Patents

Literature

73 results about "Trolley lift" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

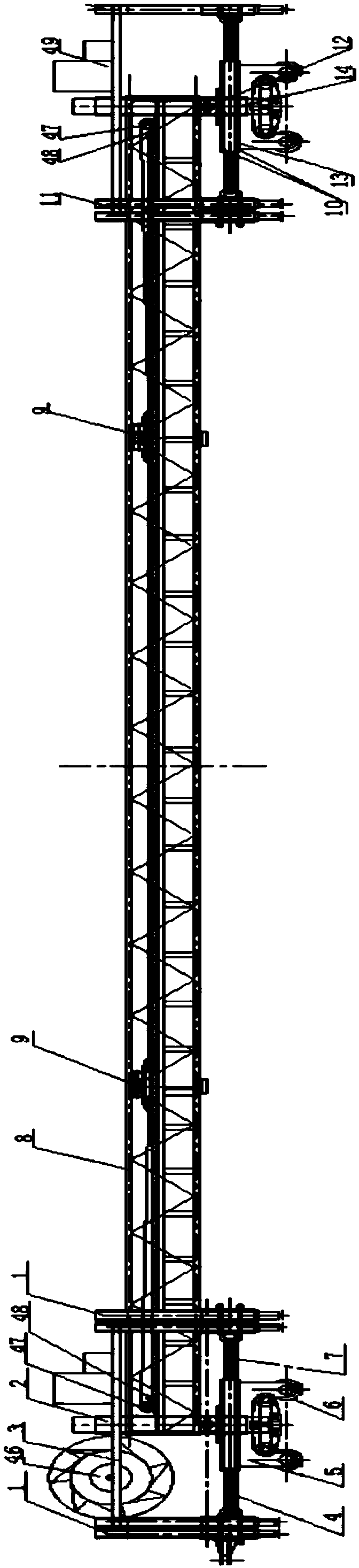

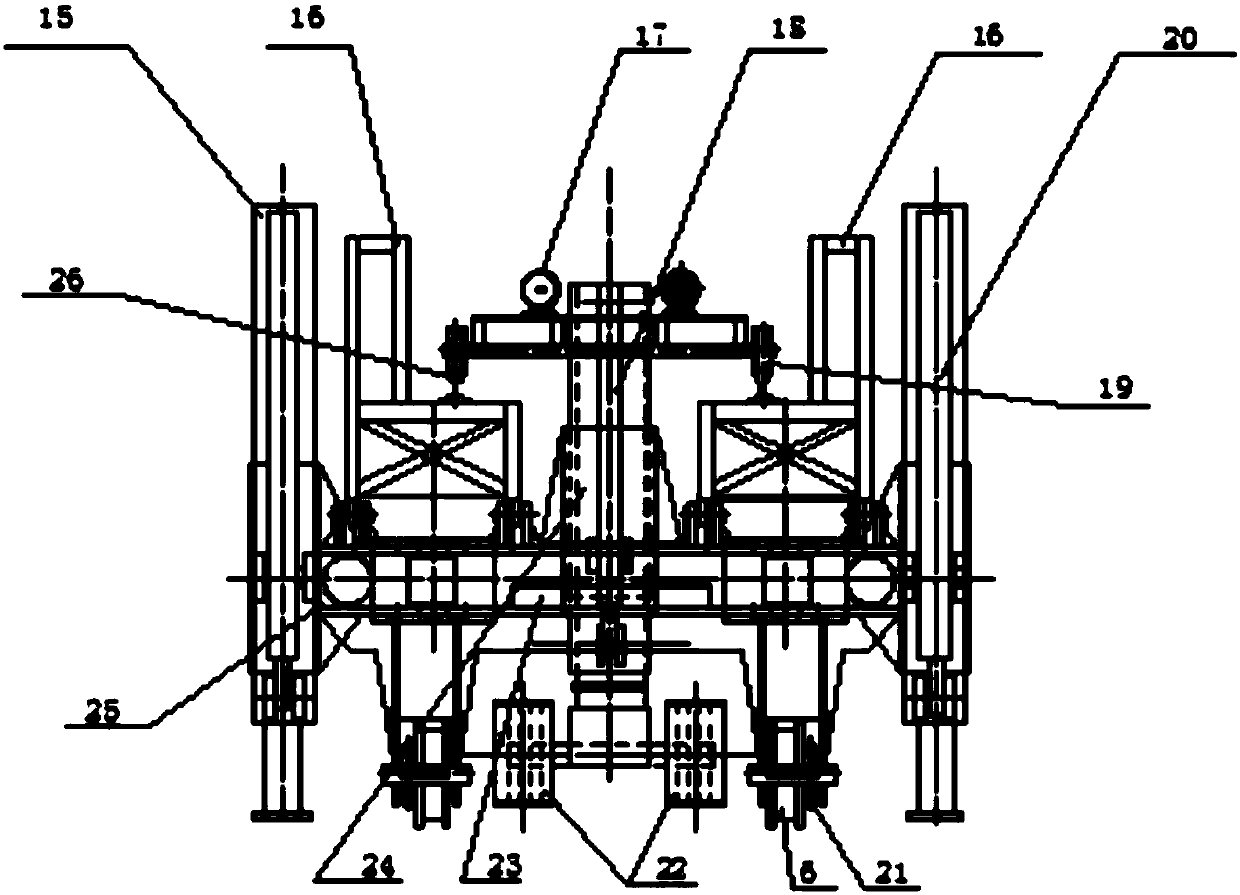

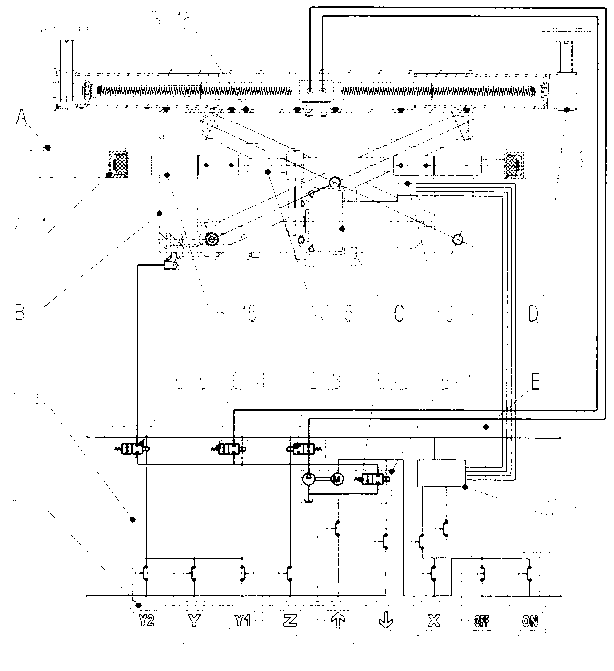

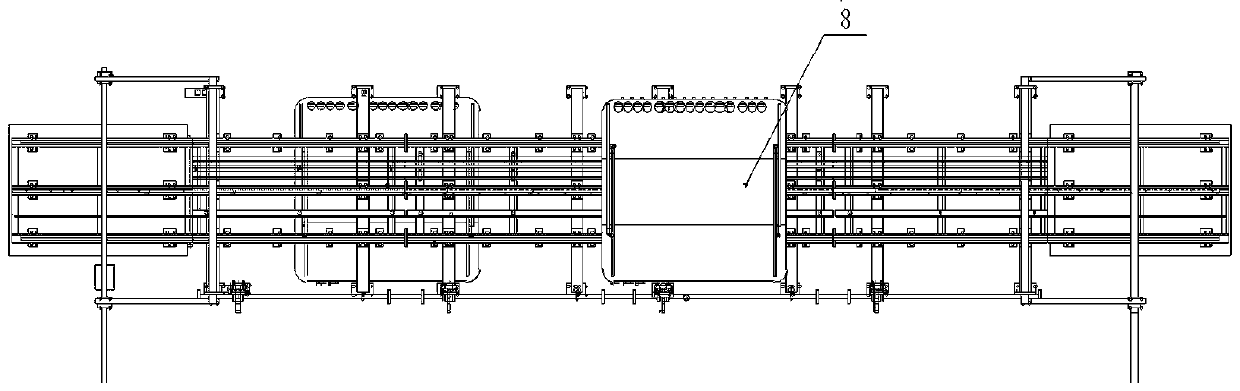

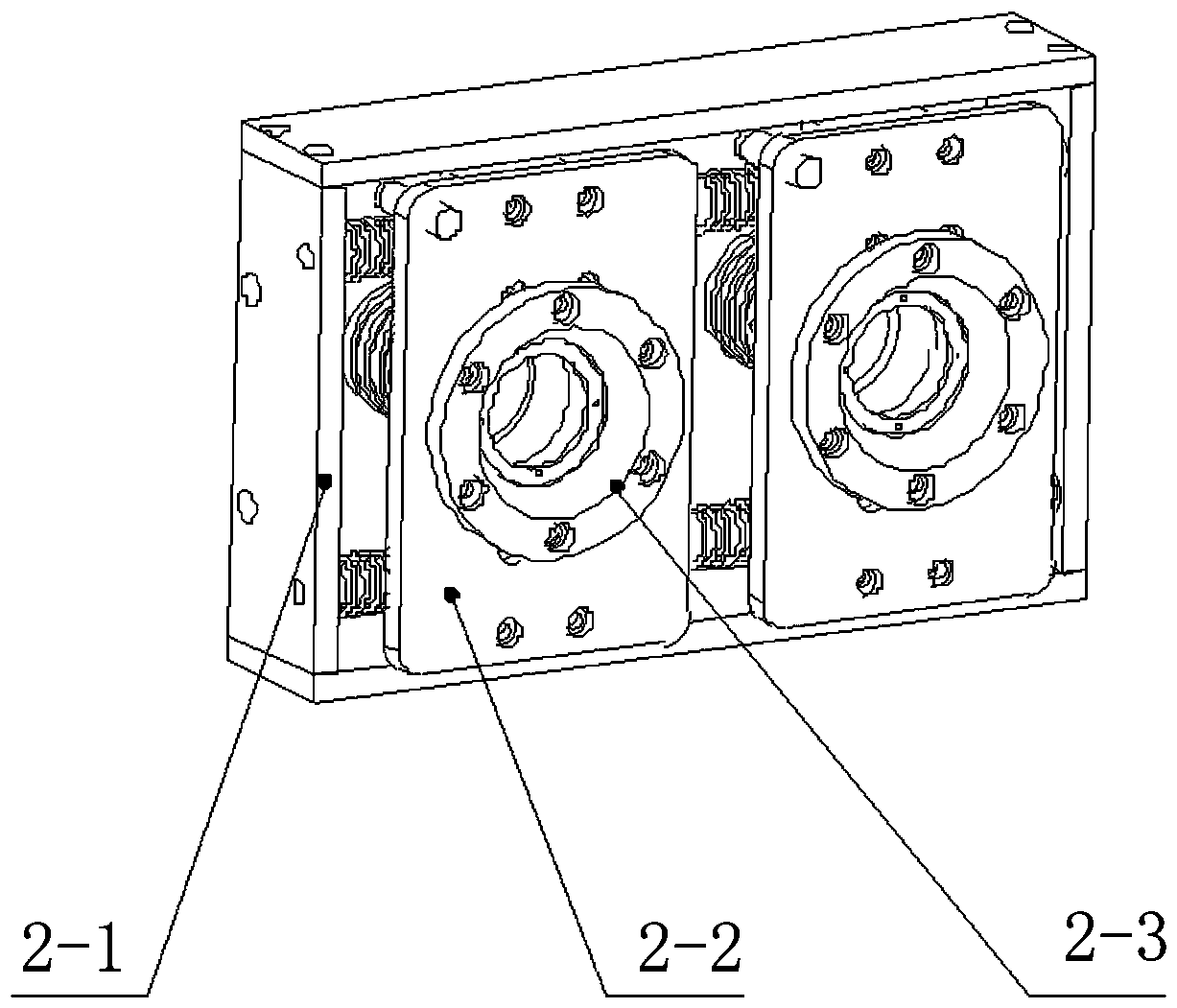

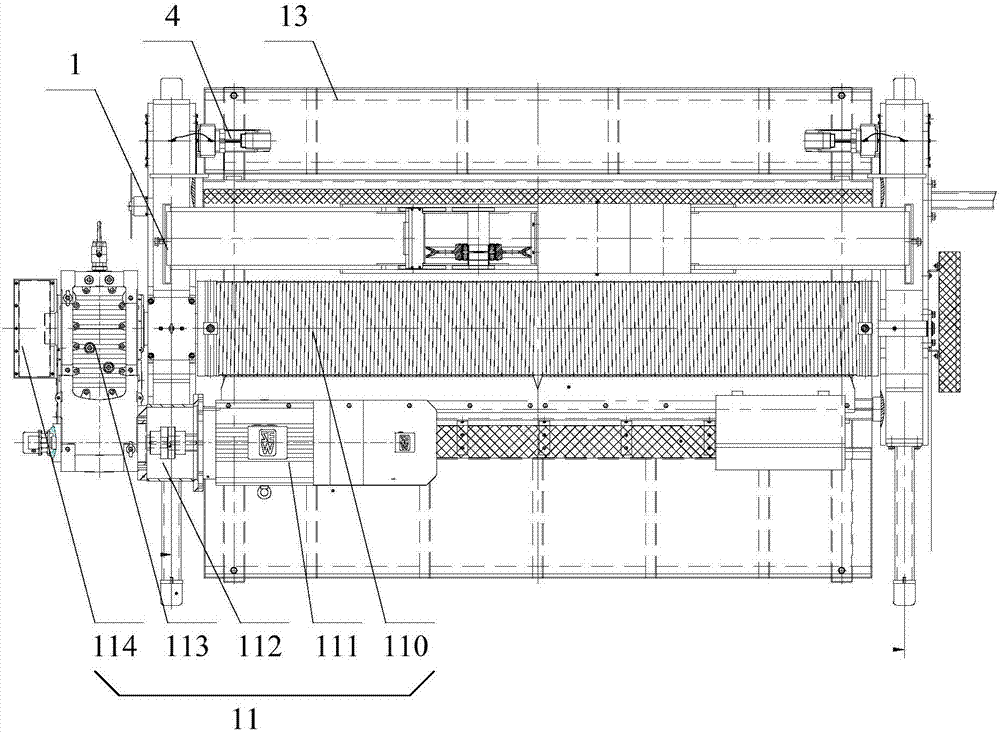

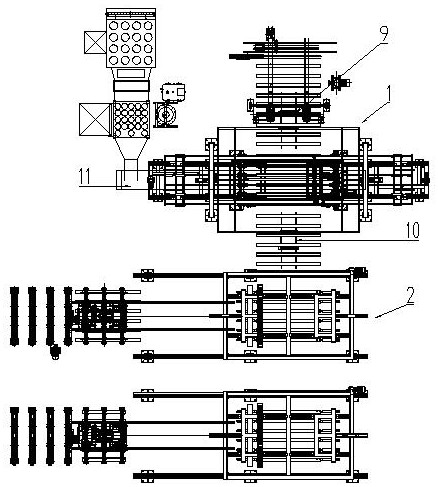

Aluminum bar saw cutting unit

ActiveCN103028780AQuick sortingGuaranteed secondary scratchesMetal sawing devicesAutomatic control devicesStructural engineeringDrive motor

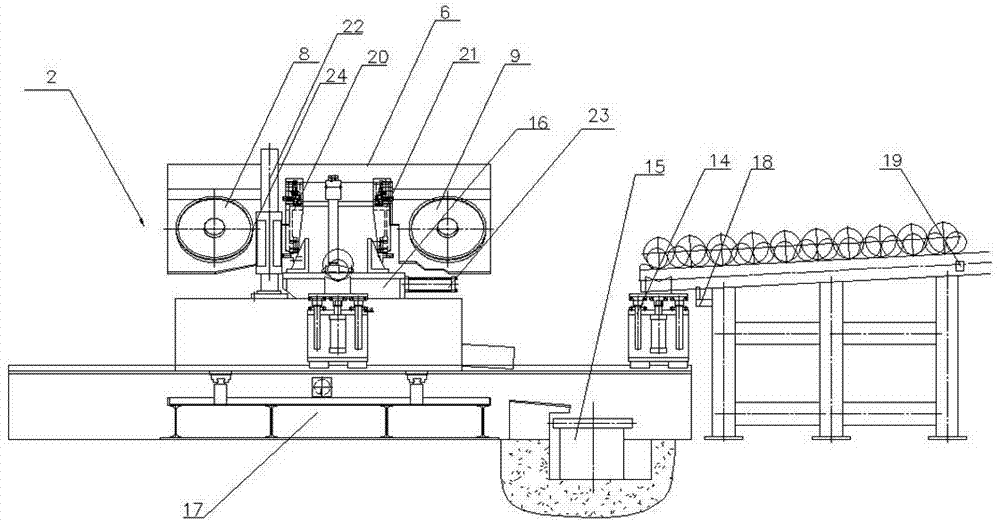

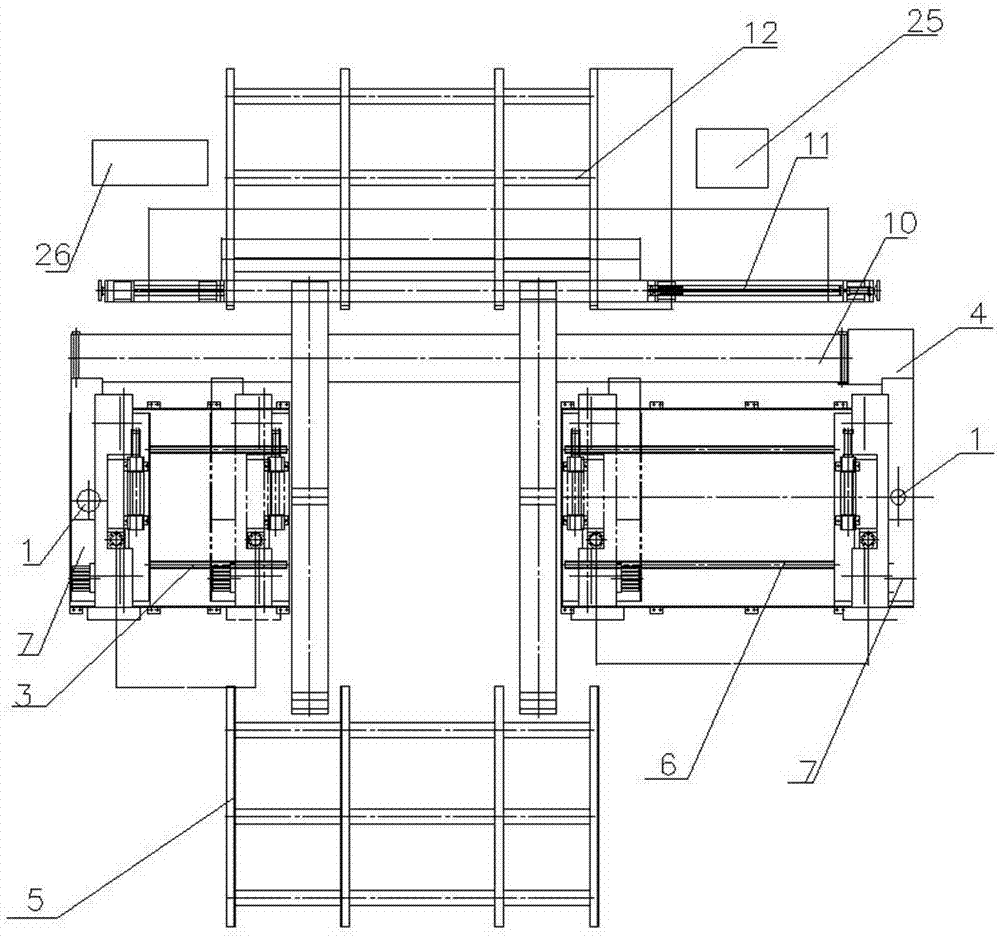

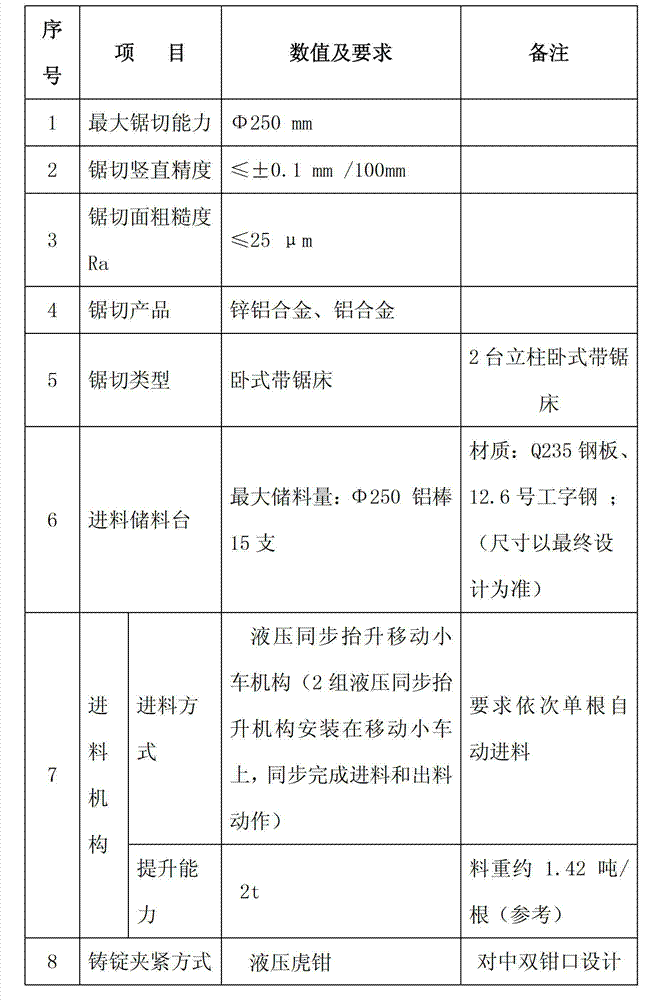

The invention relates to machining equipment, in particular to an aluminum bar saw cutting unit, which comprises a sawing machine host, a feeding mechanism, a discharging mechanism, a waste collection device, a hydraulic system and an electric control system connected with one another, wherein the sawing machine host comprises two mutually symmetric sawing machines, and a clamping device and a sizing device at one end of the sawing machines; each sawing machine comprises a pedestal, a saw carrier on the pedestal, a transmission system, a saw belt tensioning mechanism, a saw carrier feeding system, a saw belt left guide arm and a saw belt right guide arm; the transmission system comprises a driving saw wheel, a driven saw wheel, a transmission belt and a driving motor; the feeding mechanism comprises a feed and storage rack, a cast ingot leveling mechanism and a feeding and discharging lift moving trolley; the discharging mechanism comprises a feeding and discharging lift moving trolley and a discharge and storage rack; and the hydraulic system is connected with a saw belt tensioning hydraulic device, a saw cutting feed hydraulic device and a trolley lift hydraulic device. According to the aluminum bar saw cutting unit, the production efficiency and the saw cutting accuracy of the machine tool are greatly improved.

