Novel weighing device structure of shipbuilding gantry crane

A technology of gantry cranes and weighing devices, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unfavorable lifting weight changes, uneven force measurement, large errors, etc., and achieve large lifting capacity and high lifting height Larger, improved accuracy and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

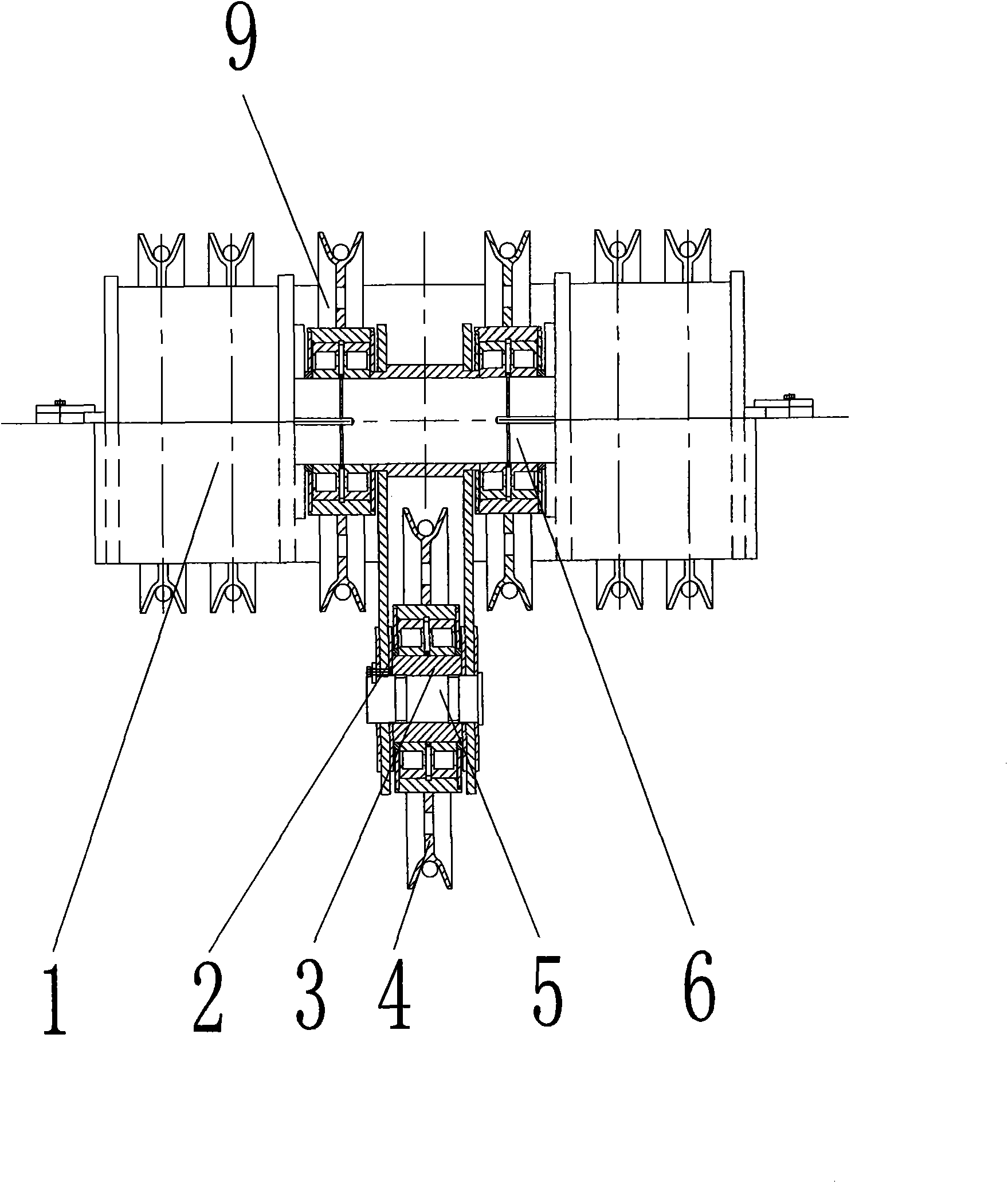

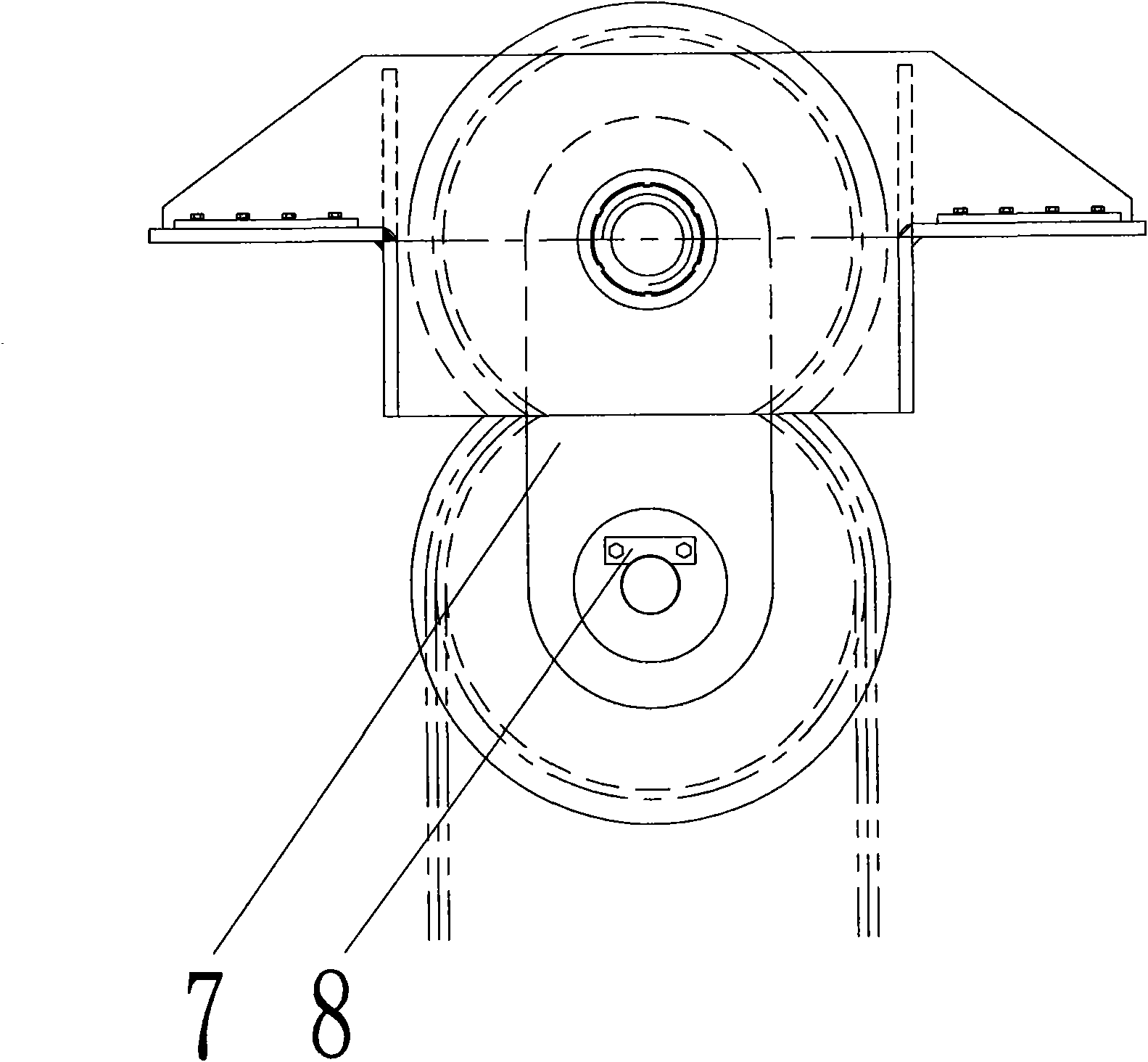

