Arranging device for installing pipetting tips into tip box

A sorting device and gun tip box technology, applied in the direction of packaging, can solve the problems of time-consuming and labor-intensive, and achieve the effect of safe operation, simple structure and high arrangement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

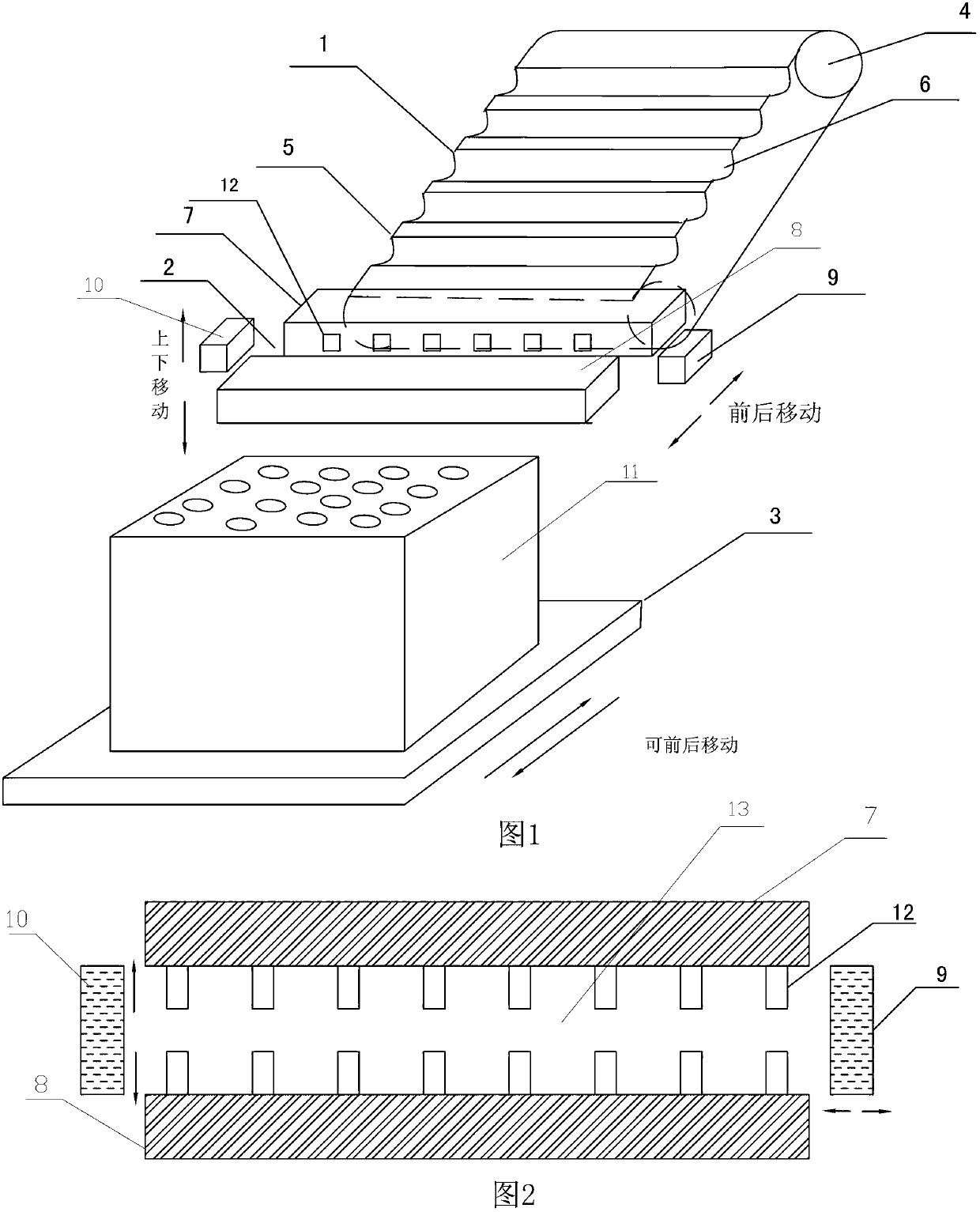

[0022] Embodiment 1: The arrangement device for installing pipette tips into the tip box includes a conveying device 1 , a tip placement device 2 , a vertical lifting mechanism and a storage table 3 for placing the tip box 11 . Transmission device 1 comprises conveyor belt 5 and transmission wheel 4, and transmission belt 5 is driven by transmission wheel 4, and transmission belt 5 is provided with the semicircle groove 6 that can hold the liquid pipette tip, and the extending direction of semicircle groove 6 and clip The extending directions of the grooves 13 are parallel. The gun tip placement device 2 is located above the gun tip box 11 and can move up and down under the action of the vertical lifting mechanism. The gun tip placement device 2 includes a clamping assembly, a splitting mechanism (not shown in the figure) and a push plate assembly , the clamping assembly includes a clamping groove 13 and is controlled by the opening and closing mechanism. The clamping assembl...