Owner:ZHE JIANG CHENLONG SAWING MACHINE CO LTD

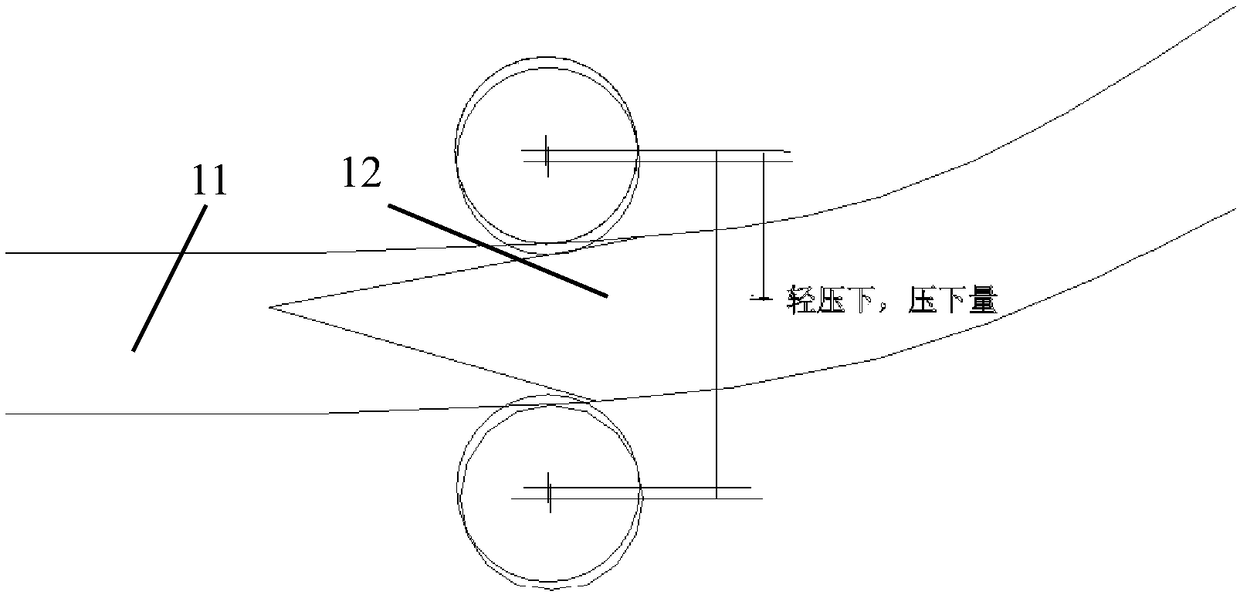

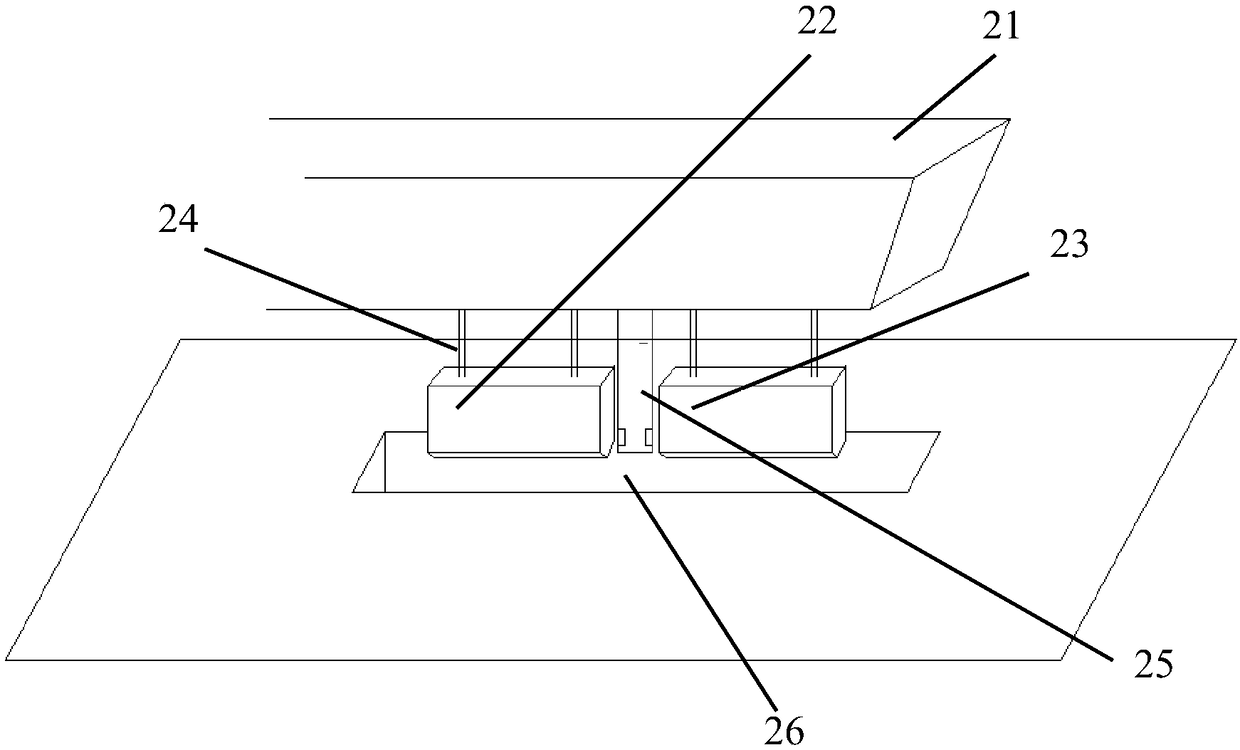

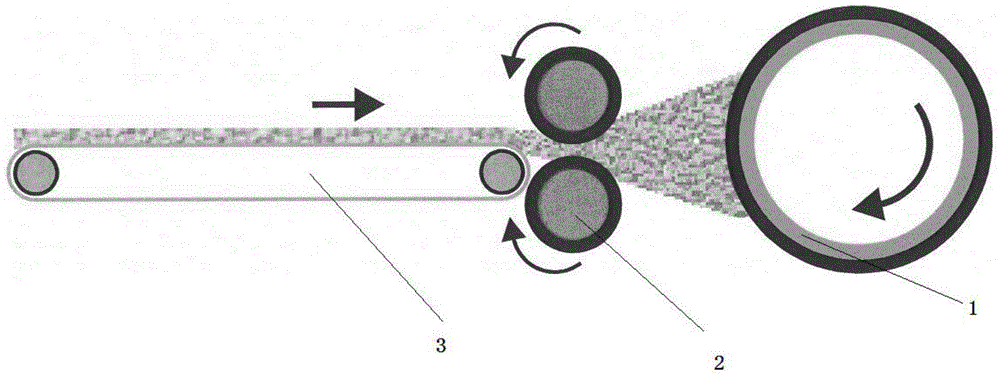

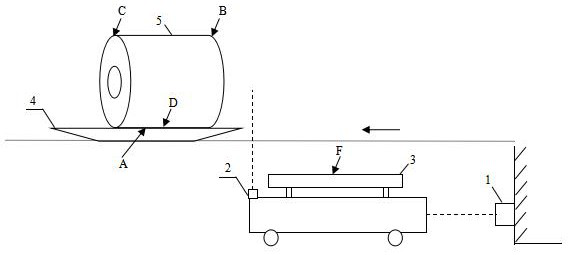

High-strength, low-temperature, and thick-gauge hot-rolled plate strip coil shape control method

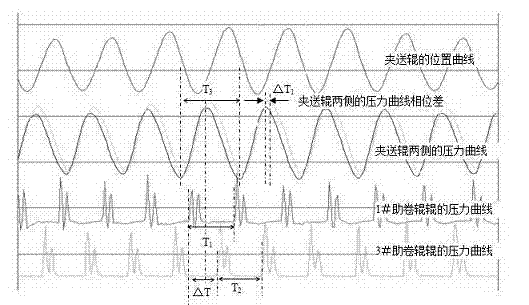

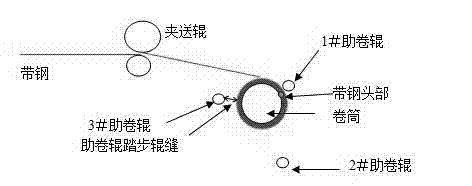

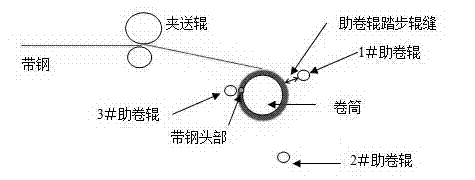

The present invention relates to a high-strength, low-temperature and thick-gauge hot-rolled plate strip coil shape control method, which is characterized in that the control method comprises that: 1) before a strip steel reaches a coiler, a clamping and conveying roller and auxiliary coiling rollers are in roller gap control manners; 2) after the clamping and conveying roller bites the strip steel, the roller gap control manner of the clamping and conveying roller is switched into a pressure control manner; 3) during coiling of the previous several circles of the strip steel by a coiling cylinder, the auxiliary coiling rollers 1#, 2# and 3# are in the pressure control manners or roller gap control manners; 4) after coiling of the previous several circles of the strip steel by the coiling cylinder, the number of the circles is set as the X0 and is manually set, the auxiliary coiling roller 2# is completely opened so as to make a coil unloading trolley lift and be ready for unloading, and the auxiliary coiling rollers 1# and 3# enter a stepping control manner and the roller gap control and pressure control alternate control manner, wherein the phenomenon that the auxiliary roller always presses on the strip steel so as to cause the strip steel surface scratch can be avoided; and 5) the clamping and conveying roller both-side pressure control PID adjuster control parameters P value and I value are adjusted.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

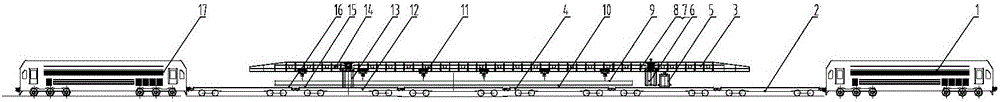

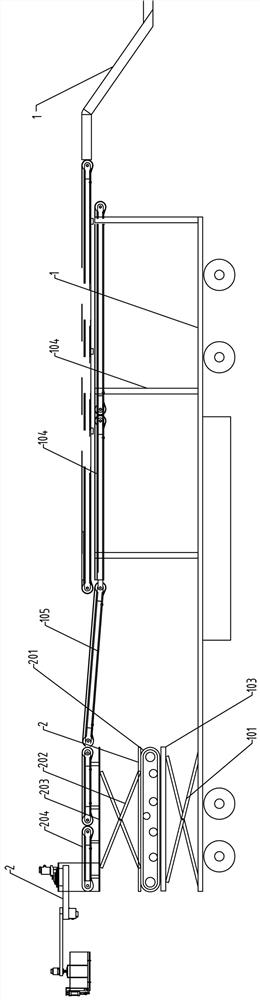

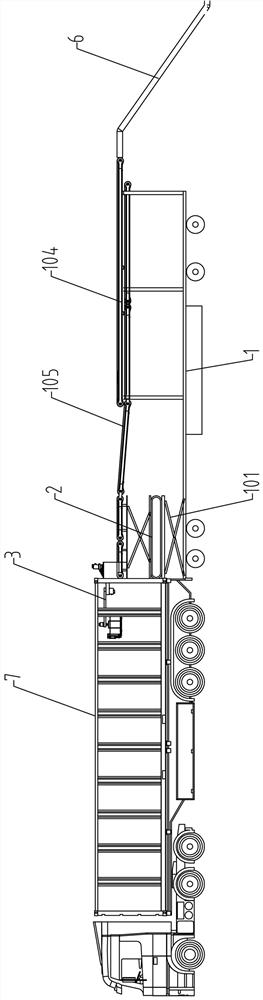

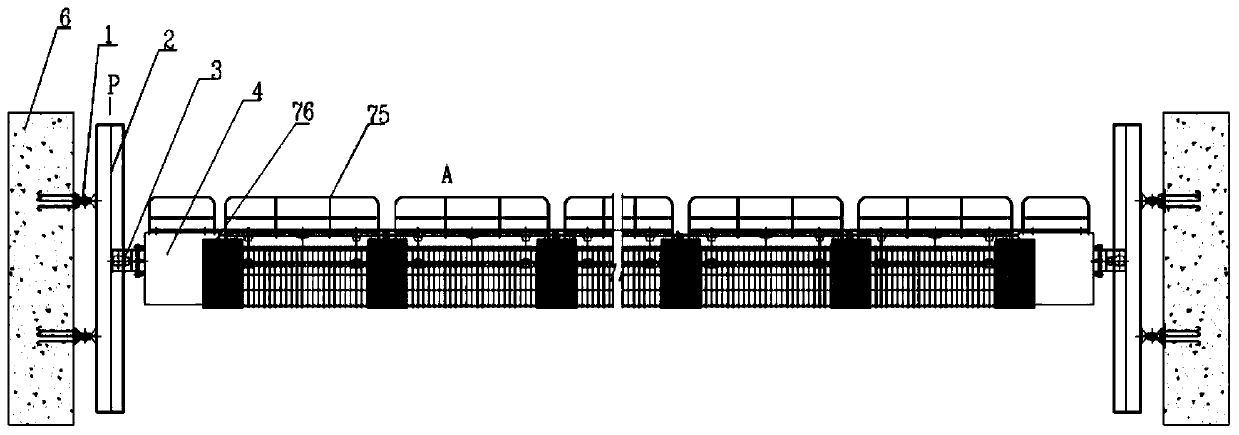

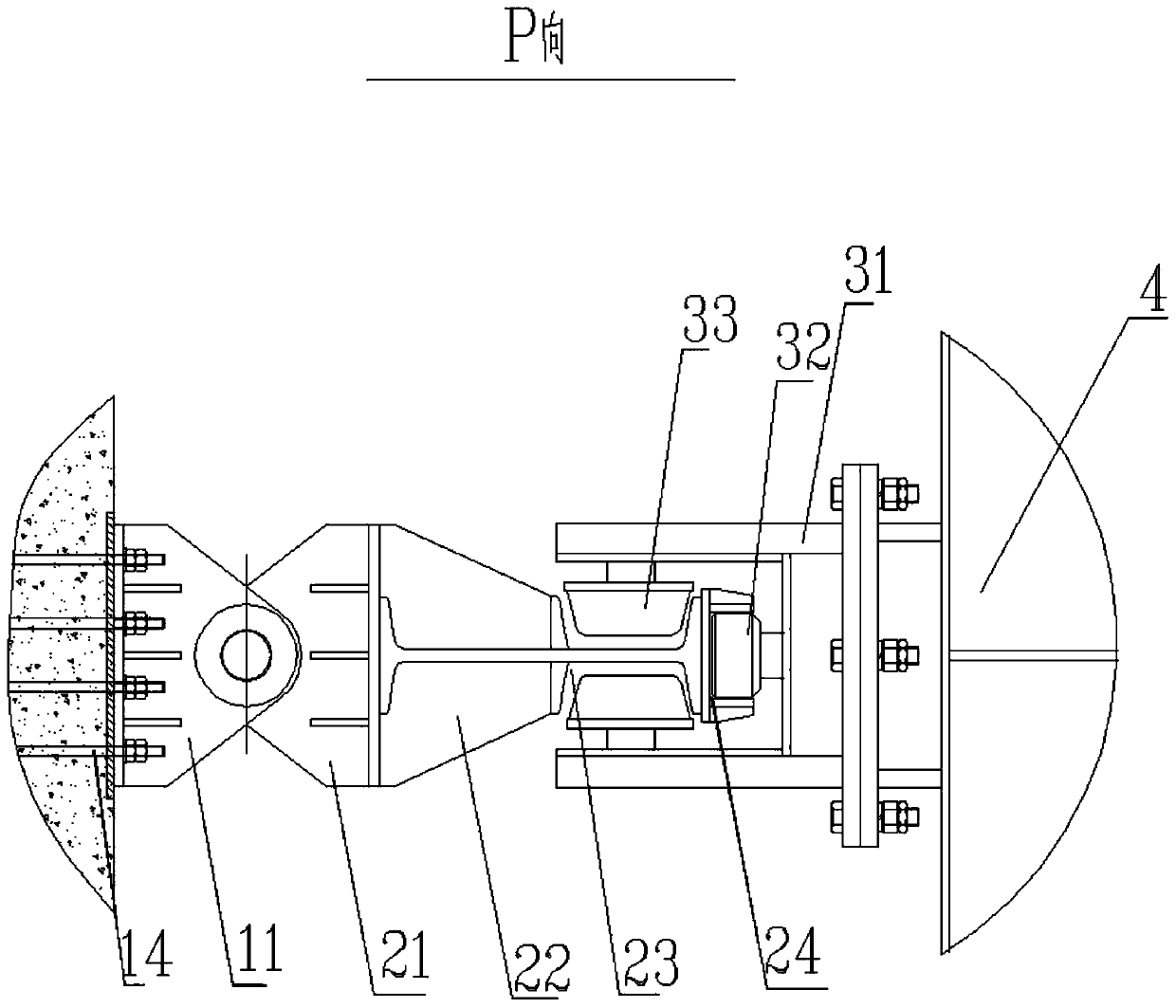

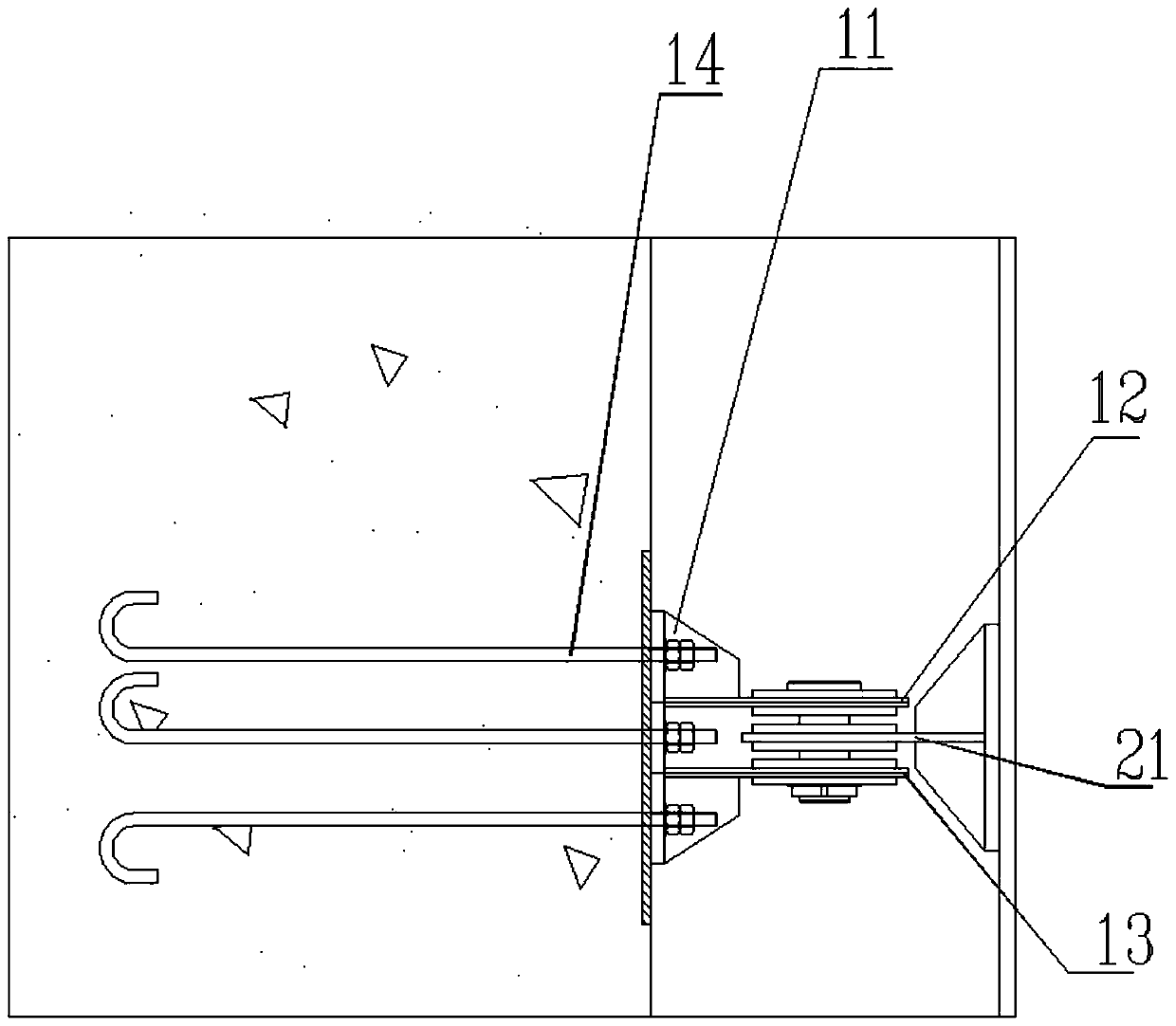

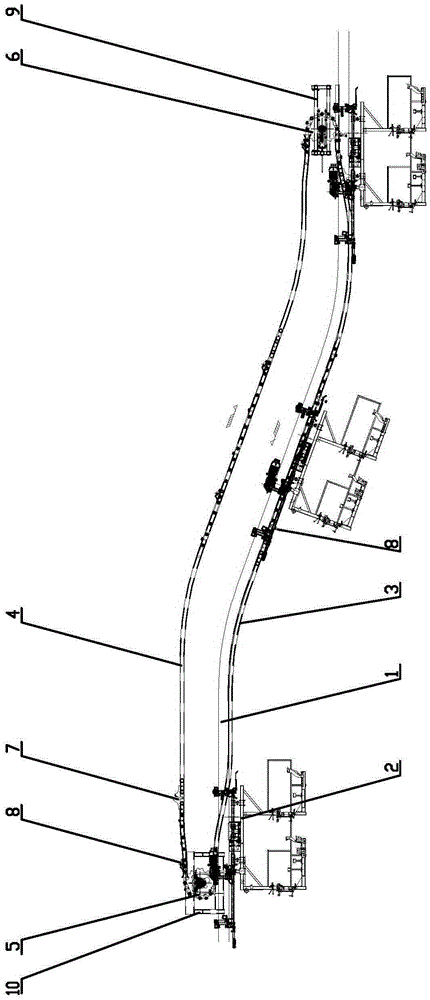

Novel track layer for urban rail traffic engineering and its construction method

PendingCN107642012AEasy to operateEasy to driveRailway track constructionIndustrial engineeringUrban rail

The invention relates to the engineering technology science and particularly relates to a novel track layer for urban rail traffic engineering and its construction method. The device comprises a lifting walking work trolley, a connection truss beam, a track walking mechanism and a supporting structure; horizontal stretching and vertical supporting structures of the lifting walking trolley are operated firstly so as to lift the whole novel track layer to the height of a track hanging and dismounting material; a hoisting trolley lifts up the track material to leave a flat trunk and a material pad; the novel track layer is forwards walked to the installing position of a track section, and then the track material is dismounted; a steel track is connected and the track section is mounted to temporarily support and fix the newly installed track section; the track is walked towards the track section hoisting position in next time to arrive at the unloading place, then the track section is hoisted to the next cycle. The device is simple in structure, convenient to operate, and low in cost; meanwhile, the safety during the working process is ensured and the efficiency is improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD +1

High-speed railway turnout large-size component replacing and laying device and method

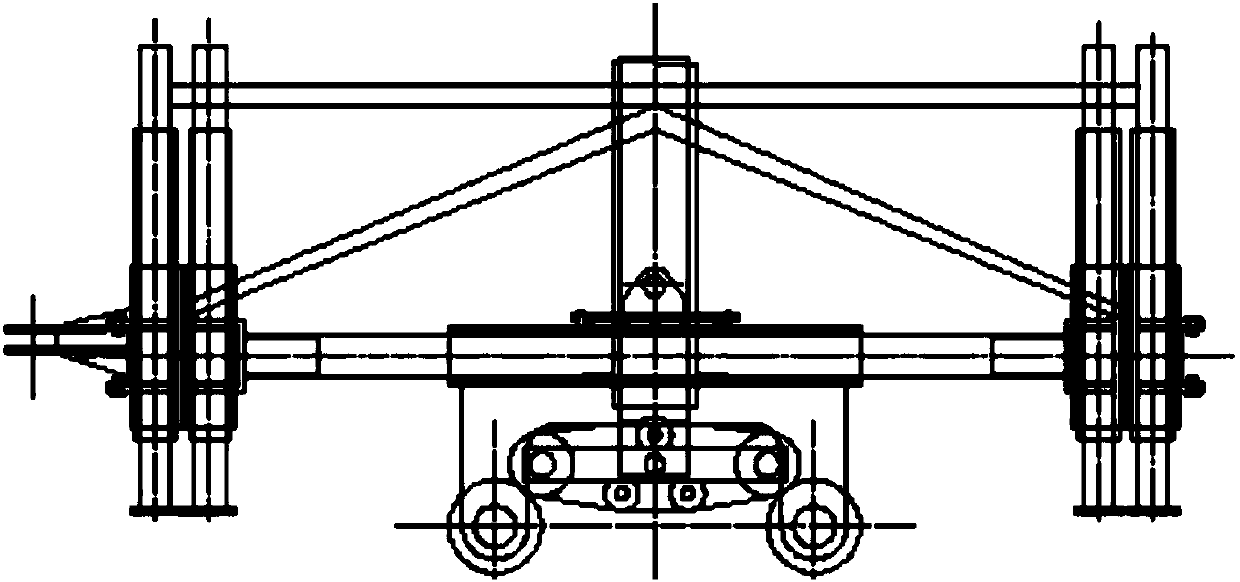

ActiveCN106049208AReduce labor intensityQuality improvementRailway track constructionBogieControl system

The invention discloses a high-speed railway turnout large-size component replacing and laying device and method. The high-speed railway turnout large-size component replacing and laying device comprises a traction rail car, a first flatcar set, a second flatcar set, a third flatcar set, a power generation rail car, an engine arm, an engine arm bogie, a movable supporting column, a fixed supporting column, a crane trolley and an electrical control system. The movable supporting column is configured at the front end of the engine arm. The movable supporting column and the fixed supporting column are configured with the engine arm through a transverse motion mechanism. The replacing and laying device is used for replacing and laying a point rail or a frog; when the point rail is replaced and laid, the point rail is lifted through the crane trolley, the first flatcar set and the second flatcar set are controlled to exiting an operation region, the crane trolley lifts the point rail to a designated region; then, an old rail is lifted to the outer side of a circuit; then, after the point rail is adjusted to an installation position, and the old rail is lifted and transported. The artificial construction method which is originally adopted is changed, labor intensity of construction workers is lowered, meanwhile, the working quality and safety are improved, and the construction operation time is shortened.

