Coating trolley lifting height adjusting device

A technology of lifting height and adjusting device, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of falling, difficulty, and changing diameter of steel pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

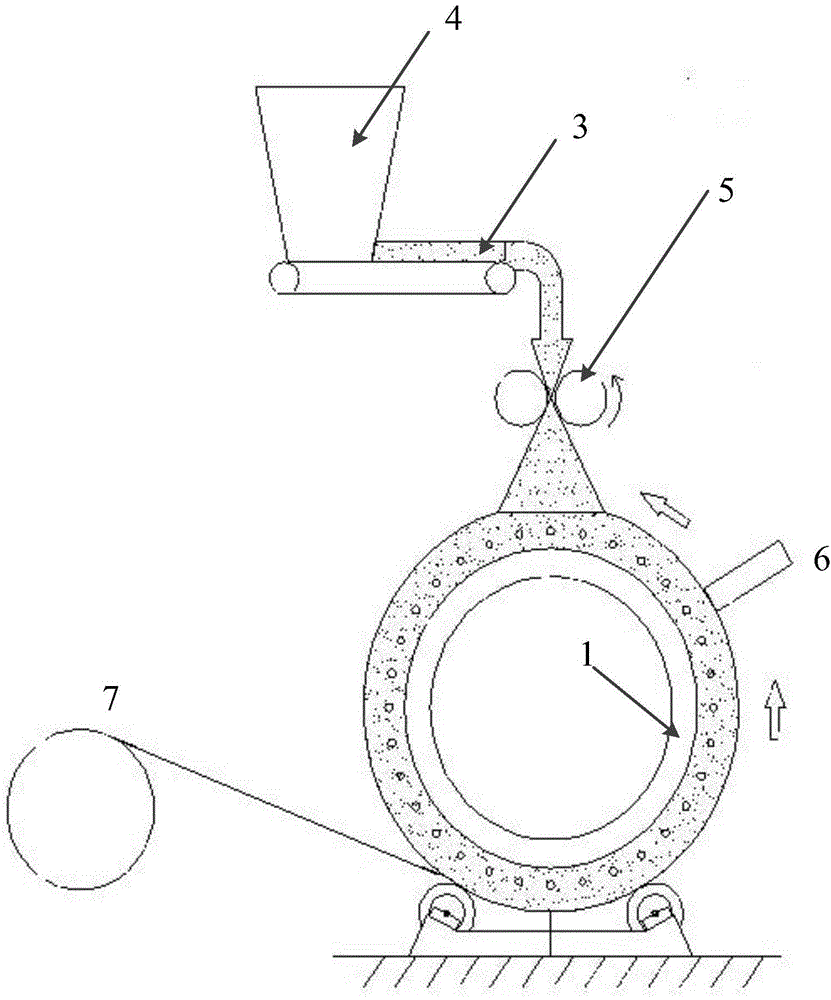

[0022] In order to make those skilled in the technical field of the present invention understand the present invention more clearly, the technical solutions of the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0023] Such as Figure 4-5 As shown, the coating trolley lifting height adjustment device disclosed in the present invention includes: trolley 11, hydraulic cylinder 12, base guide groove 13, screw wheel platform 14, screw wheel 15, screw mandrel 16, clutch 17, hand wheel 18.

[0024] Wherein, a hydraulic cylinder 12 is installed on the trolley 11 to realize the lifting of the height of the trolley 11 .

[0025] A first platform 19 is supported on the hydraulic cylinder 12 .

[0026] A base guide groove 13 is installed on the first table surface 19, and two screw mandrel wheels 14 are installed in the base guide groove 13, and a screw mandrel wheel 15 is respectively installed on the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com