Patents

Literature

36results about How to "Avoid affecting the production schedule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

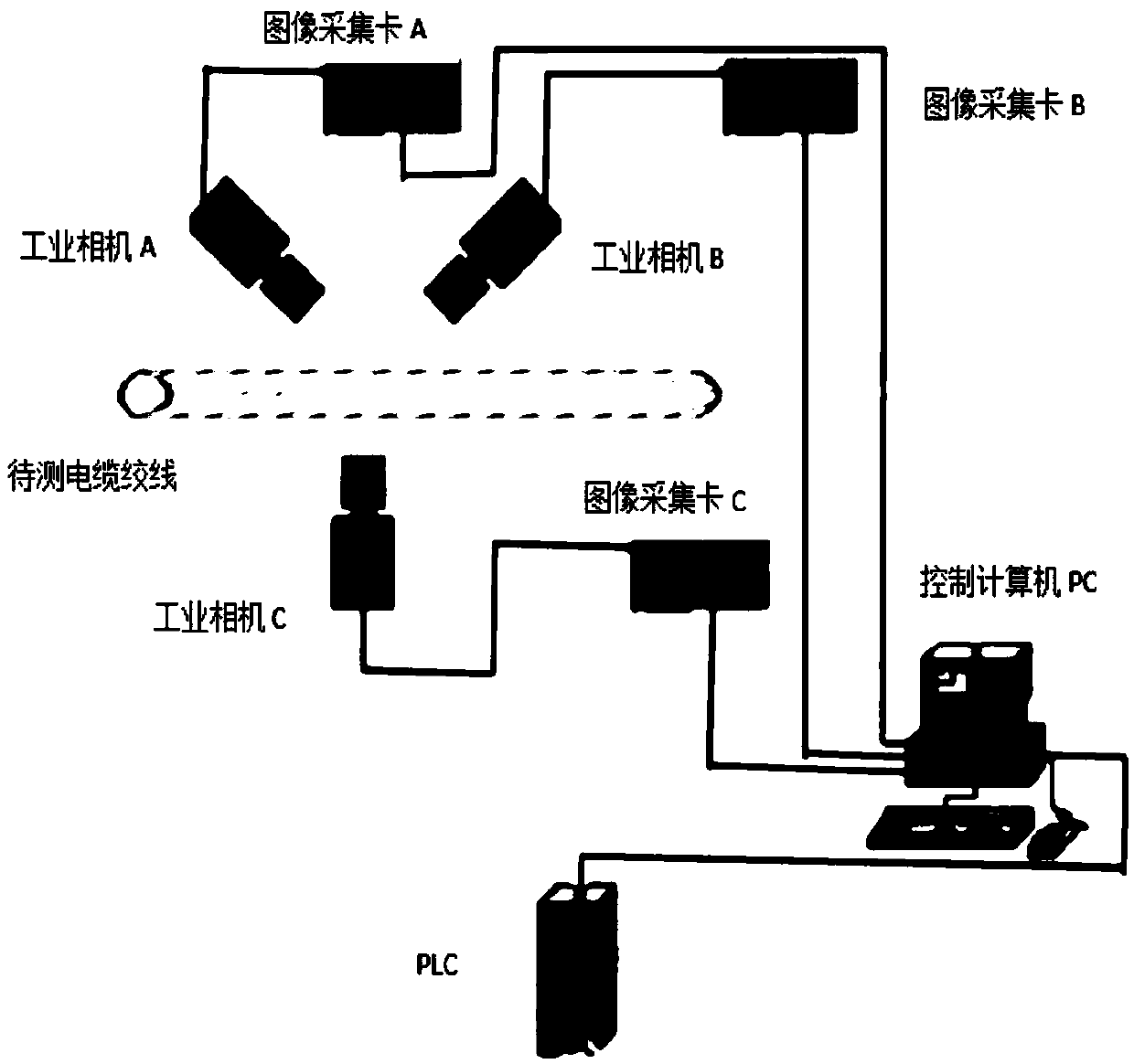

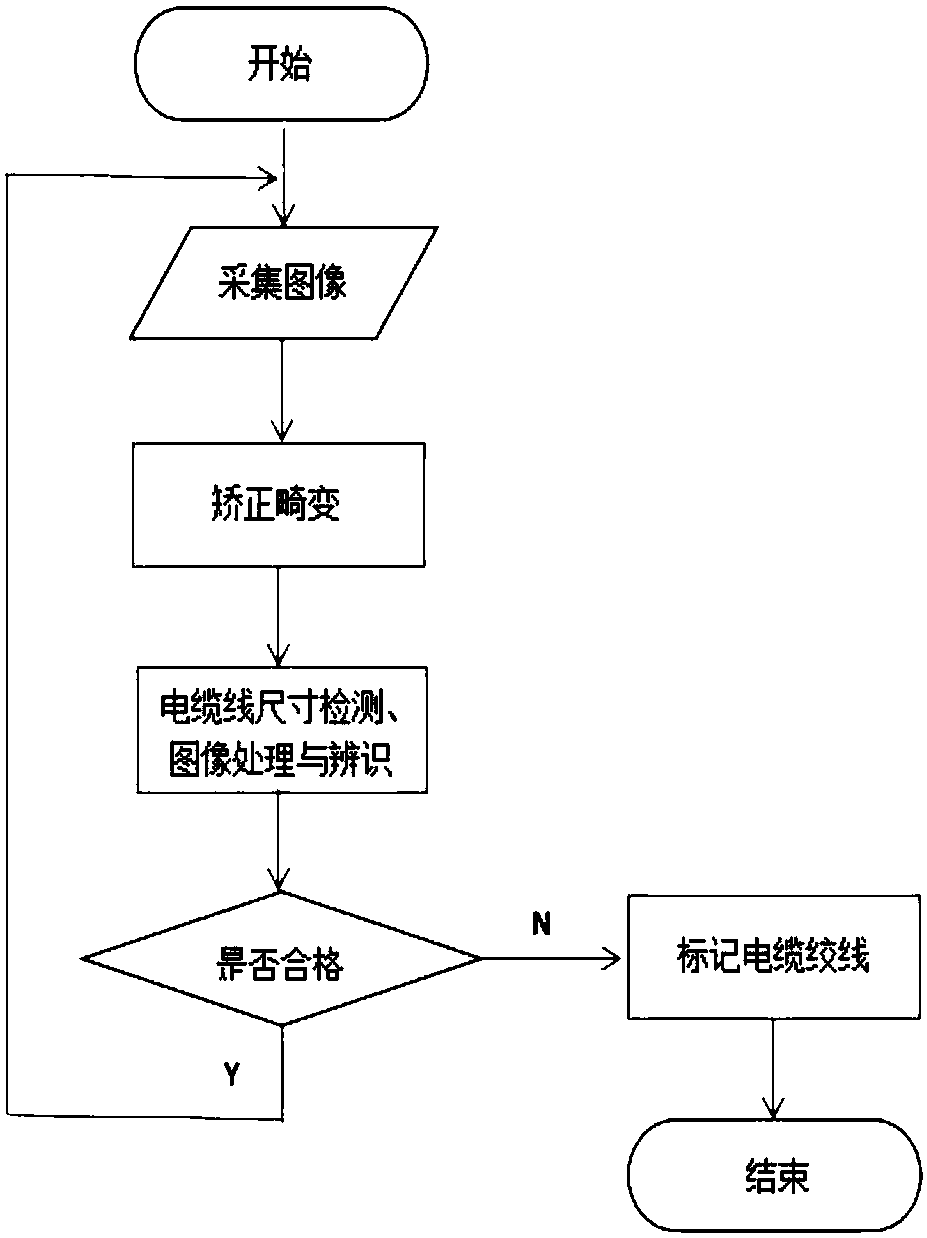

Twisted cable quality detection system based on machine vision and detection method for same

PendingCN107703148AAvoid scratchesImprove detection efficiencyOptically investigating flaws/contaminationUsing optical meansImaging processingMachine vision

The invention discloses a twisted cable quality detection system based on machine vision and a detection method for same. The system includes an image collection module, an image processing and identifying module, and a marking and positioning module. The signal receiving end of the image processing and identifying module is connected to the image collection module while a control end is connectedto the marking and positioning module. The image processing and identifying module is used for processing, identifying and size-detecting the collected image; the image collection module is used forcollecting an image of the twisted cable on line; the marking and positioning module is used for positioning and marking an unqualified twisted cable. The system can achieve on-line quality detectionand defect marking of the twisted cable, can greatly improve detection efficiency and avoid human influence, greatly reduces error, is more accurate in detection and avoids influence on production schedule due to detection. The detection is free of contact between hands and equipment and the twisted cable, so that damage on the twisted cable and injury on hands are avoided. The system is safer tooperate.