Owner:CHINA RAILWAY HEAVY MACHINERY

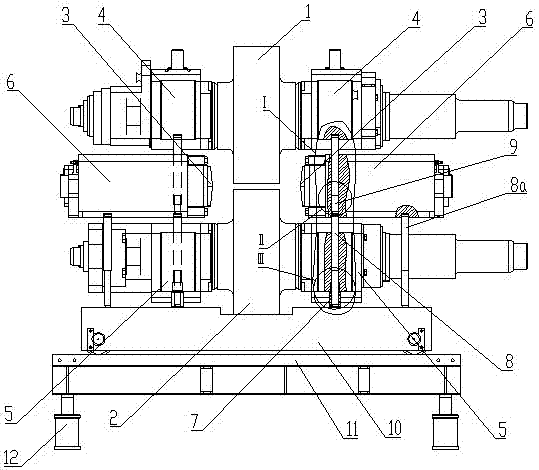

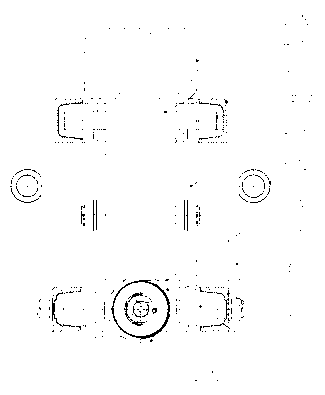

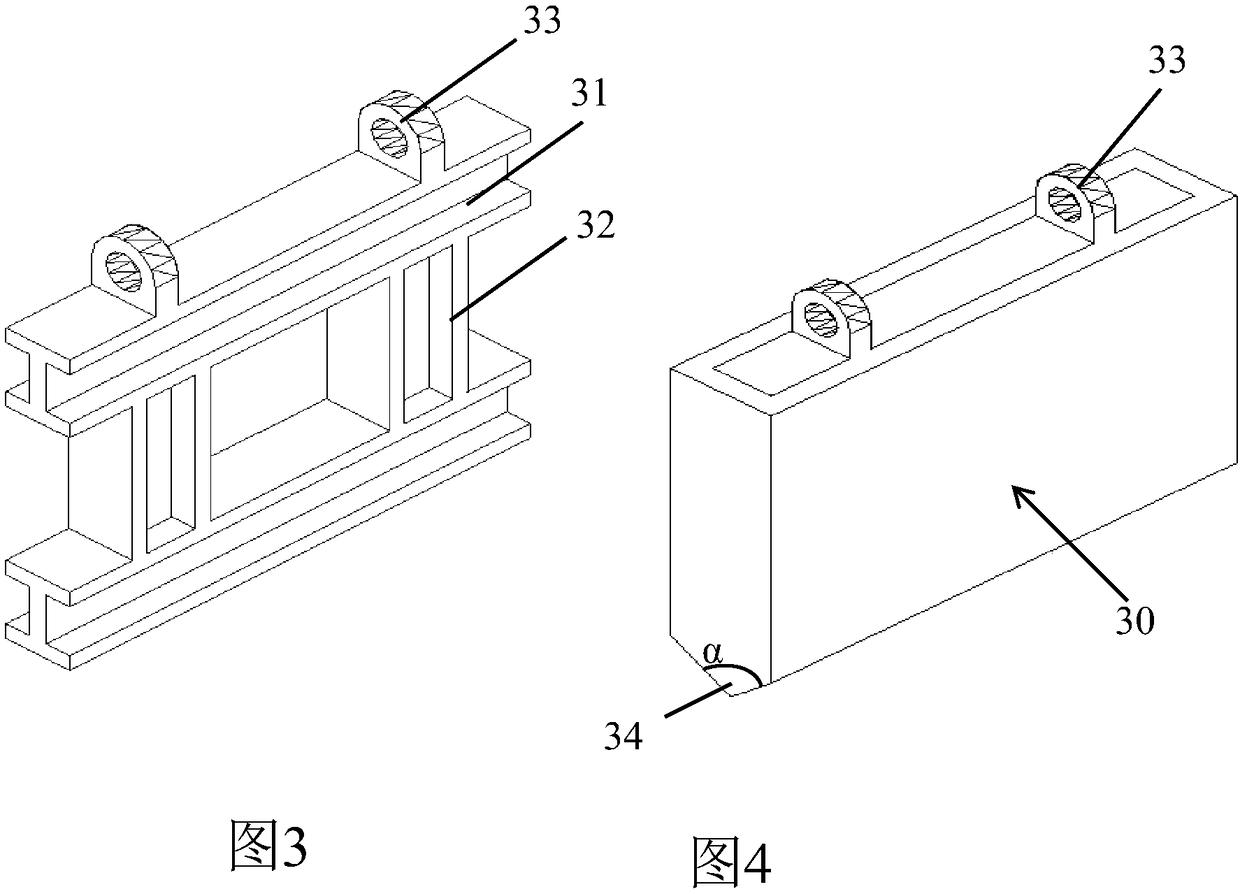

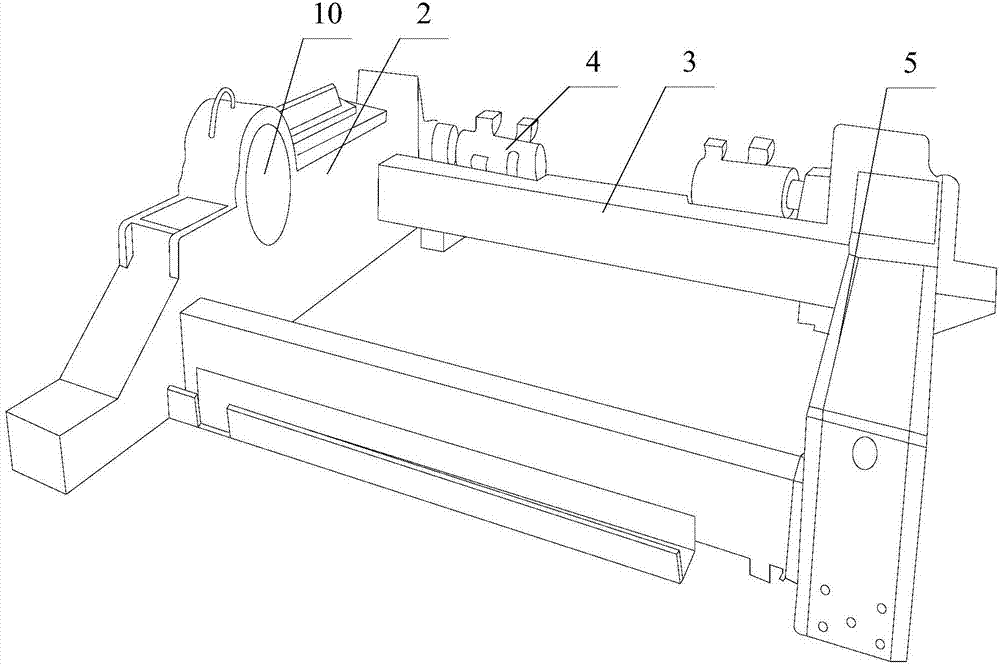

Roller set for universal mill

ActiveCN102179408AEasy to take outEasy loadingMetal rolling stand detailsRollsEngineeringExchange time

The invention discloses a roller set for a universal mill, and the roller set comprises an upper horizontal roller, a lower horizontal roller, a pair of upright rollers and a quick roller-exchanging device, wherein the upper horizontal roller is provided with two upper bearing bases; the lower horizontal roller is provided with two lower bearing bases; each upright roller is provided with a roller bearing base; and the quick roller-exchanging device comprises a lower horizontal roller positioning rod, an upright roller positioning rod, an upper horizontal roller positioning rod and a lifting roller-exchanging trolley. When the roller is needed to be exchanged, the roller-exchanging trolley lifts and then drives all the positioning rods to stretch into countersinks which are correspondingly arranged on the bearing bases, thereby realizing the reliable support positioning, integrally forming the roller set, avoiding the relative movement among rollers and abrasion of the positioning rods when the roller set is quickly moved out or loaded, and being reliable in interlocking. When the roller set is needed to work, the roller-exchanging trolley descends so as to release all the supportpositioning relationships and then the roller set can start working quickly. The roller set for the universal mill has a simple and reasonable structure and can be used for efficiently increasing thereliability and maintainability of the roller set, reducing the difficulty of roller-exchanging operation, shortening the roller-exchanging time, and increasing the production efficiency.

Owner:CISDI ENG CO LTD

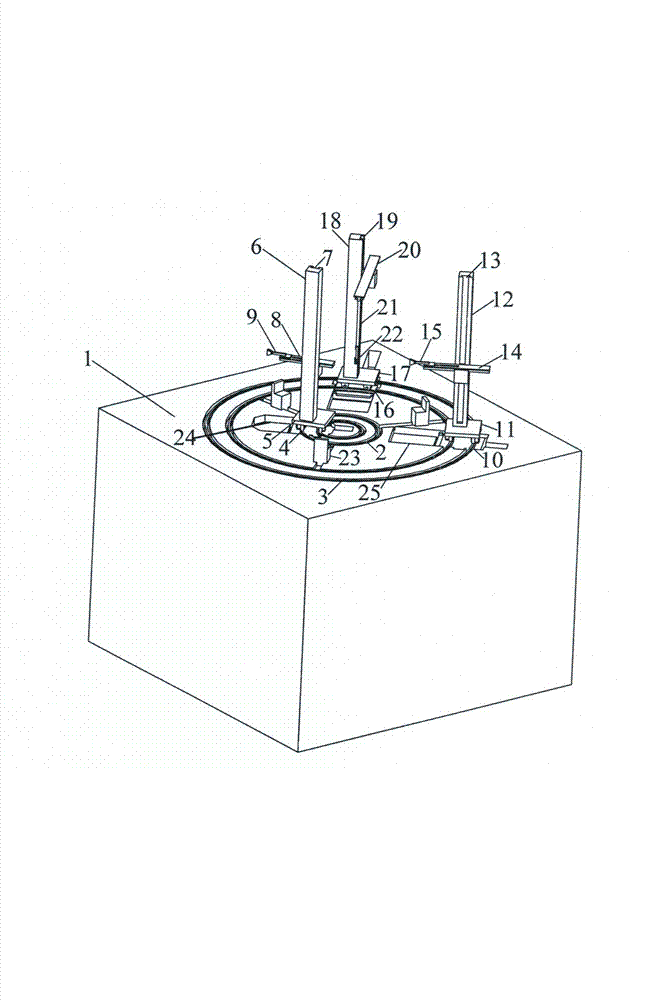

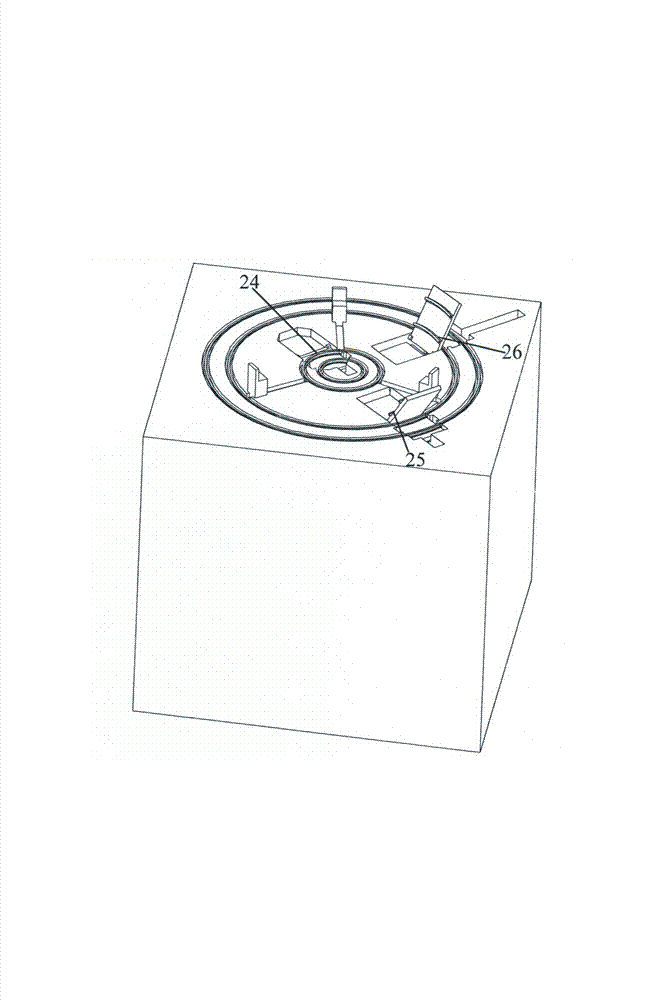

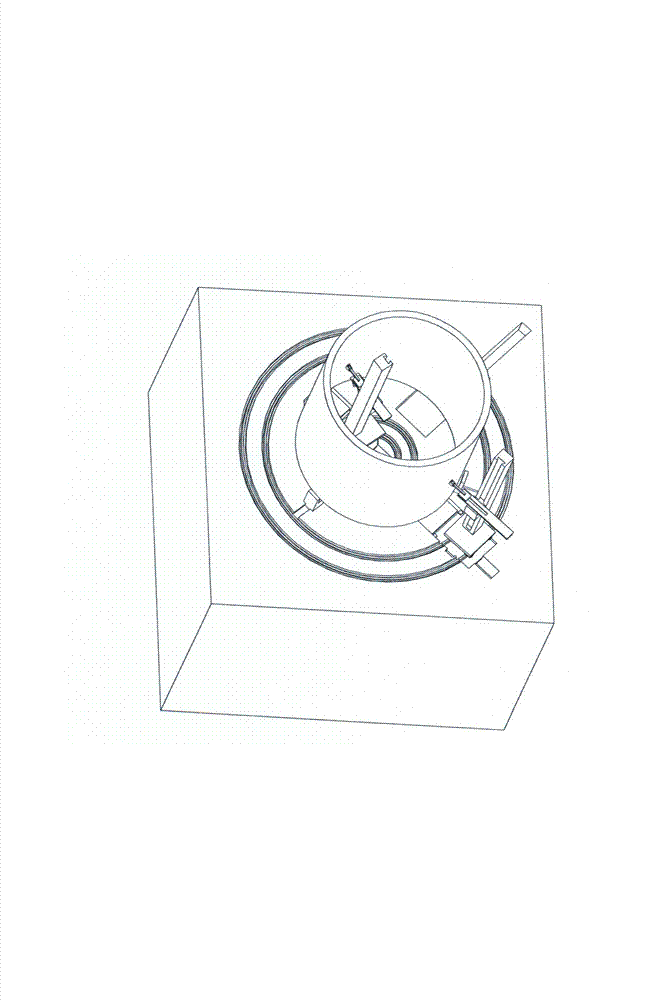

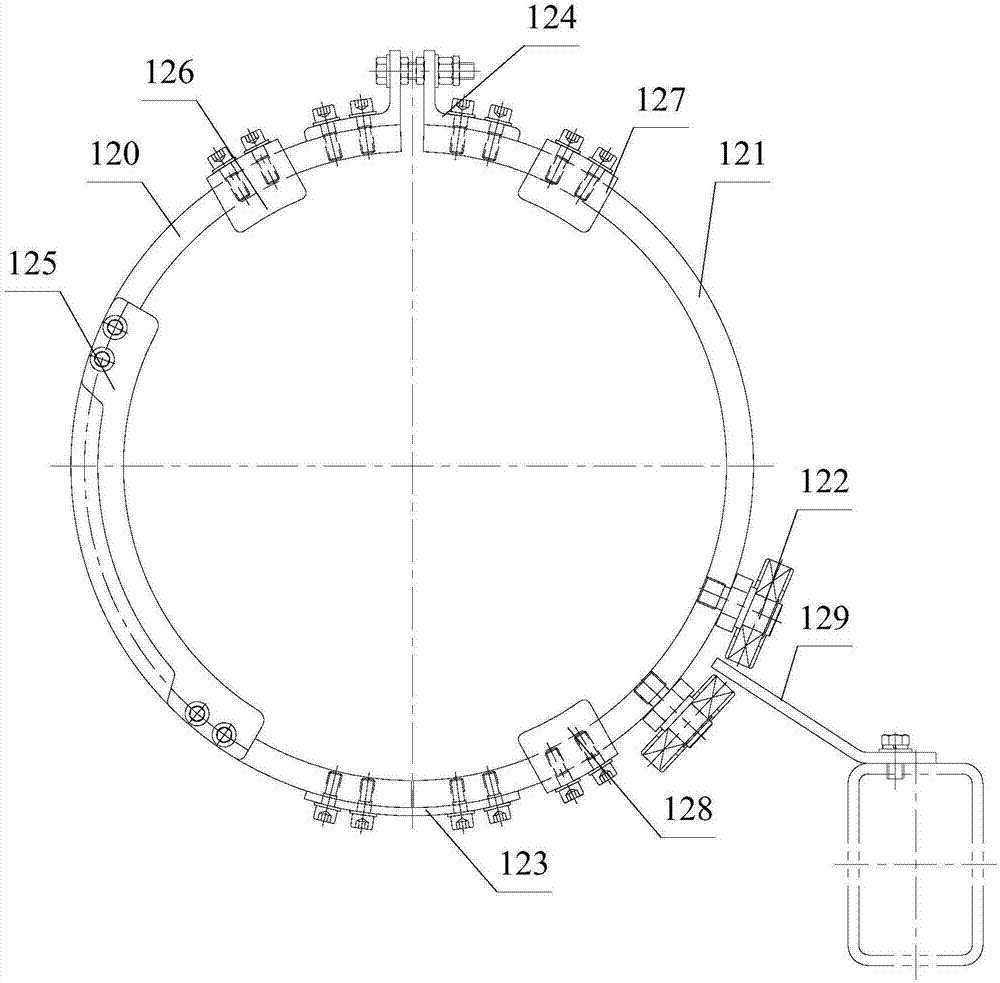

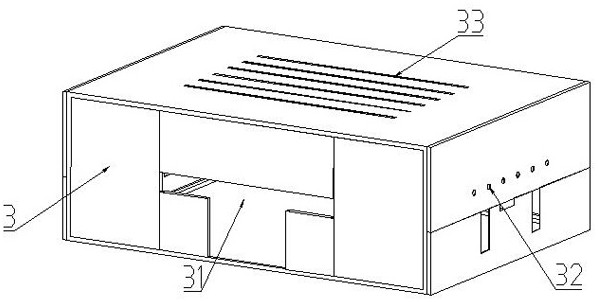

Horizontally-concealed type automatic robot ultrasonic diagnostic machine with trolleys moving on inner-outer rings

InactiveCN102809602AImprove efficiencySimple structureAnalysing solids using sonic/ultrasonic/infrasonic wavesButt jointEngineering

The invention relates to a horizontally-concealed type automatic robot ultrasonic diagnostic machine with trolleys moving on inner-outer rings. The horizontally-concealed type automatic robot ultrasonic diagnostic machine comprises a machine base with the top serving as a working platform and three detection trolleys, and is characterized in that inner ring guide rails and outer ring guide rails which are concentric are arranged on the working platform of the machine base, more than three radial jaw guide rails are circumferentially arranged on the working platform at intervals, a jaw is mounted on a moving pair of each jaw guide rail, and the three detection trolleys are an inner detection trolley, a first outer detection trolley and a second detection trolley respectively, wherein the inner detection trolley is in rolling contact with the inner ring guide rails, and the first outer detection trolley and the second detection trolley are in rolling contact with the outer ring guide rails. Besides, an inner detection trolley lifting well, a first outer detection trolley lifting well and a second detection trolley lifting well are arranged on the working platform, and well-sinking butt-joint guide rail moveable support plates and flip plates, which are capable of being in butt joint with the inner ring guide rails and the outer ring guide rails, are arranged on wellheads of the detection trolley lifting wells. The horizontally-concealed type automatic robot ultrasonic diagnostic machine with the trolleys moving on the inner-outer rings has the advantages of capability of adapting to automatic detection for various workpieces, high efficiency, simple structure, low cost and small occupied space.

Owner:YANSHAN UNIV

Double-trolley drive mechanism used for traversing type double-trolley quay crane

The invention discloses a double-trolley drive mechanism used for a traversing type double-trolley quay crane. The double-trolley drive mechanism comprises double trolley lifting mechanisms, double trolley traction mechanisms and double trolley winding systems, wherein the double trolley winding systems comprise an upper trolley winding subsystem, a lower trolley winding subsystem, an upper trolley lifting and winding subsystem and a lower trolley lifting and winding subsystem; the upper trolley lifting and winding subsystem comprises at least one first drive winding drum, at least one first lifting steel rope which is wound on the first drive winding drum and a plurality of first carrier rollers which are used for horizontally supporting the first lifting steel rope; the first carrier rollers are horizontally supported on the inner side of a girder structure by a first bracket structure; a plurality of second carrier rollers are horizontally supported on the outer side of the girder structure by a second bracket structure; and horizontal parts of the first drive winding drum and the first lifting steel rope are arranged on the inner side of a horizontal space which is formed by a horizontal part of a second lifting steel rope in an enclosing way.

Owner:HUADIAN HEAVY IND CO LTD

Movable manipulator stacking car loader and goods loading method thereof

PendingCN111908176AEasy to moveRealize stackingStacking articlesDe-stacking articlesPalletizerMachine

The invention relates to a movable manipulator stacking car loader and a goods loading method thereof. The invention adopts the technical scheme that the movable manipulator stacking car loader comprises a forwards-extending moving platform, wherein a lifting mechanism is arranged at the front end of the moving platform; a lifting platform is arranged at the top of the lifting mechanism; a manipulator stacking trolley is arranged on the lifting platform, and comprises a crawler belt moving chassis at the bottom, a trolley lifting machine on the crawler belt moving chassis, and a platform at the top of the trolley lifting machine; a stacking manipulator is arranged at the front end of the platform; a buffer conveyor and a bag feeding conveyor are arranged on the platform behind the stackingmanipulator; the buffer conveyor is connected with a rear slope conveyor; and the rear part of the slope conveyor is connected with a telescopic conveyor. According to the movable manipulator stacking car loader and the goods loading method thereof provided by the invention, the manipulator and the conveyors are combined through a crawler, and the stacking manipulator is arranged on a crawler chassis truck, so that the stability is good, and the purpose of moving the manipulator can be achieved; and through arranging a two-stage lifting structure, a lower lifting structure of the manipulatorstacking trolley is matched with the height of a carriage, so that the the movable manipulator stacking car loader is suitable for carriages with various specifications.

Owner:三维汉界机器(山东)股份有限公司

Rotatable type floating debris intercepting and discharging trolley lifting guiderail device

The invention discloses a rotatable type floating debris intercepting and discharging trolley lifting guiderail device, which comprises a hinge seat, a guiderail assembly, a sliding trolley, and an end part buoyancy tank. The hinge seat is fixedly connected with an anchoring pier, the guiderail assembly is hinged to the hinge seat,the sliding trolley is slidably connected with the guiderail assembly, the sliding trolley can slide radially on the guiderail assembly, and the end part buoyancy tank is fixedly connected with the sliding trolley; the guiderail assembly can be rotated along the hinge seat and have a certain swing angle on the hinge seat when water flow strikes a grid hanging frame and a large buoyto adapt to the horizontal change of afloating debris intercepting device, so that the sliding trolley and the guiderail assembly have a certain buffering effect and the sliding trolley and the guiderail assemblycan also slide smoothly under the impactof the water flow, the failure rate of the floating debrisintercepting device is decreased, and maintenance time is shortened.

