Novel track layer for urban track traffic engineering and its construction method

a technology for urban track traffic and construction methods, applied in railway track construction, construction, roads, etc., can solve the problems of reducing the construction space of track sections laying on the main line, affecting the appearance and performance of the structure, and reducing the working space in the narrow space, so as to save energy resources, improve work efficiency, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

ion Preparation, Track Section Hoisting and Mounting Works of the Novel Track Layer

[0096]1. Switching of the Novel Track Layer from a Running State to a Track Section Hoisting State.

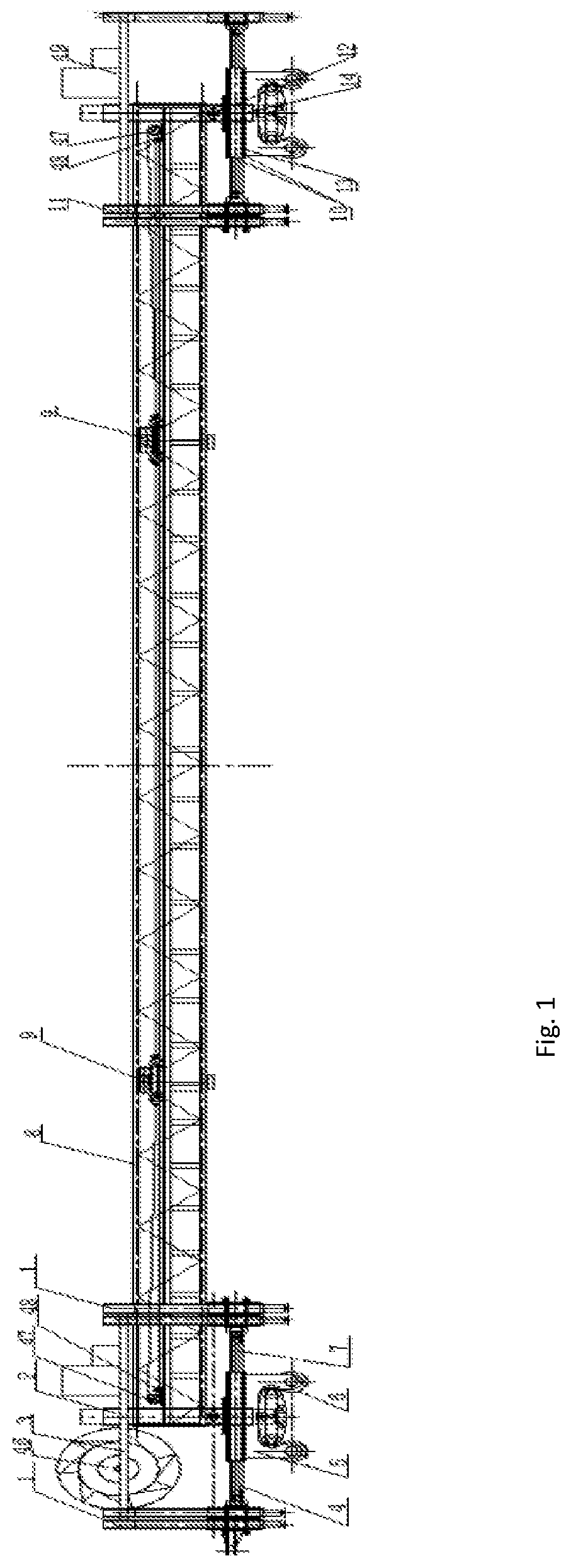

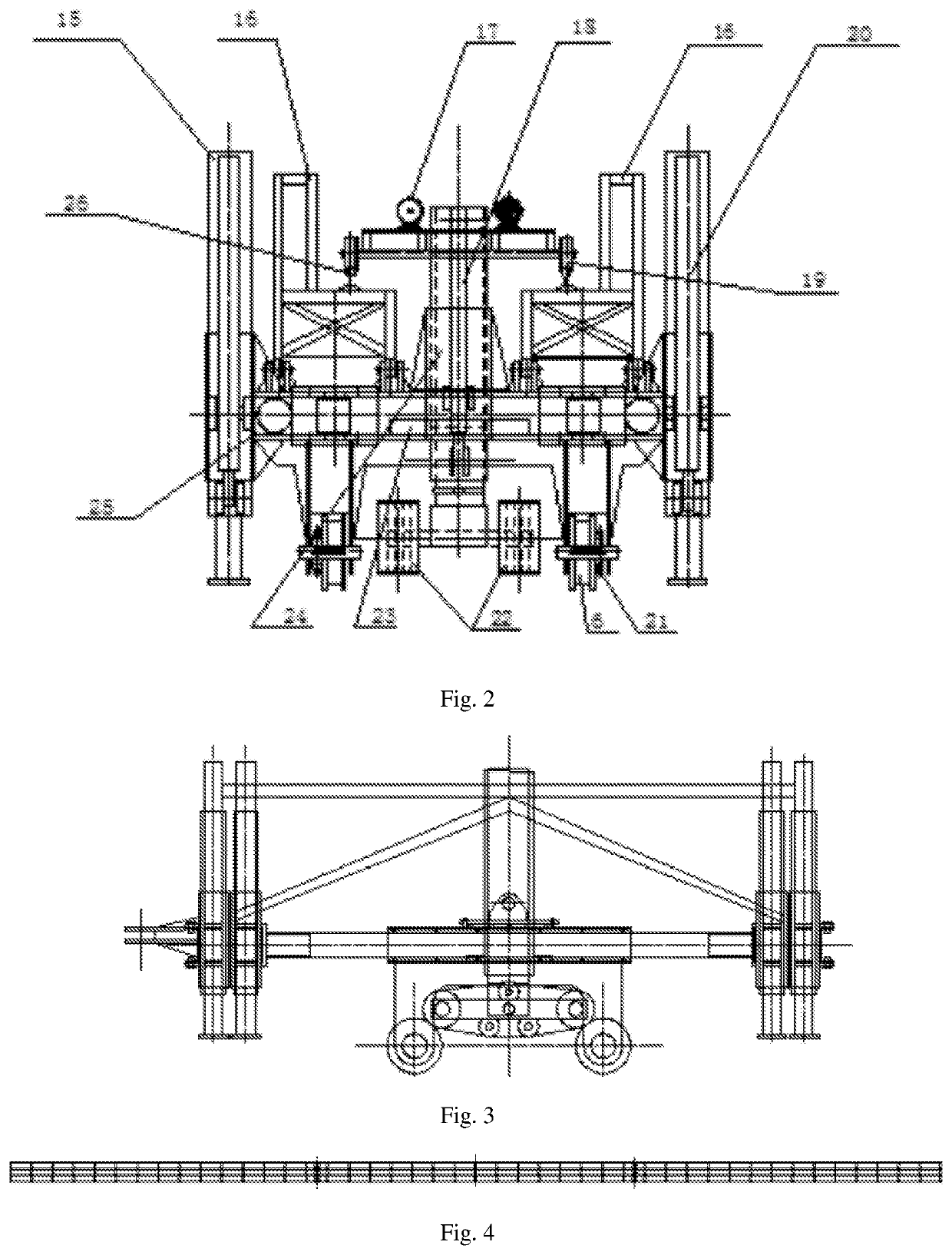

[0097]Referring to FIGS. 1-6, the main structure design of the present invention lies in that: the novel track layer consists of two lifting and walking trolleys and a connecting hoisting truss beam.

