Shore bridge trolley lifting appliance fine adjustment shifting system

A shifting system and trolley technology, applied in the direction of load block, load hanging components, transportation and packaging, etc., can solve the problems of prolonging container loading and unloading time, reducing loading and unloading efficiency, increasing energy consumption of quay cranes, etc., and achieving quick and easy fine-tuning process , Improve loading and unloading efficiency, reduce energy consumption and mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

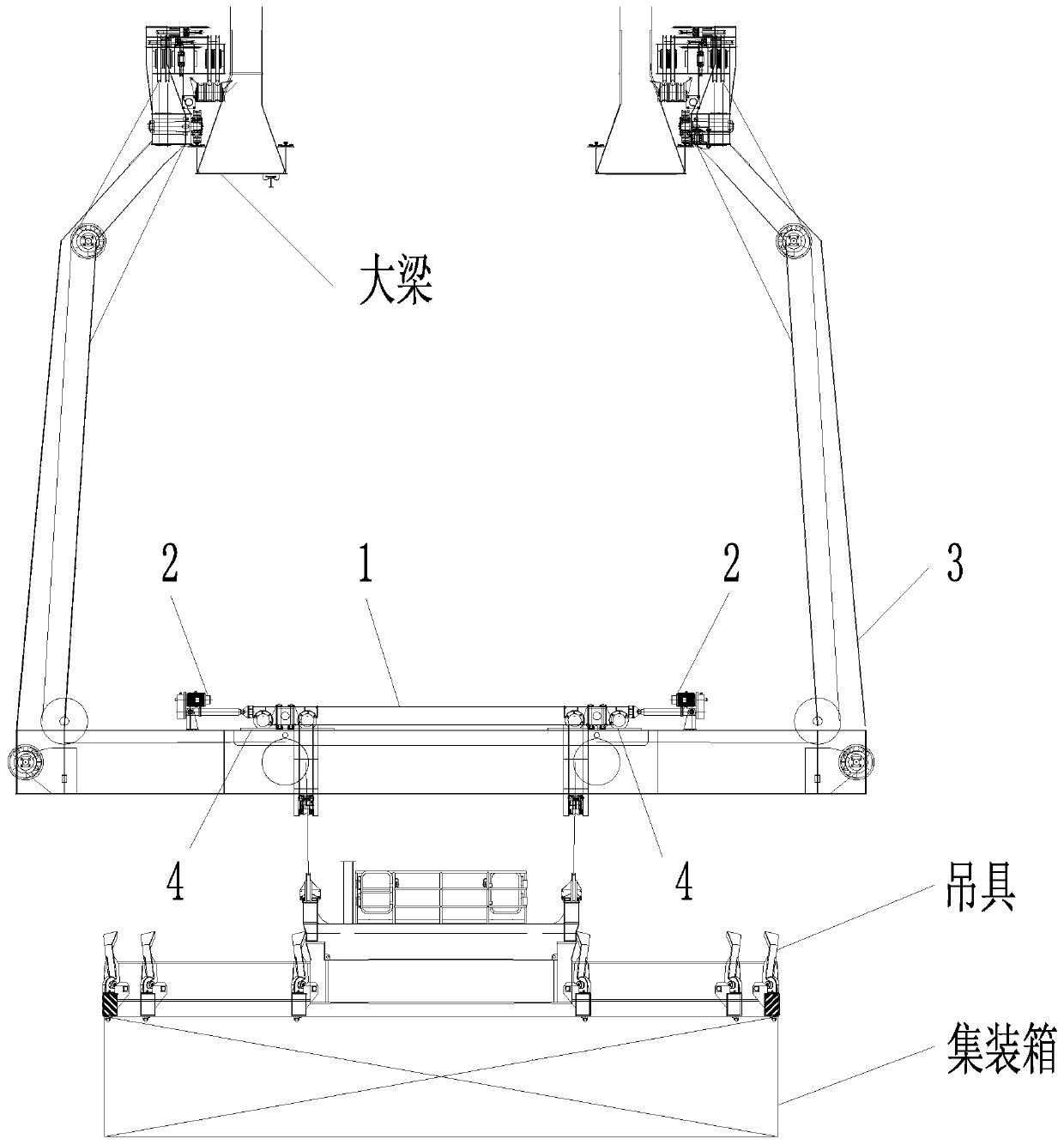

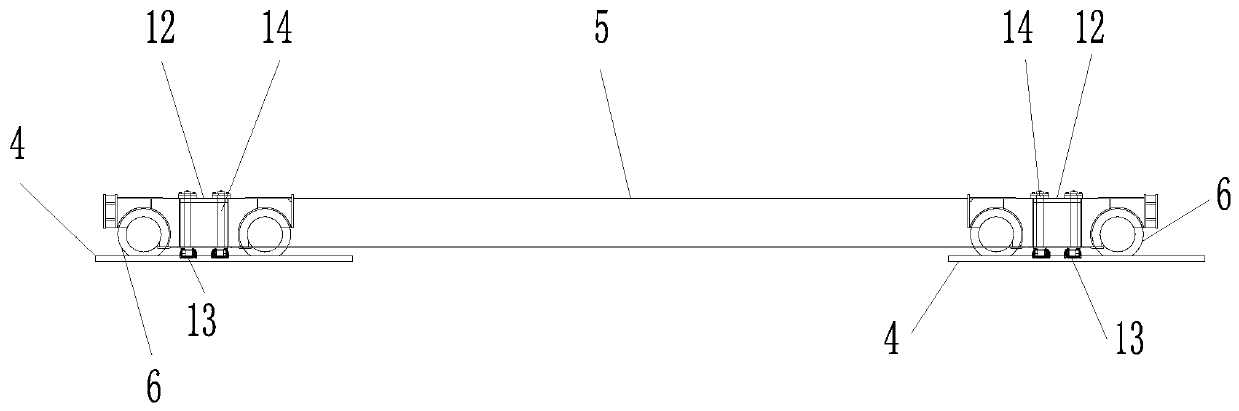

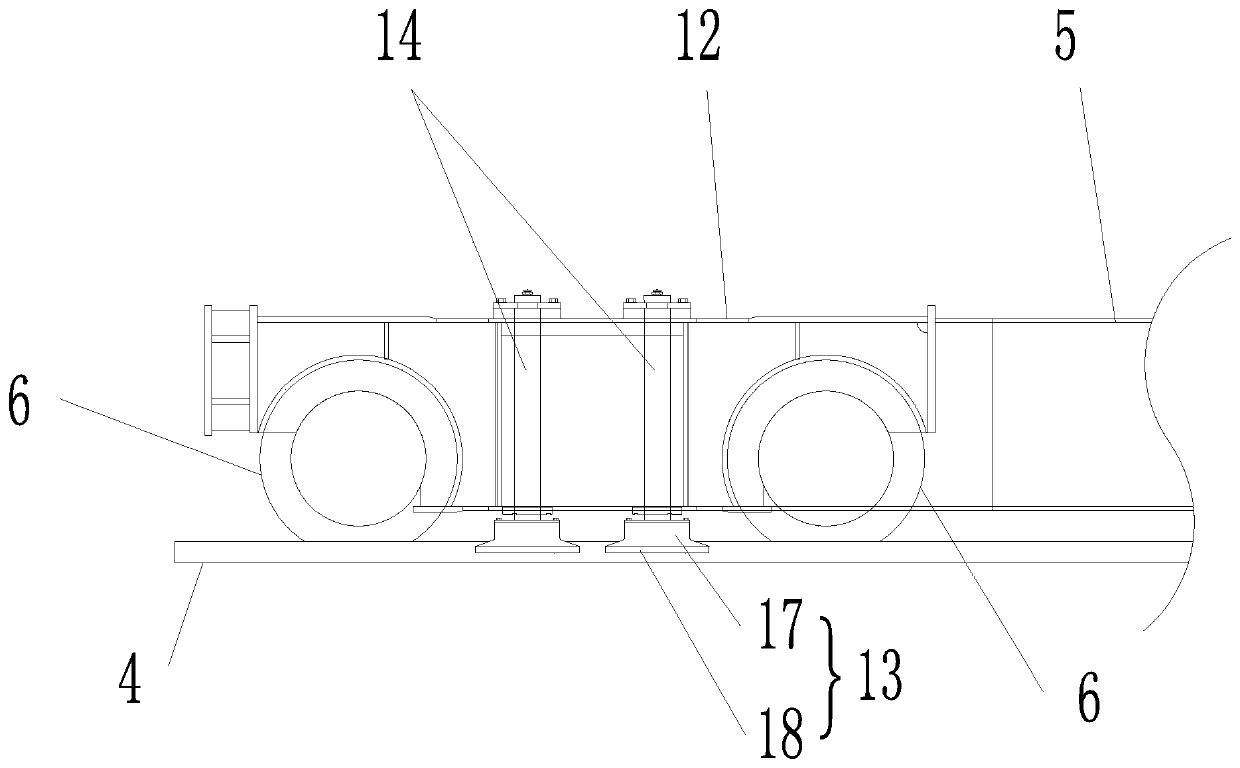

[0021] Embodiment 1 of the present invention: as figure 1 As shown, the fine-tuning and shifting system of the quay crane trolley spreader includes a mobile trolley 1 connected to the spreader, a trolley moving device 2 and a mobile trolley track 4 laid on the bottom beam of the quay crane trolley 3 . like Image 6 As shown, the trolley frame 5 is a polygonal frame, such as figure 2 or Figure 4 As shown, the