Owner:GUIZHOU UNIV

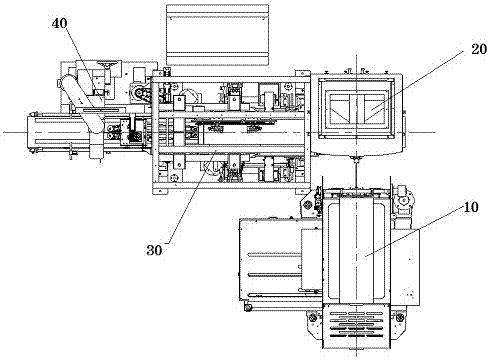

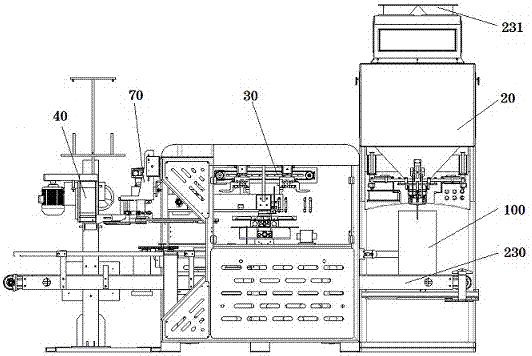

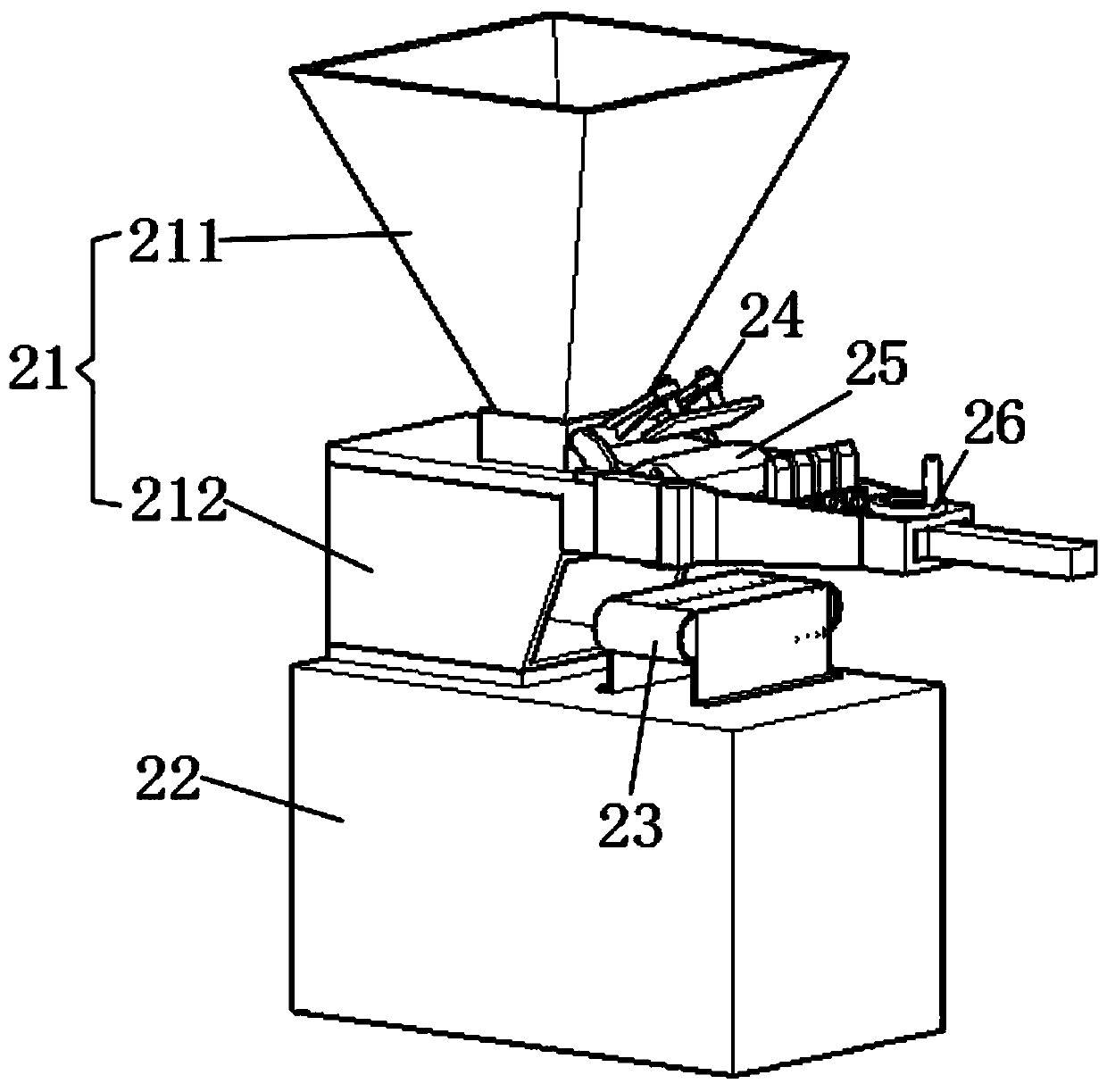

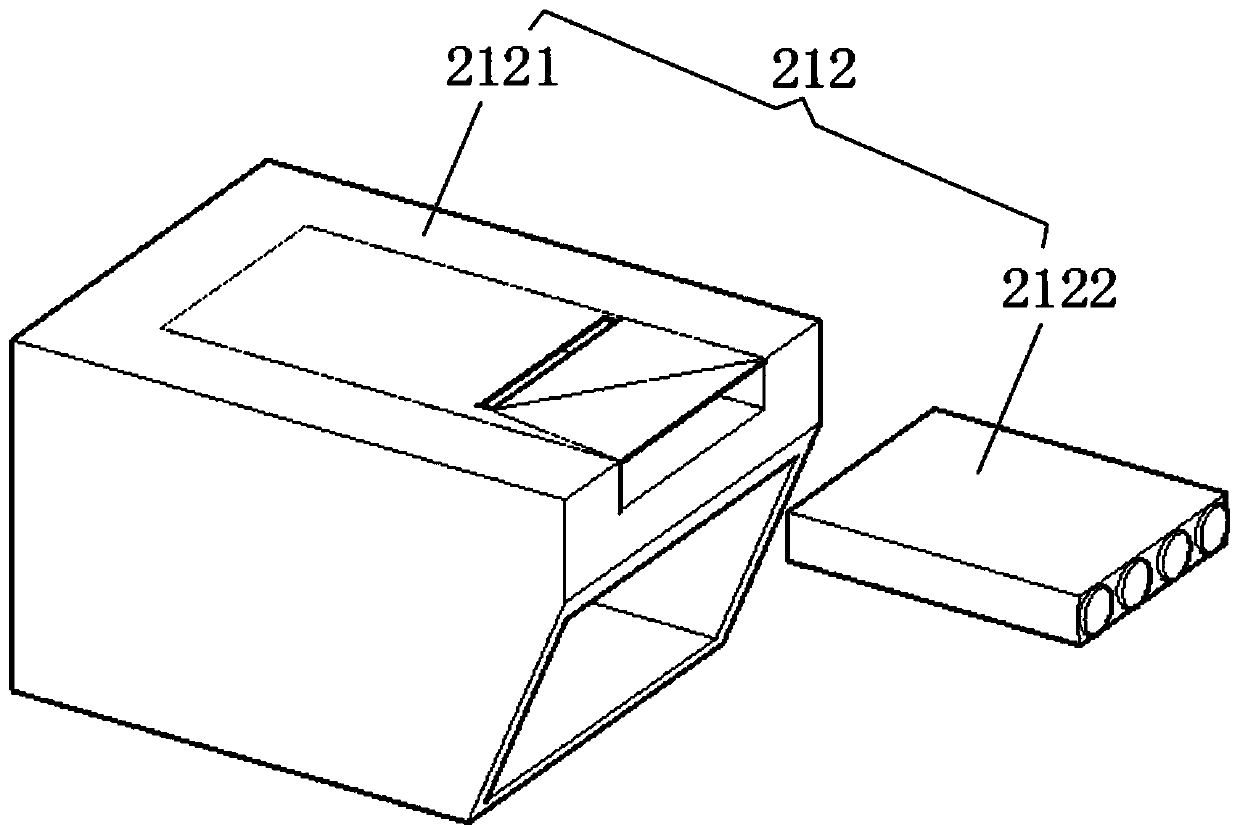

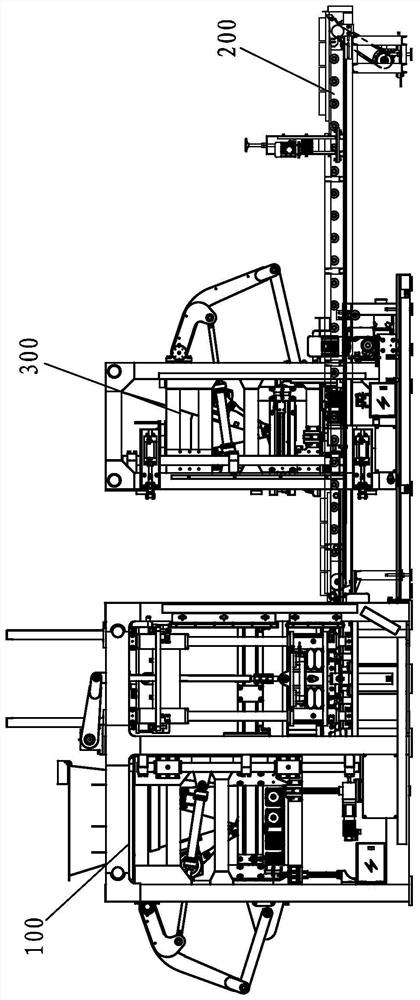

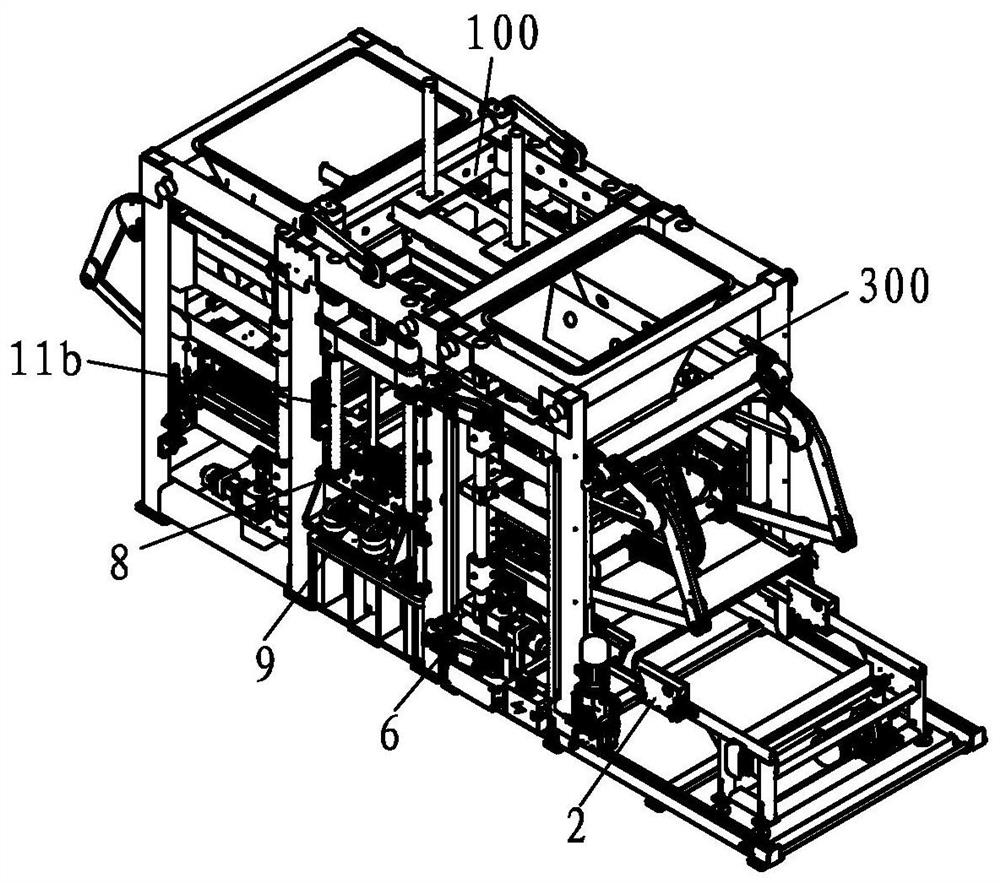

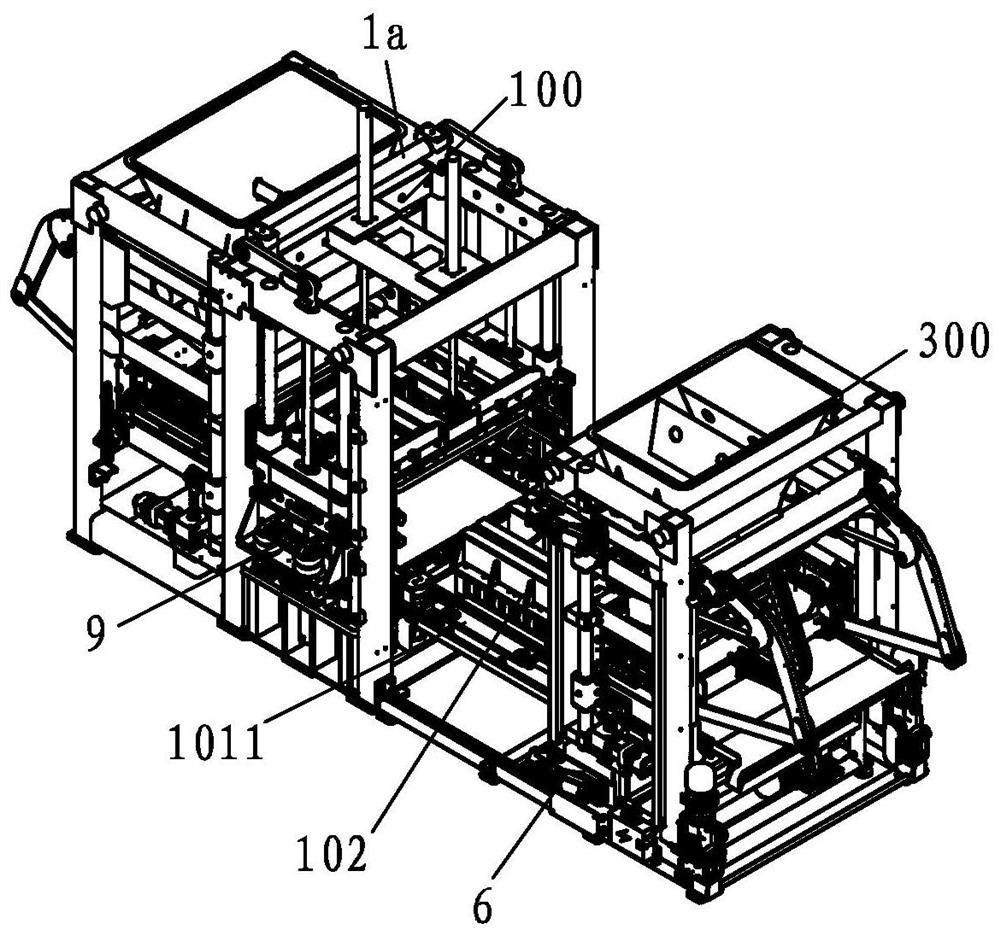

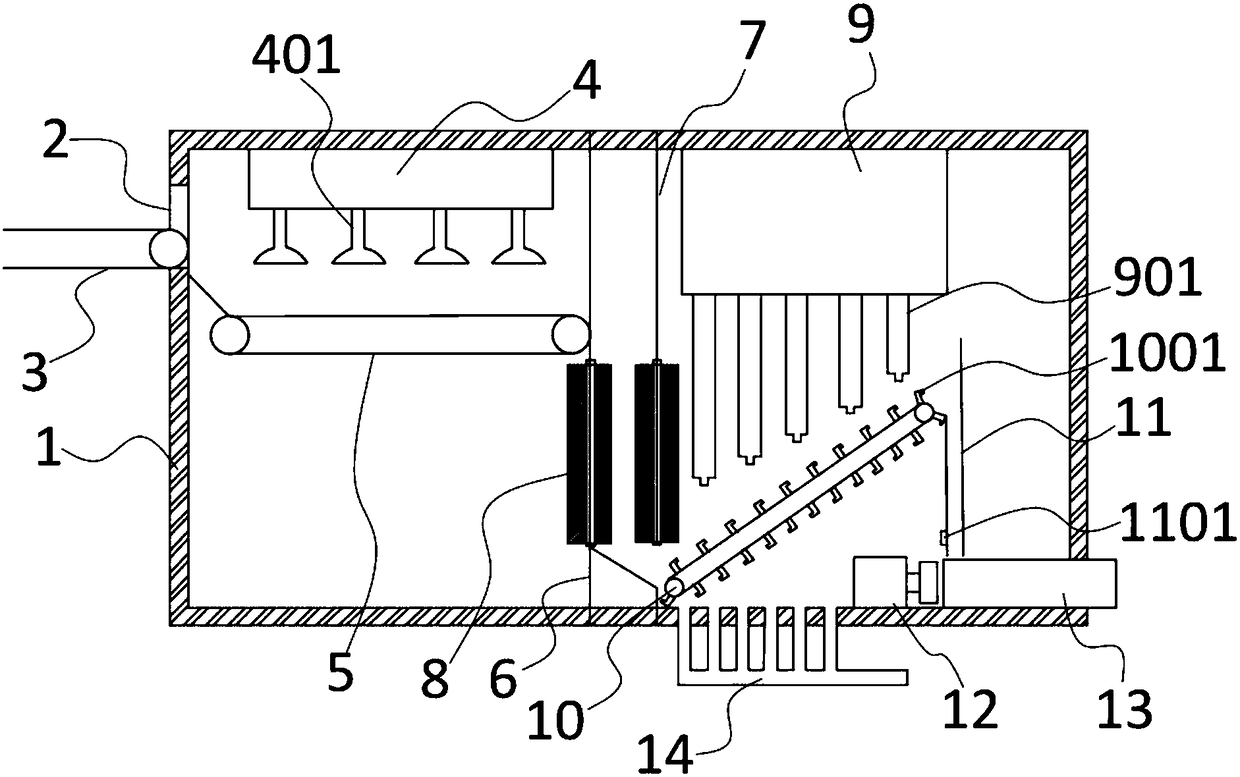

Modularized woven-bag full-automatic packaging unit and application method thereof

PendingCN107298206ASimple structureQuick assemblyWrapper twisting/gatheringSolid materialDevice failureSewing machine

The invention provides a modularized woven-bag full-automatic packaging unit and an application method thereof. The modularized woven-bag full-automatic packaging unit comprises an automatic bag feeding machine, an electronic quantitative scale, an automatic bag arranging machine and a bag sewing machine, wherein a fast positioning device is arranged between the automatic bag feeding machine and the electronic quantitative scale, a fast positioning device is arranged between the electronic quantitative scale and the automatic bag arranging machine, a fast positioning device is arranged between the automatic bag arranging machine and the bag sewing machine, the automatic bag feeding machine comprises a conveying belt, a sucker driven by a bag feeding lifting air cylinder to move up and down is arranged above the conveying belt, a swing arm driven by a swing arm drive device to rotate is arranged in the electronic quantitative scale, a bag clamping device facing the lower end of the swing arm and used for clamping a bag opening is arranged in the electronic quantitative scale, and the electronic quantitative scale comprises a bottom electronic induction scale platform and a feed inlet located above the electronic induction scale platform. The modularized woven-bag full-automatic packaging unit has the advantages that a set of full-automatic equipment is formed by modularized assembling, the work procedures are decomposed into modularized equipment which can be fast disassembled and assembled, the corresponding modules of inapplicable bags and equipment fault parts can be removed, splicing and combination can be achieved by using a fast positioning device, manual production can be used when necessary, and production schedule cannot be affected.

Owner:ZHANGZHOU JIALONG TECH INC

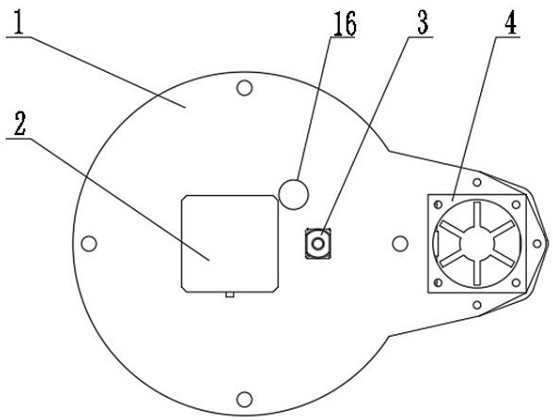

Self-cleaning protection system for industrial camera

InactiveCN112285987AWith rotation functionExtended service lifeFouling preventionCleaning using gasesMotor driveElectric machine

The invention discloses a self-cleaning protection system for an industrial camera. The self-cleaning protection system comprises a supporting plate, a dustproof cover, a rotary structure, a power structure and a dust removal structure. The rotary structure comprises an outer support and an inner support, the outer support is fixed, the inner support can rotate on the inner side of the outer support, and the dustproof cover is fixedly connected with the inner support; the power structure comprises a rotating motor, a small gear and an inner gear, the inner gear is fixedly connected with the inner support, and the rotating motor drives the dustproof cover to rotate through meshing of the small gear and the inner gear; the dust removal structure comprises a fan and an air bellow, and the fanfills air into the air bellow and then rapidly sprays the air out of the air outlet to the dustproof cover. According to the invention, through cooperation of the rotating structure, the power structure and the dust removal structure, the power structure and the rotating structure enable the dustproof cover to rotate slowly, the dust removal structure sprays high-speed airflow to remove dust on the dust cover, and therefore automatic cleaning of the dust cover is achieved; the influence of dust on the industrial camera can be effectively solved only by periodically starting the rotating motorand the fan, and manual cleaning is not needed.

Owner:HEBEI UNIV OF ENG

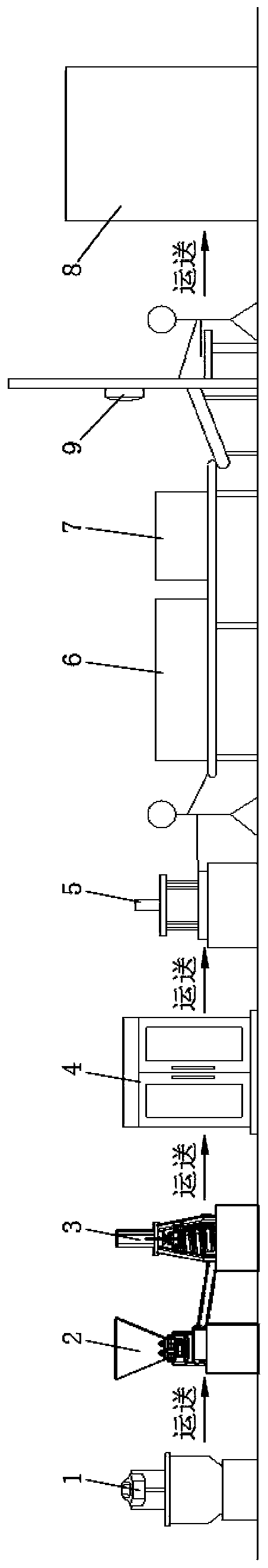

Tortilla production device and production process

InactiveCN110839668AEasy to removePrevent the defect rate from increasingBaking plantsSpecial goods bakingProcess engineeringBiology

The invention discloses a tortilla production device and production process. The tortilla production device comprises a dough batch, a dough distribution machine, a rounder, a fermentation chamber, atortilla pressing machine, a drying oven, a cooling box and a refrigerating chamber which are sequentially arranged according to a working procedure, a first conveying machine is fixedly mounted between the discharging end of the dough distribution machine and the feeding end of the rounder, the fermentation chamber ferments dough rounded by the rounder, the tortilla pressing machine presses the dough fermented by the fermentation chamber into tortillas, the drying oven bakes the flatted tortillas, a second conveying machine is fixedly mounted between an inlet of the cooling box and an outletof the drying oven, a third conveying machine is fixedly mounted at an outlet of the cooling box, the outlet end of the third conveying machine is communicated with a stacking window, the refrigerating chamber refrigerates the stacked and packaged tortillas, and a reflector is fixed one surface of the stacking window facing the third conveying machine and positioned above the third conveying machine. The tortilla production device is high in production efficiency, and faults are easily found.

