Air bed detection assembly line and air passage combining and separating device thereof

A technology of assembly line and air bed, which is applied in measurement devices, gas/liquid distribution and storage, and by measuring the acceleration and deceleration rates of fluids, etc., which can solve the problems of low inspection accuracy and achieve the effect of occupying less space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

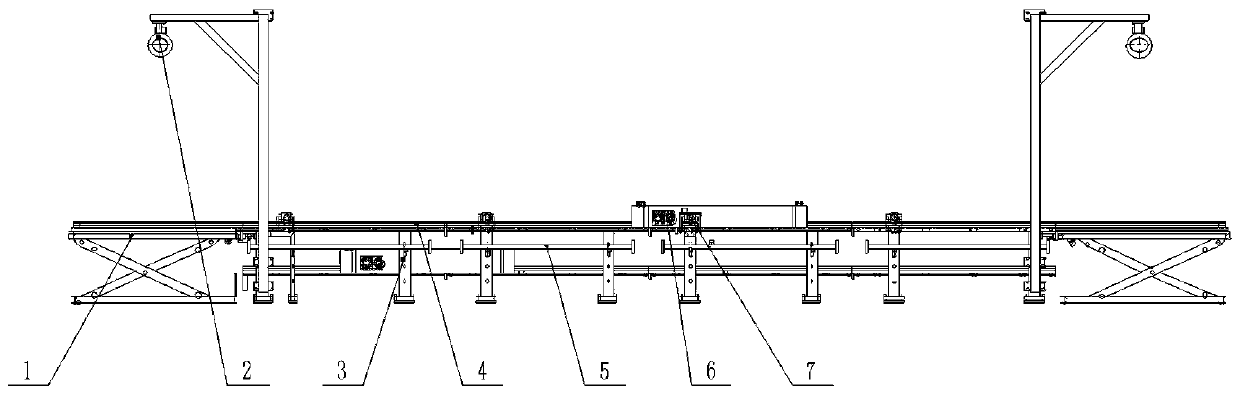

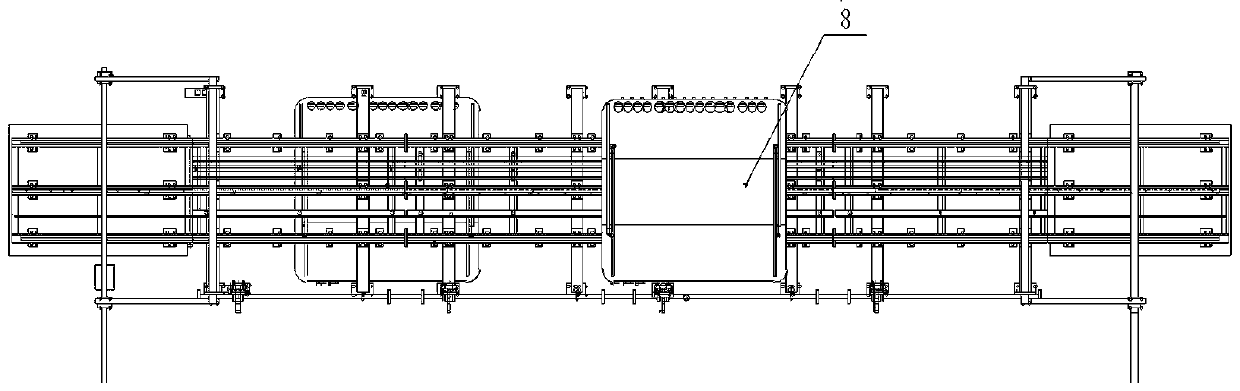

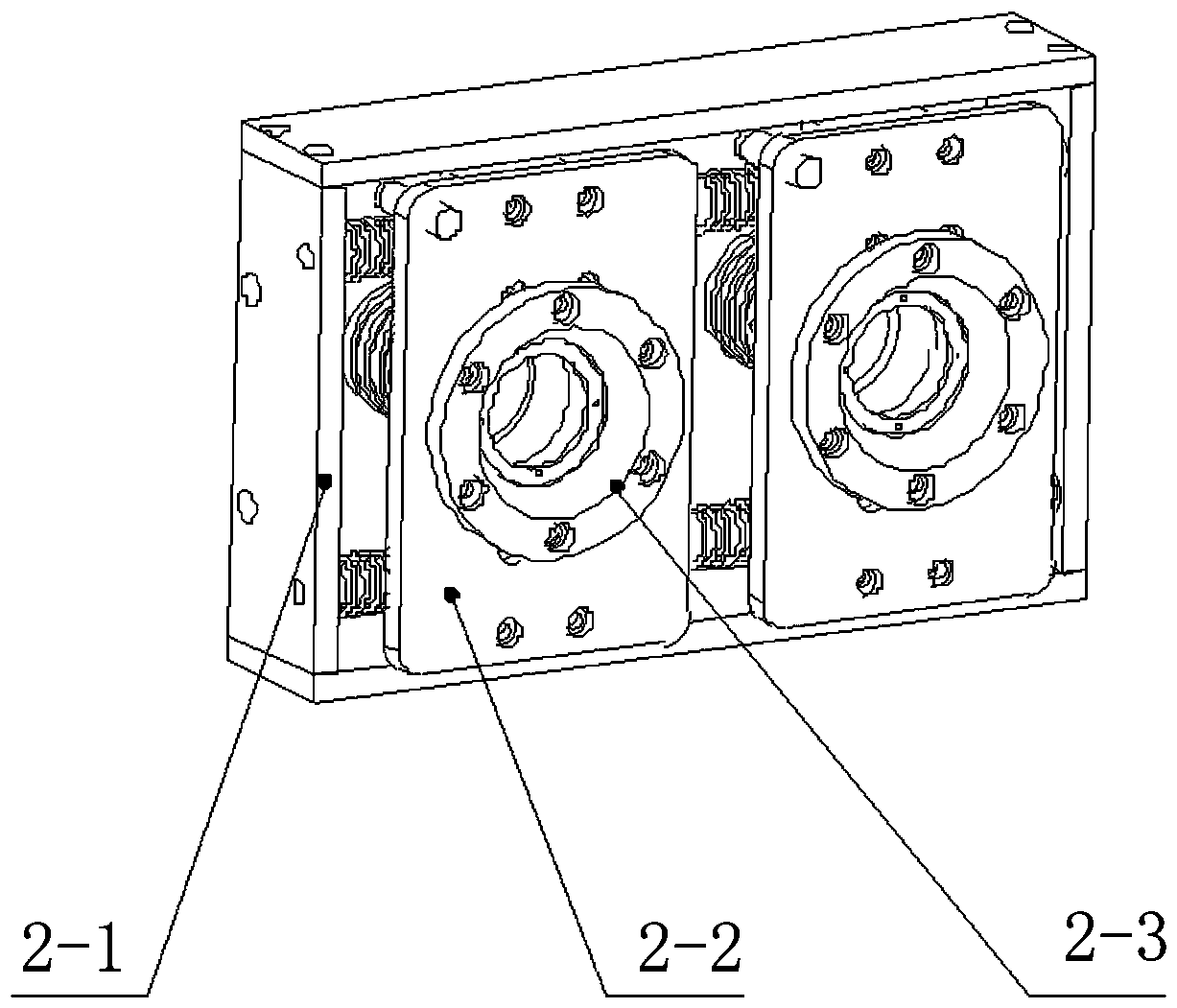

[0031] The technical idea of the present invention is to set up double-layer guide rails and lifting platforms to make the trolley work in a cycle, and the air cushion bed is placed on the mobile trolley, and the air cushion bed is automatically charged and deflated by walking to different stations to detect the airtightness of the air cushion bed. The position is the suction station. At the same time, it includes a main air circuit separation and closing device to realize the combination and separation of the mobile car carrying the air bed at different stations and the main air circuit.

[0032] Such as figure 1 and figure 2 As shown, the air bed detection assembly line and its gas path separation and closing device include upper and lower two-layer track frames 4; lifting platforms 1 are arranged at both ends of the track frame 4; main gas path gas distribution devices 7 are arranged on the track frame 4; Said main gas path distribution device 7 is connected with the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com