Sealing structure of horizontal axially split pump and mounting method of sealing structure

A technology with a horizontally split and sealed structure, which is applied to the components, pumps, and pump components of pumping devices for elastic fluids, which can solve the problems of poor reliability of glued sealing, high cost of flat gasket sealing, lack of interstage sealing, etc. problems, to achieve the effect of reducing processing and manufacturing costs, reducing the difficulty of machining, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

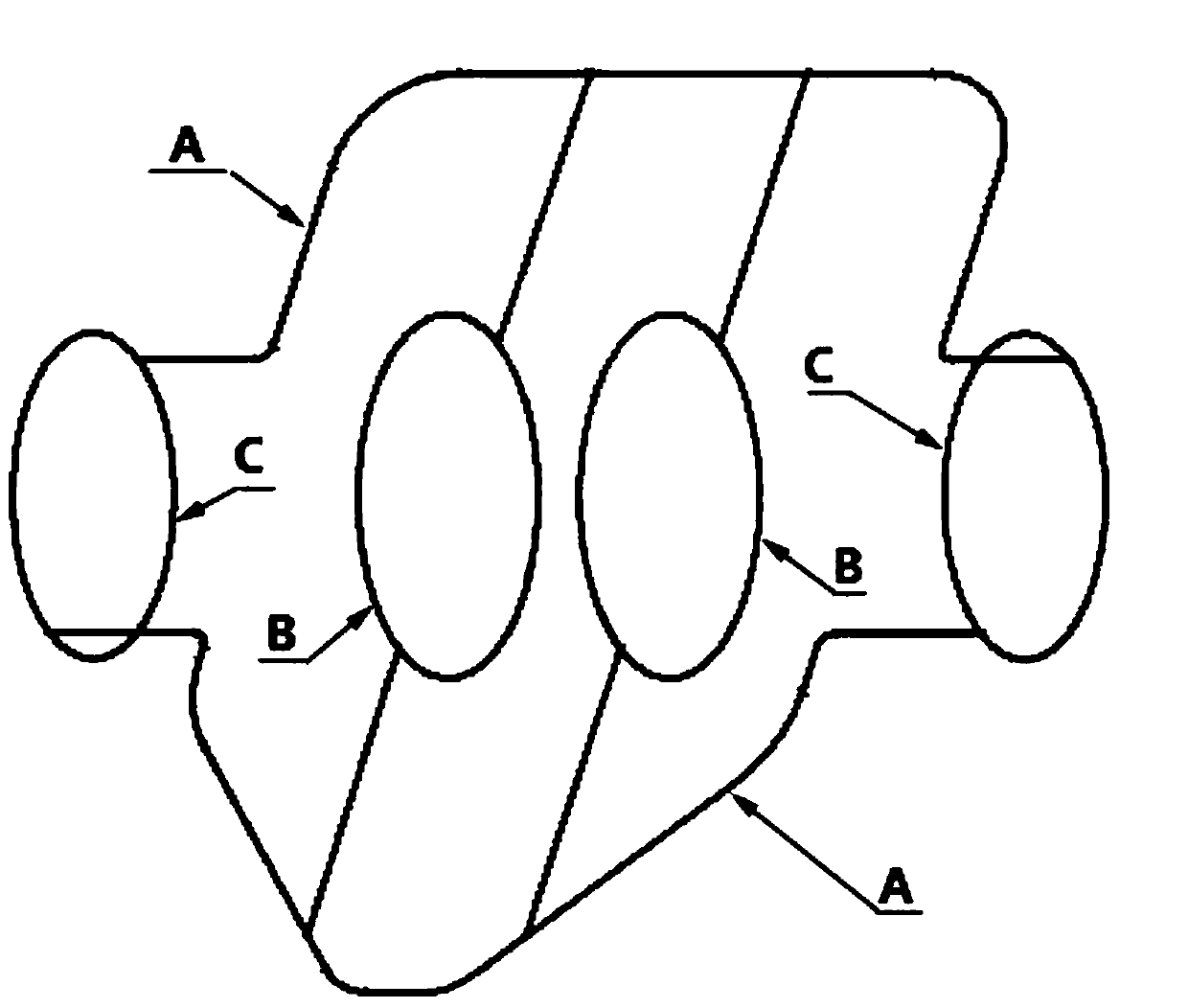

[0045] A sealing structure of a horizontally split pump comprises a three-dimensional sealing groove and an integrated sealing element adapted to the three-dimensional sealing groove.

