Novel track layer for urban rail traffic engineering and its construction method

A technology of urban rail and traffic engineering, which is applied in the field of engineering technology and science, and can solve the problems of discontinuity, occupation, and impact of temporary running rails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0096] Example 1: Construction preparation, rail row lifting and installation of new track laying machine

[0097] 1. The new track laying machine changes from the running state to the rail row hoisting state

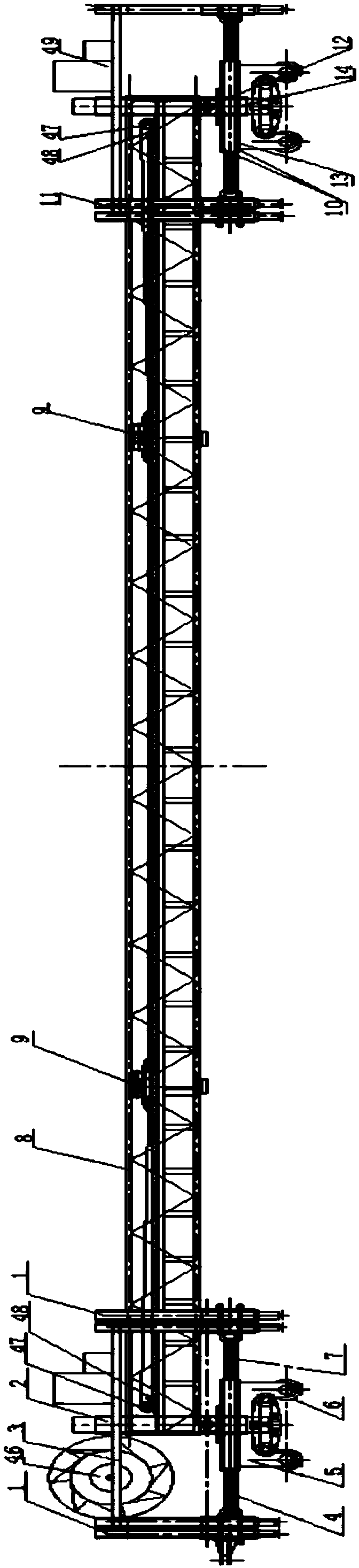

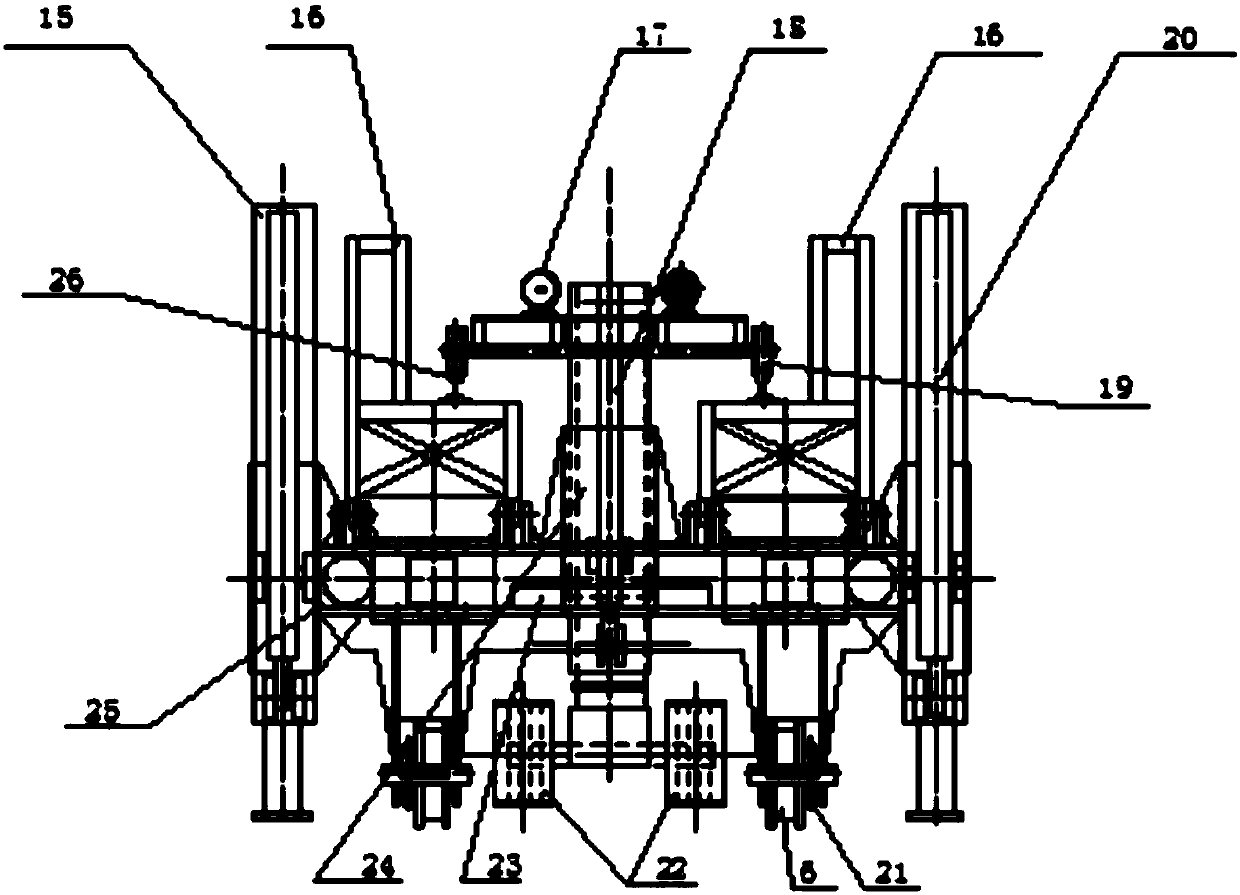

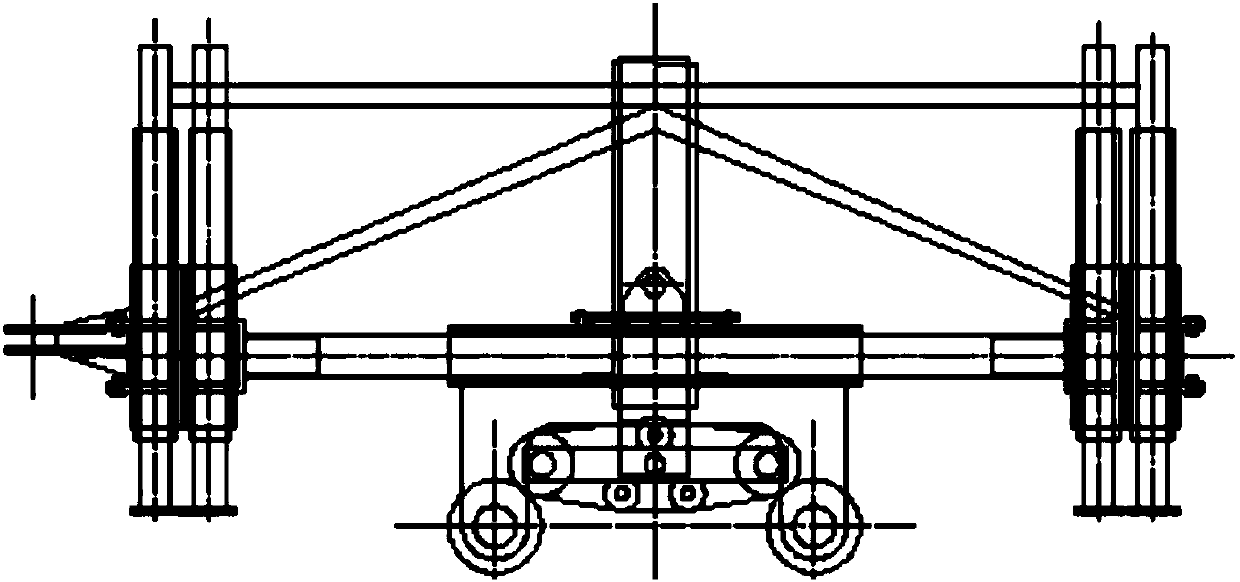

[0098] see Figure 1-6 , The main structural design of the present invention: the new track laying machine is composed of 2 lifting trolleys and connected hoisting truss beams.

[0099] see Figure 5-20 , the lifting traveling trolley is made up of a horizontal frame beam and a walking trolley, and the horizontal frame beam is made up of 2 longitudinal beams, 4 beams and an upper reinforcement structure (37). The 2 longitudinal beams are both the structural beams of the horizontal frame beam and the guide columns for the front and rear movement of the trolley, and the 4 cross beams are both the structural beams of the horizontal frame beam and the guide sleeve structure for the vertical support device of the lifting trolley to realize horizontal and lateral expansion ...

example 2

[0133] Example 2: Lifting and installation of prefabricated track slabs by new track laying machine