Owner:宿州麦香缘食品有限公司

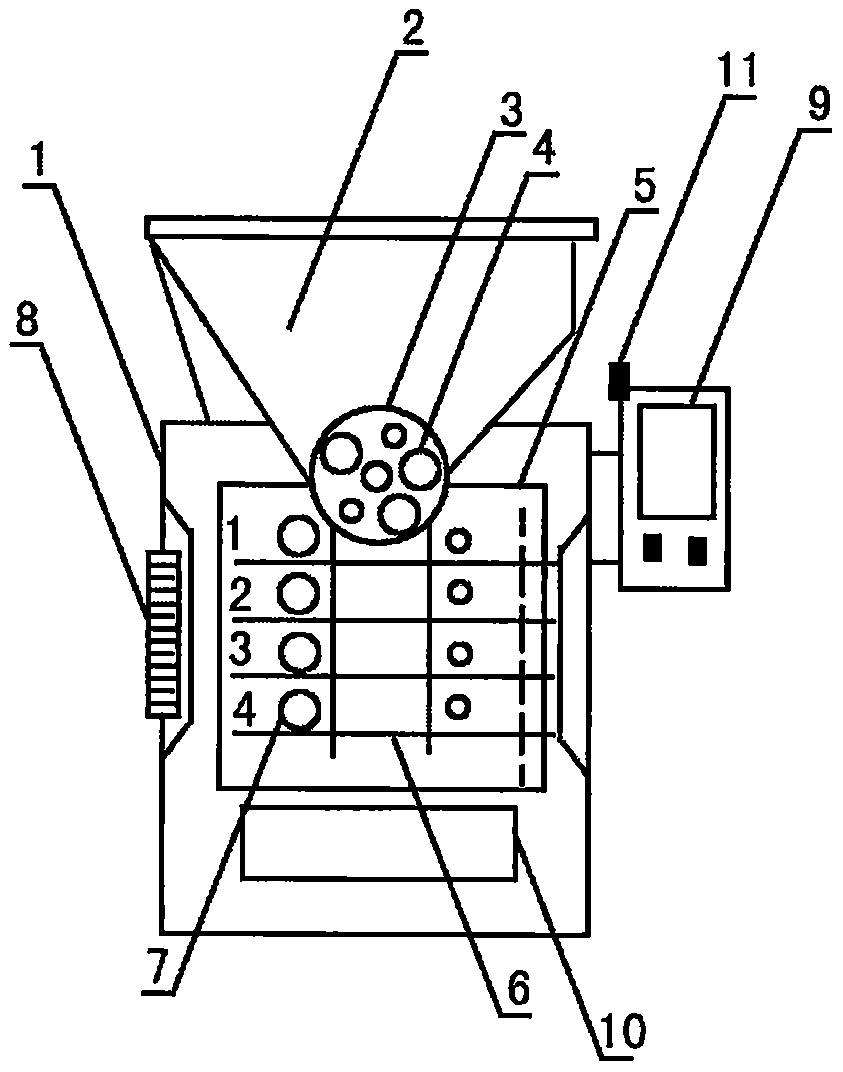

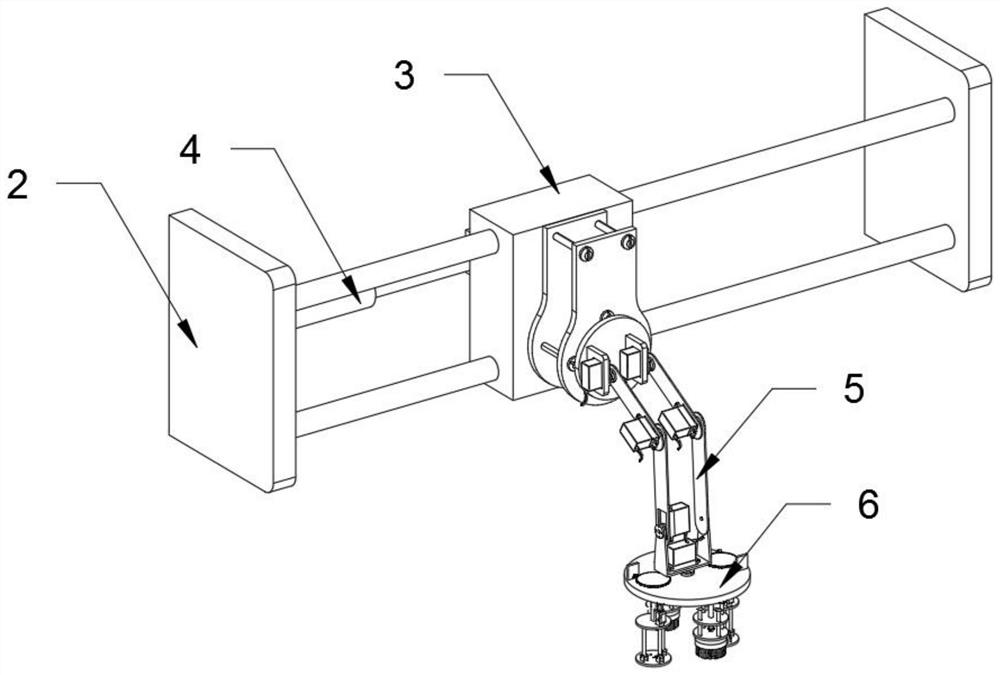

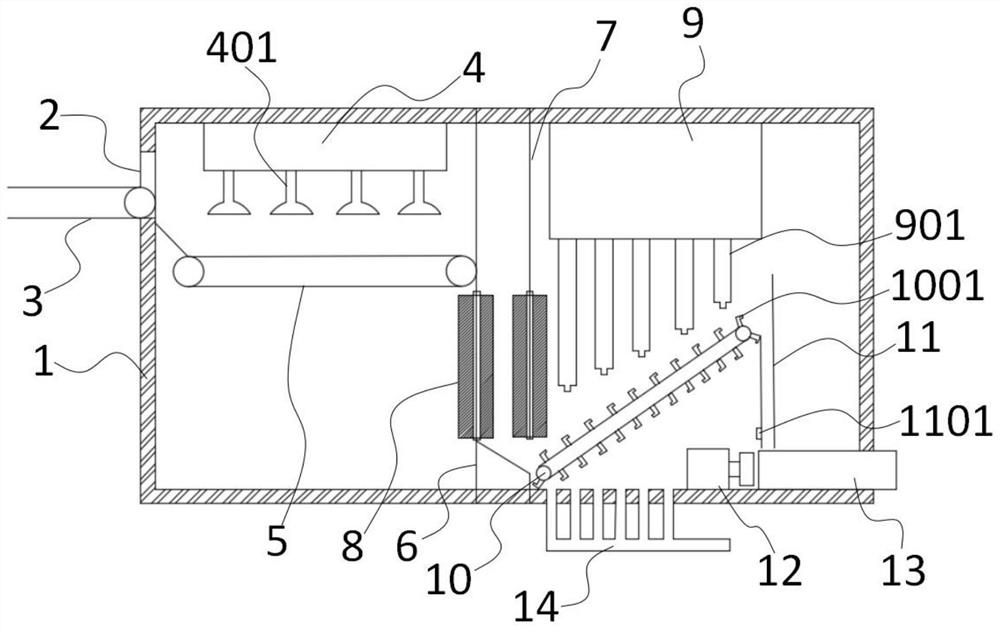

Multi-aperture ceramic microbead grinding and machining device

InactiveCN107838773AAvoid affecting the production scheduleAppearance structure function design is reasonableSpherical surface grinding machinesLapping machinesProduction scheduleStructure function

A multi-aperture ceramic microbead grinding and processing device, comprising a body (1), a feed port (2), a rotating sieving disc (3), a multi-aperture hole structure (4), and a grinding ball The components are located in the middle and lower part of the body (1), including a cylindrical storage device (5), a multi-stage grinding frame (6), and a ball groove (7). The individual differences of the microbeads sort the apertures of the sieve disc (3) from small to large, and then fall into the corresponding ball groove (7) for multi-stage grinding processing, and discharge them uniformly from the discharge port (10); set a prompting device (11 ), when the ceramic microbeads fall into an inappropriate pore structure, a corresponding prompt is issued; the design of the appearance, structure and function is reasonable, and it can effectively adapt to the microbead structure of various diameter ranges, avoiding the impact of multiple processing on its production progress. Stable, economical and practical.

Owner:XINCHANG COUNTY QIXING STREET WEICHANG HARDWARE MACHINERY PLANT

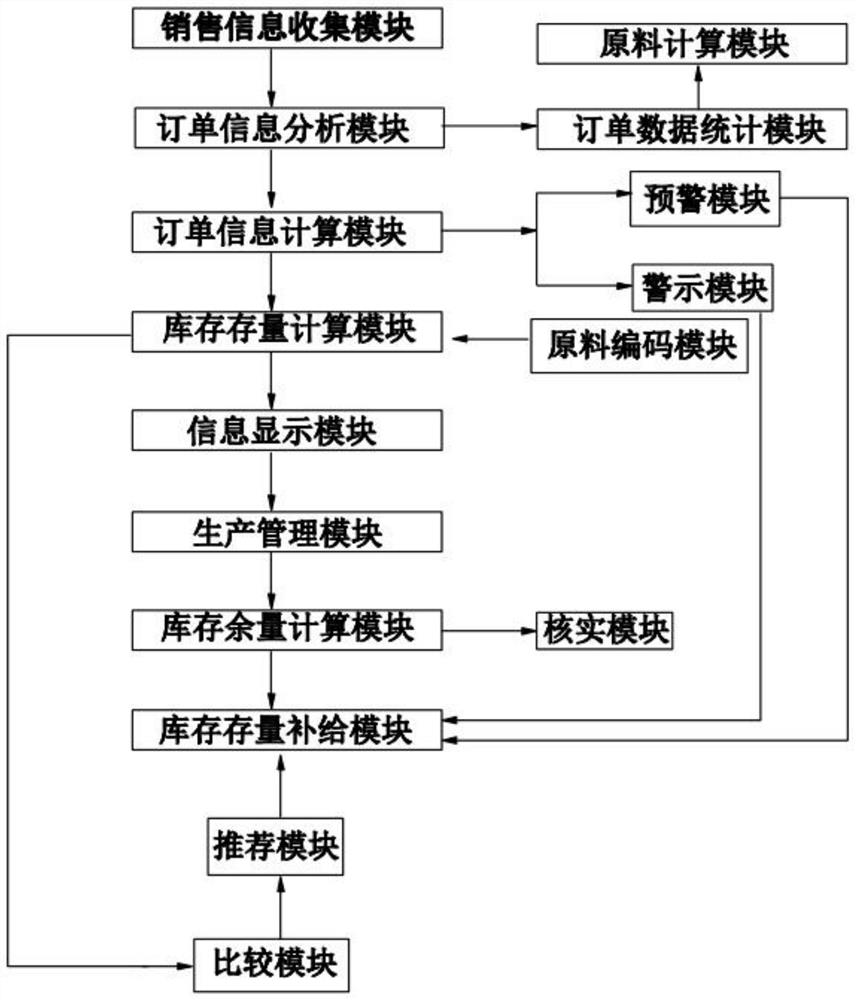

Consumption control management software product and software method for hemp biochemical degumming process

PendingCN111754164AGuaranteed continuityAvoid affecting the production scheduleBuying/selling/leasing transactionsAlarmsMaterial typeBusiness enterprise

The invention relates to the technical field of hemp biological degumming, in particular to a consumption control management software product and a software method for a hemp biochemical degumming process. The product comprises a sales management module for inputting sales order information and storing sales order sales information; a production management module used for selecting hemp biologicaldegumming material types and degumming processes according to the sales order information; and an inventory management module used for calculating the required hemp biological degumming material amount and the hemp biological degumming material inventory according to the information of the production management module. Degumming raw materials can be stored and taken, stored and the like; real-time monitoring is carried out, stock overstock caused by excessive purchasing of degumming raw materials and influence on the production schedule due to untimely purchasing of the degumming raw materials are effectively avoided, intelligent management is achieved, all departments of selling, production and warehouses are closely connected, the production continuity of enterprises is effectively guaranteed, the production efficiency is improved, and the production cost is reduced.

Owner:QINGDAO UNIV +1

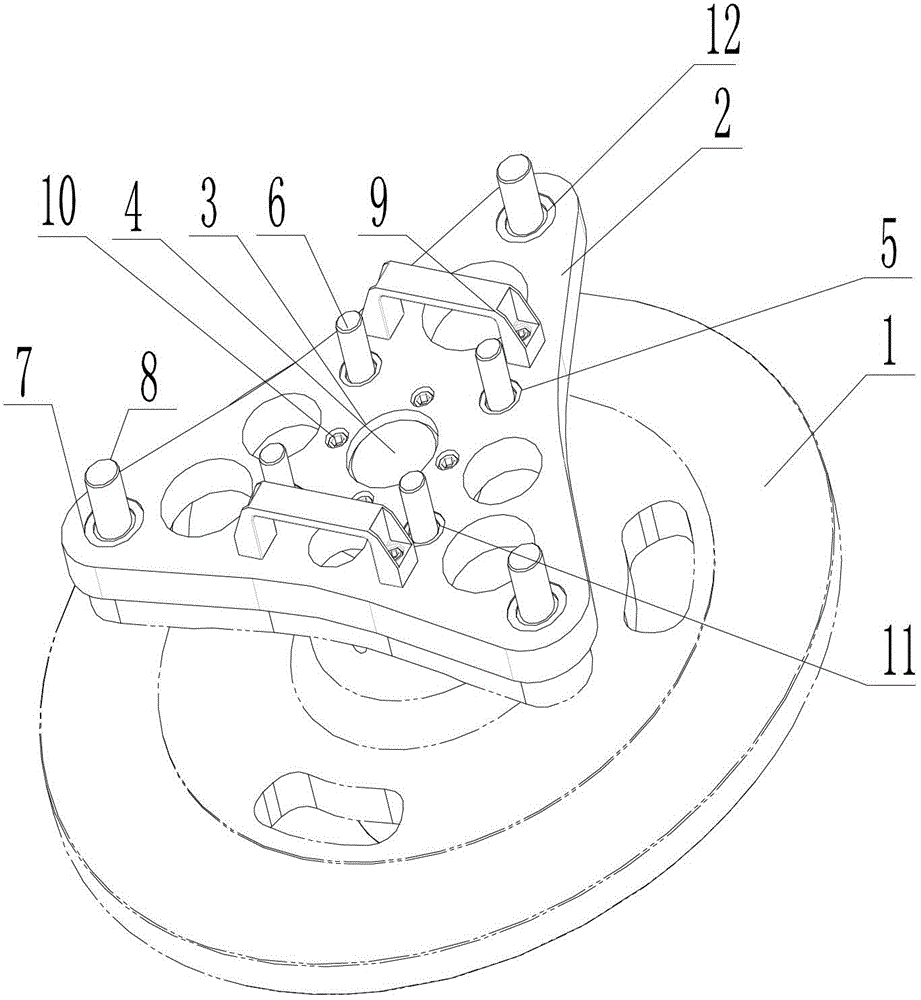

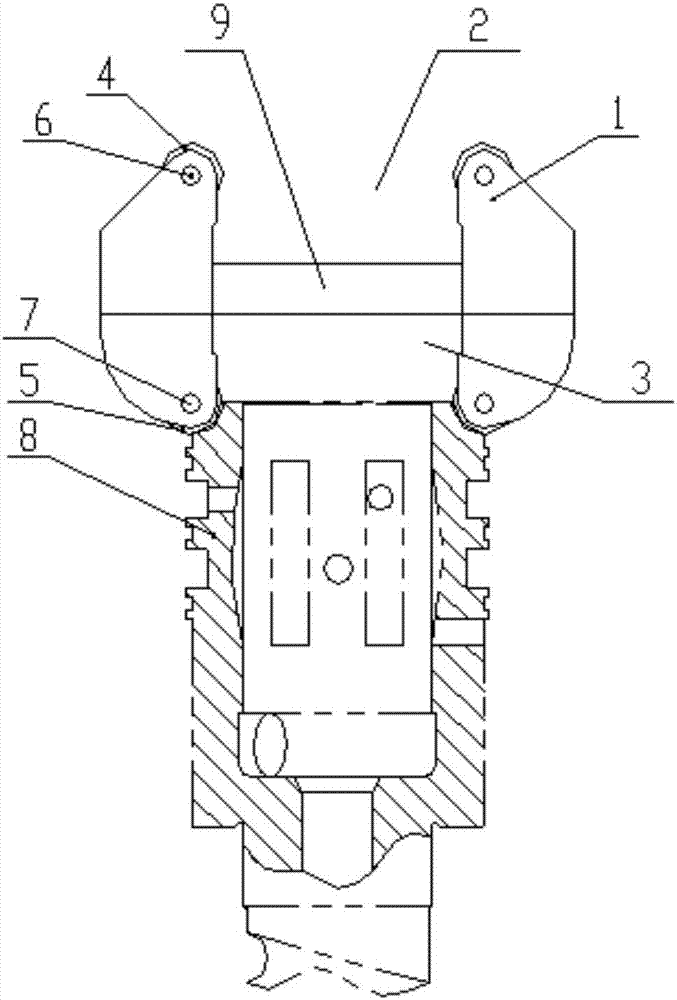

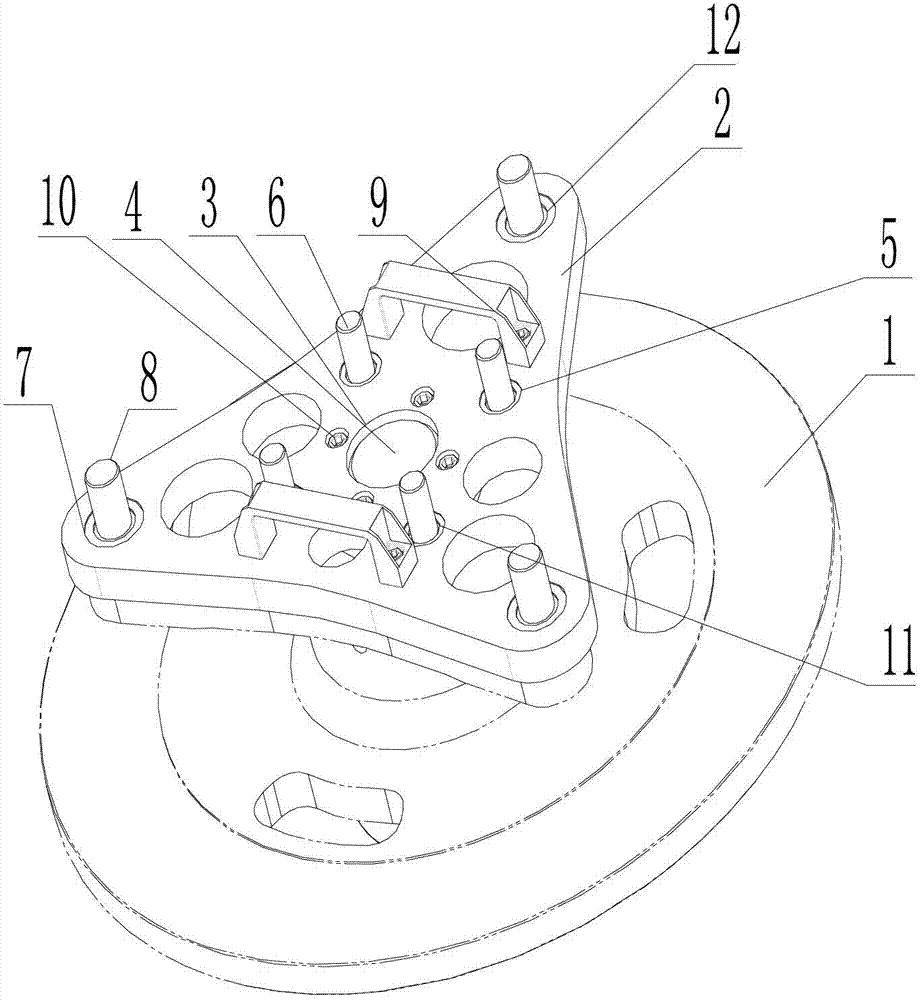

Comprehensive inspection tool for simulating component assembly position relation structure

ActiveCN103148782AShorten detection timeReduce testing costsUsing optical meansEngineeringMechanical engineering

The invention relates to a comprehensive inspection tool for simulating a component assembly position relation structure. The comprehensive inspection tool comprises a base, wherein an inspection tool body is arranged above the base, a large location pin hole is formed in the middle of the inspection tool body, a large location pin is arranged in the large location pin hole, four fixed location pin holes are formed around the large location pin, fixed location pins are arranged in the fixed location pin holes, a movable location pin hole is formed in each corner of the inspection tool body, and a movable location pin is arranged in each movable location pin hole. According to the comprehensive inspection tool, the three-coordinate detection time is shortened, the three-coordinate detection cost is lowered, and the production progress is prevented from being influenced.

