Rope-dropping-fishing-free multifunctional downhole throttler

A multi-functional choke technology, applied in the direction of production fluid, wellbore/well parts, wellbore/well valve device, etc., can solve the problem that the choke nozzle cannot be removed, and achieve significant cost reduction and efficiency increase Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

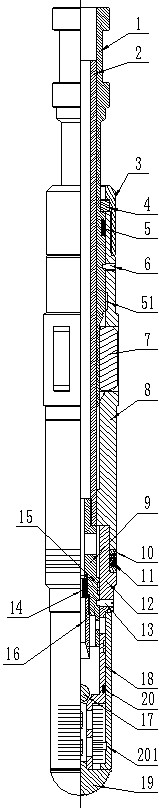

[0037] Referring to Figures 1 to 3, it is a schematic structural diagram of Embodiment 1 of the present invention, a multifunctional downhole choke free of rope fishing, which is characterized in that it includes:

[0038] salvage head 1;

[0039] A lock block body 8, the lock block body 8 is detachably connected to the outer peripheral surface of the fishing head 1, and the outer peripheral surface of the lock block body 8 is provided with a lock block hole, and the lock block 7 is slidably connected in the lock block hole. One side of the lock block 7 is in contact with the outer circumferential surface of the fishing head 1;

[0040] A limiting part, the limiting part is detachably connected to the top of the lock block body 8, and the inner peripheral surface of the limiting part is slidably connected with the fishing head;

[0041] Air nozzle seat post 2, the air nozzle seat post 2 is slidably connected to the inner circumferential surface of the fishing head 1;

[0042...

Embodiment 2

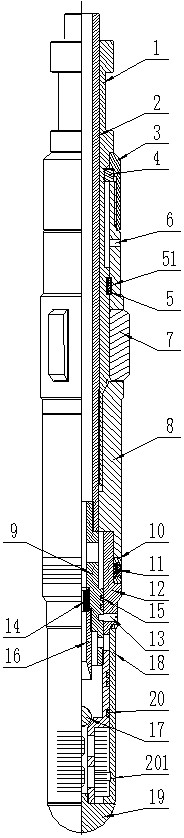

[0053] refer to figure 2 , The difference of this embodiment is: a pin 6 is arranged between the lock block body 8 and the fishing head 1 .

[0054] During actual use: the pin-6 can prevent the locking block 7 from being extruded by the large diameter of the fishing head 1 when being lowered due to small resistance, and cannot complete the normal lowering.

Embodiment 3

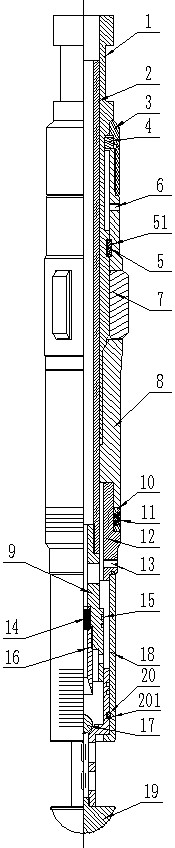

[0056] refer to Figure 2-3 and Figure 5, the difference of this embodiment is: the trigger surface on the outer peripheral surface of the fishing head 1, the diameter of the trigger surface is larger than the outer diameter of the fishing head, the outer peripheral surface of the trigger surface has an upper placement groove, and the upper placement groove An expandable C ring-5 is provided, and the outer circumferential surface of the expandable C-ring-5 is slidably connected with the lock block body 8, and the inner circumferential surface of the lock block body 8 is provided with an upper limit slot which cooperates with the expandable C-ring-5 51, and the upper limit groove 51 is located on and above the lock block 7.

[0057] In actual use: the lock block 7 is extruded by the large neck of the salvage head 1 and stuck in the slot of the preset working cylinder, and at the same time, the expandable C ring 15 then goes down to the slot 8 of the lock block body and pops o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com