Owner:SICHUAN ORIENT HYDROELECTRIC ENG

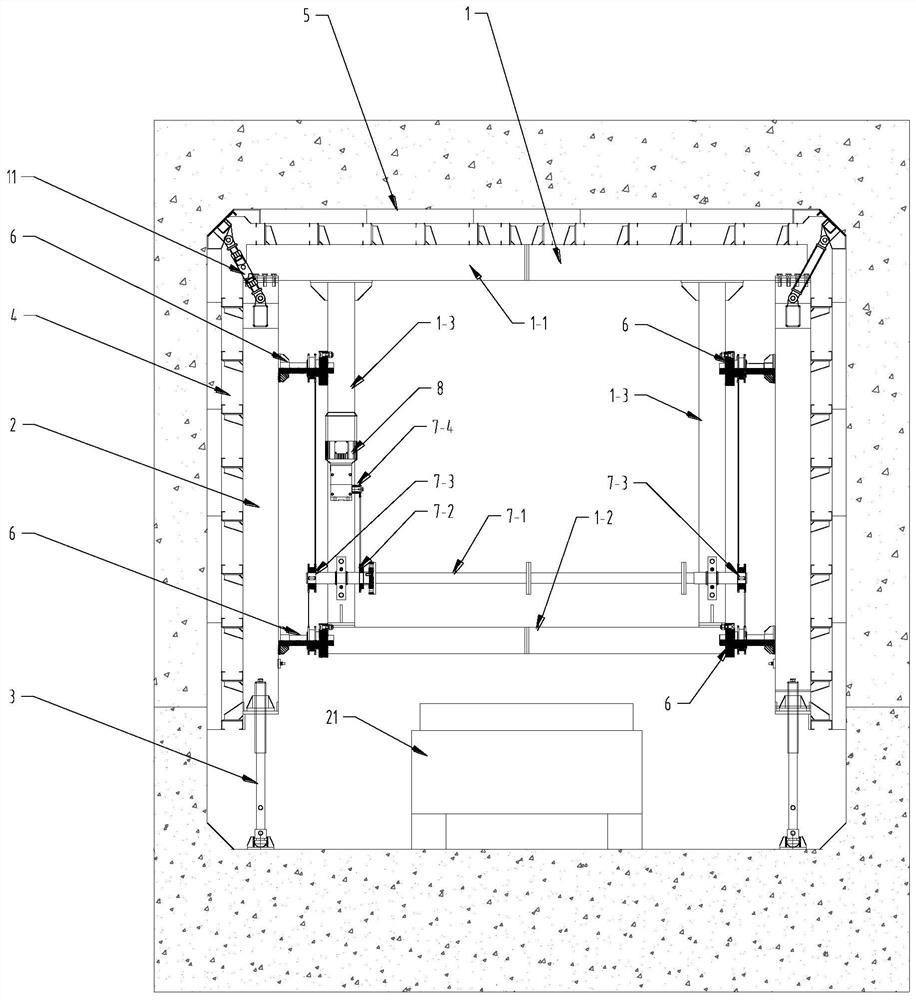

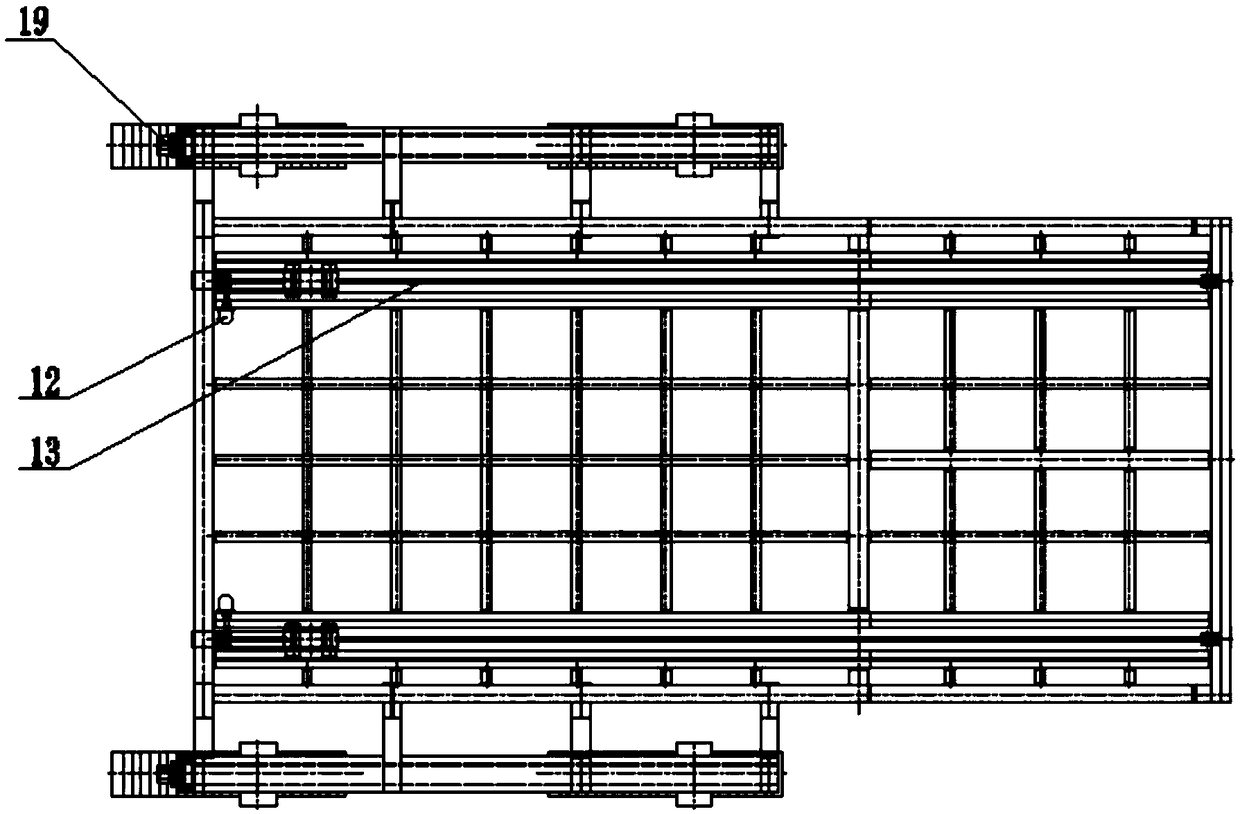

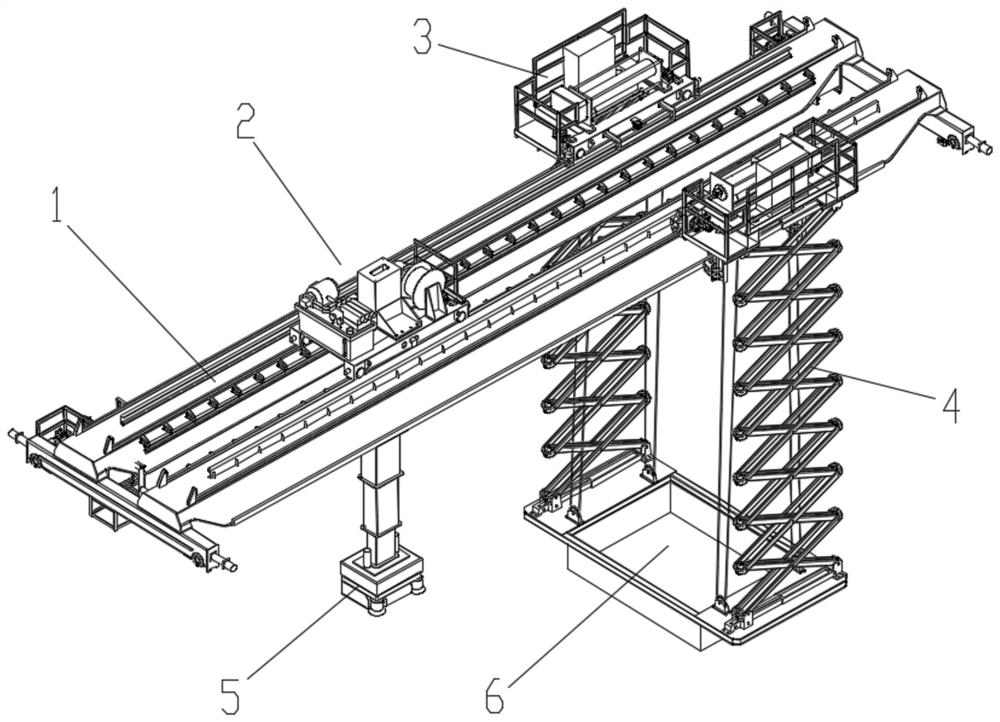

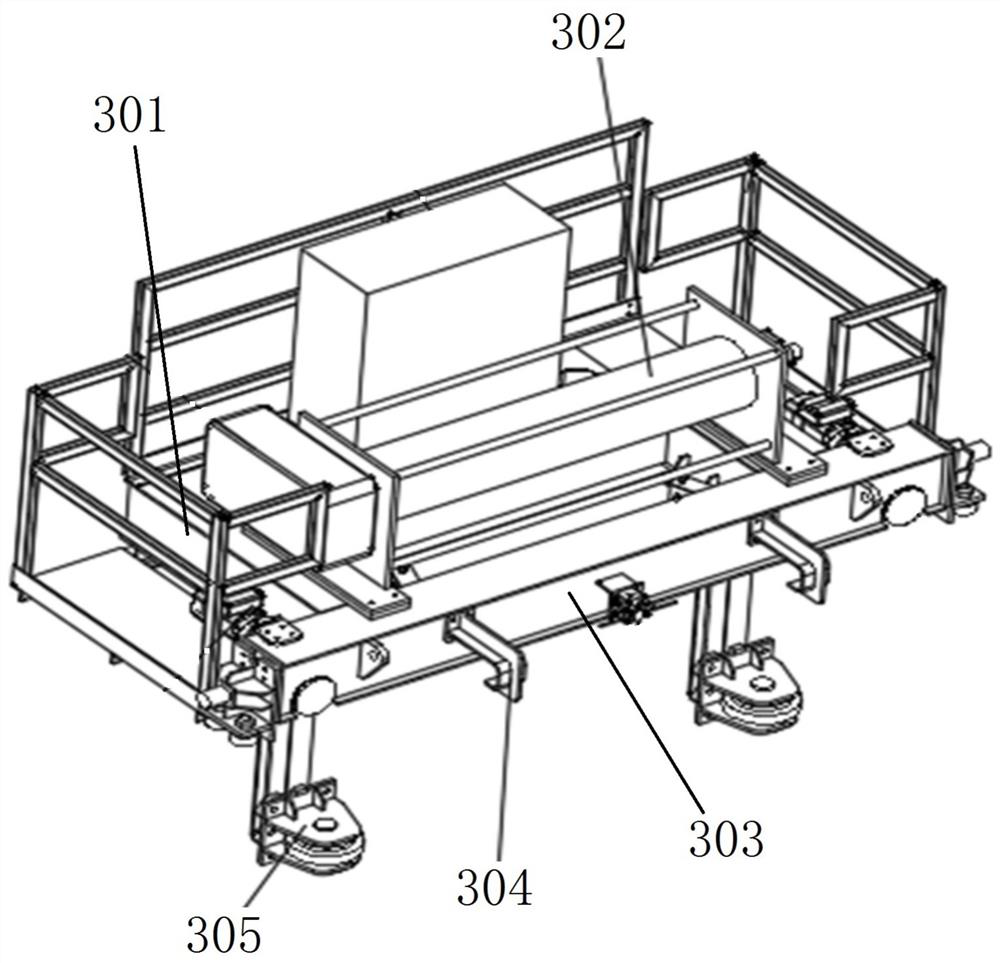

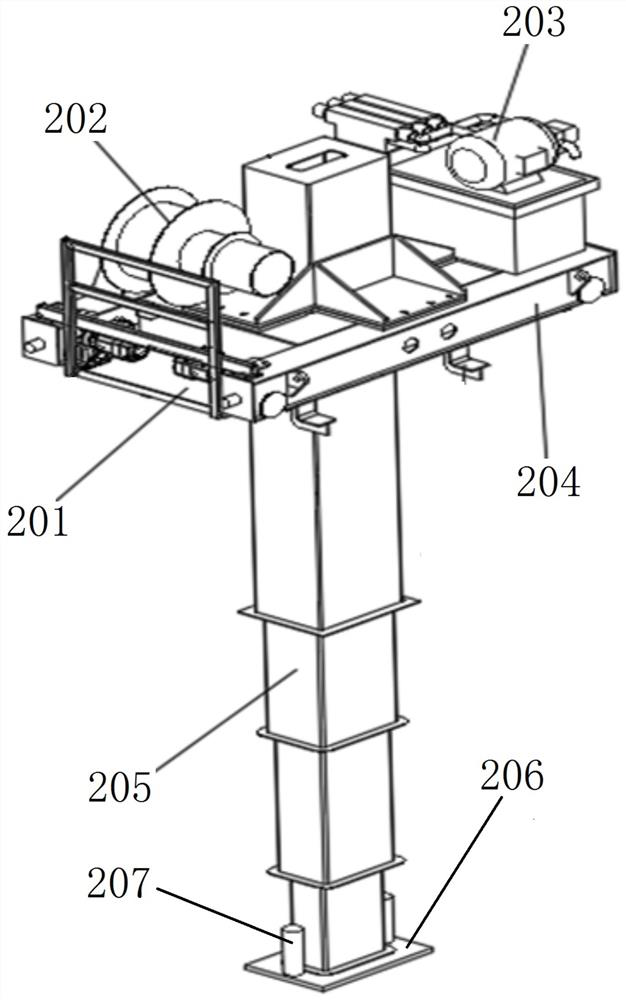

Concrete pipe gallery inner mold in-place and demolding method

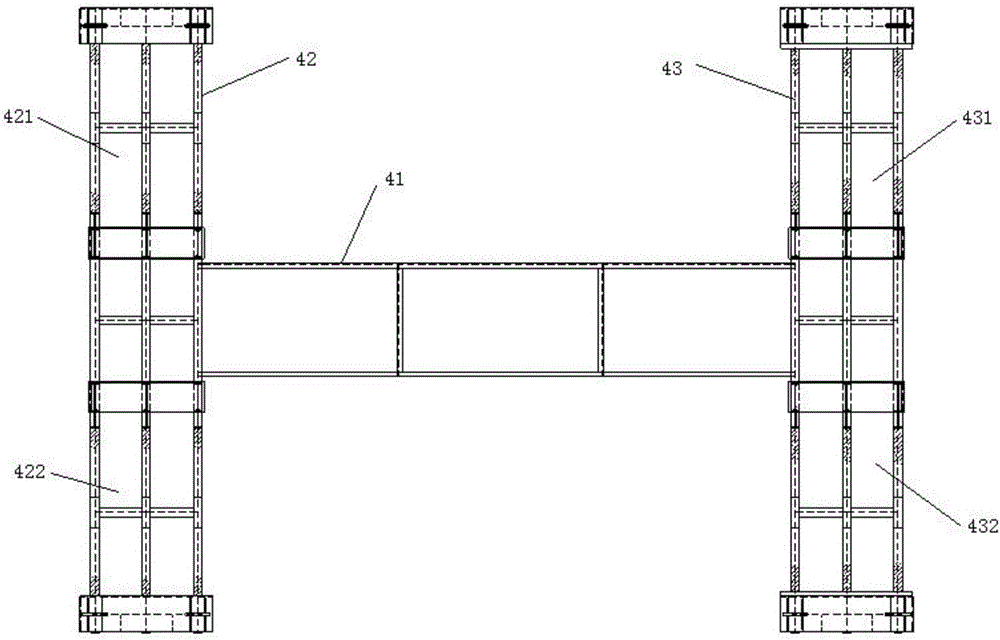

ActiveCN111749270ADoes not affect trafficDoes not affect workArtificial islandsForms/shuttering/falseworksArchitectural engineeringPipe

The invention discloses a concrete pipe gallery inner mold in-place and demolding method. The concrete pipe gallery inner mold in-place and demolding method comprises an inner mold frame and a liftingtrolley used for moving the inner mold frame in place, the inner mold frame comprises a portal frame, movable stand columns are arranged on the two sides of the portal frame, side mold plates are installed on the movable stand columns, and the movable stand columns are connected with the portal frame through translation drivers; a top mold plate is mounted at the top of the portal frame; stand column lifting supporting legs are arranged at the bottoms of the movable stand columns, and the height of the whole inner mold frame is adjusted through the stand column lifting supporting legs; and bottom middle supporting legs capable of rising and falling are further arranged at the bottom of the portal frame. During construction, the lifting trolley lifts the inner mold frame to move and be preliminarily in place, the position and the height of the side mold plate are adjusted by combining the inner mold frame, and mold erecting and demolding work is achieved.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP +1