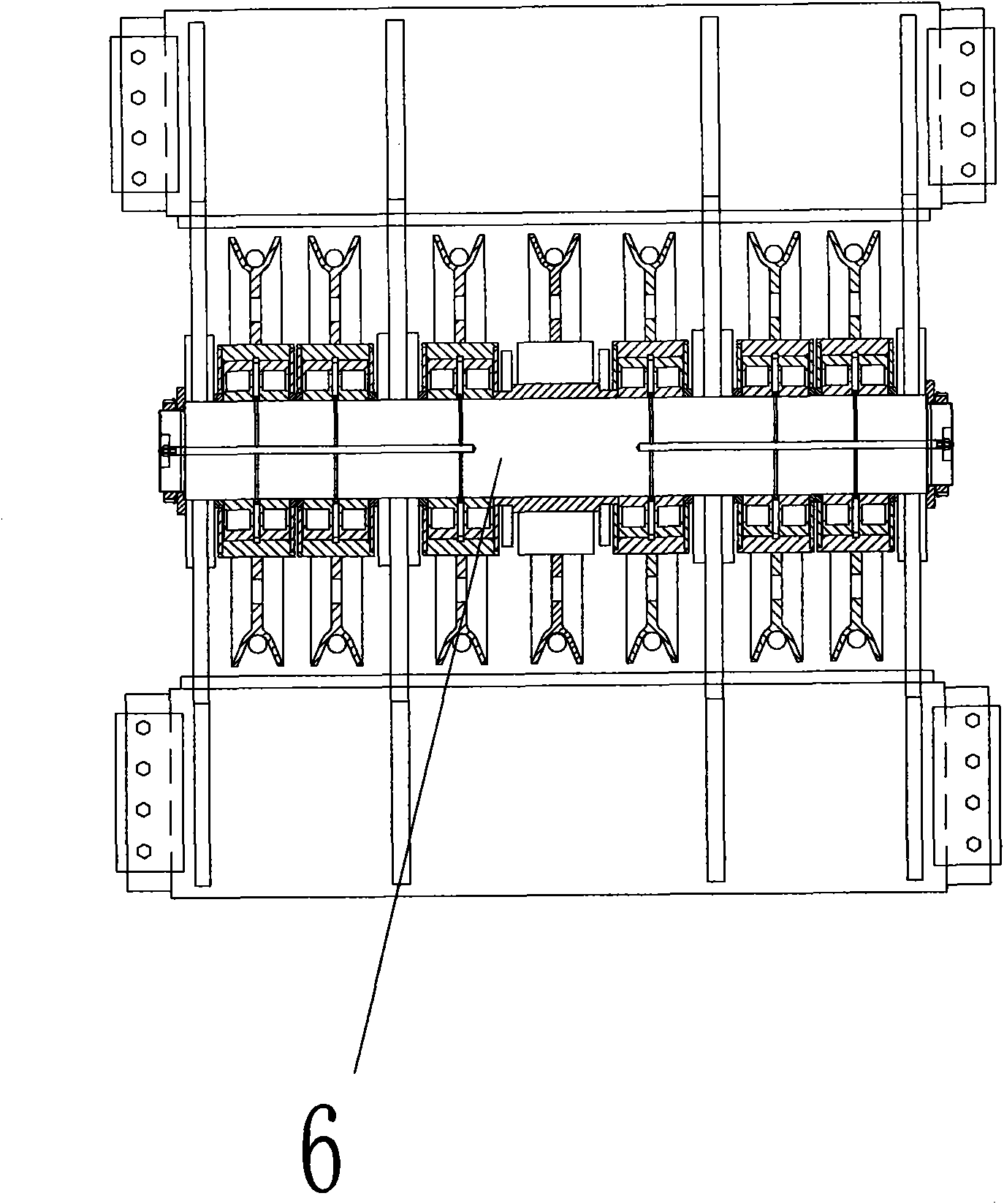

[0018] Such as figure 1 , figure 2 , image 3 The new weighing device structure of the shipbuilding gantry crane shown in has a pulley frame 1 on which a fixed pulley shaft 6 is fixed, and no less than two fixed pulleys 9 are symmetrically sheathed on the fixed pulley shaft 6 . On the fixed pulley shaft 6 and positioned at the center of the fixed pulley, a weighing pulley frame 7 is overcoated, and the weighing pulley frame 7 lower ends are provided with a weighing pulley 4 . The center of the weighing pulley 4 is equipped with a pin-type sensor 5 that is also used as a pulley shaft, and a bushing II 3 is set between the sensor 5 and the pulley 4, and the bushing II 3 can ensure the mutual assembly of the weighing pulley 4 and the sensor 5 size. In order to prevent the sensor 5 from moving axially, a baffle 8 is provided on the side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com