Coating equipment and technological method for guardrail stand column

A technology for guardrail columns and coating equipment, which is applied in the direction of surface coating liquid devices, coatings, and pre-treated surfaces, etc., which can solve the secondary pollution of dust and exhaust gas, the large difference in coating film thickness, and the impact of coating Adhesion and other problems, to achieve the effects of pipe waste heat promotion, fast curing speed, and short curing time of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A guardrail post coating equipment

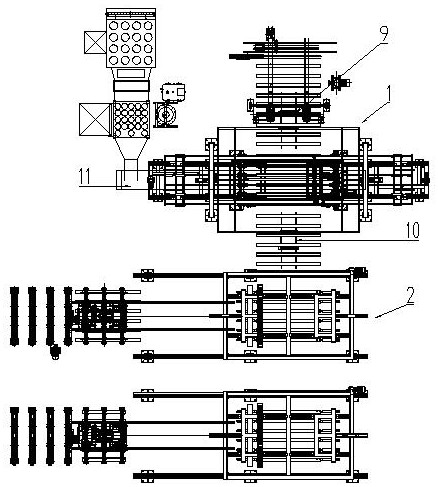

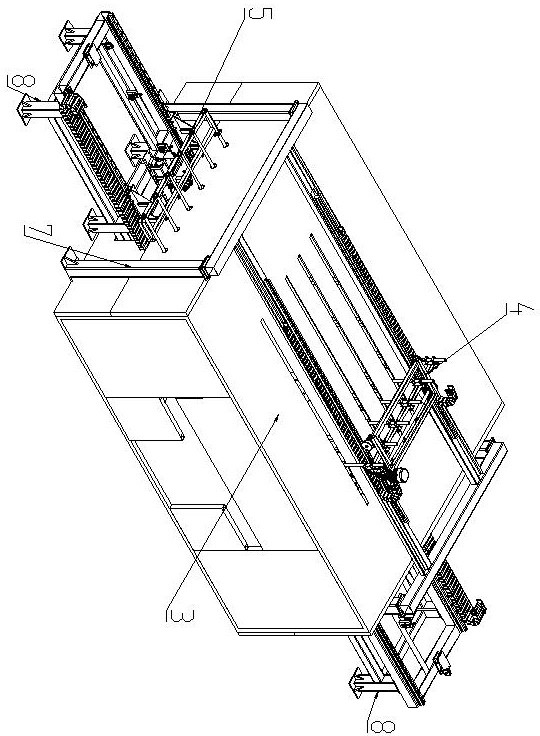

[0040] Such as figure 1 As shown, the present invention provides a guardrail column coating equipment, including a spraying system 1 and a curing system 2 arranged side by side; the spraying system 1 is for horizontal spraying, and the curing system 2 is for horizontal heating.

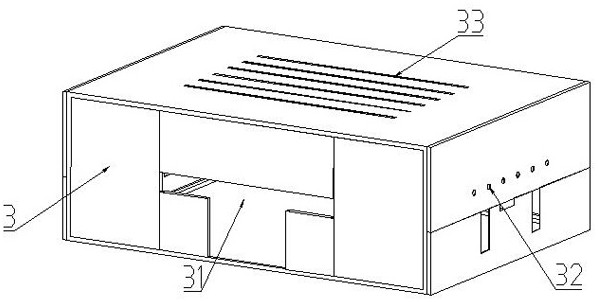

[0041] The spraying system 1 includes a powder room 3, and T-shaped ports 31 are provided on the longitudinal sides of the powder room 3 respectively, and the two T-shaped ports 31 are symmetrically arranged, and one T-shaped port 31 far away from the curing system 2 is used for feeding , a T-shaped port 31 close to the curing system 2 is used for discharging; the positions on both sides of the powder room 3 are respectively provided with a plurality of circular holes 32 uniformly distributed in a straight line, and the circular holes on the lateral sides of the powder room 3 32 is arranged symmetrically, and the round hole 32 is passed through...

Embodiment 2

[0058] Embodiment 2 A kind of guardrail post coating process

[0059] The invention provides a coating process for guardrail columns, comprising the following steps:

[0060] S1: The guardrail column is fed to the front of the powder room by the stepping mechanism, and the feeding trolley lifts a group of guardrail columns to send it to the powder room;

[0061] S2: After the guardrail column is positioned in the powder room, the pneumatic claws extend into the interior to prop up the two ends and rotate;

[0062] S3: The inner and outer spray guns move linearly to spray the inner and outer surfaces of the guardrail column;

[0063] S4: After the spraying is completed, the discharge trolley transports the guardrail column to the heating station;

[0064] S5: The support arm on one side of the heated support arm conveyer extends into the inner hole of the guardrail column from the inner hole of the porous induction coil, and the other support arm extends into the inner hole a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com