Hollow concrete partition wall plate and production method thereof

A partition wall panel and concrete technology, which is applied in the field of building materials, can solve the problems of lack of preparation of concrete hollow partition wall panels, and achieve the effects of saving storage space, light weight, and improving later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

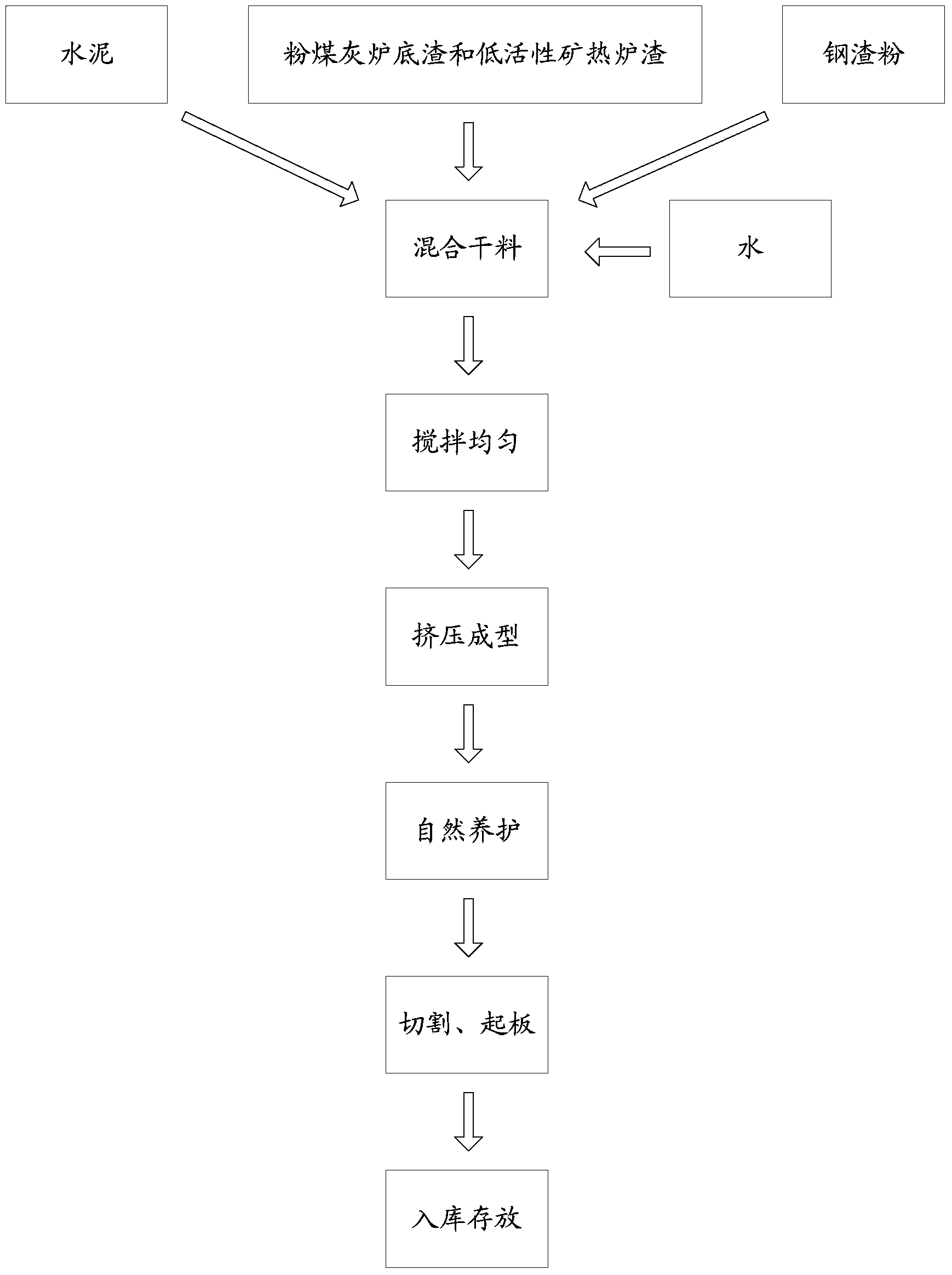

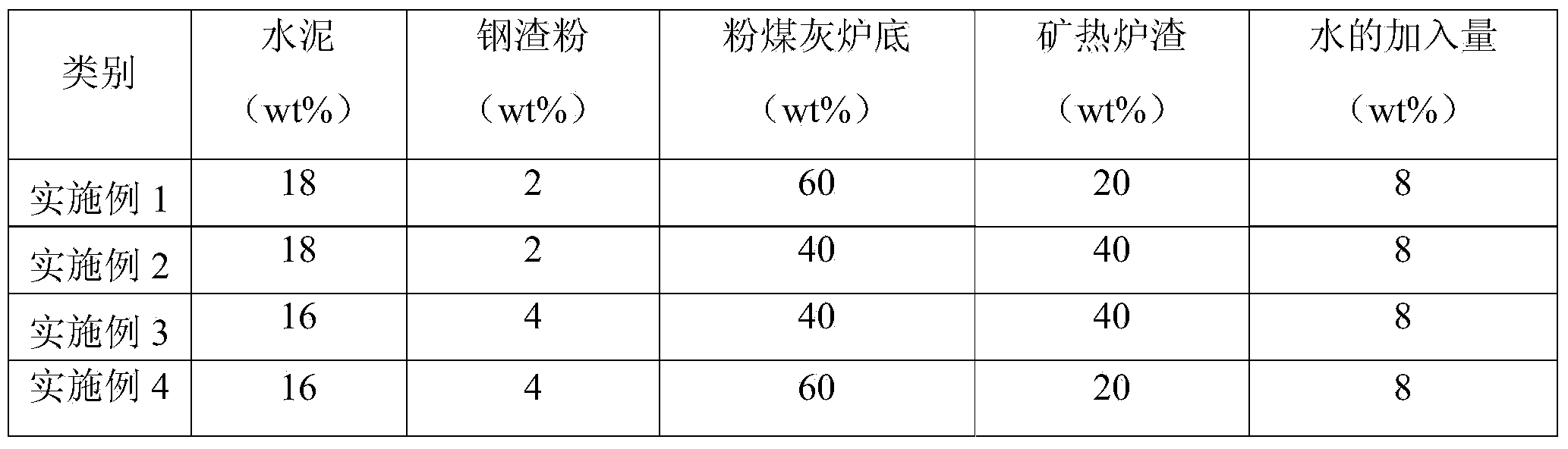

[0051] Such as figure 1As shown, take the dry material components by weight percentage: 18wt% of cement, 2wt% of steel slag powder, 60wt% of fly ash bottom slag, and 20wt% of submerged thermal slag, put them into the mixer and stir them uniformly for 3 minutes; then add water , and then stir evenly for 3 minutes, wherein the amount of water added is 0.4 times the sum of the weight of cement and steel slag powder in the dry material, and the specific data are shown in Table 1. It can be seen from Table 1 that the weight percentage of cement and steel slag powder in the dry material is 20wt% in the dry material, that is, the weight percentage of the water added in the dry material is 8wt%.

[0052] The mixed materials are transported into the extrusion molding machine by a transport truck for extrusion molding, and naturally cured for more than 7 days after molding, and then cut, lifted, inspected, numbered and put into storage. After the concrete hollow partition wall panel is...

Embodiment 2

[0054] Such as figure 1 As shown, take the dry material components by weight percentage: 18wt% of cement, 2wt% of steel slag powder, 40wt% of fly ash bottom slag, 40wt% of ore furnace slag, put them into the mixer and stir them uniformly for 3 minutes; then add water , and then