Owner:鹰普机械(宜兴)有限公司

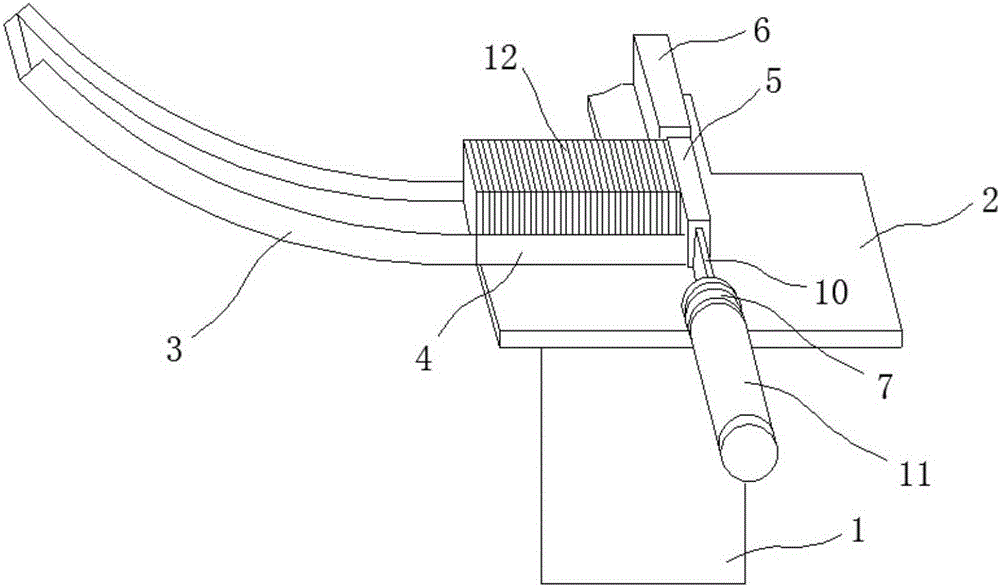

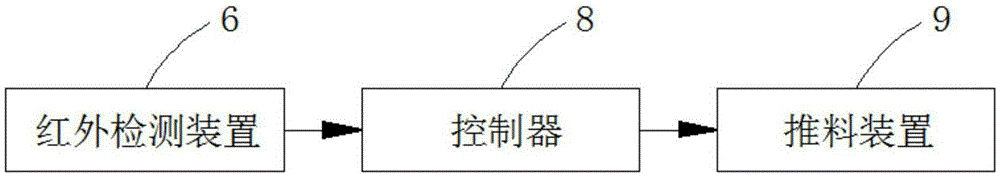

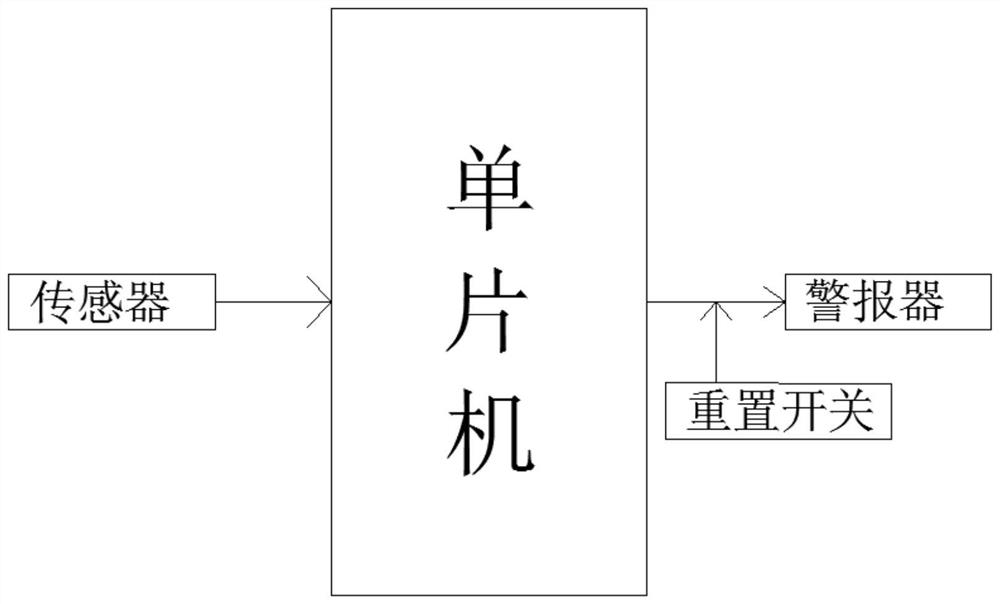

Feeding mechanism capable of giving alarm for material clamping

InactiveCN105236067AReduce labor intensityAvoid material shortage in subsequent processesOptical detectionChutesEngineeringMechanical engineering

The invention relates to a feeding mechanism capable of giving an alarm for material clamping. The feeding mechanism comprises a rack, and a supporting plate is fixedly arranged at the upper end of the rack; a gliding feeding box and a horizontal feeding box are fixedly arranged at the upper end of the supporting plate; the gliding feeding box is placed on one side of the horizontal feeding box, and a material pushing box is fixedly arranged on one side, far away from the gliding feeding box, of the horizontal feeding box; a pushing rod device is arranged on one side, perpendicular to the axis of the horizontal feeding box and the axis of the gliding feeding box, of the material pushing box, and an infrared detection device is arranged on one side, far away from the pushing rod device, of the material pushing box; the pushing rod device can stretch into the material pushing box to push parts required to be machined to pass through the infrared detection device, and the infrared detection device is connected with a controller through a circuit; and the controller is connected with an alarm device through a circuit. Compared with the prior art, the feeding mechanism is high in feeding speed, small in labor intensity of workers, capable of giving an alarm for material lacking in time, and high in feeding efficiency.

Owner:GUILIN UNIV OF AEROSPACE TECH

Concrete block repairing and cutting device

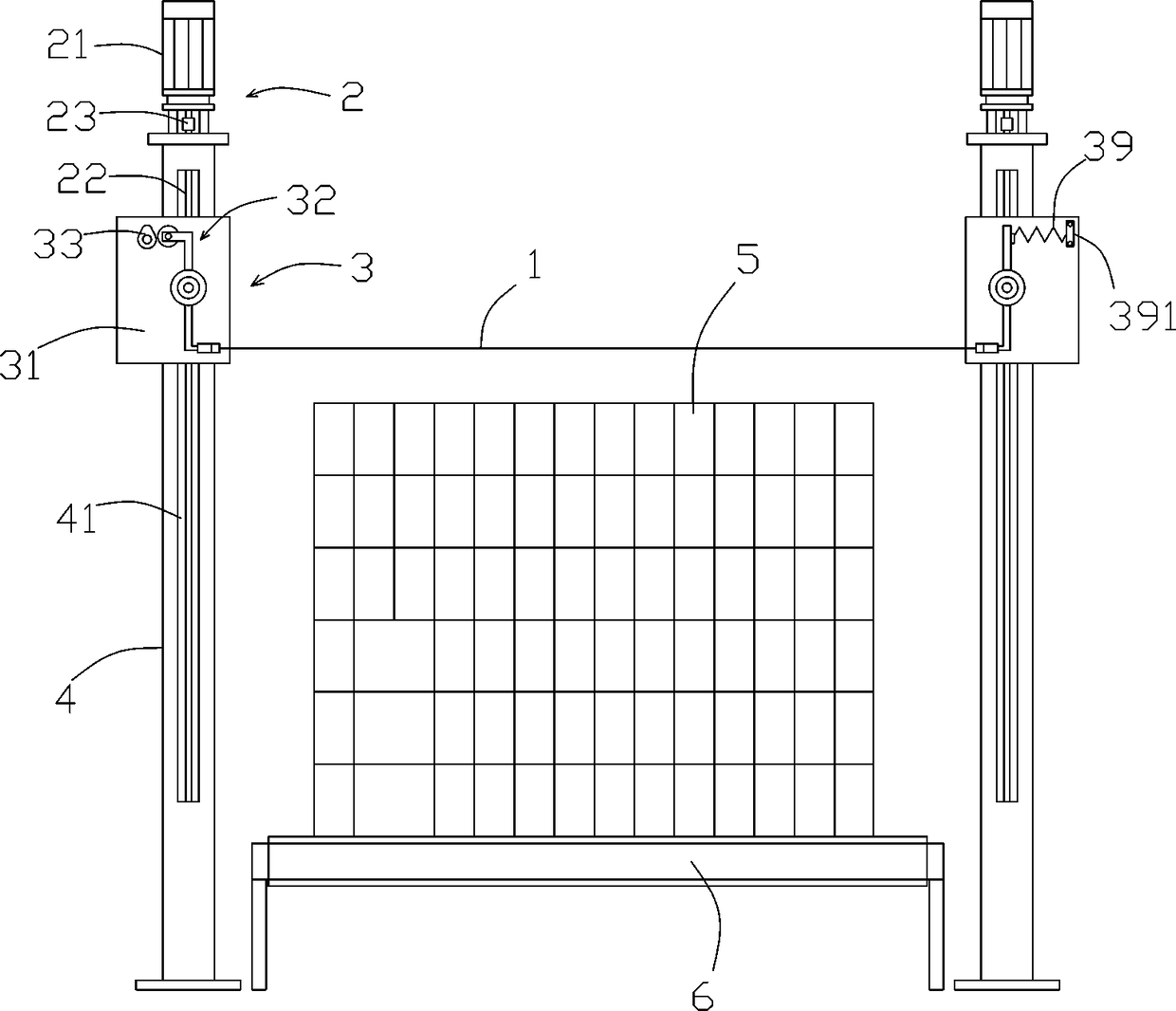

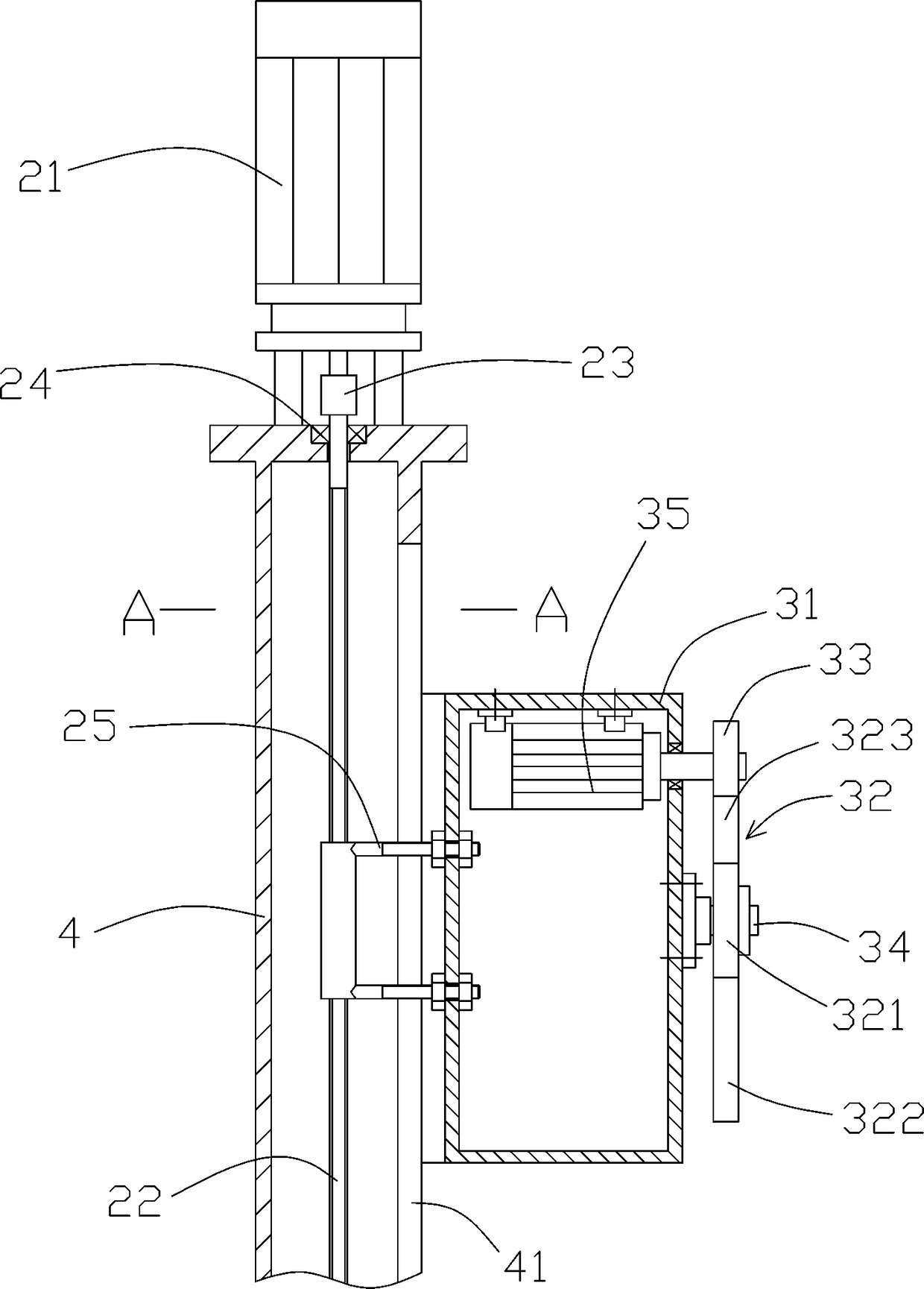

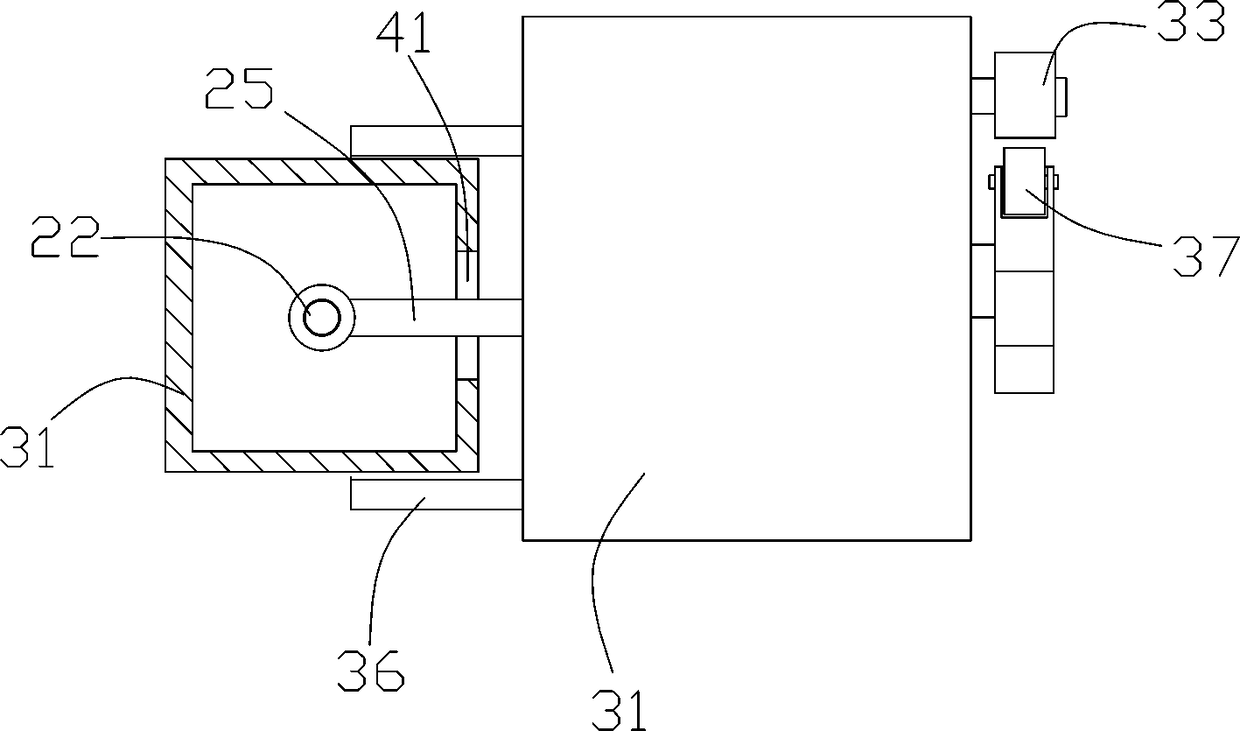

InactiveCN108656327AAvoid affecting the production scheduleAvoid compromising cut qualityCeramic shaping apparatusBall screwArchitectural engineering

The invention provides a concrete block repairing and cutting device. The concrete blocking repairing and cutting device comprises a steel wire and two sets of cutting mechanisms symmetrically arranged on the two sides of a concrete block; vertical rods are internally hollow, and one sides of the vertical rods are provided with vertical openings; each driving part comprises a first motor arrangedat the upper end of the vertical rod and a ball screw connected in the vertical rod in a shaft mode, and first motor rotating shafts are connected with screws in ball screws, and each lifting part comprises a shell, the shells are connected with nuts in the ball screws through a plurality of connecting rods, wing plates are fixedly arranged on the two sides of the shells, the vertical rods are located between the two wing plates, shaft rods are fixed on the end faces of the shells, rocker arms are installed on the shaft rods, and the two ends of the steel wire are connected to the lower ends of the rocker arms in two sets of cutting mechanisms; and a second motor is arranged in the shell of one set of cutting mechanism, a second motor rotating shaft penetrates out of the shell and then isconnected with a cam, and the cam is used for pushing the rocker arms to swing left and right.

