Roller set for universal mill

A universal rolling mill and roll group technology, applied in the direction of rolls, metal rolling stands, metal rolling mill stands, etc., can solve the problem of complex structure of spring slider mechanism, no reliable interlock, limited moving in or moving out speed, etc. problems, to achieve the effect of promoting the use, low manufacturing cost, and reducing the difficulty of roll changing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

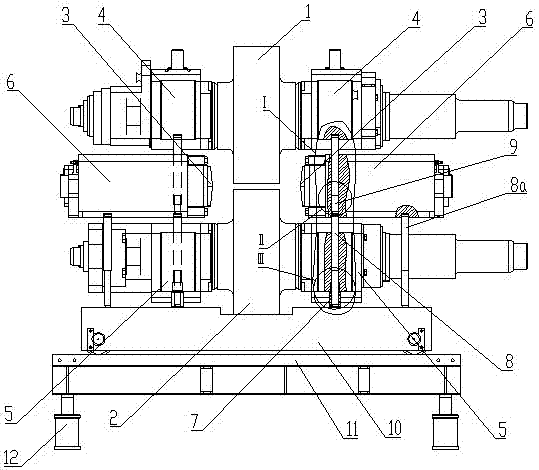

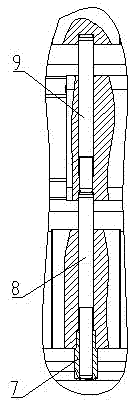

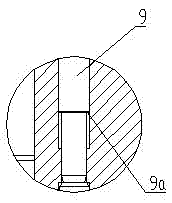

[0040] Such as Figure 1 to Figure 6 As shown, the roll set used in the universal rolling mill in this embodiment includes an upper horizontal roll 1, a lower horizontal roll 2 and a pair of vertical rolls 3 that jointly enclose a rolling passage, and the two ends of the upper horizontal roll 1 are connected to the two sides respectively. The two ends of the lower horizontal roll 2 are rotatably matched with the two lower chocks 5 respectively, and the pair of vertical rolls 3 are respectively rotatably matched with the two vertical roll chocks 6. The roll group can be moved into the universal rolling mill. The roll change operation is carried out in and out of the frame archway. The roll group also includes a quick roll change device. The fast roll change device includes four lower horizontal roll positioning rods 7 distributed on the left and right sides of the rolling channel. Four vertical roll positioning rods 8, four upper horizontal roll positioning rods 9 and a liftabl...

Embodiment 2

[0050] Such as Figure 7 and Figure 8 As shown, the roll set used in the universal rolling mill of this embodiment is compared with that of Example 1, mainly because of the difference between the roll set of the two-roll structure and the roll set of the four-roll structure, and the roll set includes the upper horizontal roll 1 and the lower horizontal roll 2. The two ends of the upper horizontal roller 1 are rotatably matched with the two upper bearing housings 4 respectively, and the two ends of the lower horizontal roller 2 are respectively rotatably matched with the two lower bearing housings 5. The roll set also includes a quick roll changing device, The quick roll changing device includes four lower horizontal roll positioning rods 7 distributed on the left and right sides of the roll gap, four upper horizontal roll positioning rods 9 and a liftable roll changing trolley 10, each side of the roll gap lower horizontal roll positioning rods and two positioning rods for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com