uniformly stirred for 3 minutes, wherein the amount of water added was 40wt% of the sum of the weight of cement and steel slag powder in the dry material, and the specific data were shown in Table 1. It can be seen from Table 1 that the weight percentage of cement and steel slag powder in the dry material is 20wt% in the dry material, that is, the weight percentage of the water added in the dry material is 8wt%.

[0055] The mixed materials are transported into the extrusion molding machine by a transport truck for extrusion molding, and naturally cured for more than 7 days after molding, and then cut, lifted, inspected, numbered and put into storage. After the concrete hollow partition wall panel is t...

Embodiment 3

[0057] Such as figure 1 As shown, take the dry material components by weight percentage: 16wt% of cement, 4wt% of steel slag powder, 40wt% of fly ash bottom slag, 40wt% of submerged thermal slag, put them into the mixer and stir them uniformly for 3 minutes; then add water , and then stir evenly for 3 minutes, wherein the amount of water added is 0.4 times the sum of the weight of cement and steel slag powder in the dry material, and the specific data are shown in Table 1. It can be seen from Table 1 that the weight percentage of cement and steel slag powder in the dry material is 20wt% in the dry material, that is, the weight percentage of the water added in the dry material is 8wt%.

[0058] The mixed materials are transported into the extrusion molding machine by a transport truck for extrusion molding, and naturally cured for more than 7 days after molding, and then cut, lifted, inspected, numbered and put into storage. After the concrete hollow partition wall panel is te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com