A lifting mechanism of a large tonnage trackless forging manipulator

A forging manipulator, large-tonnage technology, used in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc. The clamp is difficult to lift horizontally, etc., to achieve the effect of high practical value, strong movement reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

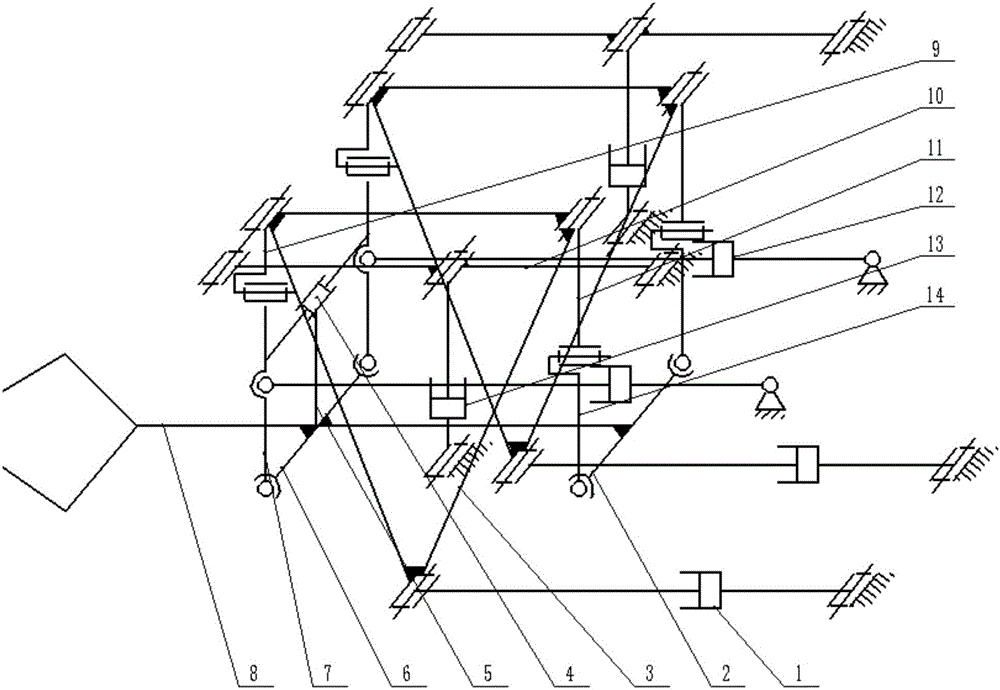

[0015] in figure 1 In the schematic diagram of the lifting mechanism of the large-tonnage trackless forging manipulator shown, the front part of the clamp spindle 8 is fixedly connected to the front cross bar 6, and the rear end of the clamp main shaft is fixedly connected to the rear cross bar 2. The ends are respectively connected to one end of a pair of front connecting rods 7 through a ball hinge, and the other ends of the pair of front connecting rods are respectively hinged to one end of a pair of front suspension rods 9 through a rotating hinge, and both ends of the rear cross rod pass through The spherical hinge is connected to one end of a pair of rear connecting rods 14. The other ends of the pair of rear connecting rods are respectively hinged with one end of a pair of rear suspension rods 11 through a rotating hinge. The left and right horizontal buffer cylinders 4 are fixedly connected by the buffer cylinder connecting rod 5. At the position where the front of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com