Owner:刘阳国

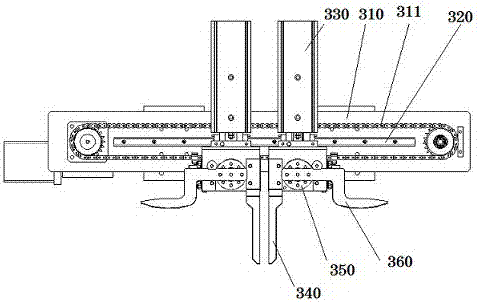

Concrete surface brick forming device capable of achieving rapid mold replacement

ActiveCN112536905AAvoid scratchesQuality assuranceDischarging arrangementSolid waste managementBrickMolding machine

The invention provides a concrete surface brick forming device capable of achieving rapid mold replacement. The concrete surface brick forming device comprises a forming machine main machine, a brickconveying machine and a surface machine, wherein the brick conveying machine is fixedly arranged at the discharging end of the forming machine main machine and used for conveying formed concrete surface bricks, and the surface machine is movably arranged at the discharging end of the forming machine main machine and used for distributing surfaces into a mold frame of the forming machine main machine. The brick conveying machine is located below a surface supporting plate of the surface machine. The surface machine comprises a jacking receding mechanism which is fixedly arranged below the surface supporting plate and used for driving the surface supporting plate to ascend and descend. Mold moving mechanisms used for conveying molds from the interior of the forming machine main machine to the exterior or conveying the molds from the exterior to the interior of the forming machine main machine are arranged on the two sides of the brick conveying machine. The concrete surface brick formingdevice has the beneficial effects that the concrete surface bricks can be rapidly conveyed out, and the production efficiency is improved; the situation that the concrete surface bricks are scratcheddue to touch in the conveying process can be avoided, the quality of the concrete surface bricks can be better guaranteed, and the yield is increased; and meanwhile, rapid mold replacement is facilitated, and time and labor are saved.

Owner:FUJIAN QUNFENG MACHINERY

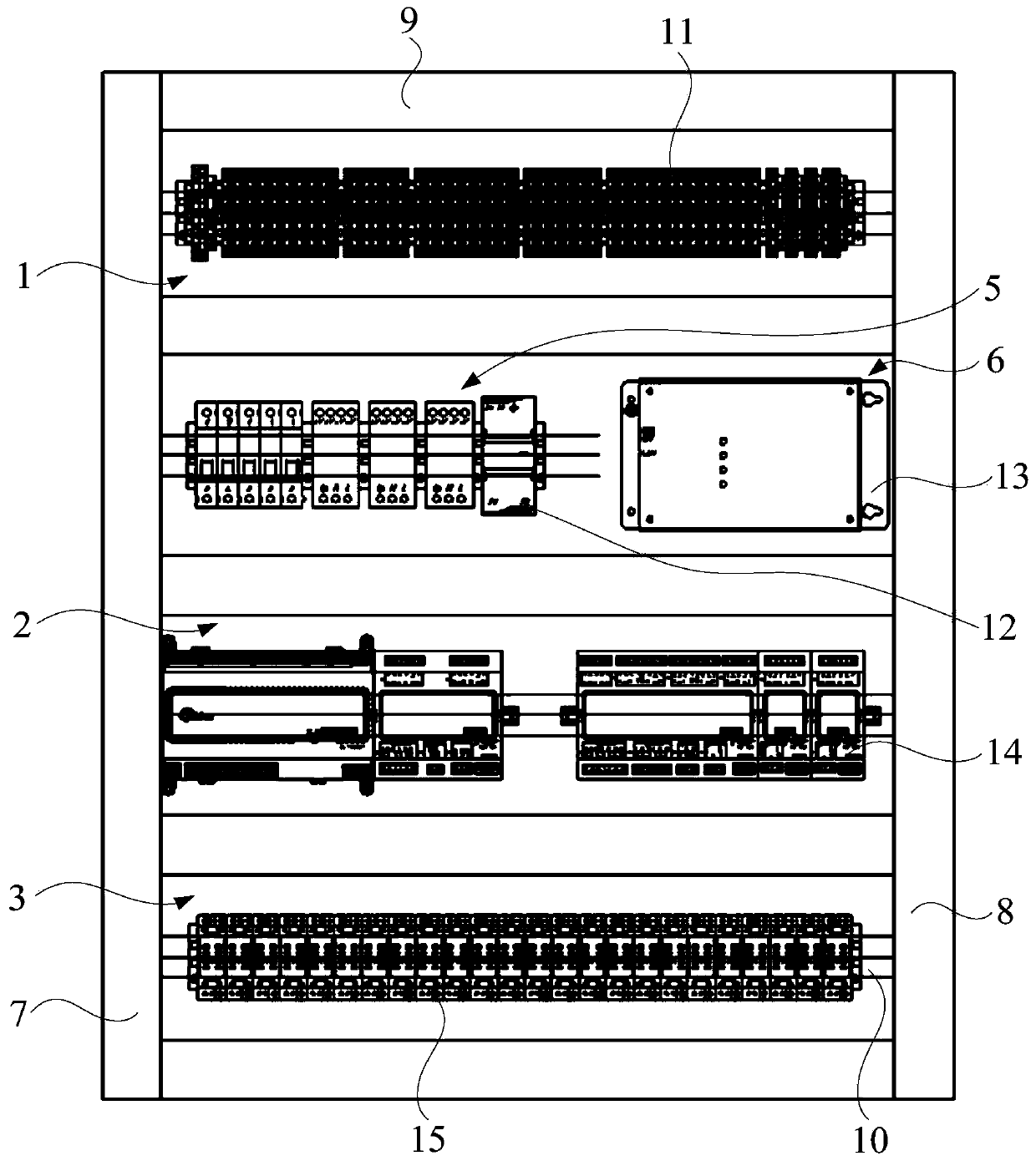

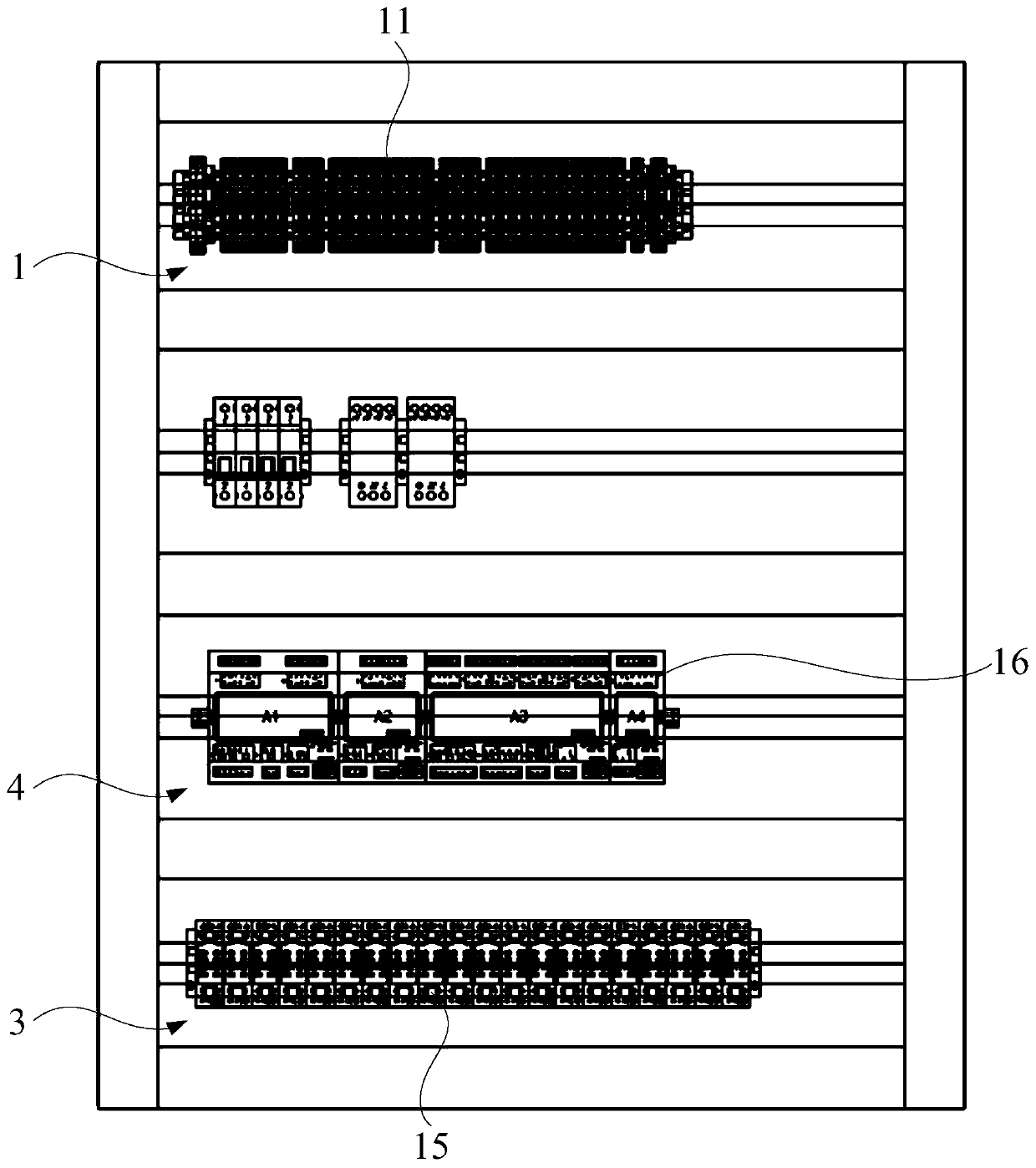

Control box

InactiveCN110177444AShorten the design cycleIncrease production speedPrinted circuit board receptaclesEngineeringMechanical engineering

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Bearing washing and discharging integrated machine

ActiveCN108543751AAvoid damageSmall footprintCleaning using toolsCleaning using liquidsHigh pressure waterHigh pressure

The invention discloses a bearing washing and discharging integrated machine and relates to the field of bearing washing. The bearing washing and discharging integrated machine comprises a case, a first conveying belt, a washing liquid box, a water tank and a telescopic device; the first conveying belt is located on the outer side of the case and one end of the first conveying belt is located in afeeding inlet; a first baffle and a second baffle are sequentially arranged inside the case, and the surfaces of the first baffle and the second baffle are provided with a plurality of through grooves side by side; rollers are arranged inside the through grooves; a plurality of sprayers are arranged at the bottom of the washing liquid box; a second conveying belt is arranged below the sprayers; aplurality of high-pressure water guns are arranged at the bottom of the water tank; a third conveying belt is arranged below the high-pressure water guns; a U-type chute is formed in one side of thethird conveying belt; and an infrared detection head is arranged on the inner wall of the U-type chute. A washing machine and a discharging machine for bearings are integrated into one machine, washing of the bearings is finished by the multiple conveying belts in sequence, the floor space of the machine is reduced, damage to the bearings in the discharging process is prevented, and the productioncost is reduced.

Owner:界首市皖俊轴承有限公司

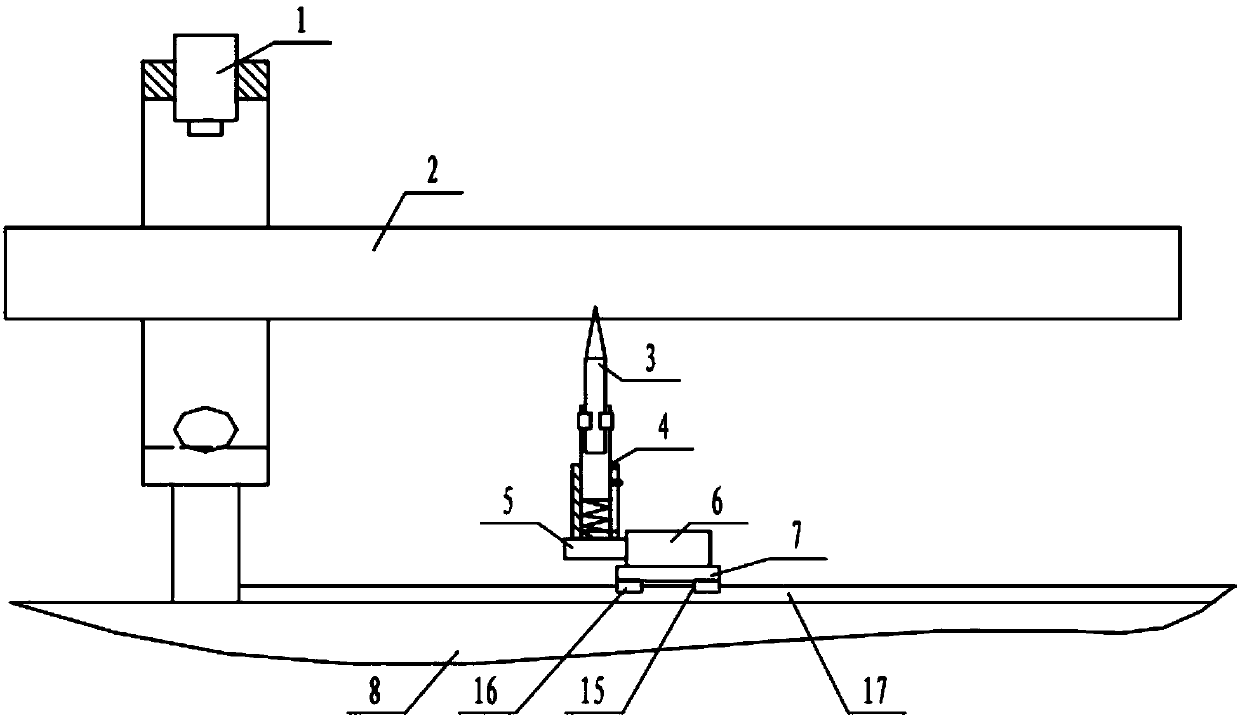

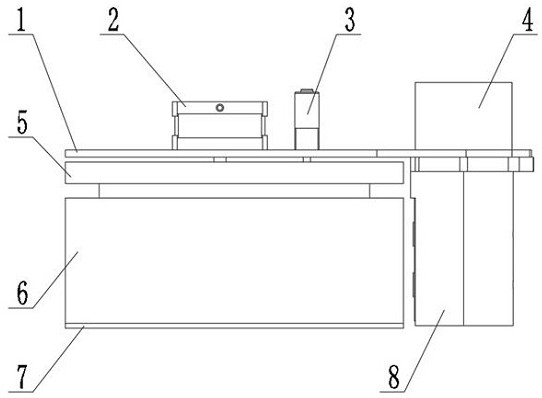

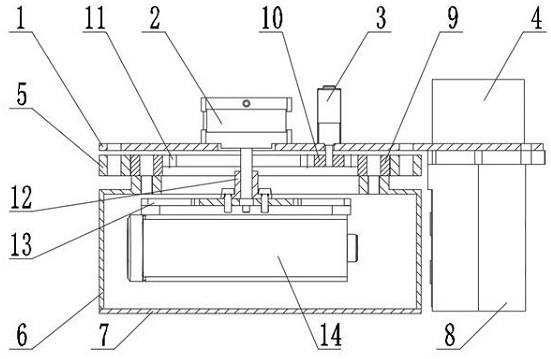

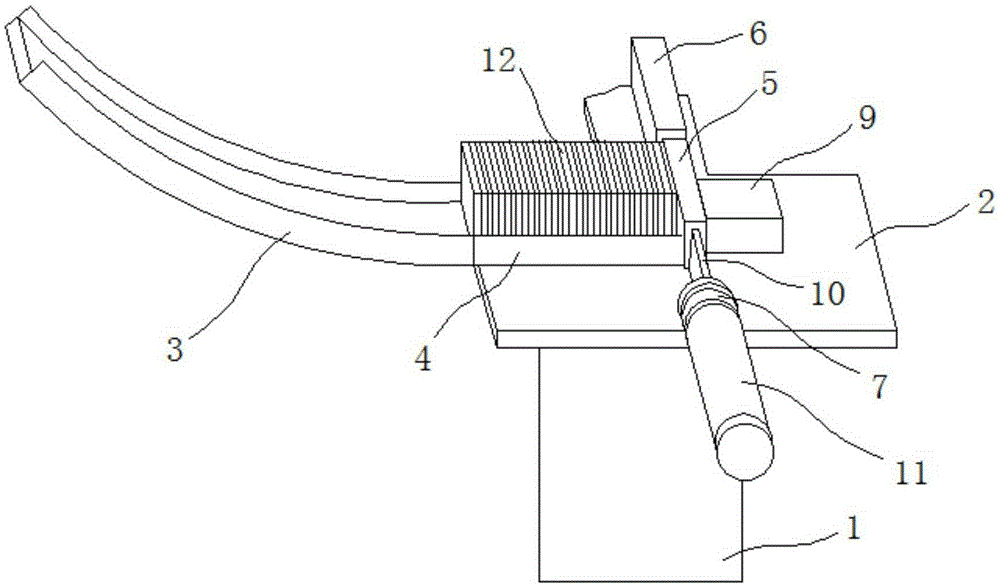

Apparatus for measuring end surface of screw rod

InactiveCN107063051AAvoid affecting the production scheduleQuick measurementMechanical counters/curvatures measurementsEngineeringMeasurement precision

The invention relates to an apparatus for measuring an end surface of a screw rod. The apparatus comprises an apparatus body; a first groove for detecting a workpiece is formed in the upper part of the apparatus body; a second groove for detecting a workpiece is formed in the lower part of the apparatus body; and the orientations of the first groove and the second groove are consistent. Rotatable not-go-end wheels are arranged at the groove walls at two sides of an opening end of the first groove; and rotatable go-end wheels are arranged at the groove walls at two sides of an opening end of the second groove. A telescopic shaft is arranged at the center of the apparatus body and can stretch out or draw back to adjust the space between two split bodies of the apparatus body; and a scale groove is formed in the telescopic shaft. Compared with the prior art, the measuring apparatus has the following advantages: the measurement precision can be guaranteed; rapid measurement can be realized; because the telescopic shaft is adjusted based on the dimension of the detected workpiece, so that adaptability to different workpieces is high; and with the scale groove, the dimension can be obtained directly.

