borehole valve arrangementsCheck valveEnvironmental geology

The invention relates to the technical field of gas field gas recovery, in particular to a rope-dropping-fishing-free multifunctional downhole throttler. The rope-dropping-fishing-free multifunctionaldownhole throttler comprises a fishing head, a lock block body, a limiting portion and a gas nozzle seat rod. The lock block body is detachably connected to the outer circumference surface of the fishing head, a lock block hole is formed in the outer circumference surface of the lock block body, a lock block is slidingly connected into the lock block hole, and one side of the lock block makes contact with the outer circumference surface of the fishing head. The limiting portion is detachably connected to the top end of the lock block body, and the inner circumference surface of the limiting portion is slidingly connected with the fishing head. The gas nozzle seat rod is slidingly connected to the inner circumference surface of the fishing head. A gas nozzle seat is knocked out through downgoing impact force of a plunger, a large passageway is formed, meanwhile the throttler can be used as a downhole positioner for a plunger drainage gas recovery measure, it is not needed to fish the throttler and trip in the downhole positioner again, and the effect of reducing the cost and increasing benefits is remarkable. A check valve is additionally arranged in the throttler, the situation that liquid slips as the plunger moves downwards during plunger drainage gas recovery is avoided, and the effect of plunger drainage gas recovery is improved.

Owner:PETROCHINA CO LTD

A low-cost silicon carbide deoxidation method

The invention discloses a low-cost silicon carbide deoxidation method, and belongs to the technical field of ladle refining. The low-cost silicon carbide deoxidation method is characterized by comprising the following process steps: slag washing, refining, electric slagging and deoxidation, wherein a deoxidizer comprises silicon carbide and calcium carbide, acceleration of a steel slag interface reaction and soft blowing. Compared with the prior art, the low-cost silicon carbide deoxidation method has the characteristics that the product deoxidation effect is good, the deoxidation cost is reduced remarkably and the product quality is stable.

Owner:RIZHAO STEEL HLDG GROUP

Method and mold structure for conical rubber spring vulcanization mold full-automatic mold opening

ActiveCN112428490ARealize fully automated production operationsImprove working conditionsDomestic articlesPolymer scienceVulcanization

The invention discloses a method and mold structure for the conical rubber spring vulcanization mold full-automatic mold opening. A mode that a glue injection insert of a vulcanization mold is fixed to a middle mold of a mold and moves up and down along with the middle mold is adopted, automatic separation between a mold glue injection barrel and a vulcanization product is completed, automatic operation of the glue injection insert is achieved, and a mode that a guide mechanism is arranged among the middle mold, petal molds and a lower mold of the vulcanization mold, so that the petal molds move up and down along with the middle mold to finish separation and closing between the two petal molds, automatic separation between the petal molds and a vulcanized product is realized, the vulcanized product is automatically ejected in a manner of arranging an ejection mechanism on the lower mold of the vulcanization mold, and a mode that a positioning mechanism is arranged between a bottom moldof the vulcanization mold and a lower flat plate of vulcanization equipment to realize quick positioning between the vulcanization mold and the vulcanization equipment. According to the method and mold structure for the conical rubber spring vulcanization mold full-automatic mold opening, full-automatic separation among mold parts and between the mold parts and the vulcanized product is achieved,and high-difficulty semi-automatic operation and structure of using a crane back and forth at present are avoided.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Sealing structure and installation method of a horizontal split pump

ActiveCN110671356BReduce in quantityReduced processing performancePump componentsPumpsImpellerEngineering

The invention provides a sealing structure of a horizontal axially split pump and a mounting method of the sealing structure. The problems that the process requirement of head-to-head metal sealing adopted for an existing horizontal axially split pump is high, the cost of flat gasket sealing is high, the reliability of gumming sealing is poor, and interstage sealing is lacked are solved. The sealing structure comprises a stereoscopic sealing groove and an integrated sealing element matched with the stereoscopic sealing groove. The stereoscopic sealing groove is formed by sealing ring sealing grooves located in the peripheries of N shell body sealing rings separately and a sealing groove in an upper pump body and a lower pump body. The sealing groove in the upper pump body and the lower pump body comprises two pump body sealing grooves in the axially split surface of the lower pump body and two pump shaft end sealing grooves. The two ends of the two pump body sealing grooves are connected with the two pump shaft end sealing grooves separately, and each sealing ring sealing groove is connected with the two pump body sealing grooves. N is determined by the stage number of the horizontal axially split pump, the impeller form and the impeller arrangement position.

Owner:西安航天泵业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com