High-speed stable production method of CQ-grade thin-gauge galvanized sheet

A stable production, thin gauge technology, applied in the field of high-speed and stable production, can solve the problems of wrinkles, unsuitable for high-speed production of thin gauge galvanized sheets, low production capacity, etc., to reduce scratches, reduce costs and increase efficiency, and order delivery. Guaranteed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0019] As shown in the figure, a method for high-speed and stable production of CQ-grade thin-gauge galvanized sheets based on the present invention is used in a continuous hot-dip galvanizing unit.

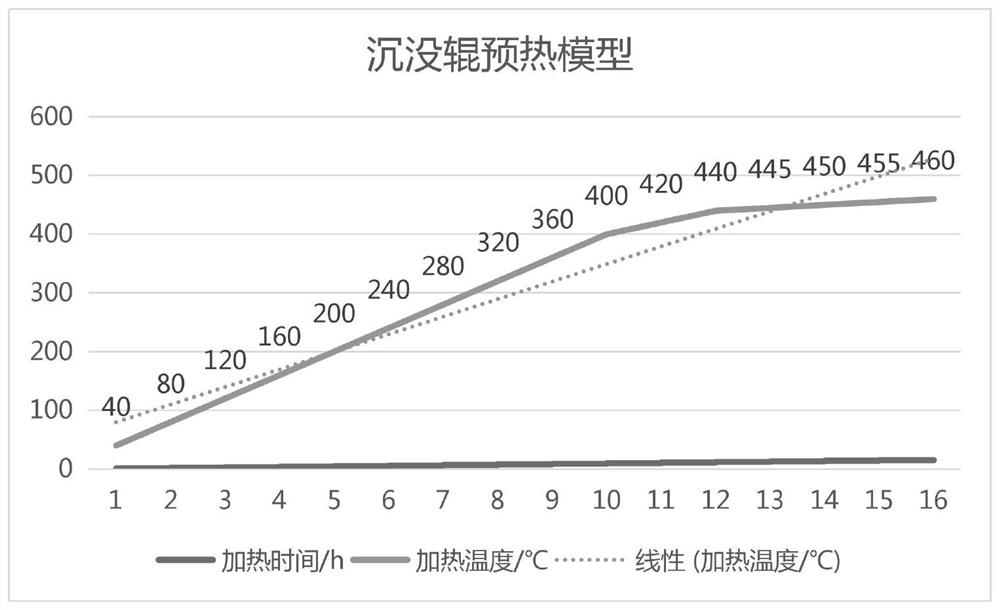

[0020] 1. Preheating of the sinking roller: before maintenance, the sinking roller is heated to 400°C for 10 hours, then heated to 440°C for 2 hours, and finally heated to 460°C for 4 hours to preheat the model. For details, see Table 1 below and attached figure 1 :

[0021] Table 1 Preheating time and temperature table of sinking roller

[0022] Heating time / h 1 2 3 4 5 6 7 8 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com