Owner:张礼芬

Part pushing and feeding mechanism

InactiveCN105236127AAdjust in timeAutomatic adjustment in timeControl devices for conveyorsEngineeringMechanical engineering

The invention relates to a part pushing and feeding mechanism which comprises a rack. A supporting plate is fixedly arranged at the upper end of the rack. A downward-sliding feeding box and a horizontal feeding box are fixedly arranged at the upper end of the supporting plate. The downward-sliding feeding box is arranged on one side of the horizontal feeding box. A material push box is fixedly arranged on the side, away from the downward-sliding feeding box, of the horizontal feeding box. A push rod device is arranged on the side, perpendicular to the axes of the horizontal feeding box and the downward-sliding feeding box, of the material push box. An infrared detection device is arranged on the side, away from the push rod device, of the material push box. The push rod device can extend into the material push box to push parts to be machined to pass the infrared detection device. The infrared detection device is connected with a controller through a circuit. The controller is connected with a material push device through a circuit. The material push device is arranged on the side, away from the horizontal feeding box, of the material push box. The side, close to the material push box, of the material push device is provided with a push plate extending into the material push box. Compared with the prior art, the feeding speed is high, the labor intensity of workers is low, an alarm indicating the lack of materials can be given out timely, and feeding efficiency is high.

Owner:GUILIN UNIV OF AEROSPACE TECH

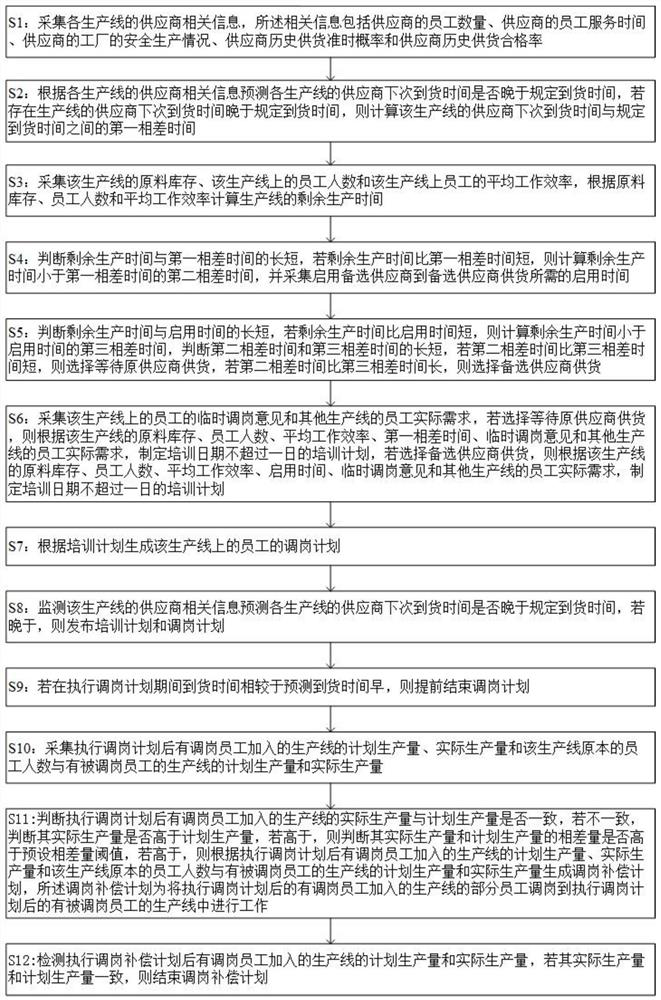

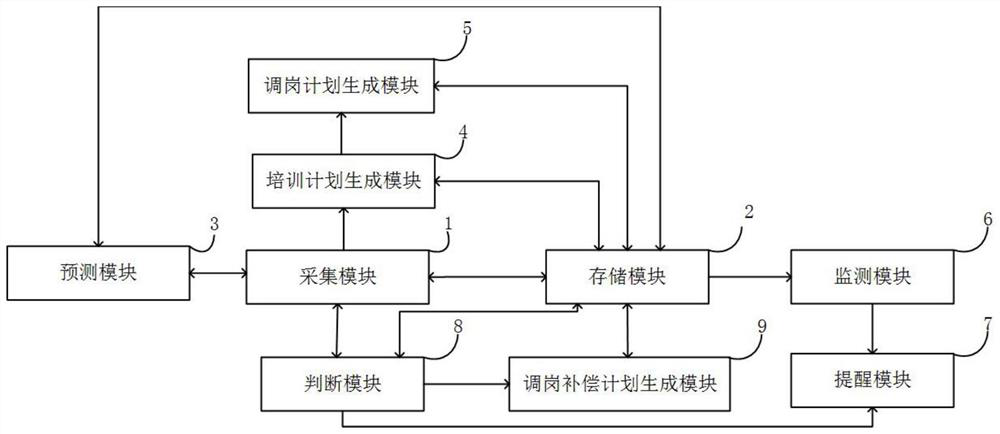

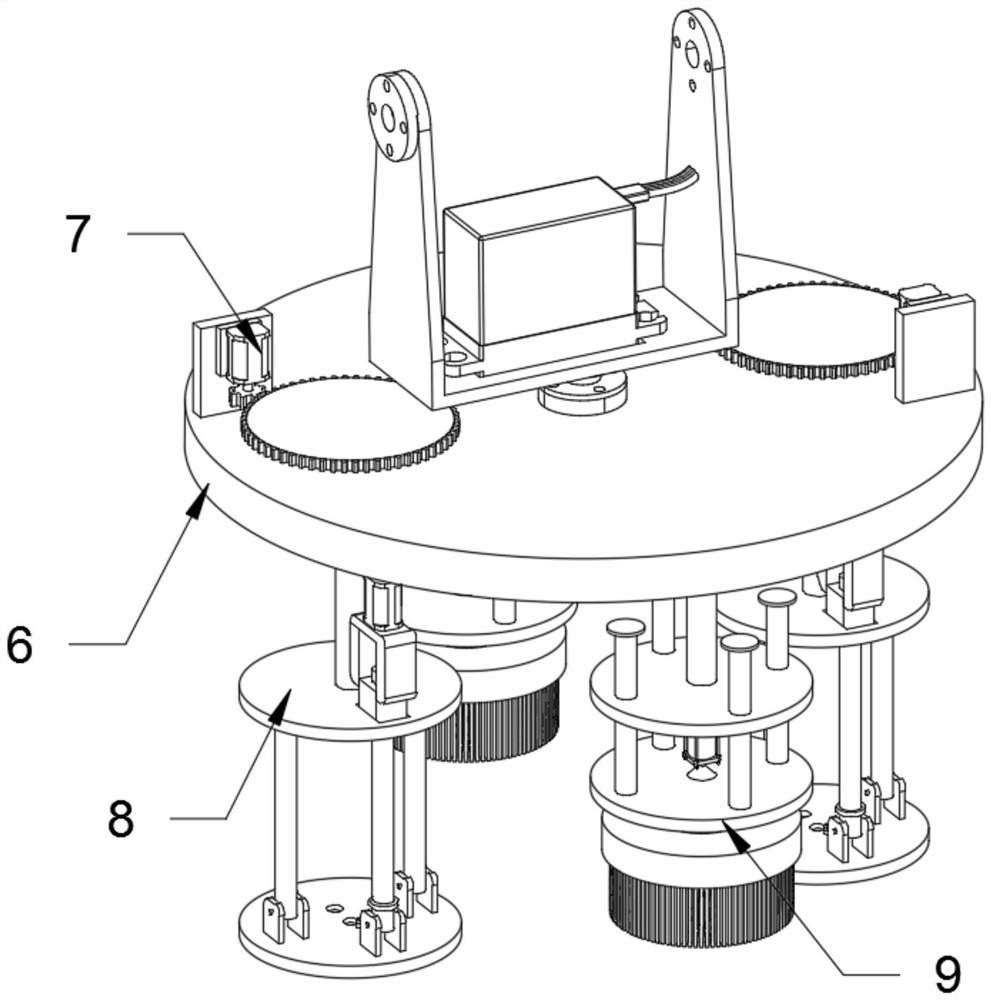

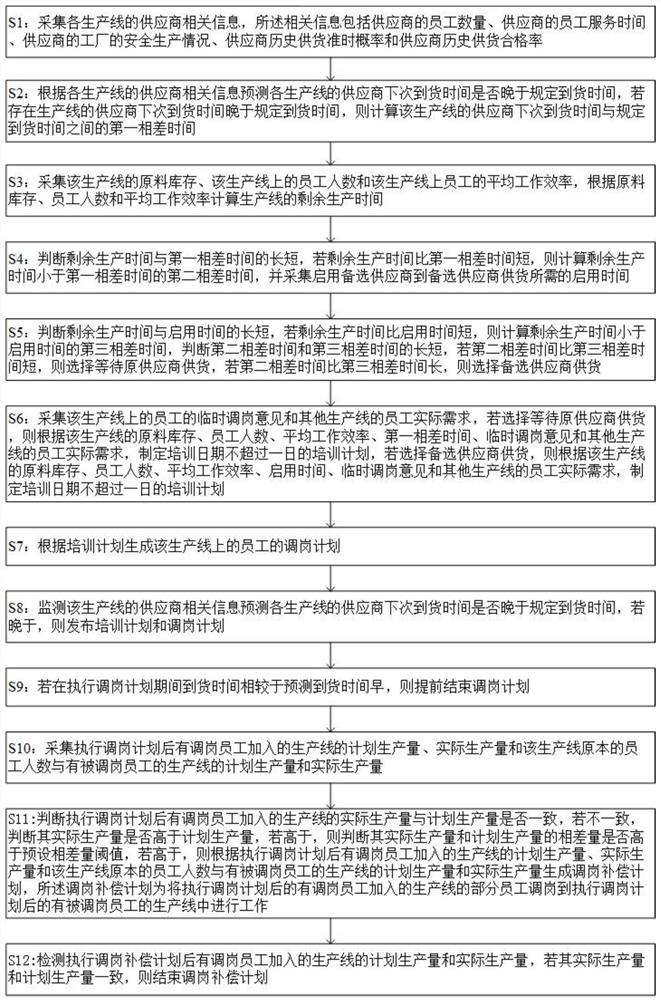

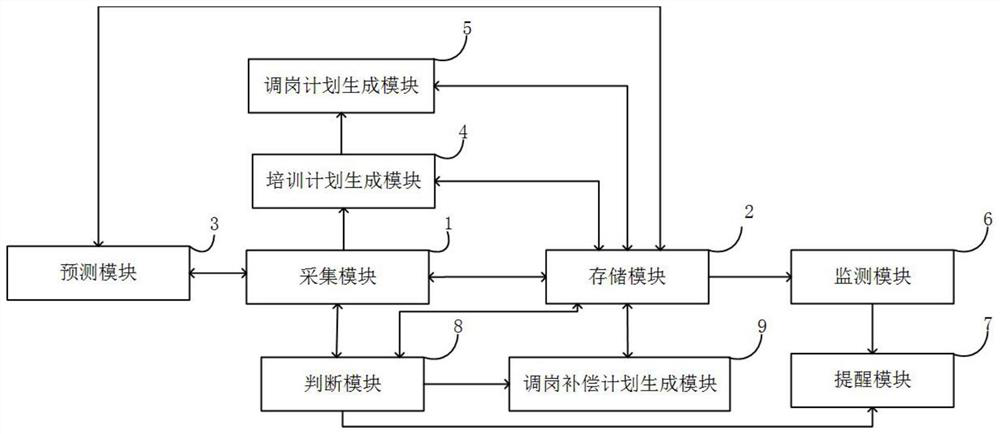

Collaborative manufacturing support system and method

ActiveCN112508390AReduce the impactGuarantee the production progressBuying/selling/leasing transactionsResourcesTraining planManufacturing services

The invention relates to the technical field of manufacturing services, in particular to a collaborative manufacturing supporting system and method, and the method comprises the steps: predicting whether the next arrival time of suppliers of all production lines is later than the specified arrival time according to the collected supplier related information of all production lines, and if yes, according to the inventory, the arrival time and the alternative supplier decisions, deciding whether to make a training plan; if yes, making a training plan of which the training date does not exceed one day according to the related data; according to the training plan, generating a job scheduling plan of employees on the production line; and monitoring supplier related information of the productionline to predict whether the next arrival time of the suppliers of each production line is later than the specified arrival time, and if yes, issuing a training plan and a job scheduling plan. According to the method, the influence of problems of individual production lines on the collaborative manufacturing process can be reduced, so that the production schedule is ensured, and the production stability is improved.

