Mixed electrolysis system for producing cathode copper

An electrolysis system and cathode copper technology, which is applied in the field of smelting, can solve problems affecting the quality of cathode copper, fracture, and influence on electric efficiency, and achieve the effects of saving huge costs and high energy consumption, shortening the process flow, and eliminating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

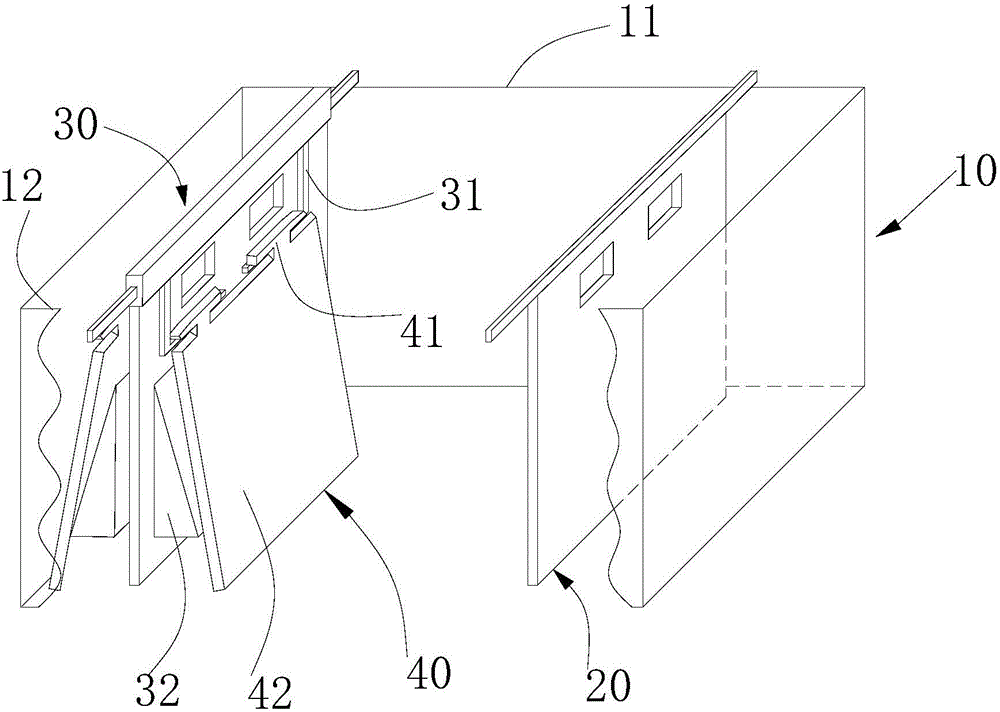

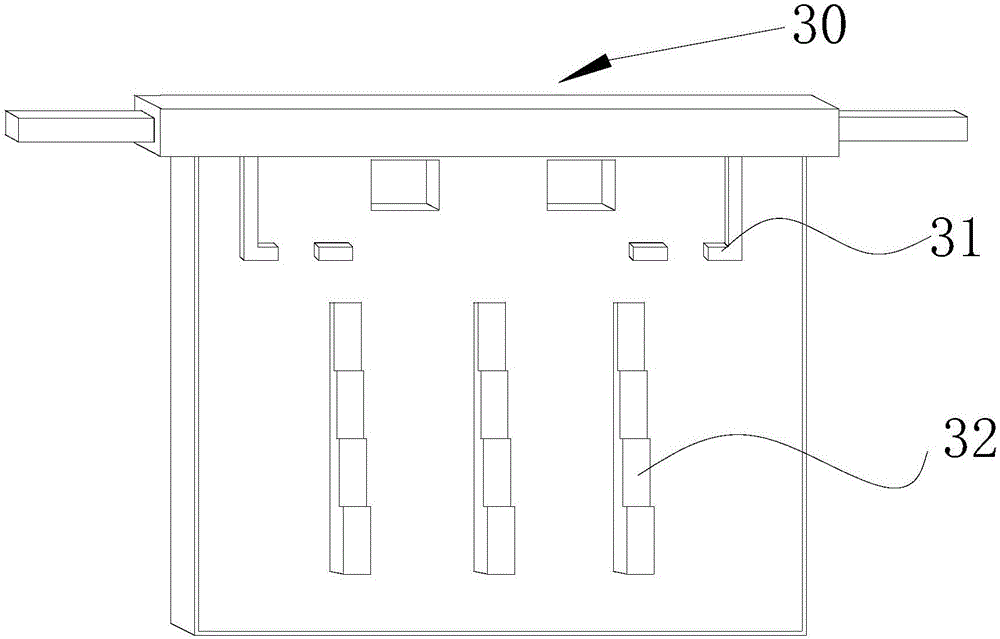

[0010] A hybrid electrolysis system for producing cathode copper, comprising an electrolytic cell 10 and an electrolyte in the cavity of the electrolytic cell 10, two parallel notch edges of the electrolytic cell 10 are laid with negative and positive conductive busbars 11, 12. The hybrid electrolysis system for producing cathode copper also includes a cathode 20 arranged in parallel along the length direction of the electrolytic cell 10 and a dedicated anode 30 for the hybrid electrolysis method. 11 and 12 are electrically connected, and the dedicated anode 30 for the hybrid electrolysis method is hung with a crude copper / residual plate 40, and the crude copper / residual plate 40 is immersed below the liquid level of the electrolyte. The thick copper / residual plate 40 can be caught by the special anode 30 for the mixed electrolysis method, so that the blister copper / residual plate 40 can be fully immersed in the electrolytic solution.

[0011] Preferably, the method of hanging...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com