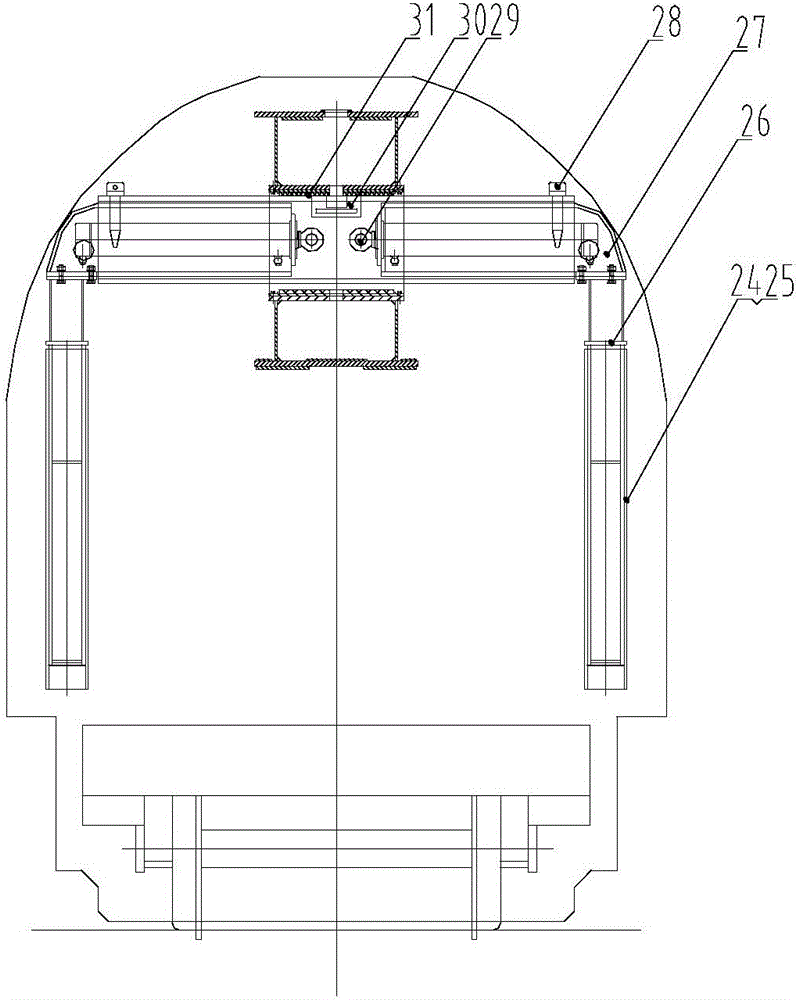

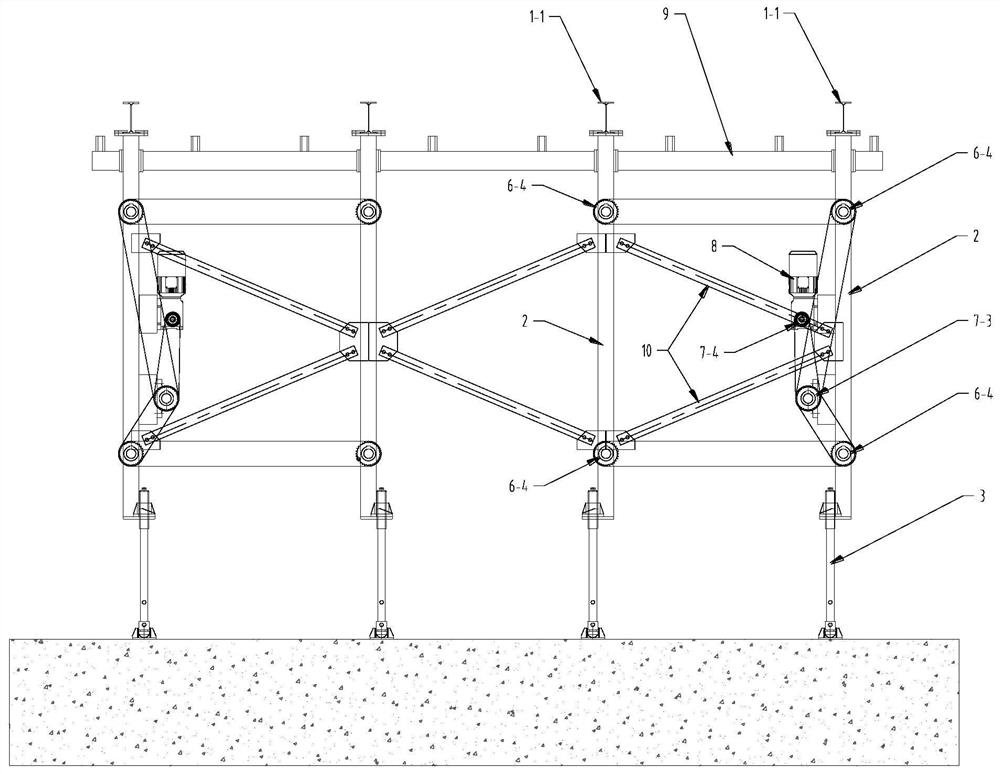

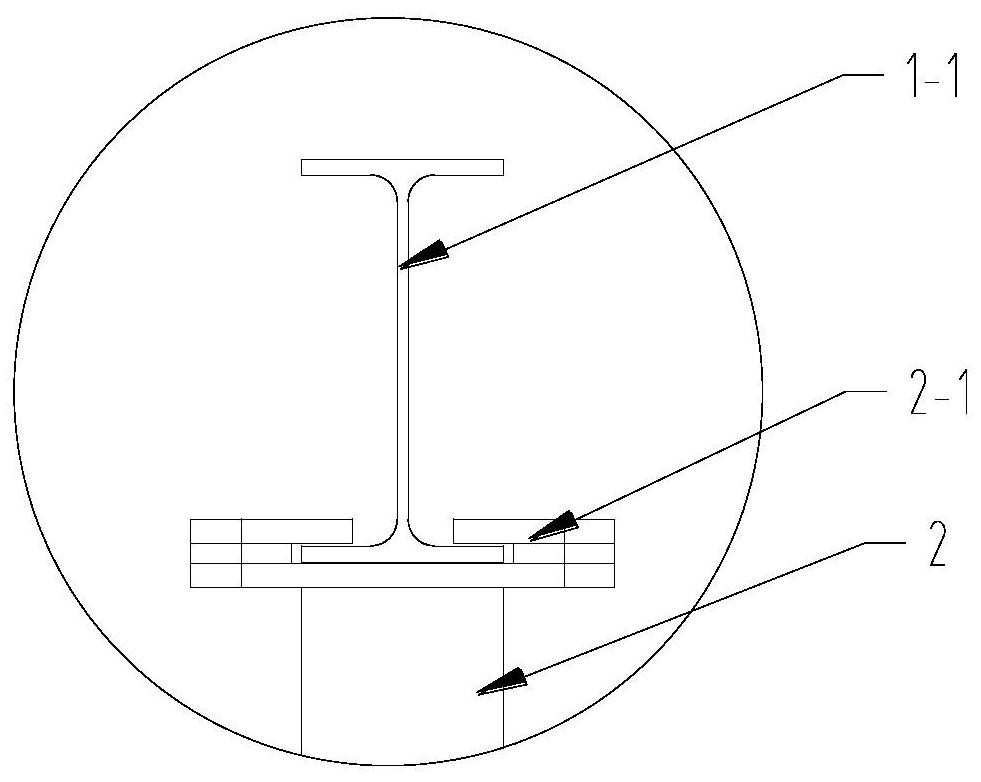

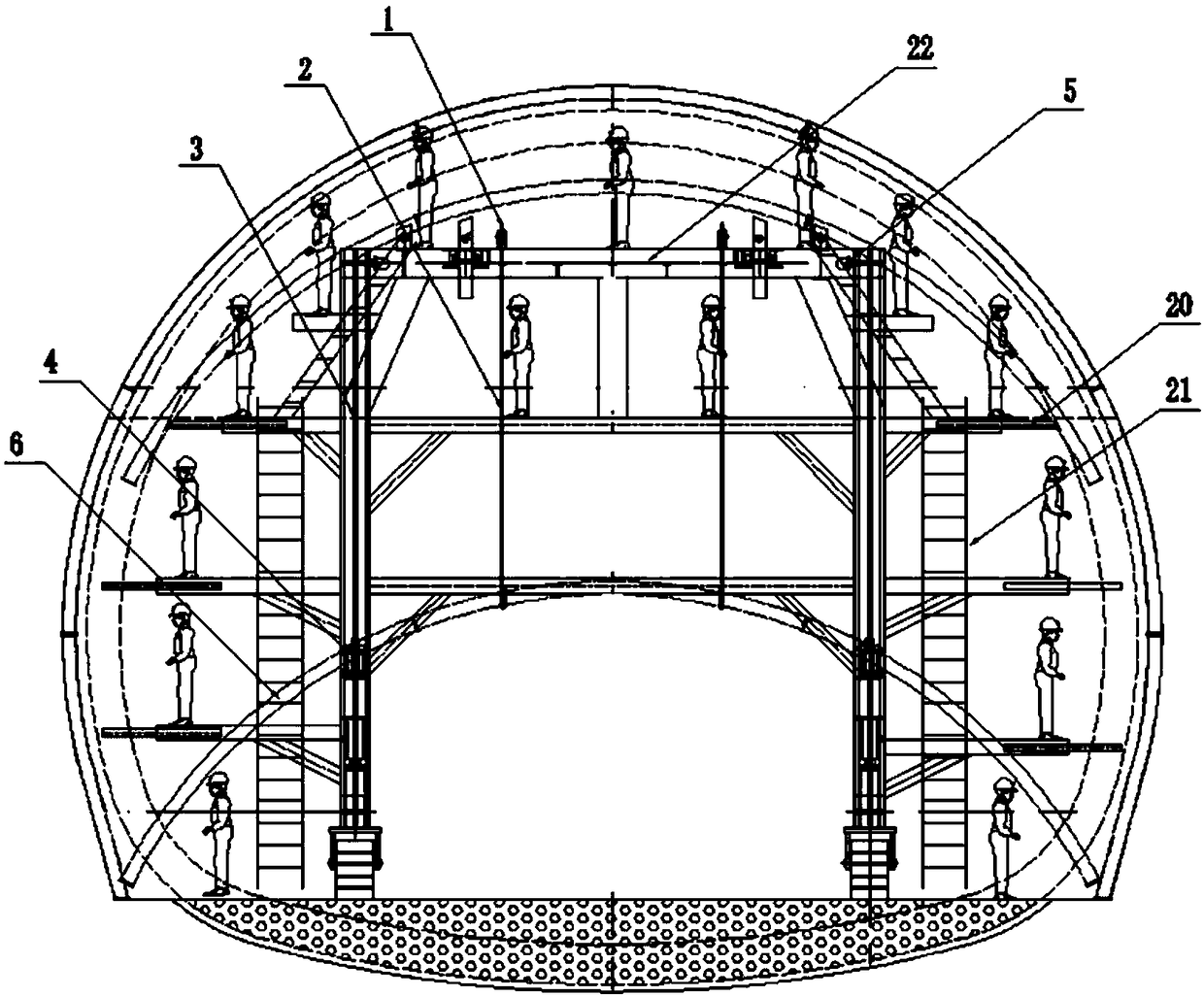

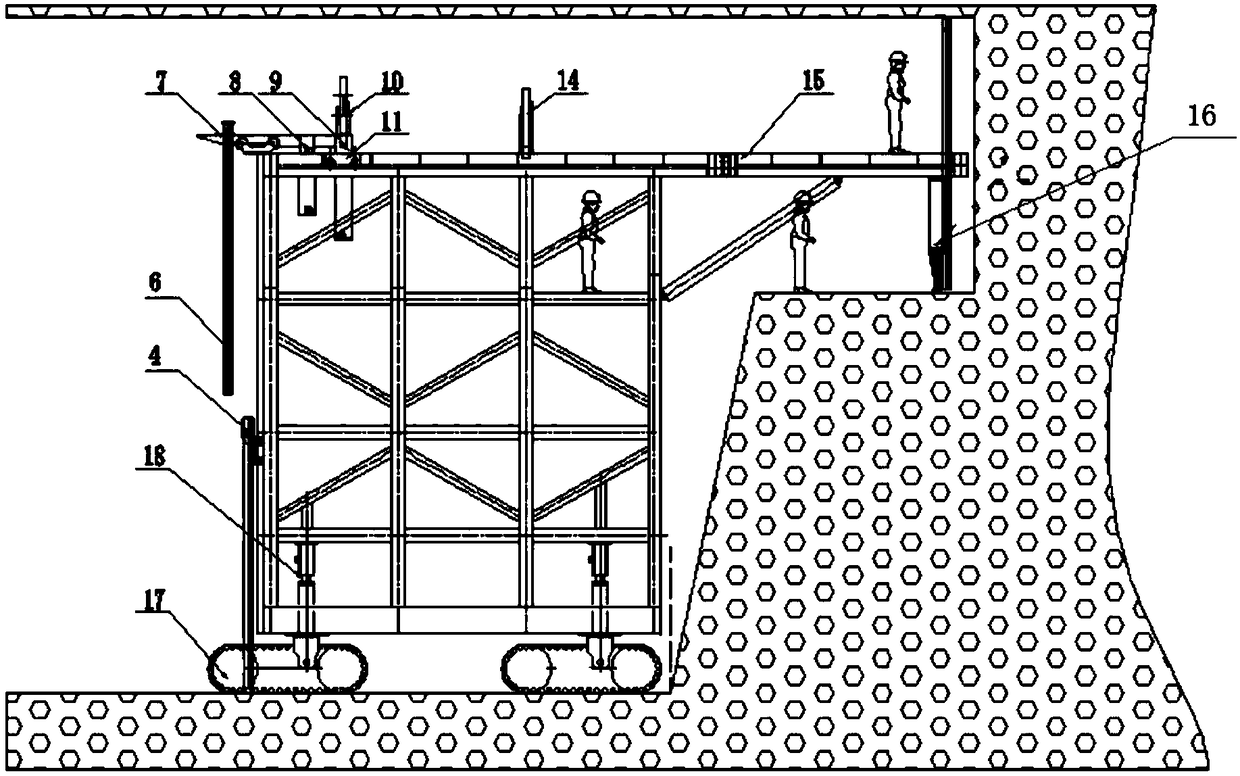

Steel arch trolley suitable for tunnel micro-step excavation method

PendingCN109236331ASave time at workRealize semi-automatic constructionUnderground chambersTunnel liningTrolley liftBuilding construction

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD

Mechanical anti-swing bridge crane for transferring and cleaning distillers' grains

ActiveCN114380195AEasy to cleanCleaned up mechanical anti-sway overhead crane, cleared by settingFood processingCleaning using toolsOverhead craneVinasse

A mechanical anti-swing bridge crane for transferring and cleaning distillers' grains in the field of special hoisting equipment for wineries comprises a cleaning device, a transferring tank and a bridge frame, the bridge frame comprises two main beams arranged side by side at intervals, and a middle trolley capable of moving and positioning along the main beams and two offset hanging trolleys are arranged between the two main beams and on the two outer sides of the two main beams respectively. The two deflected hanging trolleys are used for lifting the transfer tank, and the middle trolley lifts the cleaning device through a telescopic arm capable of vertically ascending and descending. The bridge crane is reasonable and simple in design, the stability and the positioning accuracy of all the devices in the moving process are improved, and the vinasse pool can be rapidly and cleanly cleaned.

Owner:HENAN WEIHUA HEAVY MACHINE

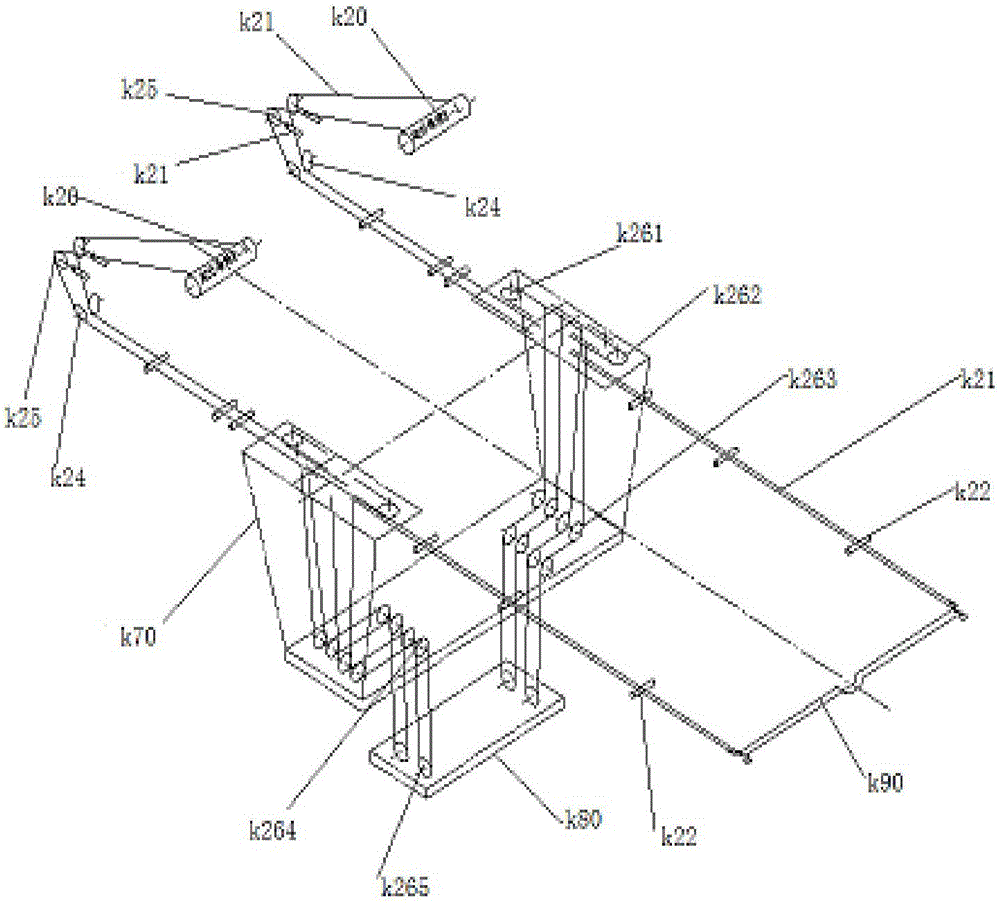

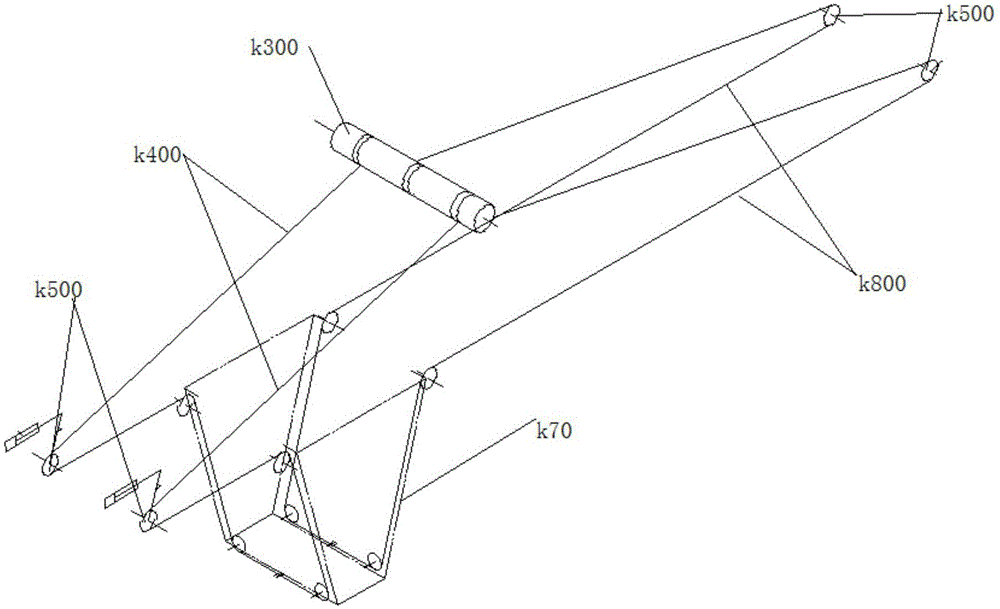

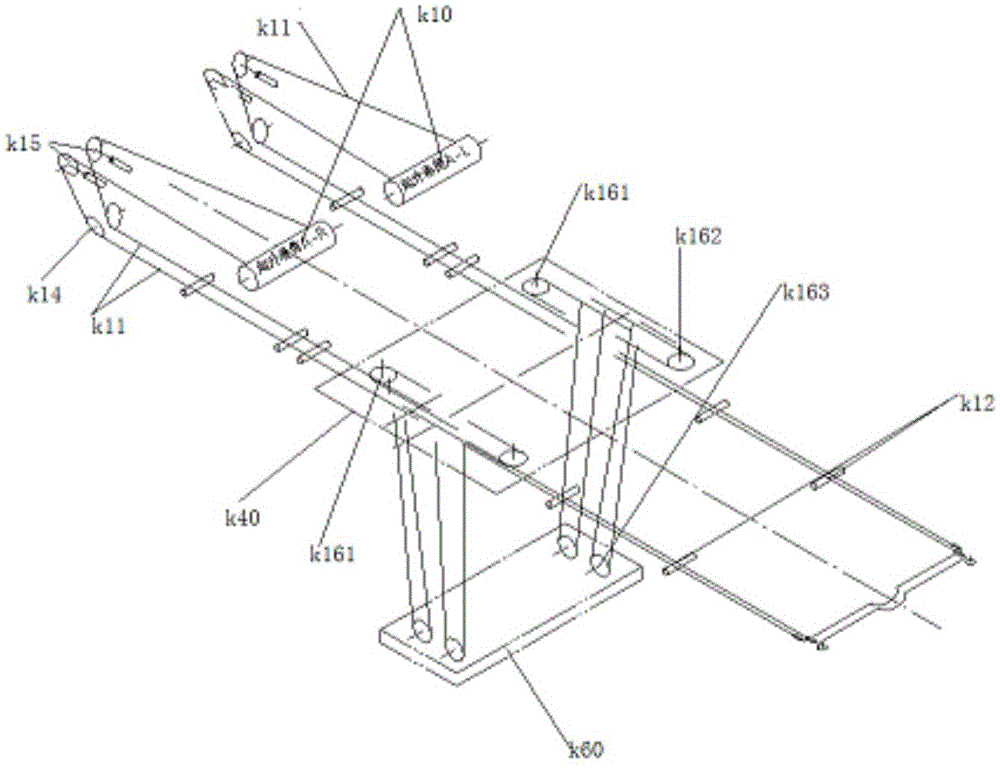

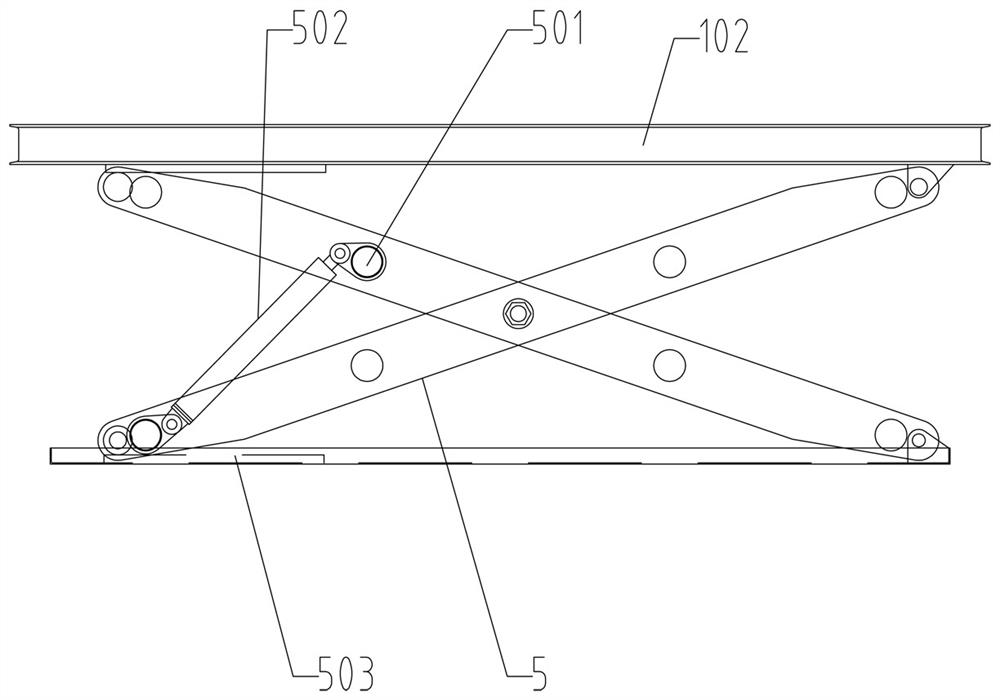

Secondary lifting mechanism for automatically positioning

InactiveCN103193181ASecure remote key operationConvenient remote key operationLifting framesSimulationMachine

The invention discloses a secondary lifting mechanism for automatically positioning. According to the basic mechanical structure, the secondary lifting mechanism comprises a lifting trolley (B), a trolley walking mechanism (C) and a bracket extending mechanism (D), wherein the trolley walking mechanism (C) drives the secondary lifting mechanism to walk to a proper position for lifting an automobile along a walking track (A-1) which is arranged between two sides of an inner frame of an automobile correcting machine platform or between lifting platforms of an automobile lifting unit through; then, a tray (D-7) moves to a proper lifting point through the bracket extending mechanism (D); and finally, a mobile workshop is lifted to a proper height through the lifting trolley (B). The secondary lifting mechanism changes discontinuous, time-consuming and arduous manual close-table (underbody sometimes) operation process, including walking positioning and bracket extending positioning, of secondary trolley lifting into a safe and portable remote key operation, is good in maneuverability and enables the automobile lifting operation process, including trolley walking and bracket lifting and extending, to tend to be continuous and smooth.

Owner:烟台三重技术股份有限公司

Inserting part device for preventing tail billet of continuous casting billet from rising and use method thereof

The invention discloses an inserting part device for preventing a tail billet of a continuous casting billet from rising and a use method thereof. The inserting part device comprises two inserting parts and four lifting frame connecting rod mechanisms, wherein the two inserting parts include a left side inserting part and a right side inserting part which are correspondingly mounted on a tundish trolley lifting supporting frame through two corresponding lifting frame connecting rod mechanisms; the left side inserting part and the right side inserting part are structured the same and are both named inserting parts; two mounting rings are fixedly welded to the top part of each inserting part; the four lifting frame connecting rod mechanisms are structured the same and are correspondingly connected to four mounting rings on the two inserting parts; each lifting frame connecting rod mechanism comprises an inserting part connecting rod, a thrust oil cylinder, a fixing frame and an oil cylinder connecting rod which are interconnected through hinge structures; and the fixing frames are fixed to the tundish lifting trolley supporting frame through bolts. The device is high in reliability of preventing rising, and is high in automatic degree of operation; and a continuous casting machine can be effectively protected.

Owner:BAOSHAN IRON & STEEL CO LTD

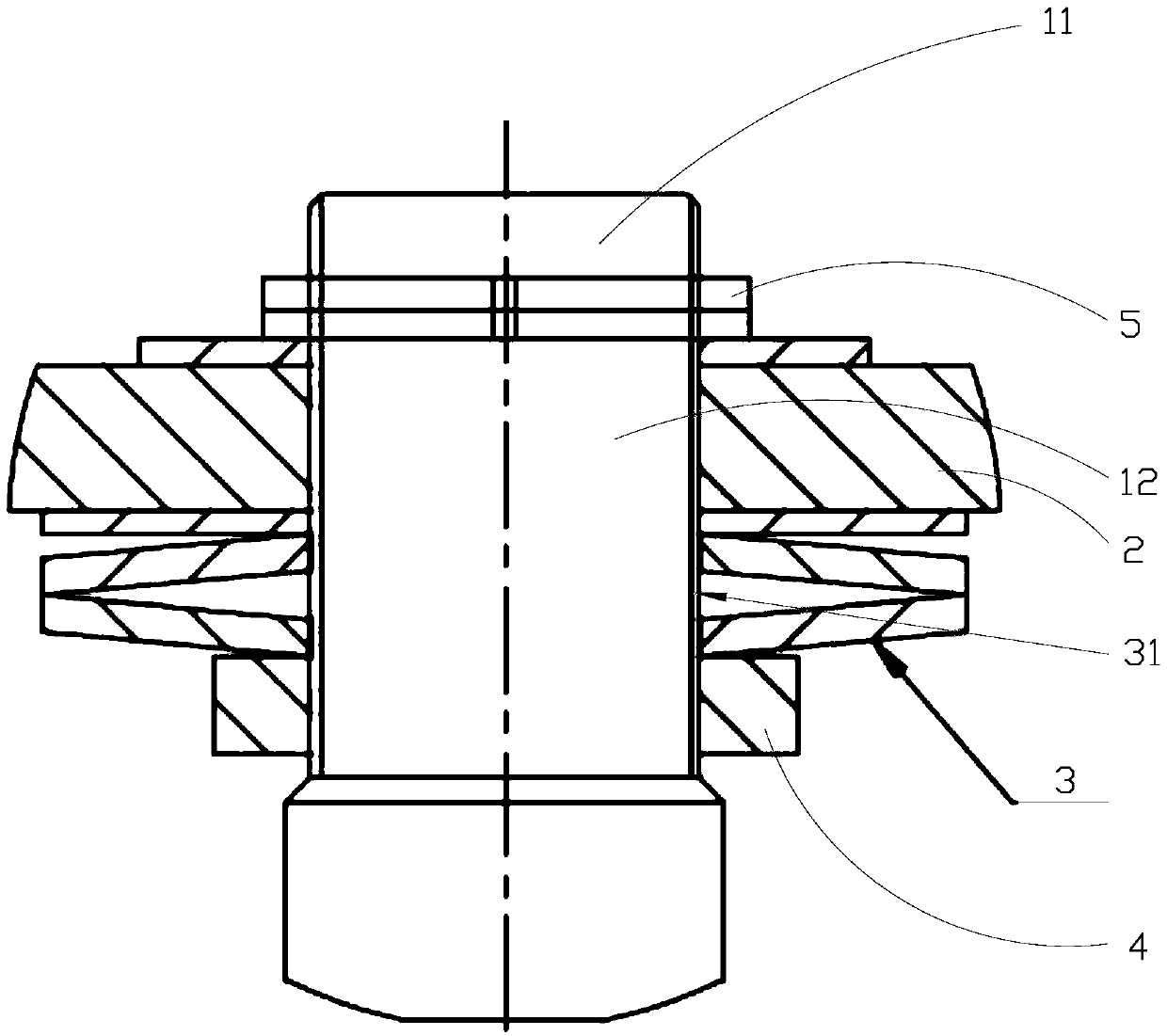

Coating trolley lifting height adjusting device

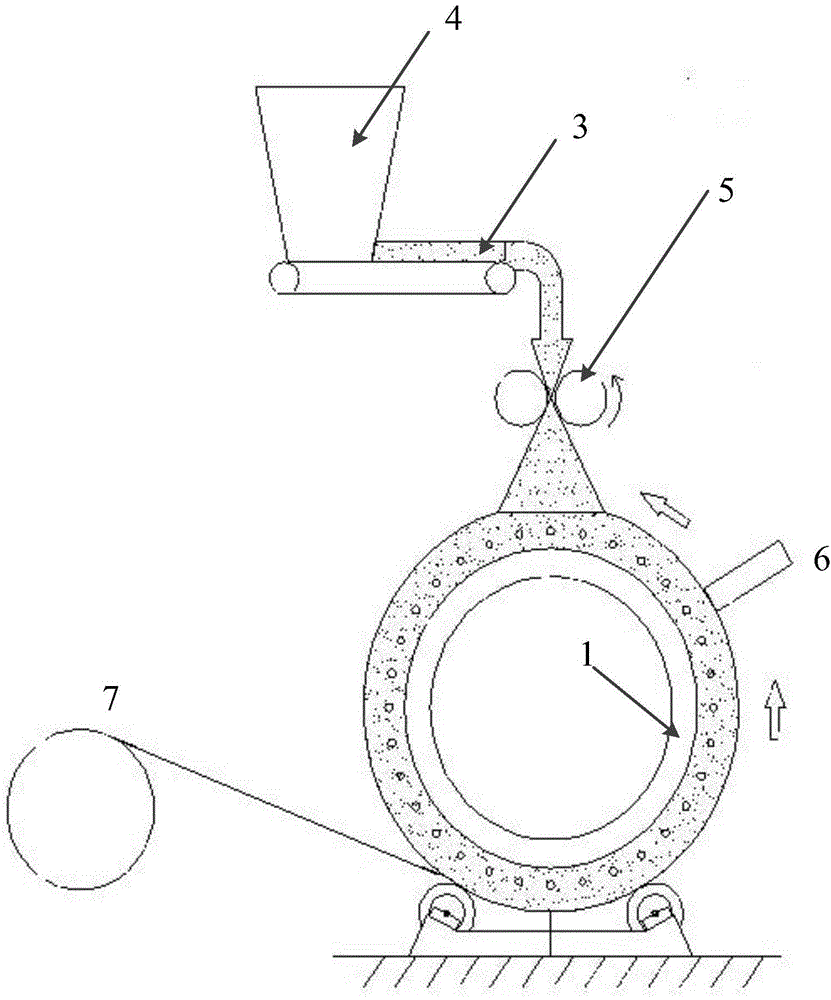

InactiveCN104647564AGood adhesionIncrease coating thicknessCeramic shaping apparatusClutchTrolley lift

