Aluminum bar saw cutting unit

A sawing and unit technology, which is applied in the direction of metal sawing equipment, sawing machine devices, metal processing machinery parts, etc., can solve the problems of insufficient sawing efficiency and single function, so as to reduce troubleshooting time, improve production efficiency, and improve The effect of sawing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the invention.

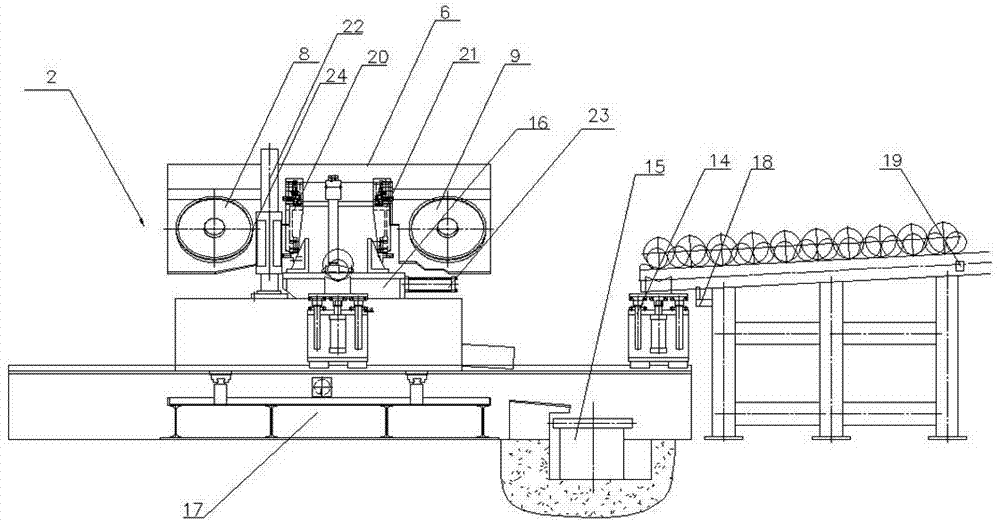

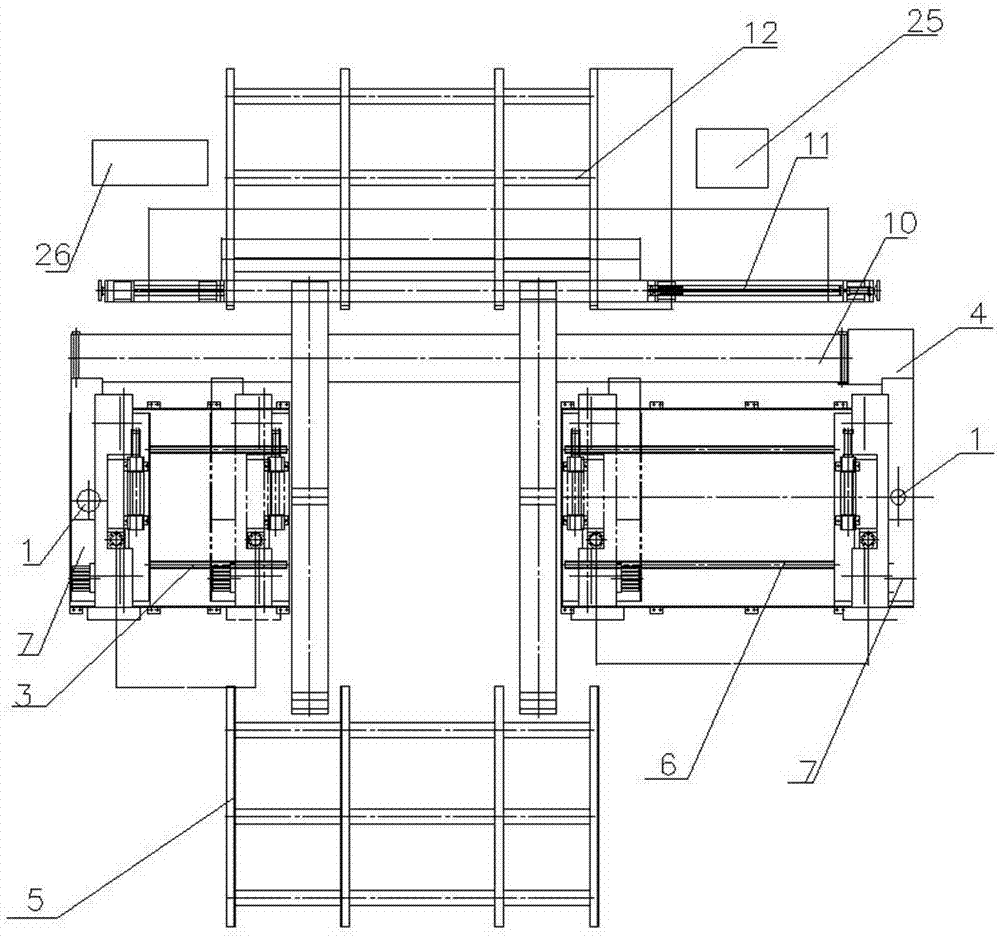

[0025] Such as figure 1 As shown, an aluminum bar sawing unit includes a saw machine host 2 connected to each other, a feeding mechanism, a material discharge mechanism, a waste collection device 4, a hydraulic system 25, and an electrical control system 26. The saw machine host 2 includes two mutually symmetrical Sawing machine 7, a clamping device and a sizing device arranged on one side of the sawing machine 7, the sawing machine 7 includes a base 17, a saw frame 6 arranged on the base 17, a transmission system, a saw band tensioning mechanism 13, and a saw frame feeding system 3 1. Saw band left guide arm 20, saw band strip right guide arm 21, transmission system includes driving saw wheel 8, driven saw wheel 9, transmission belt 24 and drive motor 1; Feeding mechanism includes feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com