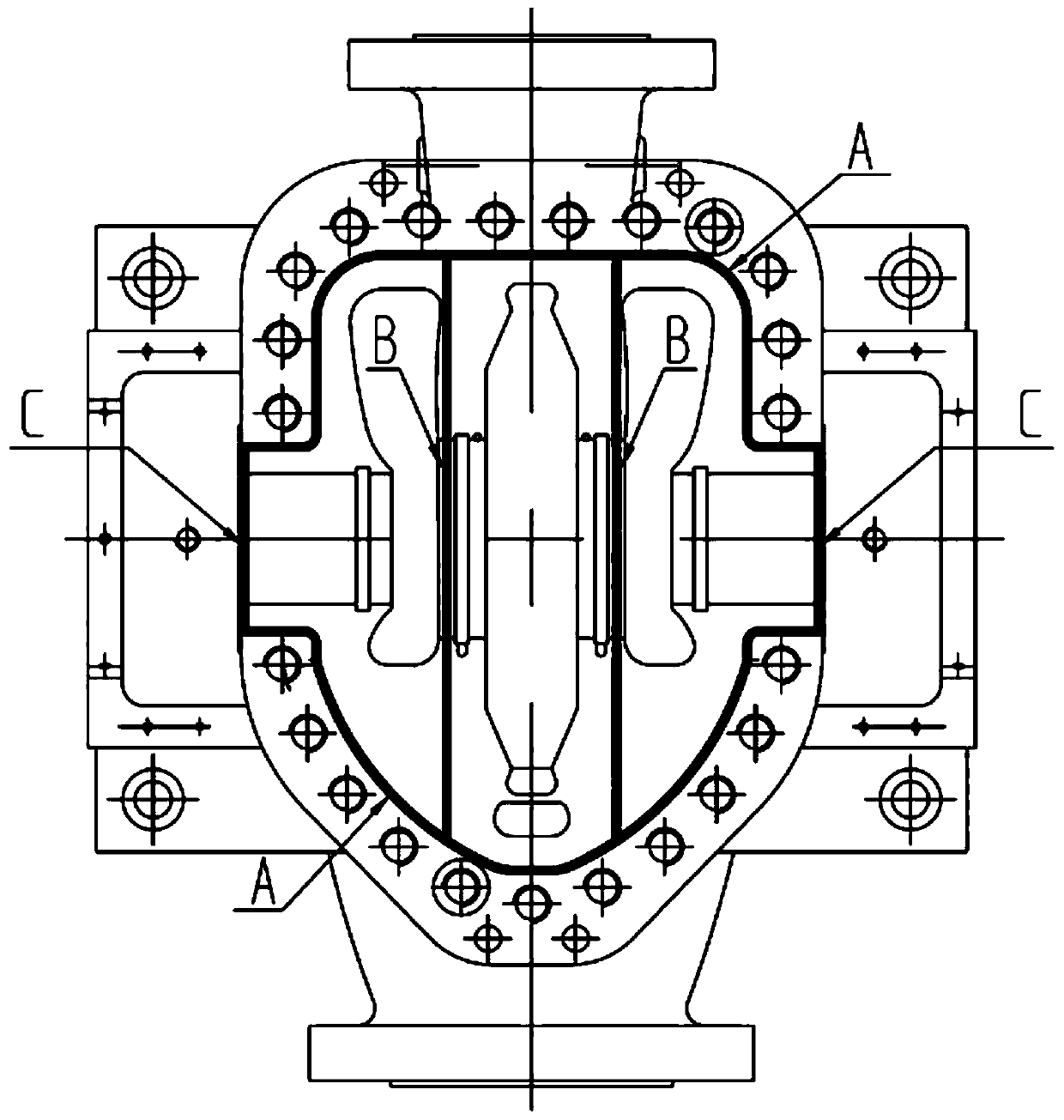

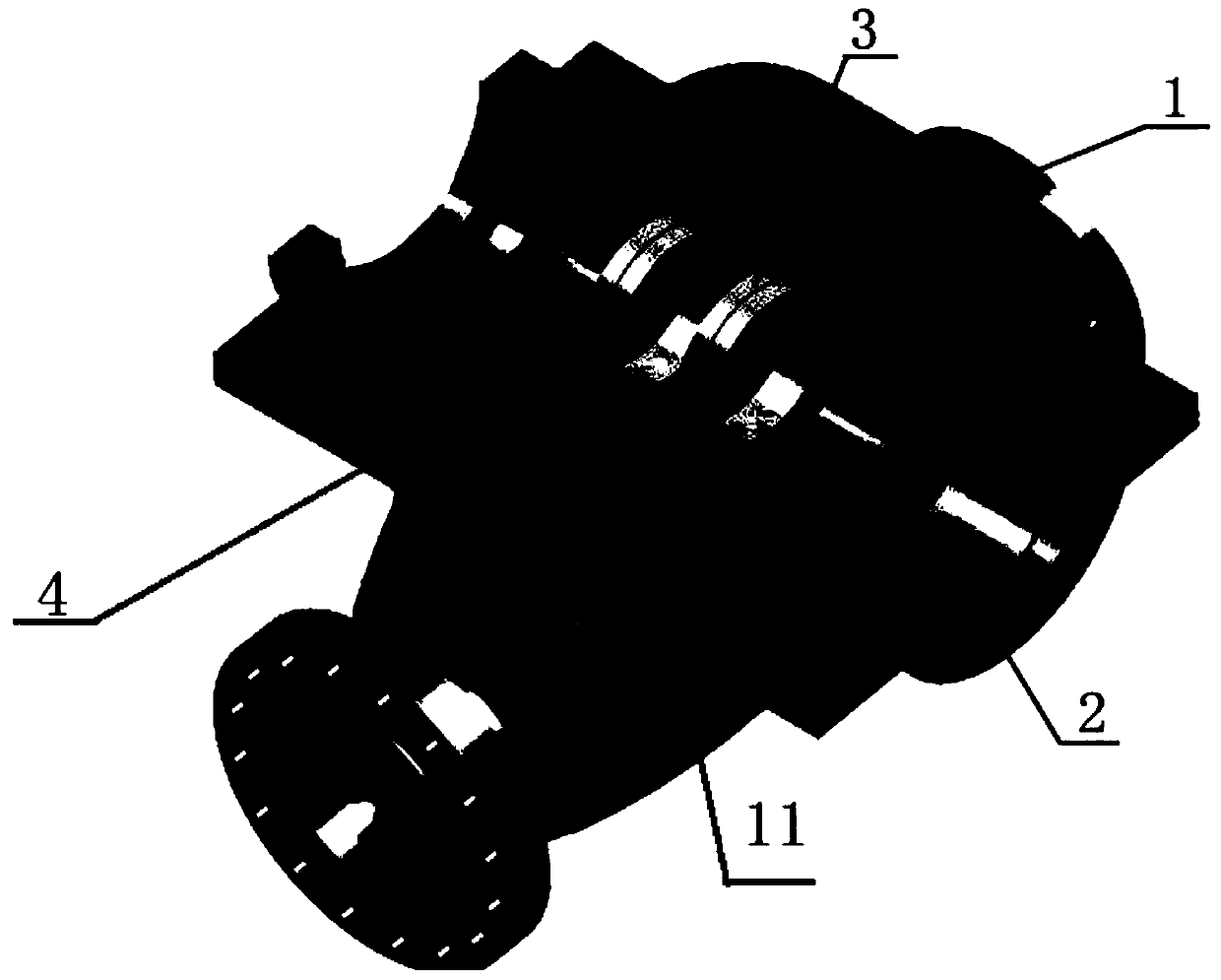

[0046] Wherein, the three-dimensional sealing groove is formed by the sealing ring sealing groove 3 located on the outer circumference of the N housing sealing rings and the sealing grooves on the upper and lower pump bodies;

[0047] The three-dimensional seal groove is formed by the seal ring seal groove 3 located on the outer circumference of the N casing seal rings and the seal grooves on the upper and lower pump bodies; the seal ring seal groove 3 should be set to avoid the stop device on the seal ring; The sealing grooves on the upper and lower pump bodies include two pump body sealing grooves 1 and two pump shaft end sealing grooves 2; the two p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com