[0134] Urban rail transit track bed slab construction is generally carried out after the construction of the section track bed slab cushion is completed. The track bed slab is a prefabricated concrete slab, the length is generally 5800mm (common version), and the length of the curve adjustment plate is generally 4500mm-5000mm. In order to facilitate the prefabricated slab Transportation, generally after laying 25m-50m track bed slabs, install rail fasteners in time to form a transportation channel. When the track slab is laid over 100m, adjust the state of the track slab and the track, and pour self-compacting concrete or other mortar materials under the track slab. The track plate and the track state are fixed to form a track line. Therefore, laying track slabs is a key process.

[0135] 1. Track plate unloading, hoisting, moving and positioning

[0136] a. Lifting of new t...

example 3

[0156] Example 3: Transition of the working surface of the new track-laying machine

[0157] see Figure 20-37 , Track construction is generally centered on the track laying base, and the construction is carried out in both directions on the up and down lines. As the key equipment for track steering, the turnout is constructed in advance. The transfer of the working surface of the new track laying machine is realized by using the completed turnout and single crossing line. There are three positions for the working surface transfer, the new working surface 1, the new working surface 2 and the new working surface 3 on the way:

[0158] 1. Retract the horizontal telescopic device of the vertical support device of No. 1 and No. 2 lifting trolleys of the new track laying machine to the travel transfer position, and retract the vertical support device to the upper limit transfer travel position and lock it. Remove the power supply of the new track laying machine, and reel the cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com