Tool type safety protective fence structure

A safety protection and tool-type technology, applied in the field of tool-type safety fence structure, can solve problems such as inconvenient disassembly and transition, difficulty in achieving mechanical strength, and inability to prevent, so as to improve mechanical strength and safety, and improve versatility And ductility, the effect of prolonging the number of repeated uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

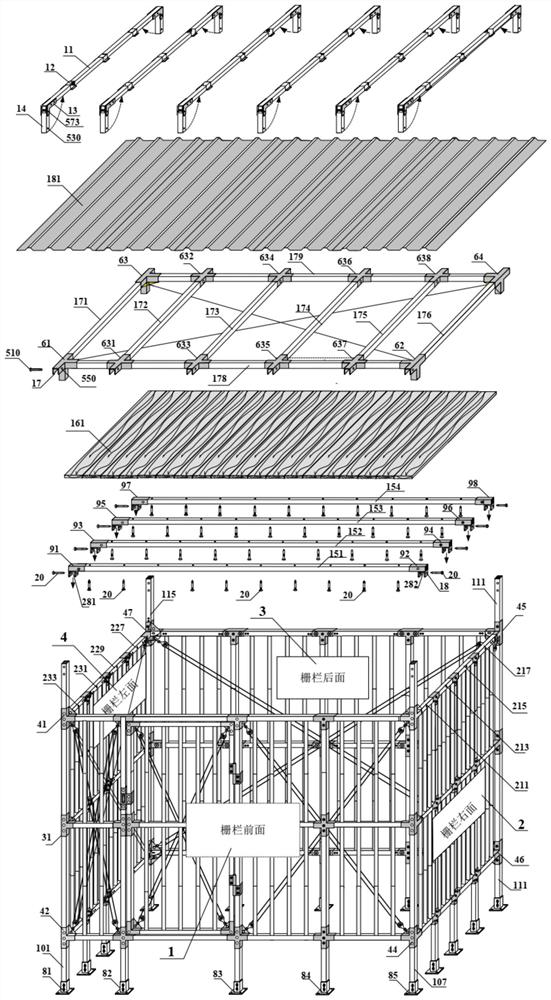

[0051] The present invention is further described below.

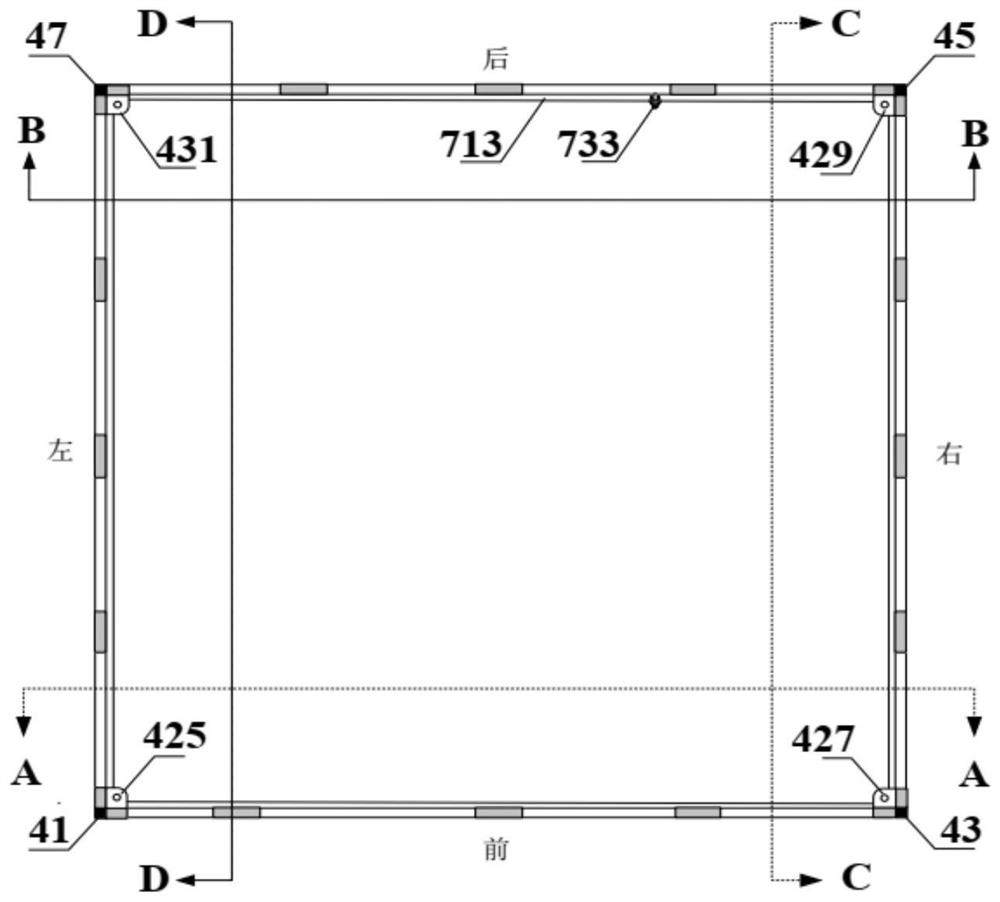

[0052] The tool-type safety fence structure disclosed by the present invention includes a fence surrounding a circumferentially closed structure, the fence includes several fence units and uprights, and the fence units are connected in a detachable manner through the uprights, and the fence units and Diagonal tension ropes are connected between the diagonal corners of the local reinforcement structure formed by the columns, and the oblique tension ropes between two pairs of diagonal corners of the local reinforcement structure cross each other, and the fence is also provided with horizontal tension ropes. The horizontal tension ropes are arranged along the perimeter of the fence to form a closed loop.

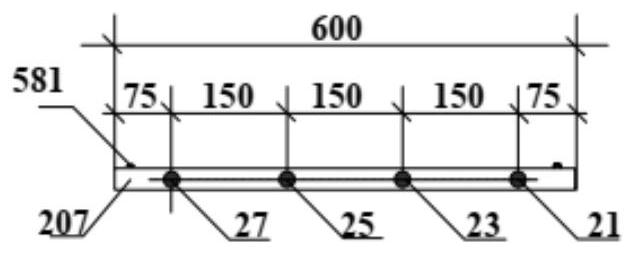

[0053] Among them, the specific design of the fence unit can be selected according to the needs. In order to achieve standardization, except for special parts such as doors, it is preferable to use the same specificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com