mobile trolley 1 includes a trolley frame 5 and a wheel set 6, the wheel set 6 is arranged below the trolley frame 5, and is fixedly connected with the trolley frame 5, and the wheel set 6 is slidably arranged on the mobile trolley track 4, and the wheel set 6 Drive the dolly frame 5 to slide on the mobile dolly track 4.

[0022] like Figure 7 As shown, the trolley moving device 2 includes a motor 7, a reducer 8, an electric push rod 9, a support 10 and a connecting seat 11, the motor 7 is connected to the reducer 8 shafts, and the reducer 8 is connected to the elec...

Embodiment 2

[0023] Embodiment 2: In the fine-tuning and shifting system of the trolley spreader of the quay crane, such as Image 6 As shown, the trolley frame 5 is a rectangular frame, and the two ends of the two long sides of the trolley frame 5 are respectively fixed with a connector 12, and the trolley moving device 2 includes four, which are symmetrically arranged on the trolley frame 5, on both sides, the four connectors 12 are respectively connected to the four trolley mobile devices 2, and the trolley mobile device 2 is connected to the connectors 12 through the connection seat 11, such as figure 2 or Figure 4 As shown, the wheel set 6 includes four sets of wheels, specifically, each set includes two wheels, and each set of wheels is arranged under four connecting heads 12 .

Embodiment 3

[0024] Embodiment 3: as Figure 7 As shown, in the fine-tuning and shifting system of the quay crane trolley spreader, the connecting seat 11 and the connecting head 12 are bolted, and the mobile trolley 1 is fixed in the middle by the trolley mobile devices 2 on both sides, and the electric push rod in the trolley mobile device 2 9 push and pull, which can realize the sliding of the mobile trolley 1 on the mobile trolley track 4. At the same time, the trolley moving device 2 can also limit the position of the mobile trolley 1, and lock the mobile trolley 1 when translation is not required to prevent the mobile trolley 1 from moving along the track 4. The moving trolley track 4 moves, and drives the lower spreader to shake, causing a potential safety hazard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com