Owner:贵州航天云网科技有限公司

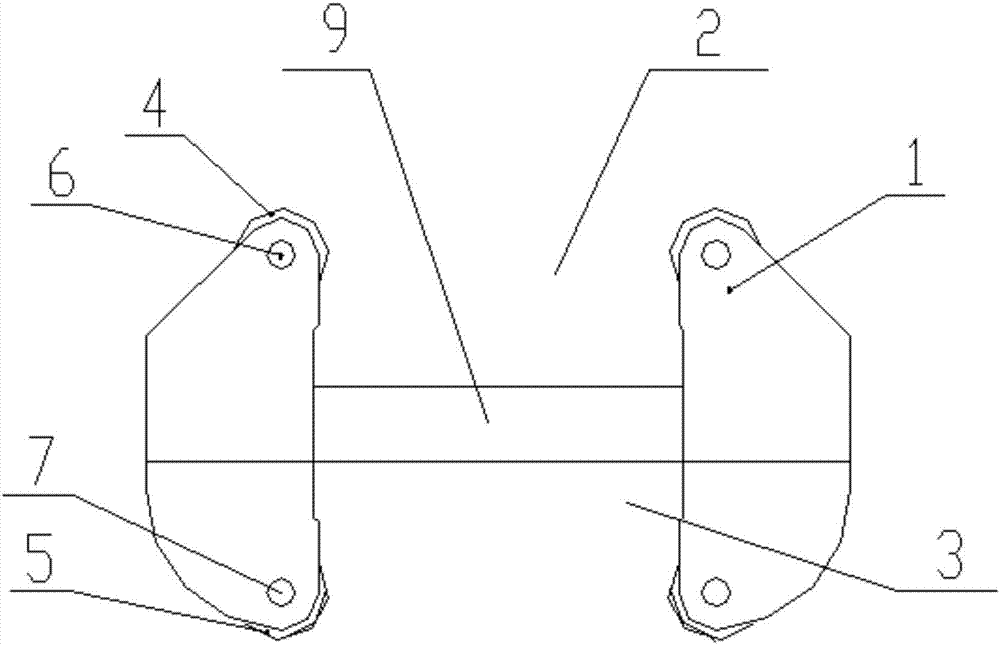

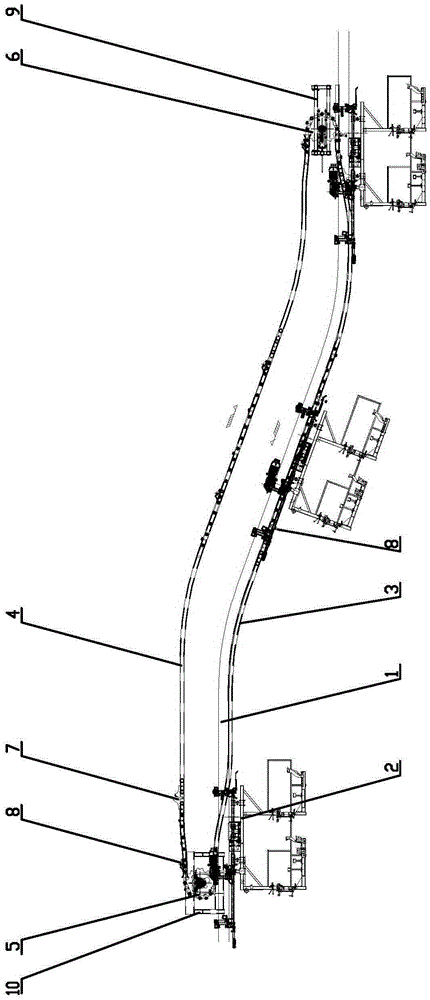

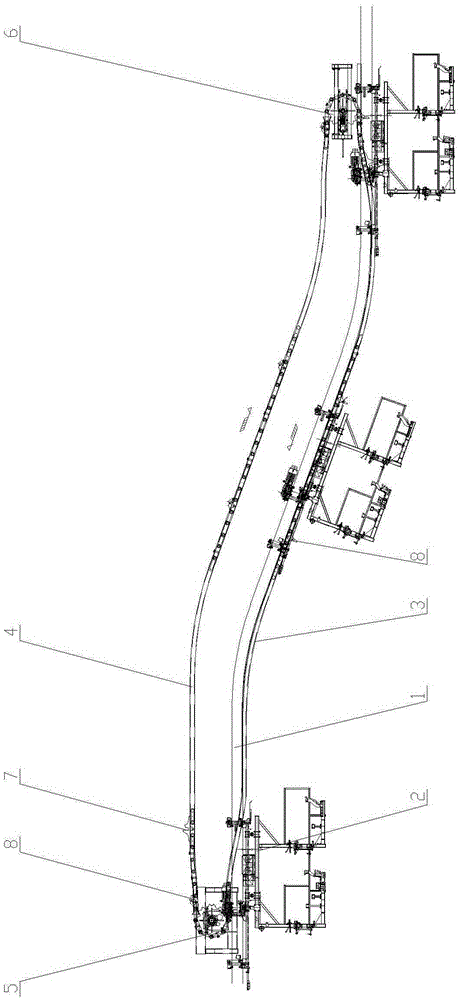

Self-propelling trolley lifting appliance with uphill assisting chain mechanism

InactiveCN105329632AEasy uphillAvoid affecting the production scheduleMechanical conveyorsEngineeringSprocket

The invention relates to a self-propelling trolley lifting appliance with an uphill assisting chain mechanism. The self-propelling trolley lifting appliance comprises a self-propelling trolley track, a self-propelling trolley lifting appliance body, push chain tracks, a push chain return rail, an assisting chain drive chain wheel, an assisting chain tensioning chain wheel, chain push heads, retraction stop push heads, an assisting chain uphill mounting frame and an assisting chain downhill mounting frame. The push chain return rail is located above the push chain tracks. The corresponding ends of the push chain tracks and the push chain return rail are connected to form an annular sealed chain track. The sealed chain track is matched with the assisting chain drive chain wheel and the assisting chain tensioning chain wheel. The push chain tracks are close to the self-propelling trolley track. The chain push heads and the retraction stop push heads are arranged on the push chain tracks and the push chain return rail respectively. The retraction stop direction of the retraction stop push heads is the downhill direction of the slope. The chain push heads and the retraction stop push heads are matched with the self-propelling trolley lifting appliance. In this way, the self-propelling trolley lifting appliance is stable in the downhill process and easy to uprise.

Owner:MIRACLE AUTOMATION ENG CO LTD

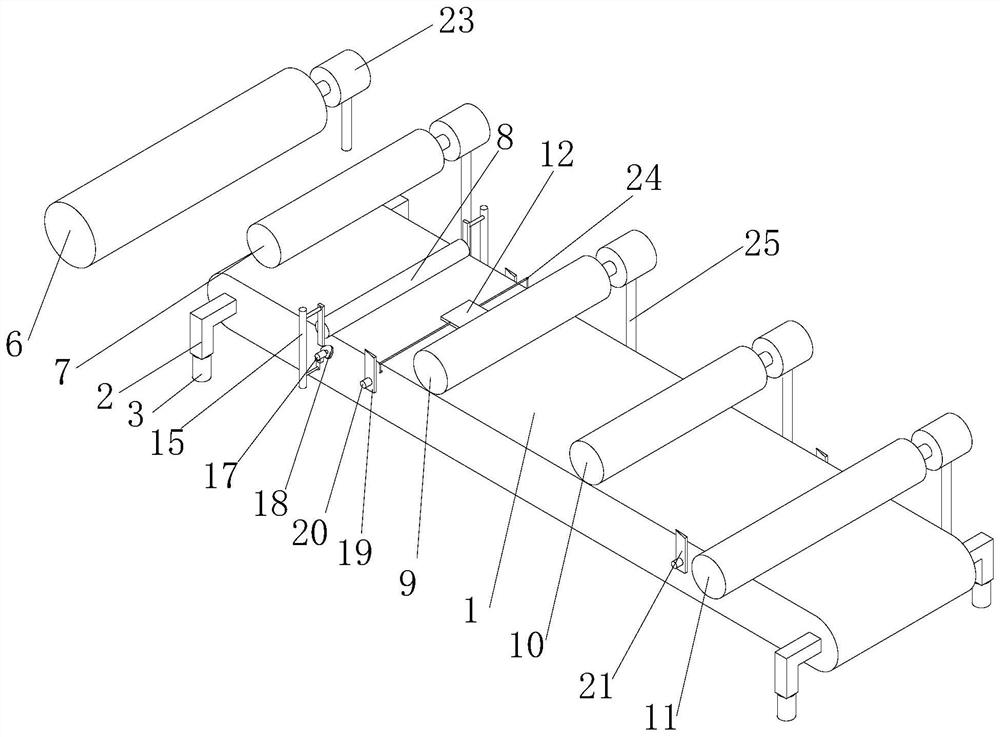

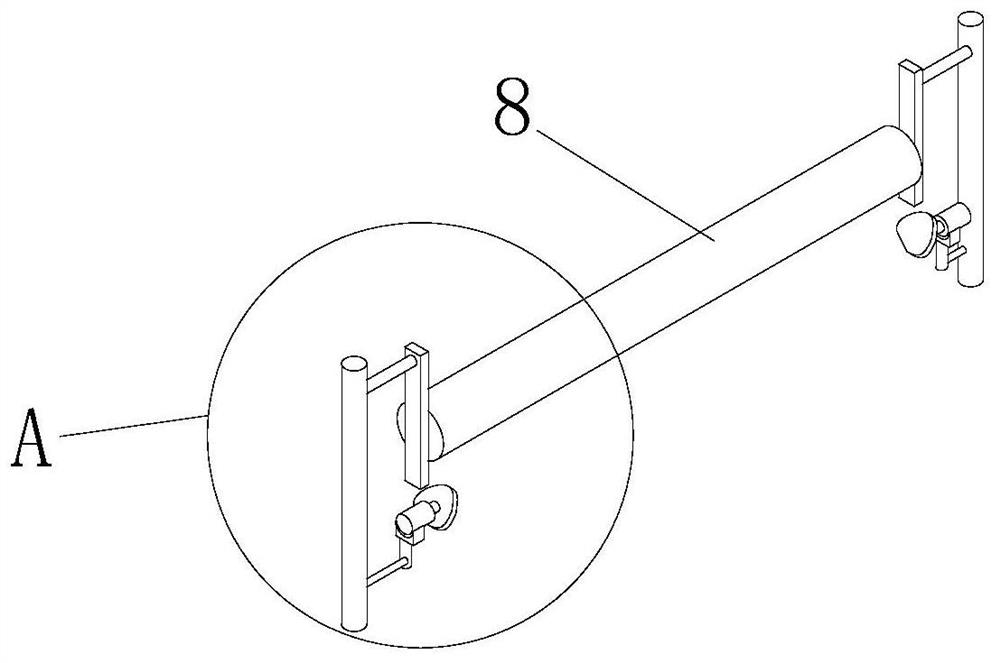

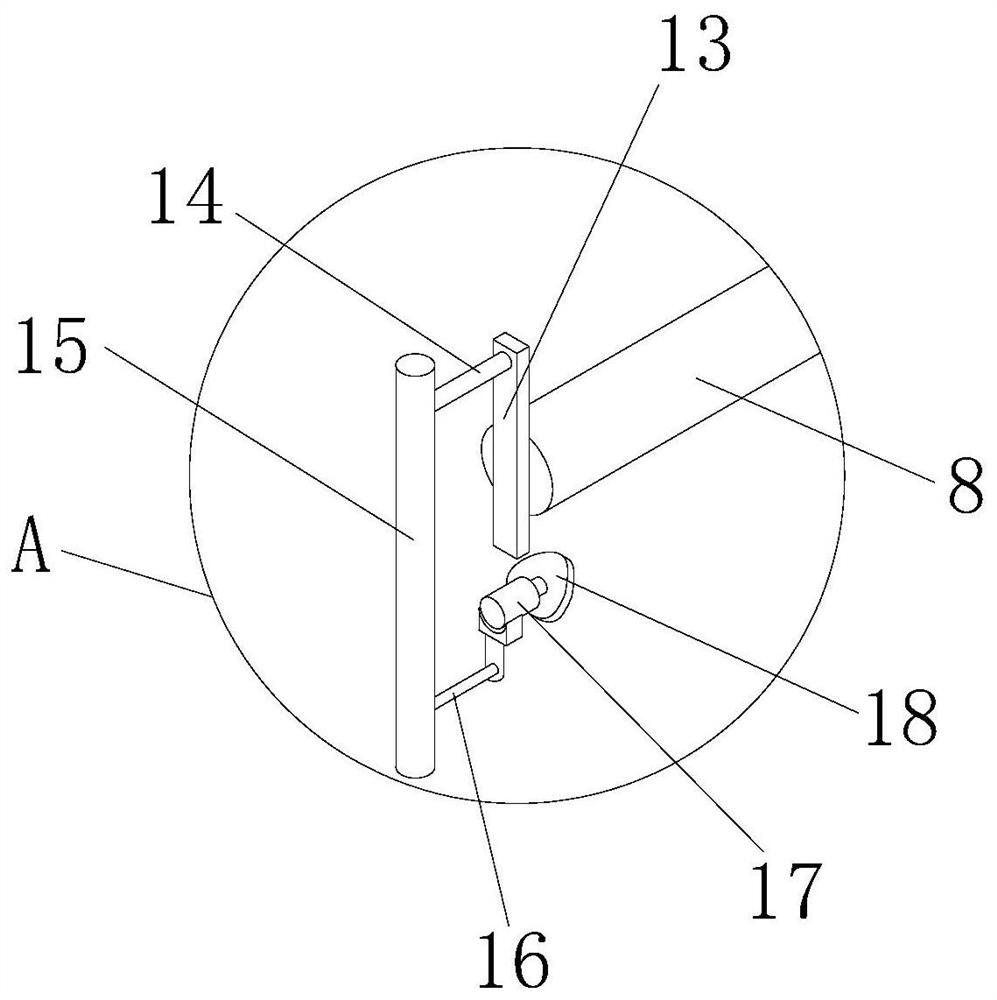

Film covering device for bathroom waterproof composite floor production

PendingCN112356433AAvoid problems such as pleatingImprove lamination efficiencyMetal working apparatusElectric machineryStructural engineering

The invention relates to the technical field of floor production, and discloses a film covering for bathroom waterproof composite floor production. The film covering device comprises a conveying belt,a support is fixedly connected to the front side of the conveying belt, a sleeve is fixedly connected to the bottom of the support, a motor support is arranged on the rear side of the conveying belt,a motor is fixedly connected to the top of the motor support, a vibration reducing device is arranged inside the sleeve, and a material pressing device is arranged at the top of the conveying belt. According to the film covering device for the bathroom waterproof composite floor production, materials are placed on the conveying belt during work, when the materials move to a brake switch, the brake switch is started to drive a feeding roller to rotate, the bottom of a floor film moves to the upper surface of a material lifting roller through the feeding roller, through rotation and movement ofthe material pressing roller, the floor film moving to the lower surface of the material pressing roller is subjected to rolling arrangement, and the situation that the floor film pleats and wrinkleswhen moving among the rollers, and consequently material film covering is affected is avoided.

Owner:湖州凯鑫智能家居股份有限公司

Cotton fiber dyeing process dye consumption supervision software product and software method

PendingCN112232738AKnow the inventory situation in real timeReduce backlogBuying/selling/leasing transactionsLogisticsCotton fibreIndustrial engineering

The invention relates to the technical field of cotton fiber dyestuff supervision, in particular to a cotton fiber dyeing process dye consumption supervision software product and a software method, and the software product comprise a sales information collection module, an order information analysis module, an order information calculation module, an inventory calculation module, an information display module, a production management module, an inventory allowance calculation module, and an inventory replenishment module; the software product can analyze the expected demand quantity of dye materials according to the usage quantity of the dye materials while ensuring the dye receiving safety management, thereby effectively avoiding the influence on the production schedule caused by inventory overstock and untimely purchase of the dye materials due to excessive purchase of the dye materials, and judging whether the safety inventory can be maintained in the production or not, so as to find materials which are not sufficiently supplied in the scheduling process and perform material purchasing in real time, thereby achieving the sustainable production of enterprises, enabling all departments of the enterprises to be closely matched, and reducing the production cost while improving the production efficiency of the enterprises.