Embodiment 2

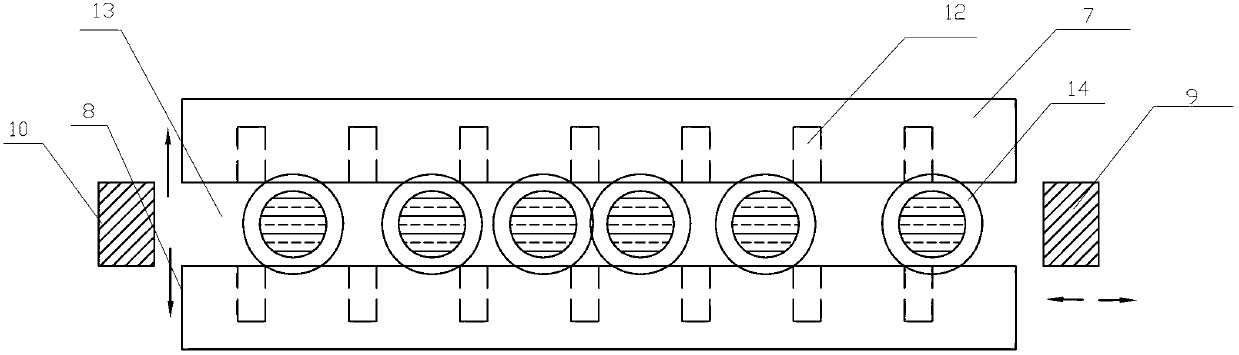

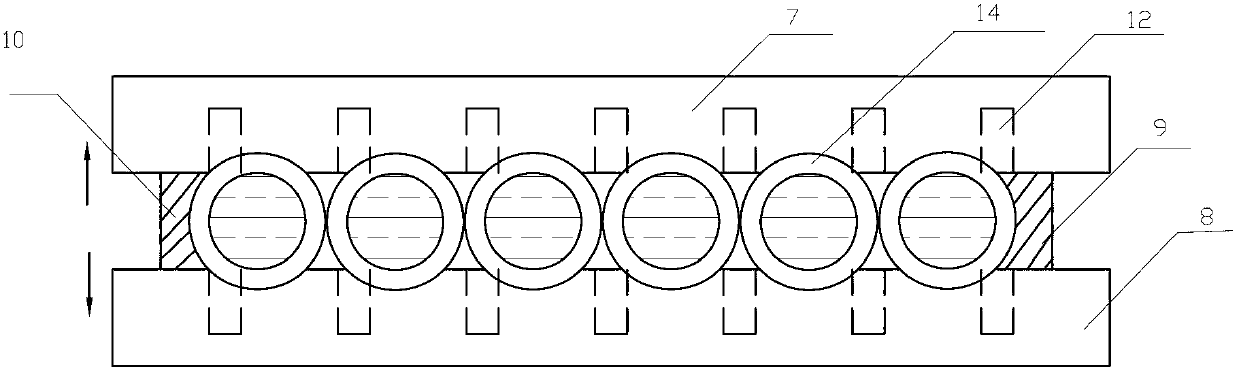

[0023] Embodiment 2: Another sorting scheme implementation of the sorting device in which the pipette tip is installed in the tip box is similar to that of Example 1, the difference is that there are retractable insertion rods 12 evenly spaced on the inner side of the clamping assembly. The pipette tips are closely arranged in front of the clamping groove 13, and the insertion rod 12 is retracted into the clamping assembly. The push plate assembly located at both ends of the clamping groove 13 closely arranges all the pipette tips 15 in the clamping groove 13 . At this time, the distance between the closely arranged pipette tips 15 does not correspond to the round hole spacing on the tip box 11 . After the insertion rod 12 is stretched out, it is located between the tube bodies of the two pipette tips 15, and evenly separates the closely arranged pipette tips 15 in the clamping groove 13. At this time, the pipette tips 15 are aligned with the pipette tips. The hole position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com