The invention discloses a coating trolley lifting height adjusting device. The coating trolley lifting height adjusting device specifically comprises a trolley, a hydraulic cylinder, a pedestal guide groove, a screw rod wheel table, a screw rod wheel, a screw rod, a clutch and hand wheels, wherein the hydraulic cylinder is arranged on the trolley to lift the height of the trolley; a first tabletop is supported on the hydraulic cylinder; a pedestal guide groove is formed in the first tabletop; two screw rod wheel tables are arranged in the pedestal guide groove; a screw rod wheel is arranged on each screw rod wheel table; the two screw rod wheels are connected through two screw rods; the clutch is connected between the two screw rods, so that the distance between the two screw rod wheels is adjusted; one hand wheel is arranged at the outer end of each screw rod. The device can adjust the spraying height of a pipeline, so that no matter how the caliber size is changed, the spraying height and a spraying central point are always kept fixed, the attachment rate of concrete during pipeline coating is greatly improved, and waste of a material can be effectively reduced, and the coating thickness of a pipeline concrete counterweight layer is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

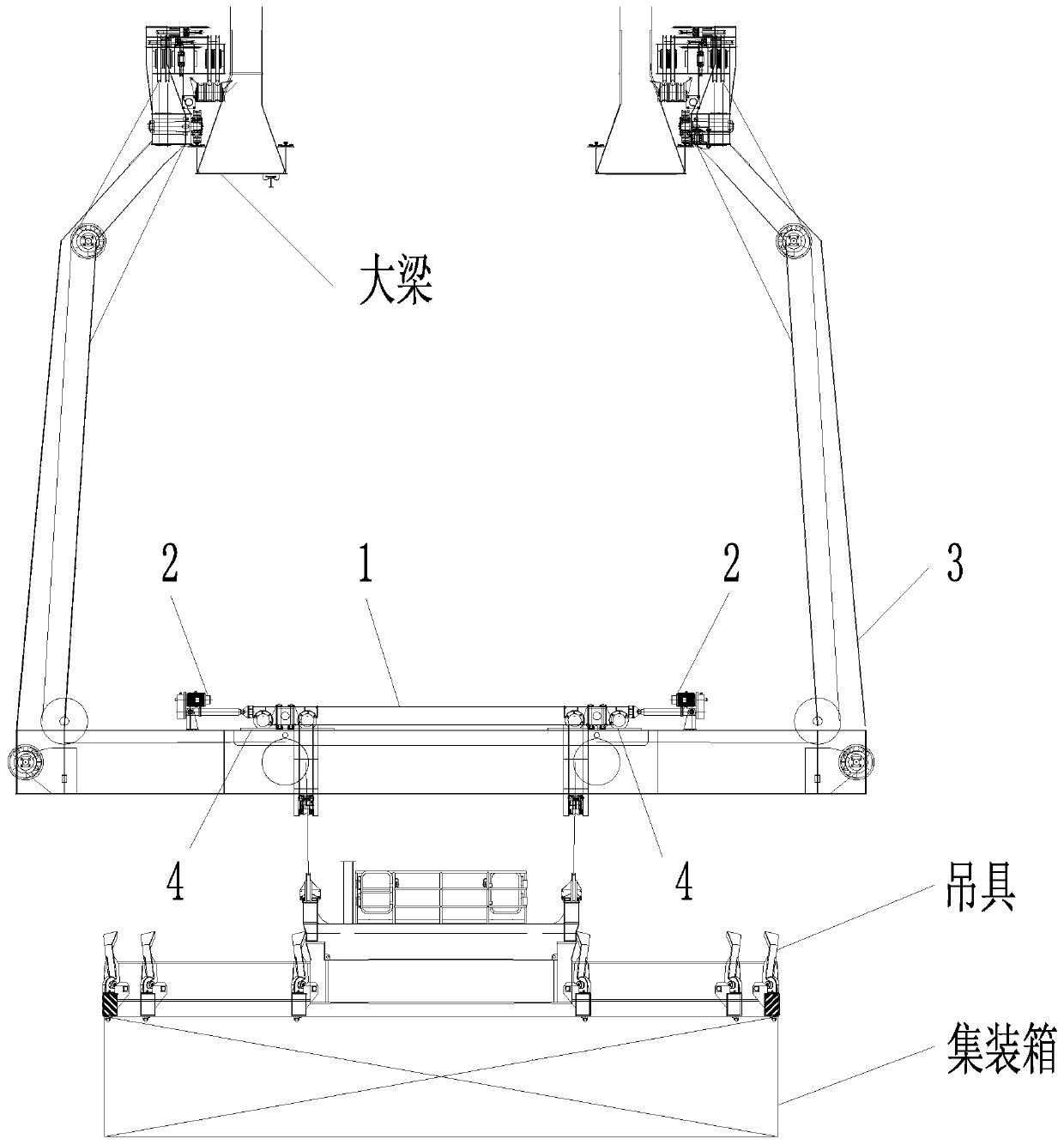

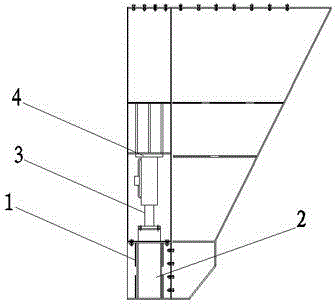

Container crane and method for loading and unloading containers using crane

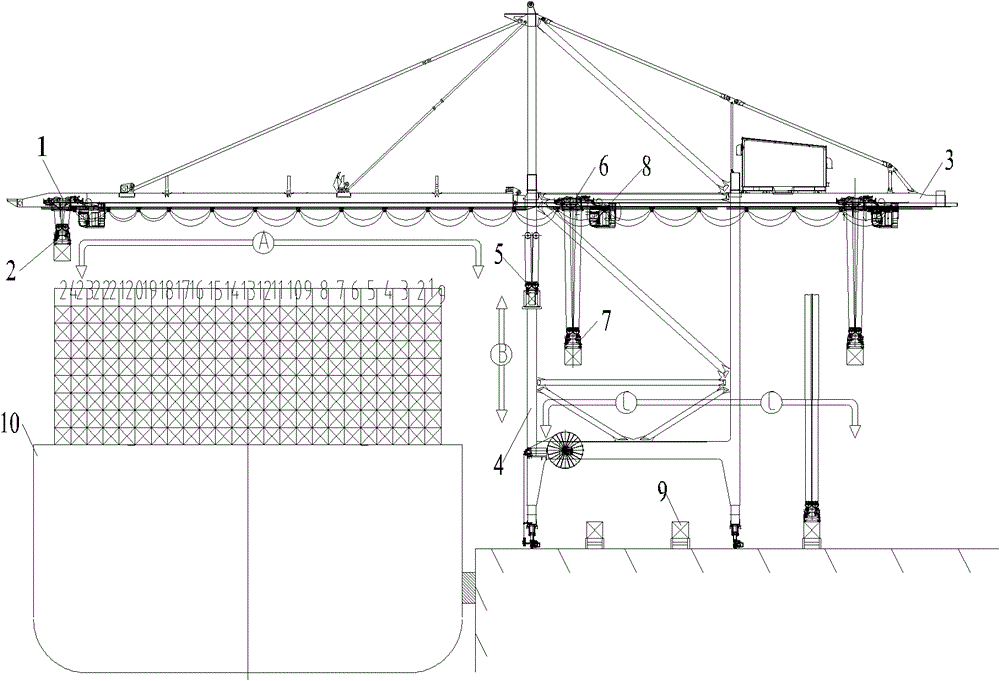

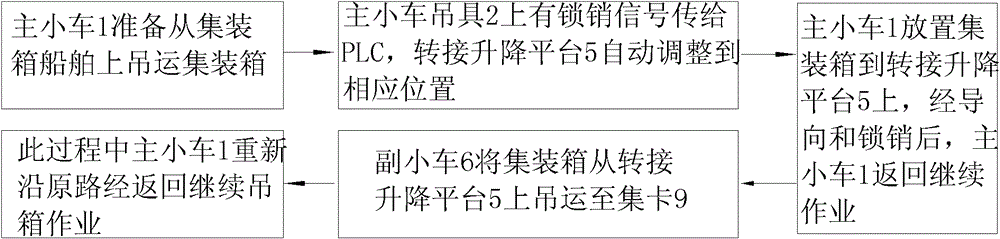

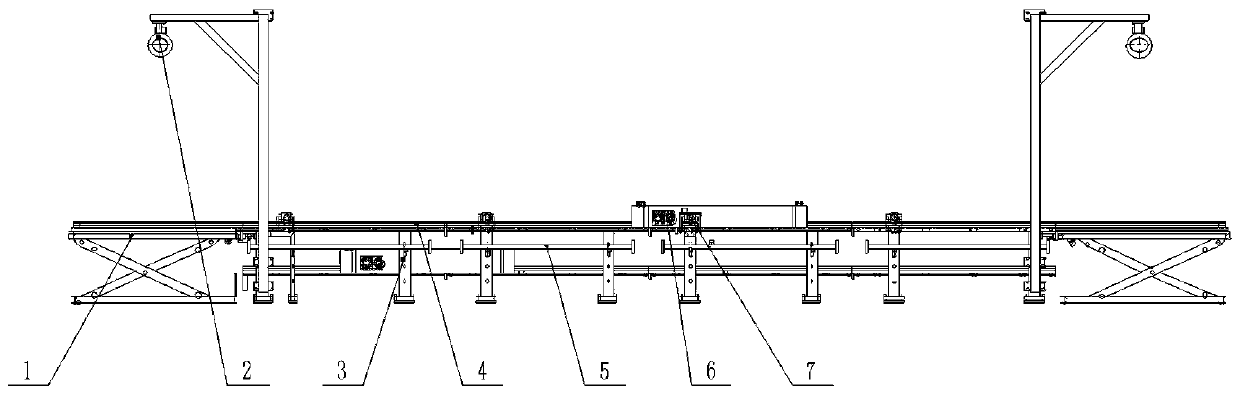

InactiveCN102139831BReasonable optimization of combined job node settingsReduce waiting time for card collectionTrolley cranesContainer craneEngineering

The invention provides a container crane and a method for loading and unloading containers using the crane. The container crane comprises a crane girder (3), a main trolley (1) which can move along the crane girder (3), a main trolley lifting appliance (2) which moves along with the main trolley (1), a support pillar (4), a transferring and lifting platform (5) for lifting up and down the containers to be loaded and unloaded, and an auxiliary trolley mechanism, wherein, the auxiliary trolley mechanism comprises an auxiliary trolley (6) which is movably arranged along the crane girder (3), andan auxiliary trolley lifting appliance (7) which is arranged on the auxiliary trolley (6) and is used for loading and unloading the containers on the transferring and lifting platform (5). The container crane provided by the invention has the advantages of reasonably optimizing setup of combined operation nodes, maximally reducing the possibility of waiting for a container truck during the loading and unloading process, enhancing cost performance of equipment, and improving operating efficiency. The container crane is used for loading and unloading the containers by utilizing the method.

Owner:SANY MARINE HEAVY IND

Air bed detection assembly line and air passage combining and separating device thereof

ActiveCN107764490ASmall footprintIncrease or decrease the stationMeasurement of fluid loss/gain ratePipeline systemsWork cycleAssembly line

An air bed detection assembly line and an air passage combining and separating device thereof. The air bed detection assembly line is characterized in that it comprises upper and lower rail frames; two ends of the rail frames are provided with elevating platforms; a main air passage separating device is arranged on the rail frames; the main air passage separating device is connected with a main air passage; a trolley is disposed on the rail frames and is in engaged transmission with a rack on the rail frames via a gear; and the trolley has a trolley air inlet device. The trolley operates cyclically in virtue of two guide rails and the elevating platforms. An air bed is placed on the moving trolley and drives to different stations to be automatically inflated and deflated and to be subjected to airtightness detection. The last station is an air exhaust station. Further, the invention discloses a main air passage splitting device to realize a requirement that the moving trolley carryingthe air bed is combined or separated from the main air passage at different stations.

Owner:SHENYANG POLYTECHNIC UNIV

Construction method for carrying out rolling compaction and slope reinforcement on faced dam

InactiveCN101936007AHigh precisionImprove securityExcavationsUltimate tensile strengthRapid construction

The invention discloses a construction method for carrying out rolling compaction and slope reinforcement on a faced dam. The method comprises the following steps: before construction, installing and fixing a first-floor template, then carrying out rolling compaction on a bedding material, and embedding tie bars into the bedding material; after the first floor is subject to rolling compaction to be qualified, utilizing a mechanical lifting template 5CM to carry out mortar pouring; after the mortar strength is allowed, arranging a lifting trolley on an end template, installing a second-floor template for carrying out rolling compaction, and utilizing a trolley lifting template to carry out mortar pouring after the second floor is subject to rolling compaction to be qualified; in the process of constructing a third floor, arranging a rack track capable of moving up and down on two templates at the end, moving the trolley to the orbital position, utilizing a jack to jack up the trolley, then rotating a running gear for 90 degrees, and placing onto the track, thus enabling the trolley to run to a track on the second-floor template to operate; and utilizing the trolley to lift the constructed first-floor template for a certain height, translating to the third floor, installing into a proper position, carrying out rolling compaction, and repeating the operation in this way until finishing the construction. The construction method has the advantages of little interference to the site and rapid construction progress.