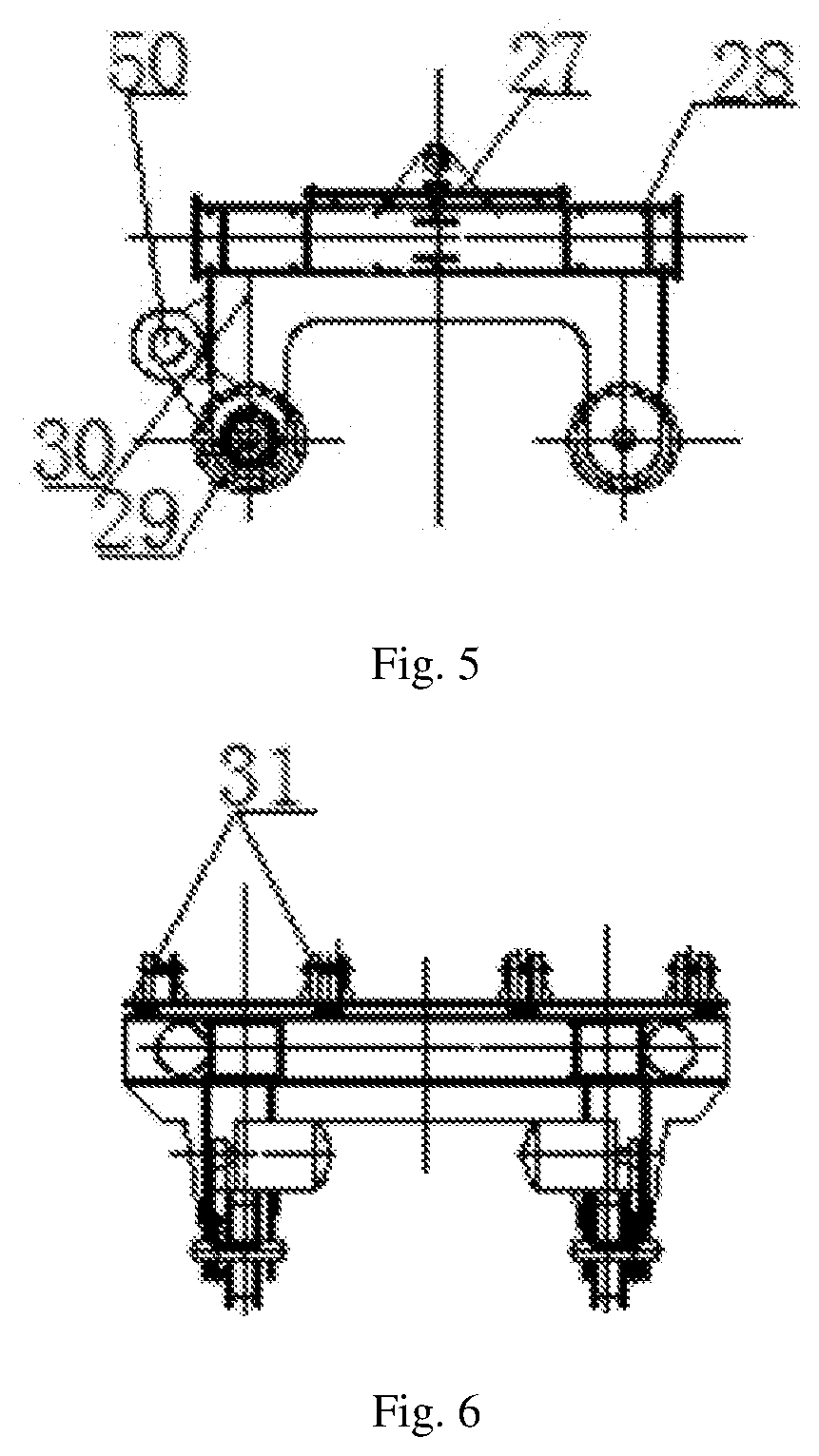

[0098]Referring to FIGS. 5-20, each lifting and walking trolley consists of a horizontal frame beam and a running car. The horizontal frame beam consists of two longitudinal beams, four crossbeams and an upper reinforcing structure (37). Each of the two longitudinal beams acts both as a structural beam of the horizontal frame beam and as a guide column for the running car to move back and forth. Each crossbeam acts both as a structural beam of the horizontal frame beam and as a guide sleeve structure for a vertical supporting structure of the lifting and walking trolley to extend horizontally and laterally. A...

example ii

nd Mounting Construction of Prefabricated Track Plate of the Novel Track Layer

[0131]the laying construction of an urban rail transit track bed is generally carried out after the construction of an interval track bed cushion is completed. The track bed plate is a prefabricated concrete plate generally having a length of 5800 mm (normal version). A curved controlling plate generally has a length of 4500 m to 5000 mm. In order to transport the prefabricated plate conveniently, it is general to mount a steel rail fastener in time after a track bed plate of 25 m to 50 m is layed, to form a transport passage. When the track plate is layed to over 100 m, the track plate and the track state are adjusted. The track plate and the track state are fixed by pouring self-compacting concrete or other mortar material under the track plate to form a track line. Therefore, the laying of the track plate is a key procedure.

[0132]1. Unloading, Hoisting, Moving and Positioning of the Track Plate:

[0133]a....

example iii

Working Surfaces of the Novel Track Layer

[0153]Referring to FIGS. 20-37, the track construction is generally centered on a track-laying base, and upper and lower lines are constructed in both directions. The track switch as key equipment for track steering is constructed in advance. The transfer of working surfaces of the novel track layer is realized by layed track switches and single crossovers. There are three positions in working surface transfer, on the way to a new working surface 1, a new working surface 2 and a new working surface 3:

[0154]1. withdrawing horizontal extension devices of the vertical supporting devices of the No. 1 and No. 2 lifting and walking trolleys of the novel track layer back to a running transfer position; withdrawing the vertical supporting device back to an upper limit transfer running position, and locking; dismounting a power supply of the novel track layer, and rolling a cable into the cable reel; disconnecting the track running wheels of the novel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com