Sorting robot of laser cutting machine and part sorting method of sorting robot

A laser cutting machine and robot technology, applied in sorting, laser welding equipment, manipulators, etc., can solve the problems of inability to achieve safe adsorption, inability to automatically distribute suction cup adsorption, and inability to fully automate, to improve work efficiency and speed. The effect of effective automatic sorting of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

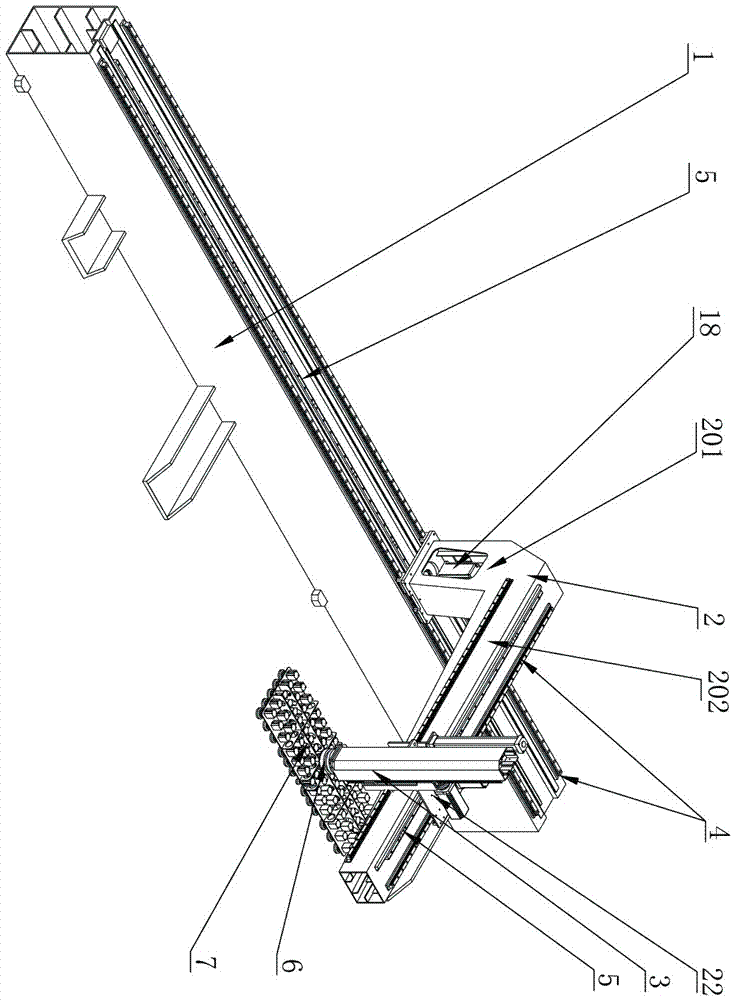

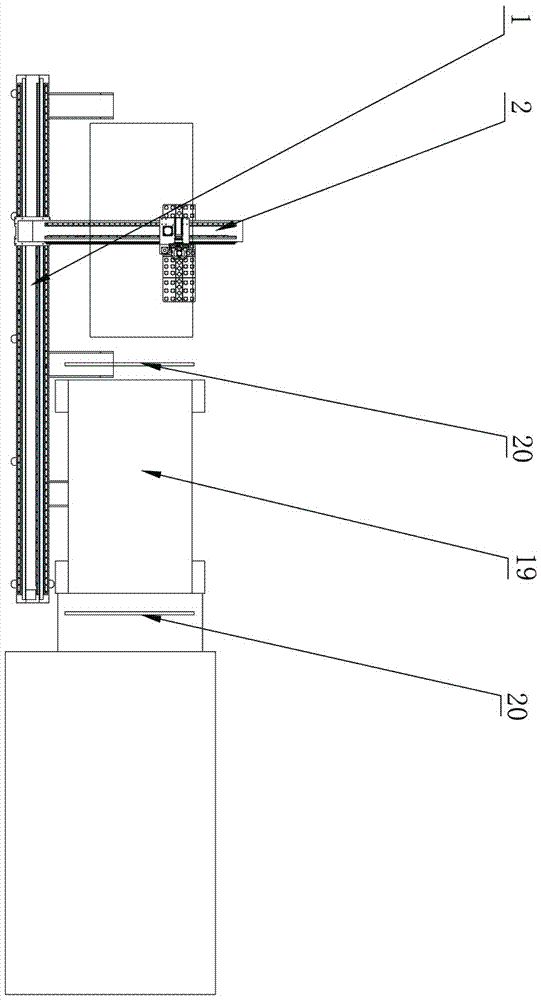

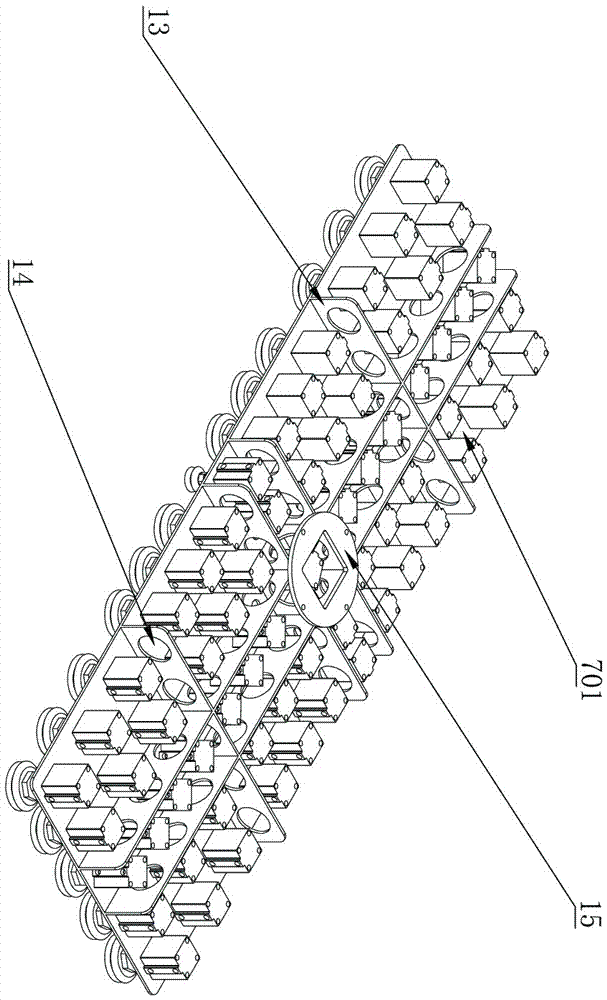

[0031] Such as Figure 1-12As shown, the purpose of the present invention is achieved in this way: a laser cutting machine sorting robot, including an X-axis support seat 1 arranged on the ground, a Y-axis support seat 2 arranged with the X-axis support seat 1, and a Y-axis support seat 2 arranged with the Y-axis support seat. The Z-axis support seat 3 provided on the support seat 2, the X-axis support seat 1, the Y-axis support seat 2 and the Z-axis support seat 3 are respectively provided with a track 4 and a rack 5, and the Y-axis support seat 2 includes a Y-axis longitudinal support seat 201 and the Y-axis transverse support seat 202, the Y-axis longitudinal support seat 201 is set through a sliding mechanism in conjunction with the track 4 on the X-axis support seat 1, and the Z-axis support seat 3 and the Y-axis transverse support seat 202 are connected by a connecting piece 22; Z The shaft supporting seat 3 is equipped with a C-axis supporting seat 6, and the C-axis sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com