Owner:SINOHYDRO BUREAU 5

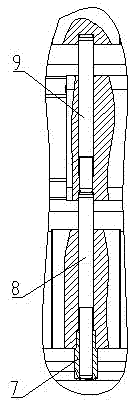

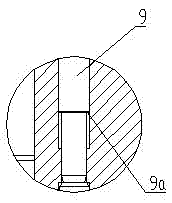

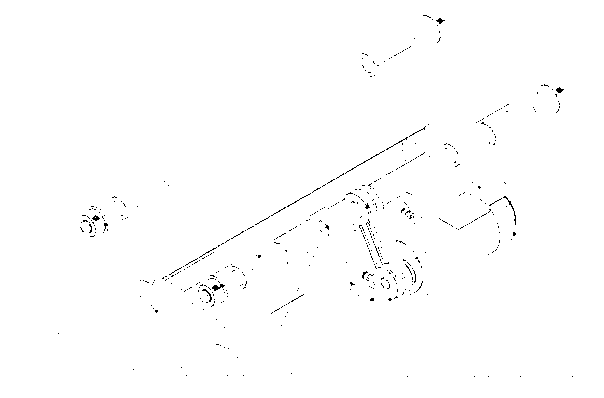

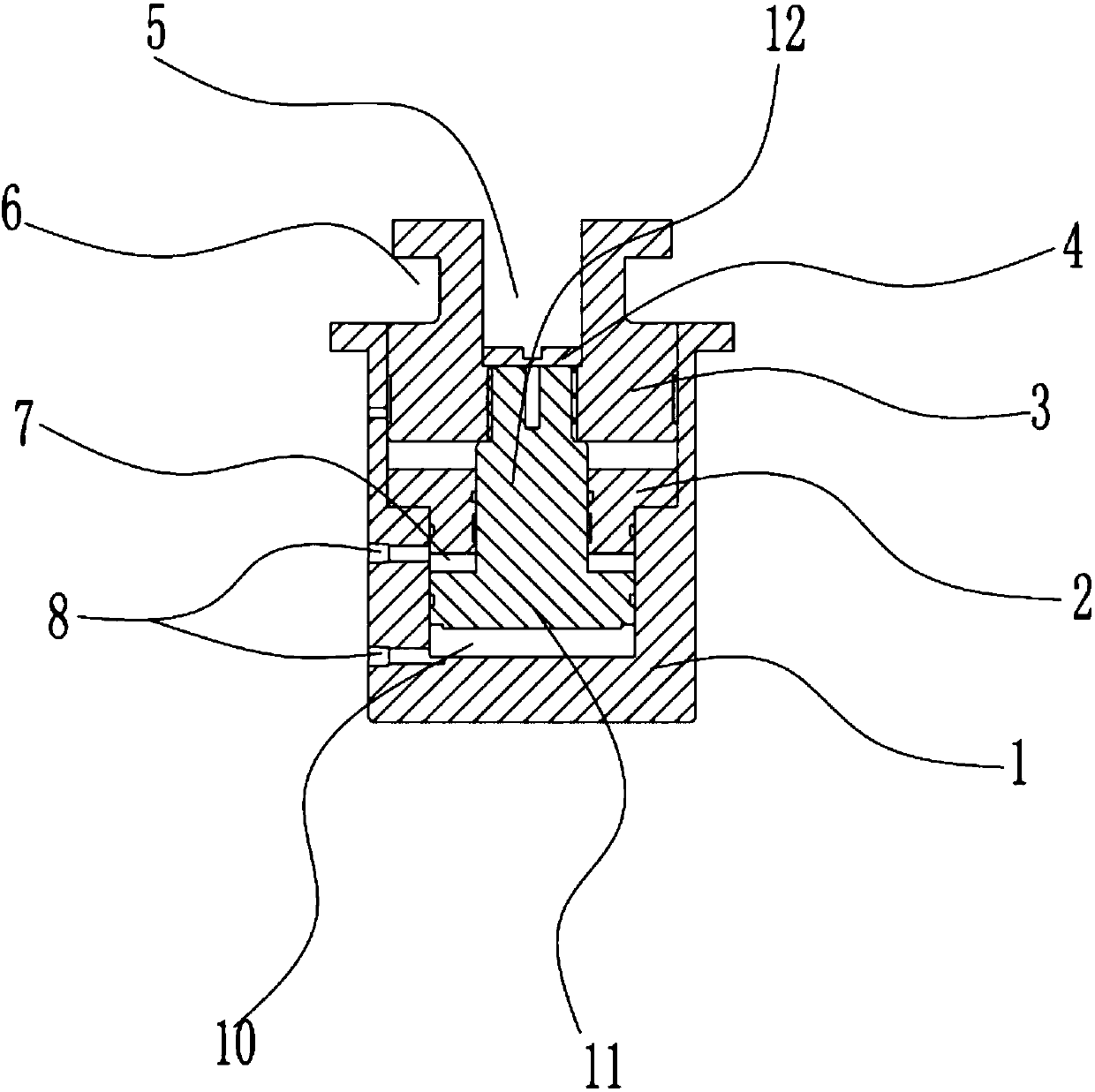

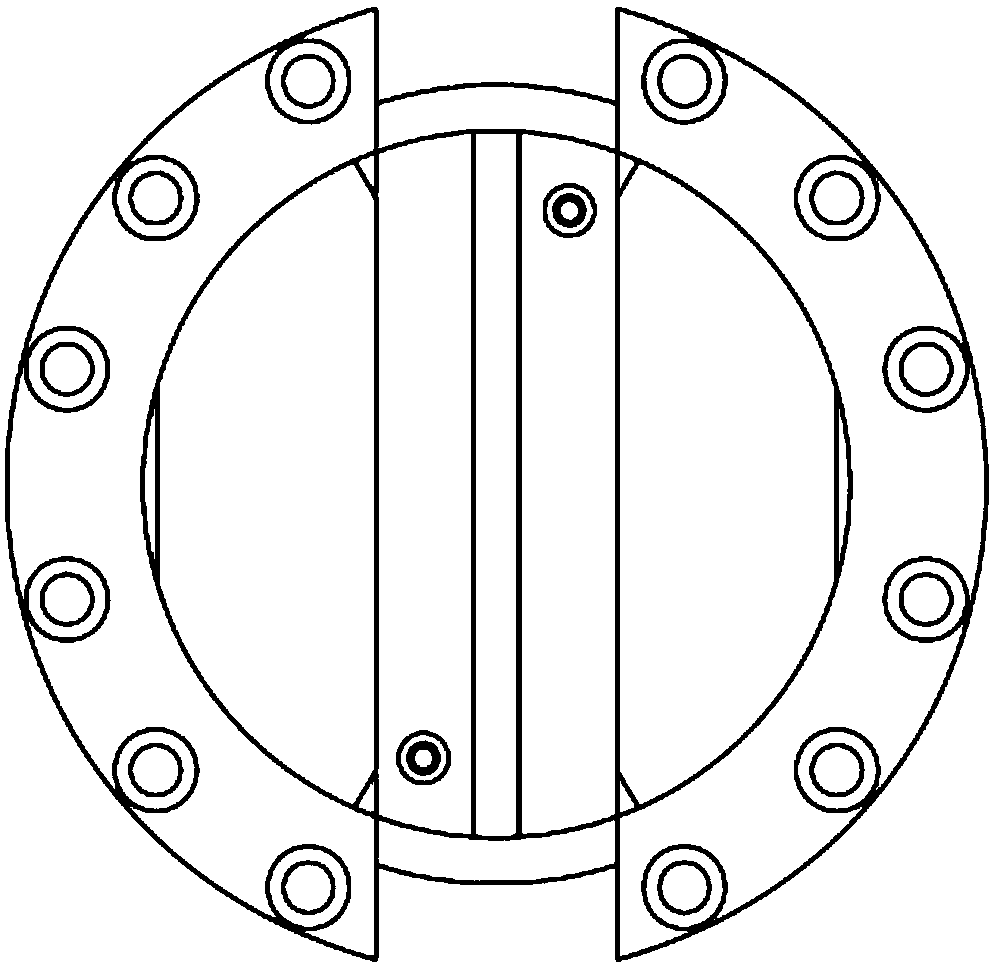

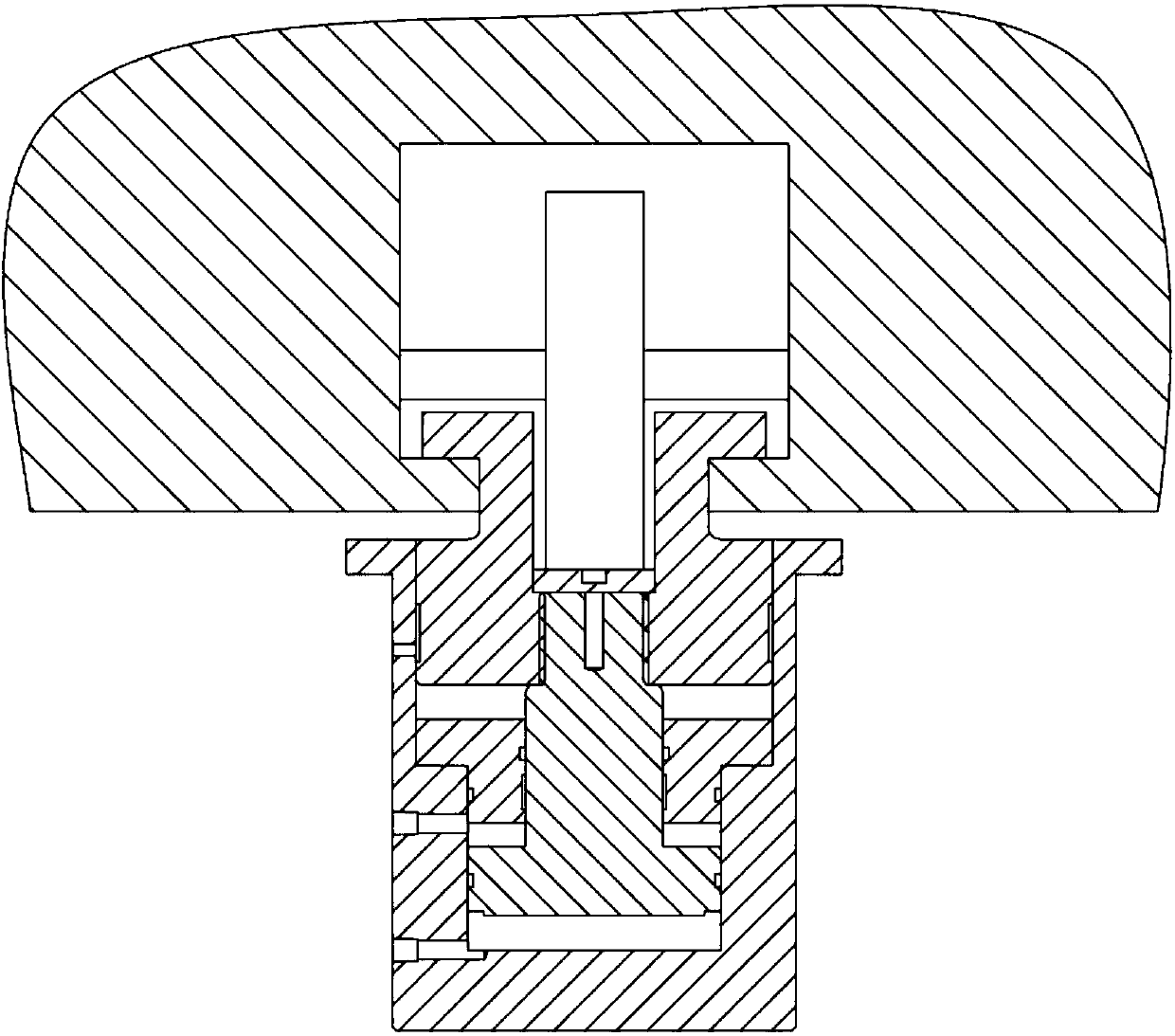

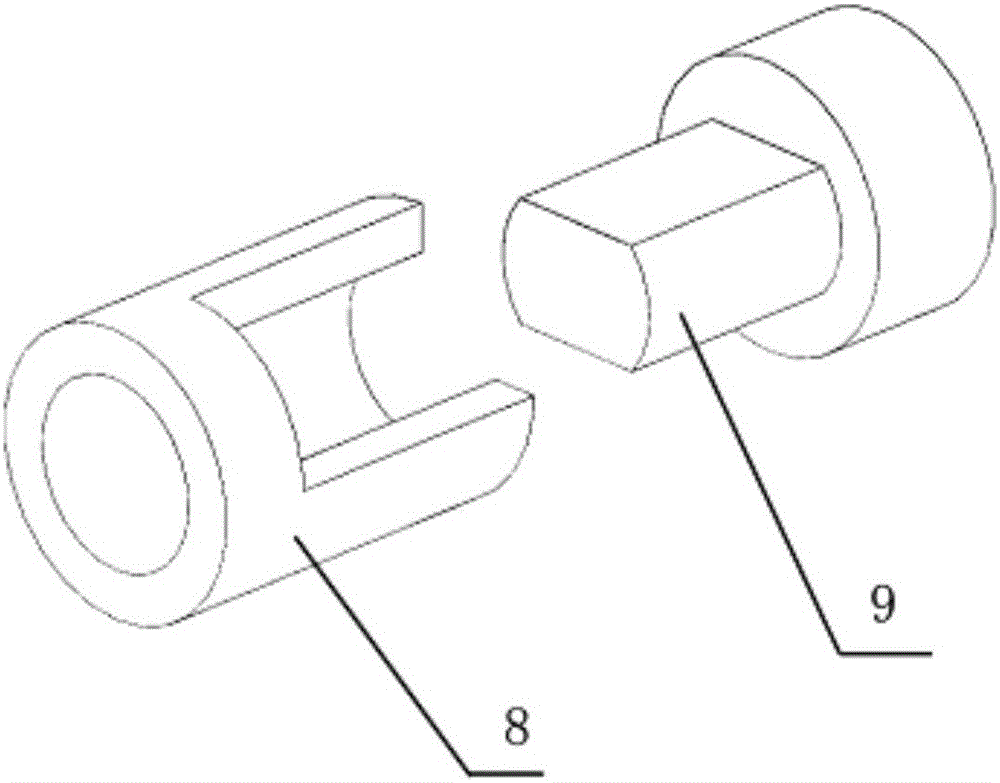

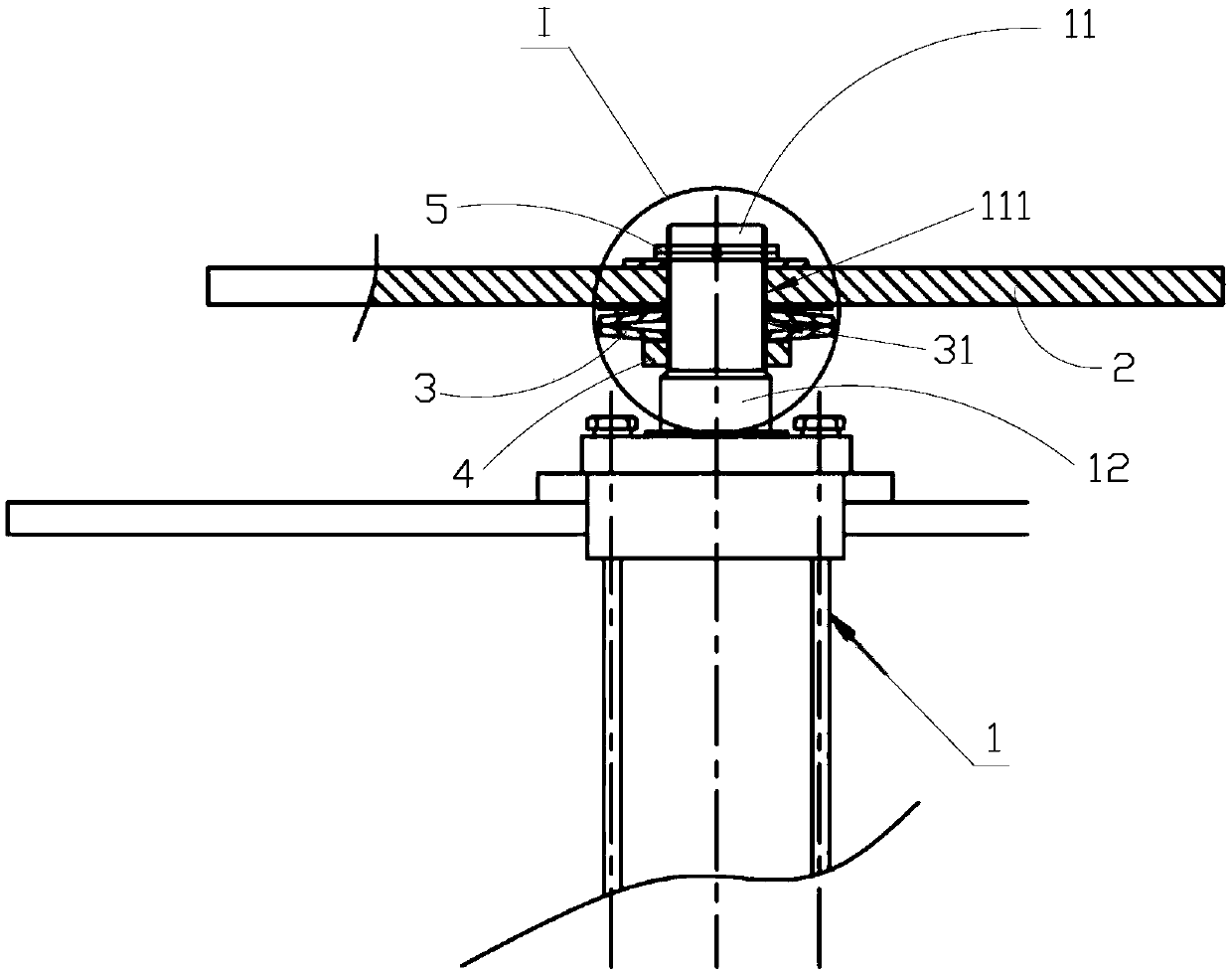

Punching machine trolley lifting and clamping mechanism

The invention relates to a punching machine trolley lifting and clamping mechanism which comprises an oil cylinder main body and a gripper; the upper end of the oil cylinder main body is opened; the middle part of the inner side of the oil cylinder main body is provided with a gland; the lower side of the gland is provided with a piston in an up-down lifting manner; the opening in the upper end ofthe oil cylinder body is provided with the gripper in an up-down sliding manner; a through groove is formed in the middle part of the gripper in a radial direction; an axial piston rod of the pistonpenetrates through the gland upwards to extend into the lower end of the through groove of the gripper; and the upper end of the axial piston rod is provided with a rail which is arranged in the through groove. The punching machine trolley lifting and clamping mechanism is simple in structure, small in size, convenient to install, high in structural strength and relatively stable in lifting and clamping.

Owner:NINGBO BOXIN MACHINERY

Ultralow-altitude winch trolley and crane

InactiveCN107188038AMitigate technical issues with inefficient useLower lifting heightWinding mechanismsTravelling gearDrive wheelHeight decrease

The invention relates to the technical field of hoisting equipment, in particular to an ultra-low altitude winch trolley and a crane. The ultra-low-altitude hoisting trolley includes a frame, and the frame includes a first beam and a second beam arranged in parallel, and the lower parts of the first beam and the second beam are equipped with a driving wheel set and a driven wheel set. A connecting beam is arranged between the first beam and the second beam, and the connecting beam is provided with a traveling motor for driving the driving wheel set; the first beam is provided with a mounting hole, and the second beam is provided with a The support frame corresponding to the installation hole, the lifting device is connected to the support frame through the installation hole, and the bottom surface of the lifting device is lower than the upper end surfaces of the first beam and the second beam. In order to alleviate the technical problems existing in the prior art that are restricted by the height of the factory building, the hoisting height of the hoisting trolley is reduced, the effective lifting height is reduced, and the use efficiency of the hoisting trolley is low.

Owner:HENAN SINOKO CRANES

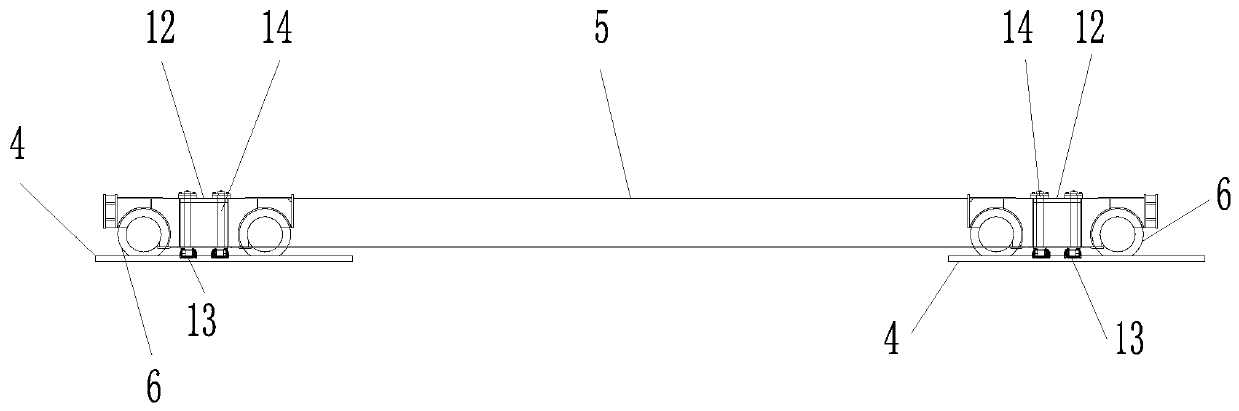

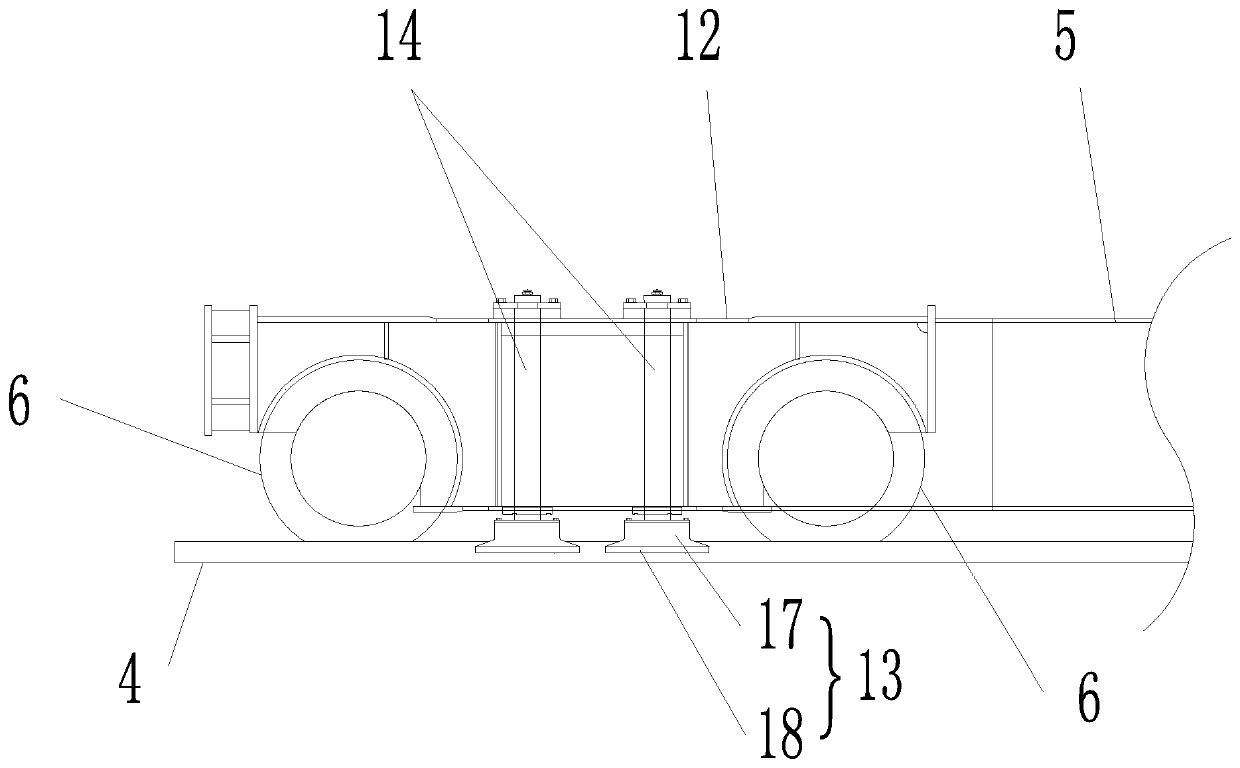

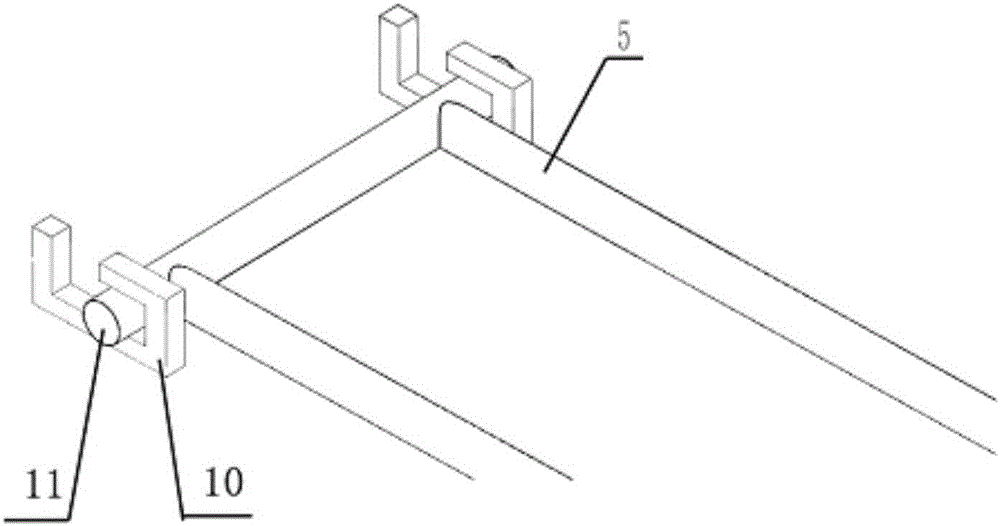

Shore bridge trolley lifting appliance fine adjustment shifting system

PendingCN109987514ASafe and stable operationFine-tuned shift implementationTrolleysEngineeringReducer

The invention discloses a shore bridge trolley lifting appliance fine adjustment shifting system. The system comprises a mobile trolley for connecting with a lifting appliance, trolley moving devicesand a mobile trolley rail laid on a bottom cross beam of a shore bridge trolley; the mobile trolley comprises a trolley rack and a wheel set, the trolley track is a polygon frame, the wheel set is arranged below the trolley rack, and is fixedly connected with the trolley rack, the wheel set is arranged on the mobile trolley rail in a sliding manner, each trolley moving device comprises a motor, aspeed reducer, an electric push rod, a support and a connecting base, the motors and the speed reducers are in shaft connection, the speed reducers are in shaft connection with the electric push rods,the electric push rods are connected with the connecting bases, the connecting bases are connected with a frame of the trolley rack, one ends of the supports are fixedly connected with the electric push rods, and the other ends of the supports are fixedly connected with the bottom cross beam of the shore bridge trolley. The loading and unloading efficiency of a container can be improved, meanwhile, the structure is stable, and the influence of external adverse factors can be resisted to a certain degree.

Owner:华电蓝科科技股份有限公司

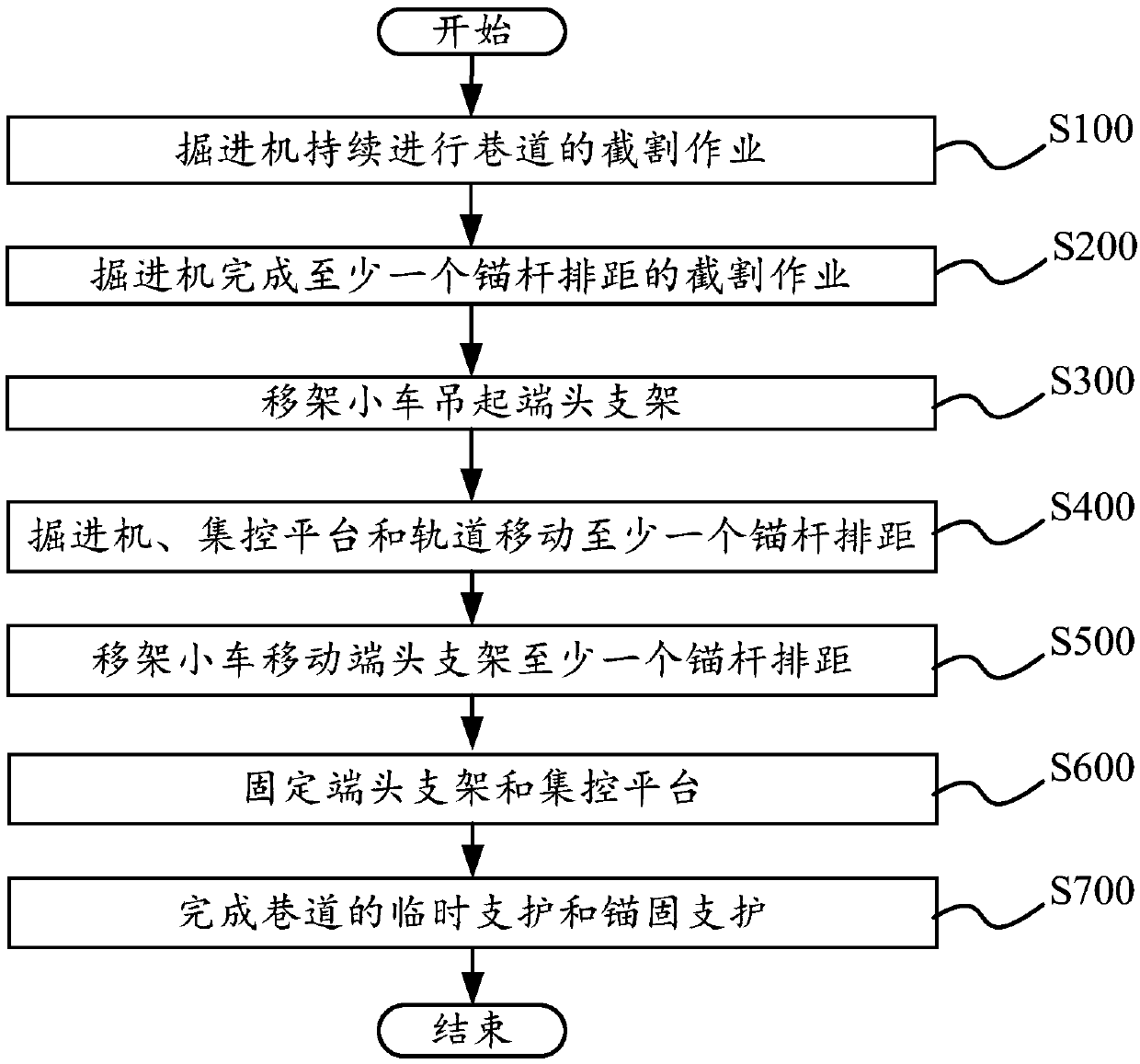

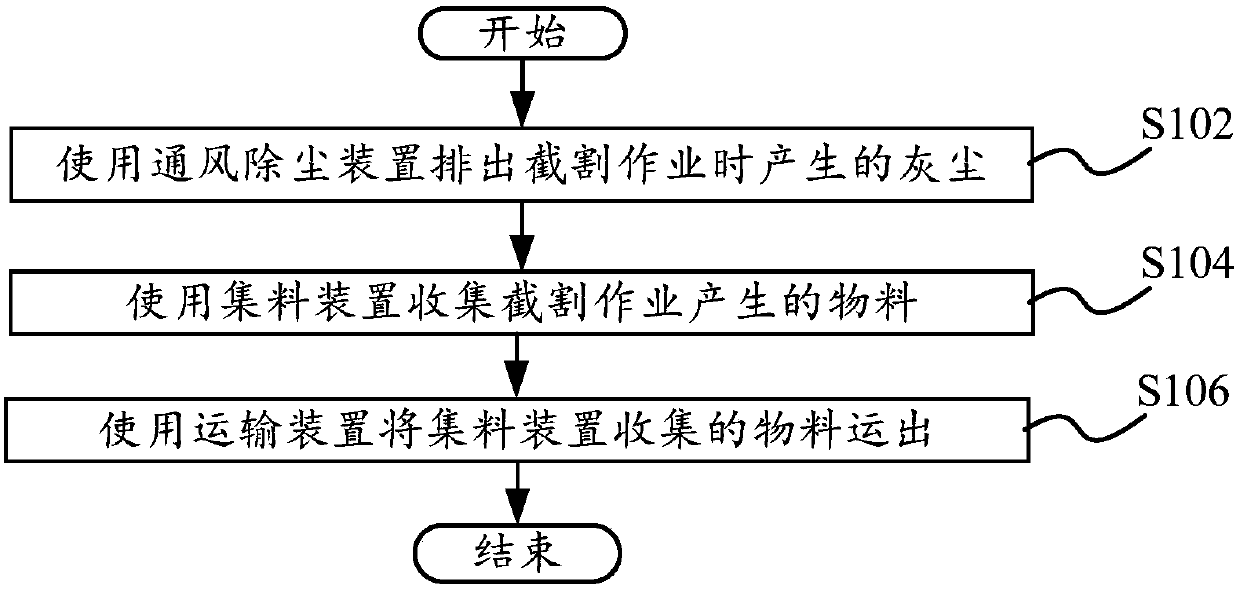

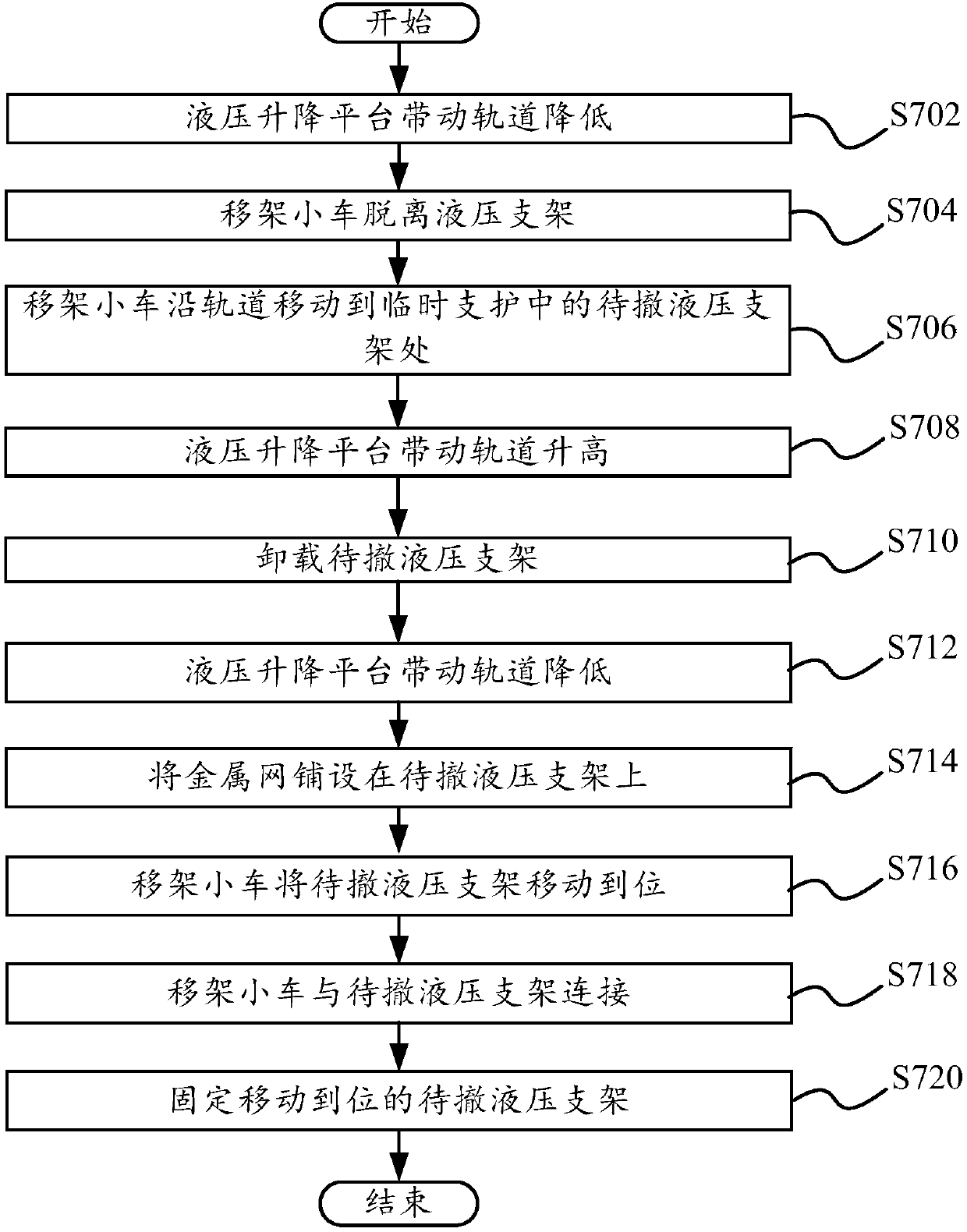

Parallel operation process of digging, protecting and anchoring and parallel operation system of digging, protecting and anchoring

InactiveCN109869146ASolve the force problemFix stability issuesSlitting machinesMine roof supportsEngineeringCoal

The invention provides a parallel operation process of digging, protecting and anchoring and a parallel operation system of digging, protecting and anchoring. The parallel operation process of digging, protecting and anchoring comprises the following steps that a roadway is continuously cut by a roadheader; the roadheader completes the cutting operation of at least one anchor rod row spacing; a frame moving trolley lifts an end bracket; the roadheader moves at least one anchor rod row spacing; the frame moving trolley moves at least one anchor rod row spacing of the end bracket; and the end bracket is fixed; and temporary support and anchoring support of the roadway are completed. Through the technical scheme of the parallel operation process of digging, protecting and anchoring and the parallel operation system of digging, protecting and anchoring, a highly automated, intelligent and integrated high-efficiency comprehensive tunneling production system is realized. The parallel operation process of digging, protecting and anchoring and the parallel operation system of digging, protecting and anchoring are mainly suitable for the driving construction of a coal roadway and a half-coal and half-rock roadway supported by an anchor net in coal mines, and further are applicable to similar tunnel construction in non-coal mines.

Owner:SANY HEAVY EQUIP

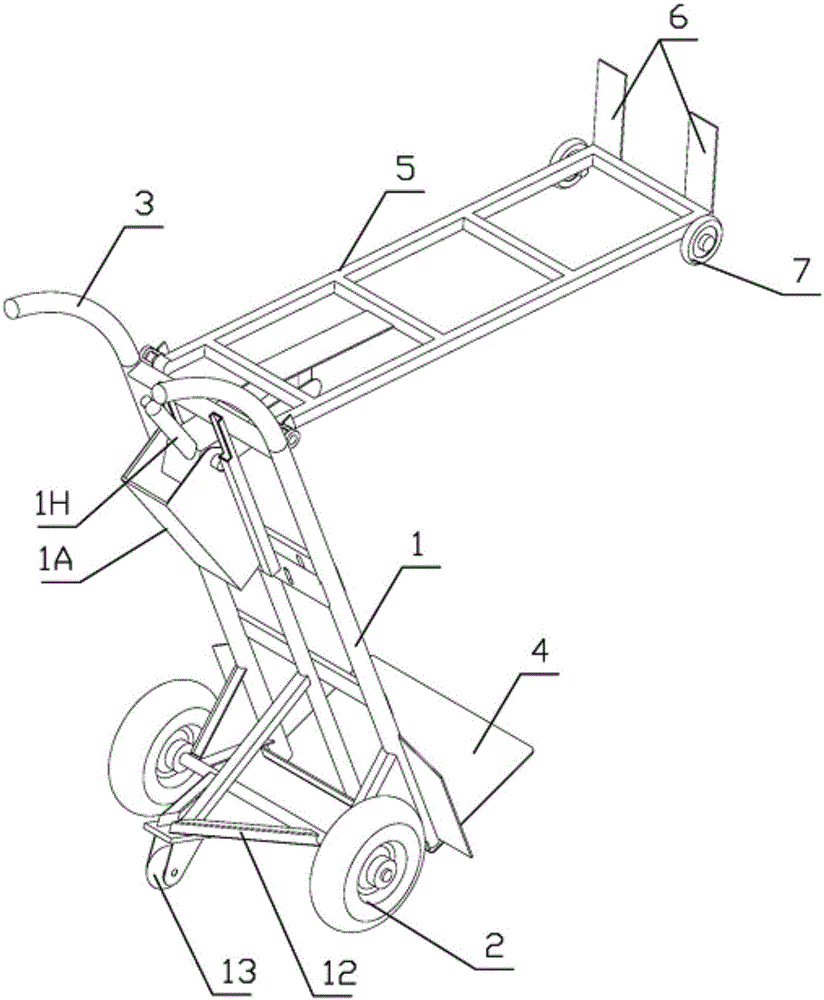

Combined trolley lifted by jack

The invention relates to a trolley for transferring cargoes, and specifically relates to a combined trolley lifted by a jack. The combined trolley comprises a chassis, front wheels arranged at the front end of the chassis, and handgrips arranged at the rear end of the chassis, wherein a supporting plate is fixedly arranged at the front end of the chassis; a hinge mechanism is arranged at the rear end of the chassis; the hinge mechanism is connected with a shelf; a shelf supporting plate is arranged at the front end of the shelf; a lifting mechanism is arranged on the chassis; and o telescopic lifting arm of the lifting mechanism acts on the shelf. The combined trolley is reasonable in structure, has the functions of transferring the cargoes on a flat ground and lifting to load, and can reduce the labour intensity, and improve the transferring and loading efficiency of the cargoes.

Owner:郭菲

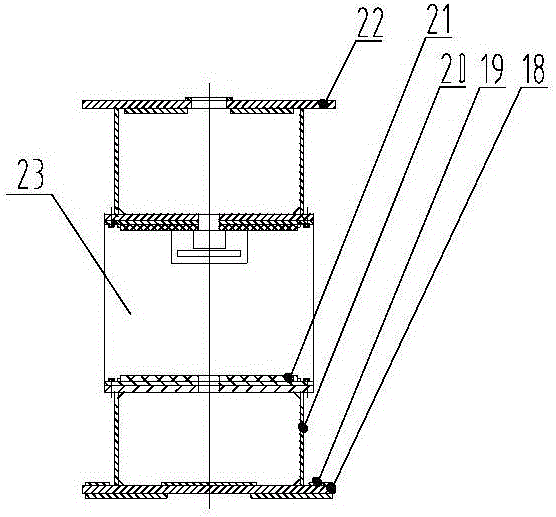

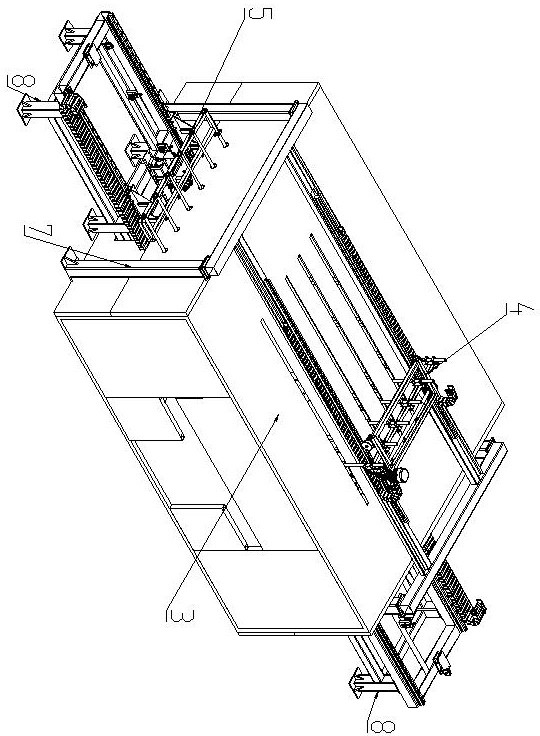

Deduster trolley portal stabilizing system

InactiveCN105569680AImprove stabilityImprove seismic performanceUnderground chambersTunnel liningPush upsPetroleum engineering

A deduster trolley portal stabilizing system relates to the lining trolley technical field, and is characterized by comprising an inner sleeve, an outer sleeve, a lifting oil cylinder, and a lifting oil cylinder seat; the inner sleeve is arranged in the outer sleeve; the lifting oil cylinder is arranged above the inner sleeve; the lifting oil cylinder seat is arranged above the lifting oil cylinder. The trolley lifting oil cylinders are arranged on the bottom, so the whole trolley including portal can be pushed up when the trolley is in position lining, thus providing better stable and anti-vibration effect.

Owner:HEFEI LIQING ENVIRONMENTAL PROTECTION EQUIP

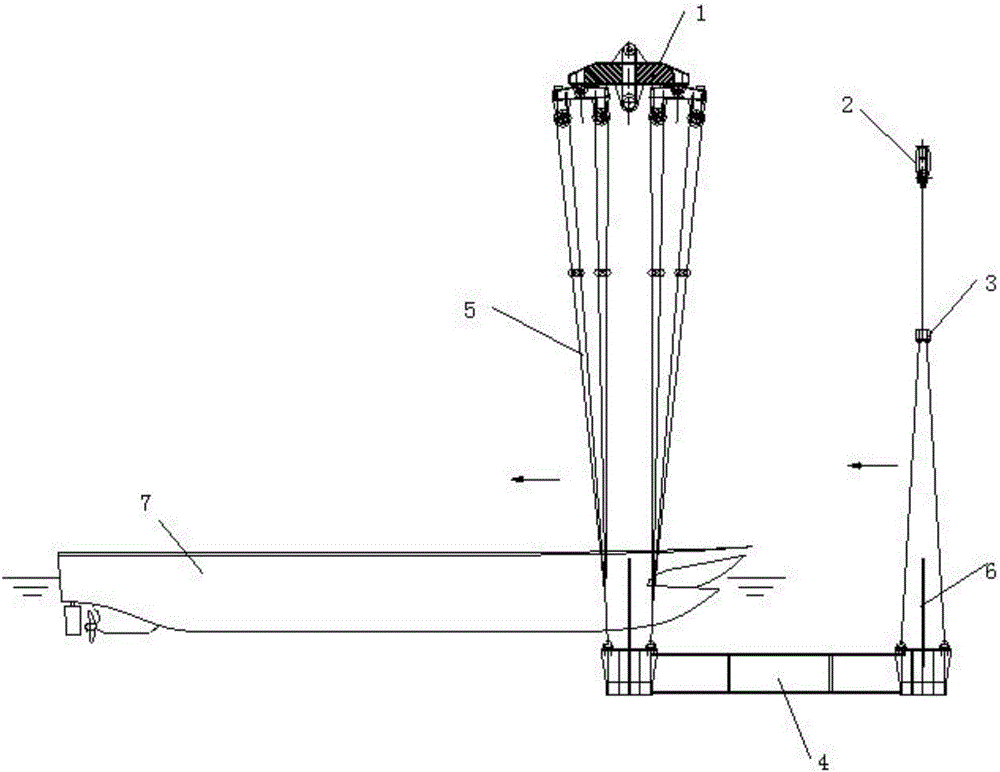

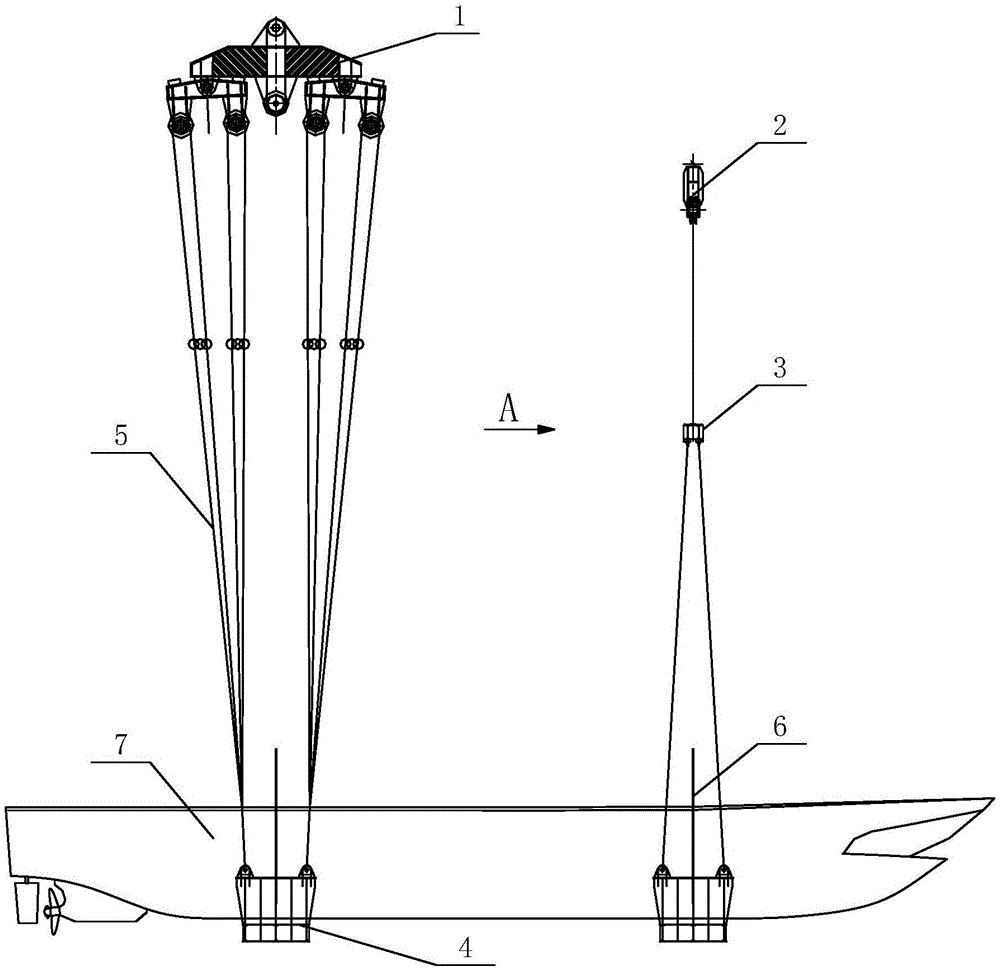

Hoisting device and method for transferring ship on to bank or in dry dock

ActiveCN106629378AThe operating water depth requirement is smallSimple processLoad-engaging elementsMarine engineeringSteel frame

The invention provides a hoisting device and method for transferring a ship on to a bank or in a dry dock. The hoisting device comprises a fore poppet, a channel steel frame and a stern poppet, wherein one end of the channel steel frame is vertically connected with the fore poppet, and the other end of the channel steel frame is vertically connected with the stern poppet; positioning marker posts are vertically arranged on the side surfaces of the fore poppet and the stern poppet; an upper trolley lifting bar of a gantry crane is connected with two ends of the fore poppet or the stern poppet through hoisting wires; the upper end of a hoisting beam is connected with a lower trolley lifting bar of the gantry crane through the hoisting wires, and the lower end of the hoisting beam is connected with the fore poppet and the stern poppet through the hoisting wires. The hoisting device is simple in structure and convenient to operate.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Self-propelling trolley lifting appliance with uphill assisting chain mechanism

InactiveCN105329632AEasy uphillAvoid affecting the production scheduleMechanical conveyorsEngineeringSprocket

The invention relates to a self-propelling trolley lifting appliance with an uphill assisting chain mechanism. The self-propelling trolley lifting appliance comprises a self-propelling trolley track, a self-propelling trolley lifting appliance body, push chain tracks, a push chain return rail, an assisting chain drive chain wheel, an assisting chain tensioning chain wheel, chain push heads, retraction stop push heads, an assisting chain uphill mounting frame and an assisting chain downhill mounting frame. The push chain return rail is located above the push chain tracks. The corresponding ends of the push chain tracks and the push chain return rail are connected to form an annular sealed chain track. The sealed chain track is matched with the assisting chain drive chain wheel and the assisting chain tensioning chain wheel. The push chain tracks are close to the self-propelling trolley track. The chain push heads and the retraction stop push heads are arranged on the push chain tracks and the push chain return rail respectively. The retraction stop direction of the retraction stop push heads is the downhill direction of the slope. The chain push heads and the retraction stop push heads are matched with the self-propelling trolley lifting appliance. In this way, the self-propelling trolley lifting appliance is stable in the downhill process and easy to uprise.

Owner:MIRACLE AUTOMATION ENG CO LTD

Coating equipment and technological method for guardrail stand column

PendingCN112604910AThickness differenceSmall footprintPretreated surfacesCoatingsStructural engineeringSmall footprint

The invention discloses coating equipment for a guardrail stand column. The coating equipment for the guardrail stand column comprises a transverse spraying system and a transverse heating curing system, the spraying system comprises a powder room, an outer spraying movement device is installed at the top of the powder room, two sets of inner spraying movement devices which are oppositely arranged are arranged on the two sides of the powder room, and two sets of clamping rotation devices which are oppositely arranged are arranged in the powder room. The invention also discloses a coating technological method for the guardrail stand column. The method comprises the steps that a feeding trolley lifts the guardrail stand column and conveys the guardrail stand column into the powder room, after the stand column is positioned in the powder room, clamping jaws stretch into the interior to support the two ends and rotate, an inner spray gun and an outer spray gun move linearly to conduct rotary spraying on the inner surface and the outer surface of the stand column, and automatic conveying and transverse heating curing are conducted after spraying. According to the coating equipment and the coating technological method for the guardrail stand column, powder can be quickly cured, and the adhesive force of a coating can be improved; the powder coating can be more uniform, and the thickness range of the coating is reduced; and internal spraying and external spraying can be achieved at the same time, the equipment occupied area is small, the equipment integration degree is high, and the manufacturing cost is low.

Owner:潍坊东方钢管有限公司

Cast-rolling coil stripping trolley with elastic support

InactiveCN111054777AReduce the detection rate of quality defectsReduced wall thicknessEngineeringStructural engineering

The invention belongs to the technical field of aluminum foil production equipment, and particularly discloses a cast-rolling coil stripping trolley with elastic support, wherein the cast-rolling coilstripping trolley comprises a coil stripping trolley lifting oil cylinder and a coil stripping trolley tray; an elastic buffer piece is arranged between the coil stripping trolley lifting oil cylinder and the coil stripping trolley tray. Compared with the prior art, the cast-rolling coil stripper car with the elastic support has the advantages that a group of belleville springs are additionally arranged between the top of a piston rod of the cast-rolling machine coil stripping trolley and the tray base of the coil stripping trolley, and the compression space of the belleville springs just meets the thickness of a cast-rolling rolled plate. Through the characteristic that the belleville springs contract slowly when being steessed, the thickness of the rotating wall of a coil is reduced when the trolley unloads coils, force applied to a trolley riding wheel is increased, and thus cast-rolled coil surface deep pressing damage is eradicated. And the detection rate of the cast-rolled coiled plate surface quality defects can be greatly reduced.

Owner:SNTO TECH GRP

A method for automatic centering of aluminum coils by transport trolley

ActiveCN111776576BReduce duplication of effortHigh precisionControl devices for conveyorsStorage devicesEngineeringMechanical engineering

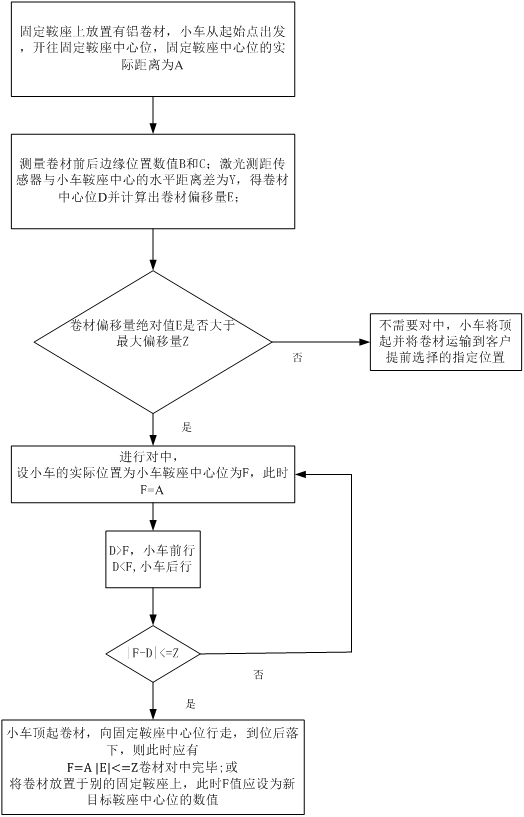

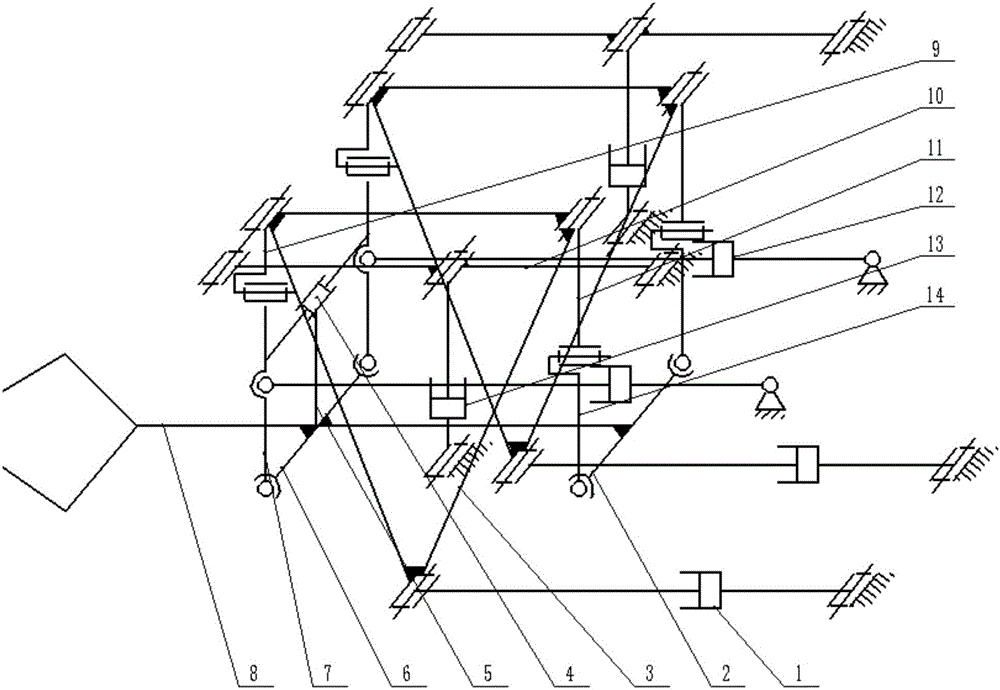

The invention relates to a method for automatic centering of an aluminum coil on a cargo location by a transport trolley. The actual distance measured from the center of a fixed saddle is A; the values B and C of the front and rear edge positions of the coil are measured; The horizontal distance difference is Y, get the coil center position D and calculate the coil offset E; judge whether the absolute value E of the coil offset is greater than the maximum offset Z, and if so, perform alignment; otherwise, no alignment is required ; Judgment |F‑D|<=Z, if so, the trolley lifts the coiled material, walks towards the center of the fixed saddle, and falls down after it is in place, then there should be F=A|E|<=Z coiled material alignment Finish; or place the coil on another fixed saddle, at this time the F value should be set to the value of the center of the new target saddle; otherwise, continue to align. The invention adopts the transport trolley to automatically find the center of the aluminum coil in the cargo position, instead of adjusting the centering by hoisting the coil with the crane or man-operating the centering of the trolley, which has high precision and high efficiency and reduces repetitive labor of operators.

Owner:CHINALCO RUIMIN

A lifting mechanism of a large tonnage trackless forging manipulator

InactiveCN104014706BSimple structureImprove carrying capacityForging/hammering/pressing machinesForging manipulatorMechanical engineering

The invention discloses a large-tonnage lifting mechanism for a trackless forging manipulator. The front portion and the rear portion of a main clamp shaft are fixedly connected with a front cross bar and a rear cross bar respectively, the two ends of a front connection bar are hinged to the front cross bar and a front hanging bar, and the two ends of a rear connection bar are hinged to the rear cross bar and a rear hanging bar. A left-to-right horizontal buffering cylinder is fixedly connected to the front portion of the main clamp shaft, and the two ends of the left-to-right horizontal buffering cylinder abut against the front hanging bar. The other end of the front hanging bar and the other end of the rear hanging bar are connected with the front endpoints and the rear endpoints of a pair of triangular frames, and inclined cylinders are connected with the lower endpoints of the triangular frames and a machine frame. Upper connection bars are connected with the front endpoints of the triangular frames and the machine frame. A front-to-back horizontal buffering cylinder is connected with the front hanging bar and the machine frame. Lifting cylinders are hinged to the middle portions of the upper connection bars and the machine frame. The large-tonnage lifting mechanism is symmetrically distributed with the main clamp shaft as the center and is simple in structure, good in synchronism and high in bearing capacity, the lifting motion trail of a clamp is close to a straight line, the position accuracy is high, and the view of a driver control console is wide.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com