Owner:QINGDAO UNIV

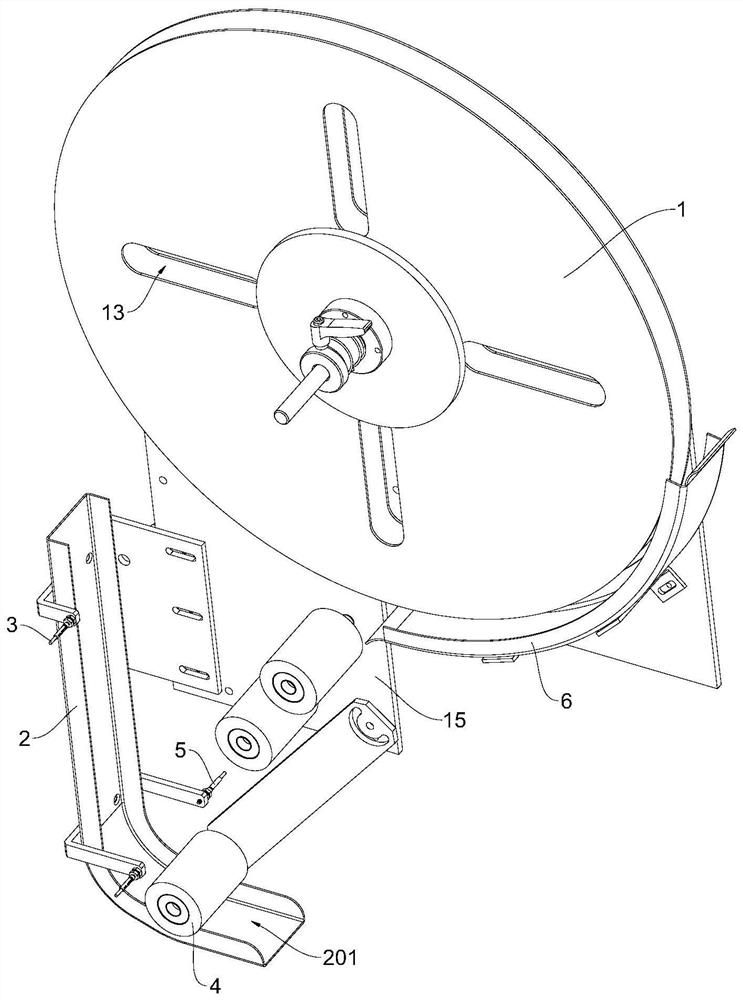

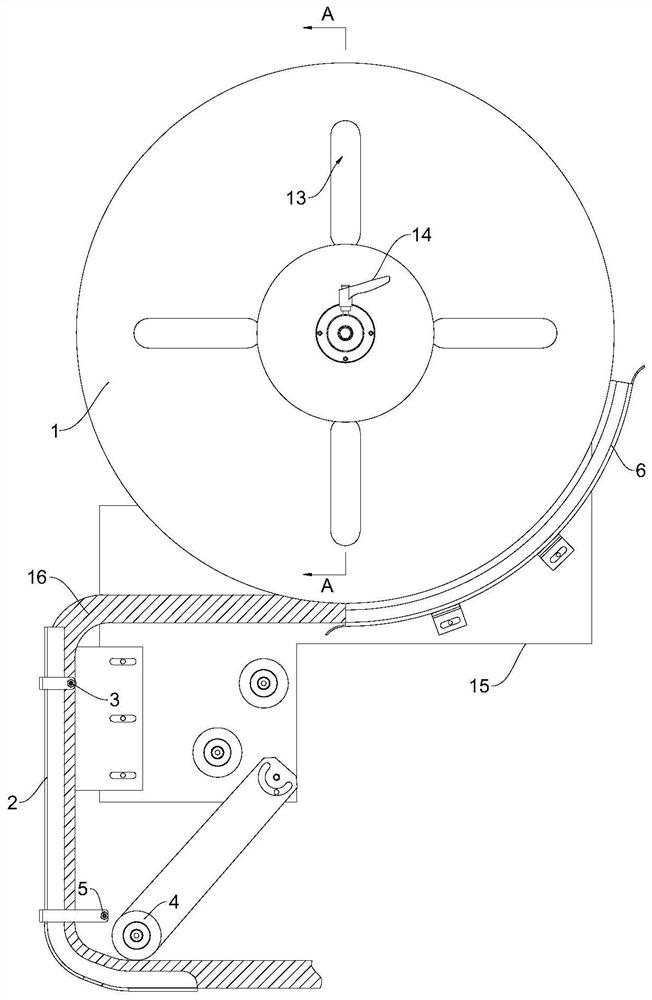

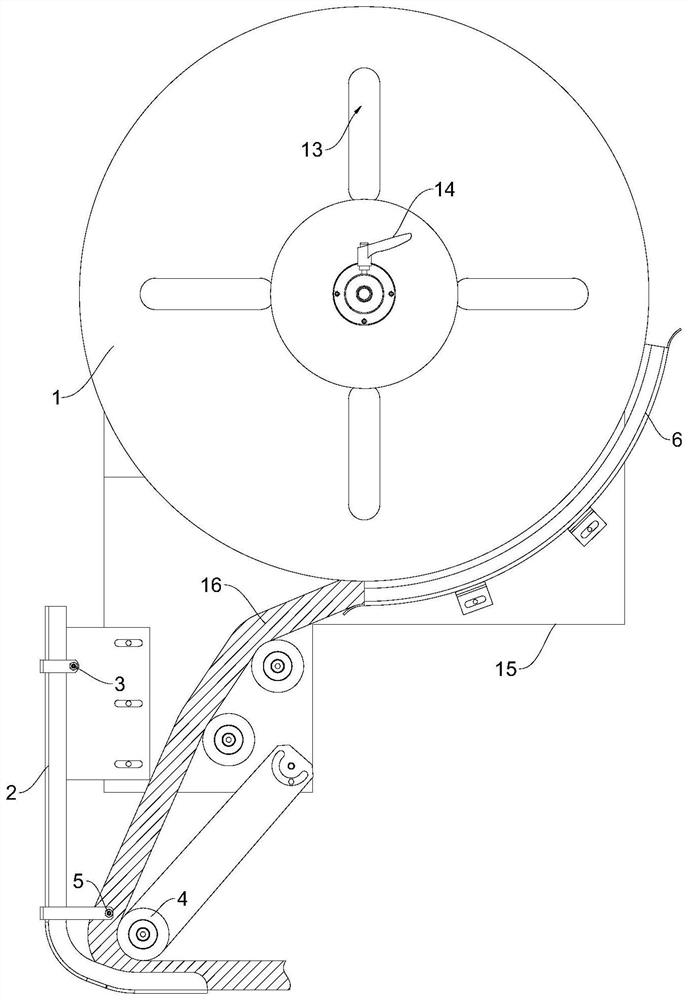

Carrier tape unwinding detection mechanism

ActiveCN113911843AAvoid affecting the production scheduleFilament handlingGeological measurementsPhysicsEngineering

The invention discloses a carrier tape unwinding detection mechanism. The carrier tape unwinding detection mechanism comprises a rotatable unwinding disc, a traction device, a guide piece and a first detection element, and the rotatable unwinding disc is used for unwinding a carrier tape; the traction device is used for pulling the carrier tape unwound from the unwinding disc; the guide piece is used for accommodating the redundant carrier tape between the unwinding disc and the traction device; and the first detection element is used for detecting whether the redundant carrier tape exists in the guide piece or not. The carrier tape unwinding detection mechanism has the advantages that whether the carrier tape is completely placed or not can be conveniently detected, and the situation that the production schedule is affected due to the fact that operators do not observe that the carrier tape is completely placed in time is avoided.

Owner:MIANYANG HI TECH ZONE HONGQIANG TECH

Multi-process transfer printing equipment for negative angle micron morphology on the surface of ceramic materials

ActiveCN111186219BAvoid getting in the wayDoes not affect the use of sprayingTypewritersPower drive mechanismsElectric machineryBrush

The invention provides multi-process transfer printing equipment for ceramic material surface negative angle micron forms. The multi-process transfer printing equipment for the ceramic material surface negative angle micron forms comprises an equipment body, motors B and brush heads; a sliding adjusting frame is welded to the front end face of the equipment body, and a sliding base is slidably connected to the sliding adjusting frame; and shaft bases are welded to the bottom end face of an installing base, and disc-shaped installing bases B are welded to the bottom end faces of the shaft bases. Through arrangement of sweeping structures, on the one hand, the motors B can drive the brush heads to rotatably sweep the ceramic surface; and on the other hand, electric telescopic rods B are arranged on the sweeping structures, the brush heads can be retracted through the electric telescopic rods B after sweeping is finished, the state of the sweeping structures is switched to the stopping state, and the condition that obstruction is caused to spraying is prevented. Compared with an existing device, the ceramic surface can be swept firstly before spraying, and the sweeping structures areadjustable structures, so that normal spraying use is not influenced after sweeping is finished.

Owner:JIAXING UNIV

A collaborative manufacturing support system and method

ActiveCN112508390BReduce the impact of collaborative manufacturing processesImprove production stabilityBuying/selling/leasing transactionsResourcesSupporting systemTraining plan

The invention relates to the technical field of manufacturing services, specifically a collaborative manufacturing support system and method. The method includes predicting whether the next arrival time of the suppliers of each production line is later than the specified arrival time based on the collected supplier-related information of each production line. If it is later than the delivery time, then according to the inventory, arrival time and alternative suppliers, it is necessary to make a training plan; if necessary, make a training plan with a training date of no more than one day according to relevant data; generate the training plan according to the training plan Job adjustment plan for employees on the production line; monitor the relevant information of the suppliers of the production line to predict whether the next arrival time of the suppliers of each production line is later than the specified arrival time, and if it is later, release the training plan and job adjustment plan. This solution can reduce the impact of individual production line problems on the collaborative manufacturing process, thereby ensuring production progress and improving production stability.

Owner:贵州航天云网科技有限公司

A bearing cleaning and cutting machine

ActiveCN108543751BAvoid damageSmall footprintCleaning using toolsCleaning using liquidsStructural engineeringHigh pressure water

The invention discloses a bearing cleaning and blanking integrated machine, which relates to the field of bearing cleaning. The invention includes a machine case, a first conveyor belt, a cleaning liquid box, a water tank and a telescopic device; the first conveyor belt is located outside the machine case and one end of the first conveyor belt is in the feed port; a first baffle plate and a second baffle plate are arranged in sequence in the machine box; The surfaces of the first baffle and the second baffle are arranged side by side with several through grooves; rollers are installed in the through grooves; several nozzles are arranged at the bottom of the cleaning liquid box; a second conveyor belt is arranged under the nozzles; several high-pressure water guns are arranged at the bottom of the water tank; A third conveyor belt is arranged under the water gun; a U-shaped chute is arranged on one side of the third conveyor belt; an infrared detection head is arranged on the inner wall of the U-shaped chute. The invention integrates the cleaning machine and the unloading machine of the bearing into one machine, and uses multiple conveying belts to complete the cleaning of the bearing in sequence, thereby reducing the occupied area of the machine, preventing the bearing from being damaged during the unloading process, and reducing the production cost.

Owner:界首市皖俊轴承有限公司

Multi-process transfer printing equipment for ceramic material surface negative angle micron forms

ActiveCN111186219AAvoid getting in the wayDoes not affect the use of sprayingTypewritersPower drive mechanismsElectric machineryBrush

The invention provides multi-process transfer printing equipment for ceramic material surface negative angle micron forms. The multi-process transfer printing equipment for the ceramic material surface negative angle micron forms comprises an equipment body, motors B and brush heads; a sliding adjusting frame is welded to the front end face of the equipment body, and a sliding base is slidably connected to the sliding adjusting frame; and shaft bases are welded to the bottom end face of an installing base, and disc-shaped installing bases B are welded to the bottom end faces of the shaft bases. Through arrangement of sweeping structures, on the one hand, the motors B can drive the brush heads to rotatably sweep the ceramic surface; and on the other hand, electric telescopic rods B are arranged on the sweeping structures, the brush heads can be retracted through the electric telescopic rods B after sweeping is finished, the state of the sweeping structures is switched to the stopping state, and the condition that obstruction is caused to spraying is prevented. Compared with an existing device, the ceramic surface can be swept firstly before spraying, and the sweeping structures areadjustable structures, so that normal spraying use is not influenced after sweeping is finished.

Owner:JIAXING UNIV

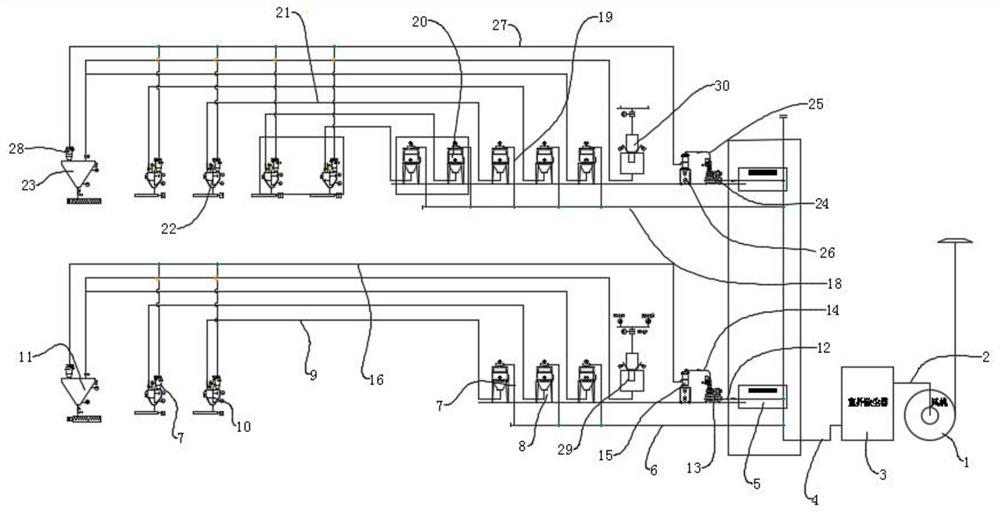

Lithium battery feeding dust removal system and dust removal method

PendingCN112957989AAvoid congestionImprove uniformityTransportation and packagingMixer accessoriesDust controlProcess engineering

The invention discloses a lithium battery feeding dust removal system and a dust removal method. According to the technical scheme, the system comprises a draught fan; the air outlet end of the draught fan is connected with an outdoor dust remover through a first air path, and the air outlet end of the outdoor dust remover is connected with two external first-party dust removers through a second air path; a first branch is fixedly communicated with the second air path, a plurality of second branches are communicated with the first branch, the plurality of second branches are respectively connected to the top of a first feeding station, and the discharge ends of the plurality of first feeding stations are respectively connected with a first metering bin and a first main material bin through third branches, wherein one external first-party dust remover is connected with a first high-pressure fan through a fourth branch; according to the lithium battery feeding dust removal system, the raw materials can be prevented from being blocked when being mixed, the feeding uniformity in the lithium battery production process can be improved, and the influence on the production progress can be avoided.

Owner:WUXI LINGOOD MACHINERY TECH

Self-propelled trolley lifting appliance with auxiliary chain mechanism

The invention relates to a self-propelled trolley lifting appliance with an auxiliary chain mechanism. A self-propelled trolley rail is provided with a straight segment and a gradient segment. A self-propelled trolley walking wheel is arranged on a self-propelled trolley lifting appliance body and matched with the self-propelled trolley rail. Auxiliary chain mounting frames are fixed to a gradient inlet and a gradient outlet of the self-propelled trolley rail respectively. An auxiliary chain drive chain wheel is arranged on the auxiliary chain mounting frame at the gradient inlet of the self-propelled trolley rail, and an auxiliary chain tensioning chain wheel is arranged on the auxiliary chain mounting frame at the gradient outlet of the self-propelled trolley rail. A chain push rail is close to the self-propelled trolley rail. Chain push heads and retaining push heads are arranged on the chain push rail and a chain push return rail and are matched with the self-propelled trolley lifting appliance body. The self-propelled trolley lifting appliance goes downhill smoothly and goes uphill easily.

Owner:MIRACLE AUTOMATION ENG CO LTD

Comprehensive inspection tool for simulating component assembly position relation structure

ActiveCN103148782BShorten detection timeReduce testing costsMechanical measuring arrangementsEngineeringMechanical engineering

The invention relates to a comprehensive inspection tool for simulating a component assembly position relation structure. The comprehensive inspection tool comprises a base, wherein an inspection tool body is arranged above the base, a large location pin hole is formed in the middle of the inspection tool body, a large location pin is arranged in the large location pin hole, four fixed location pin holes are formed around the large location pin, fixed location pins are arranged in the fixed location pin holes, a movable location pin hole is formed in each corner of the inspection tool body, and a movable location pin is arranged in each movable location pin hole. According to the comprehensive inspection tool, the three-coordinate detection time is shortened, the three-coordinate detection cost is lowered, and the production progress is prevented from being influenced.

Owner:鹰普机械(宜兴)有限公司

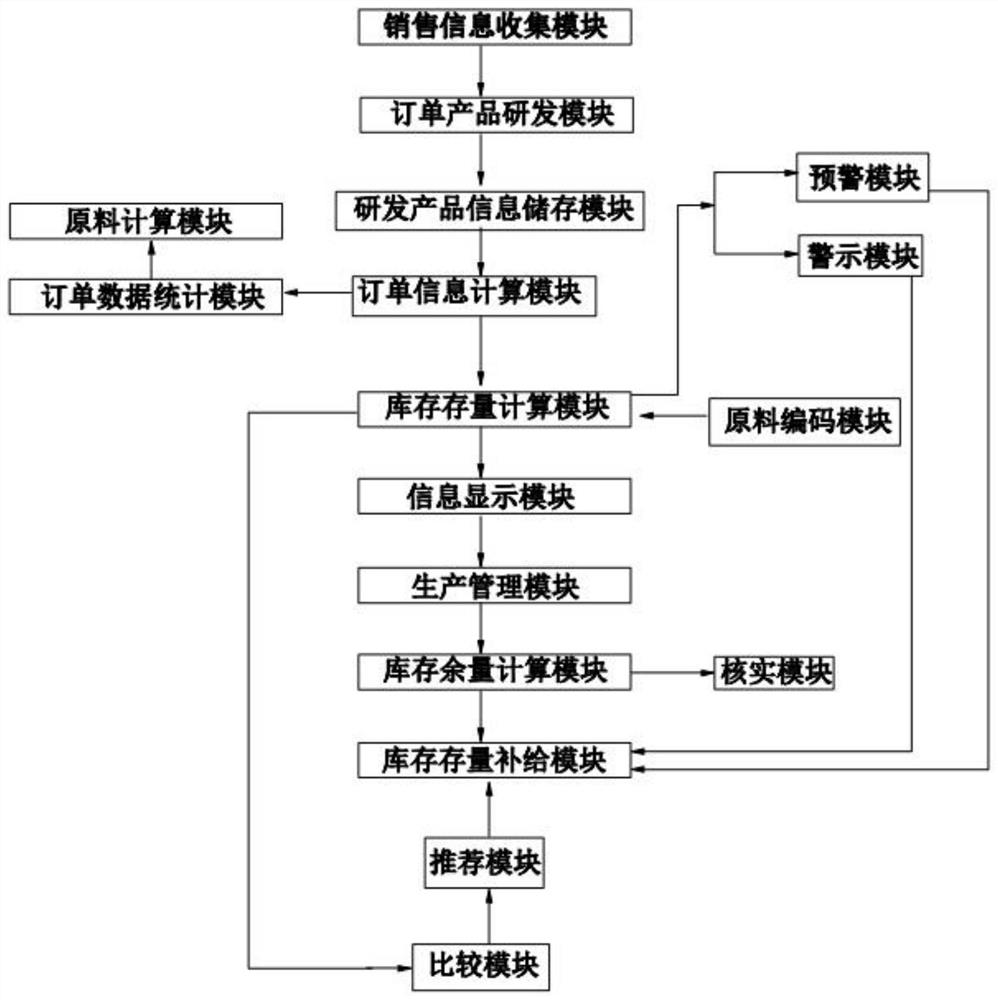

Polyester fiber dyeing process dyestuff consumption supervision software product and software method

PendingCN112070445AKnow the inventory situation in real timeReduce backlogDigital data information retrievalLogisticsPolyesterFiber

The invention relates to the technical field of polyester fiber dyestuff supervision, in particular to a polyester fiber dyeing process dyestuff consumption supervision software product and a softwaremethod, the software product comprise a sales information collection module, an order product research and development module, a research and development product information storage module, an orderinformation calculation module, an inventory calculation module and an information display module, and a production management module, an inventory allowance calculation module and an inventory replenishment module. The software product can update warehouse-out and warehouse-in conditions of the dyestuff at any time, analyze expected demand of the dyestuff, effectively avoid influence on production schedule caused by inventory overstock and untimely purchase of the dyestuff due to excessive purchase of the dye materials, and avoid whether safe stock can be maintained in production or not, so as to discover insufficient supply of materials in scheduling, purchase the materials in real time, and improve production efficiency. Meanwhile, enterprise research and development production automation is achieved, all departments of an enterprise are closely matched, and enterprise production efficiency is improved.

Owner:QINGDAO UNIV

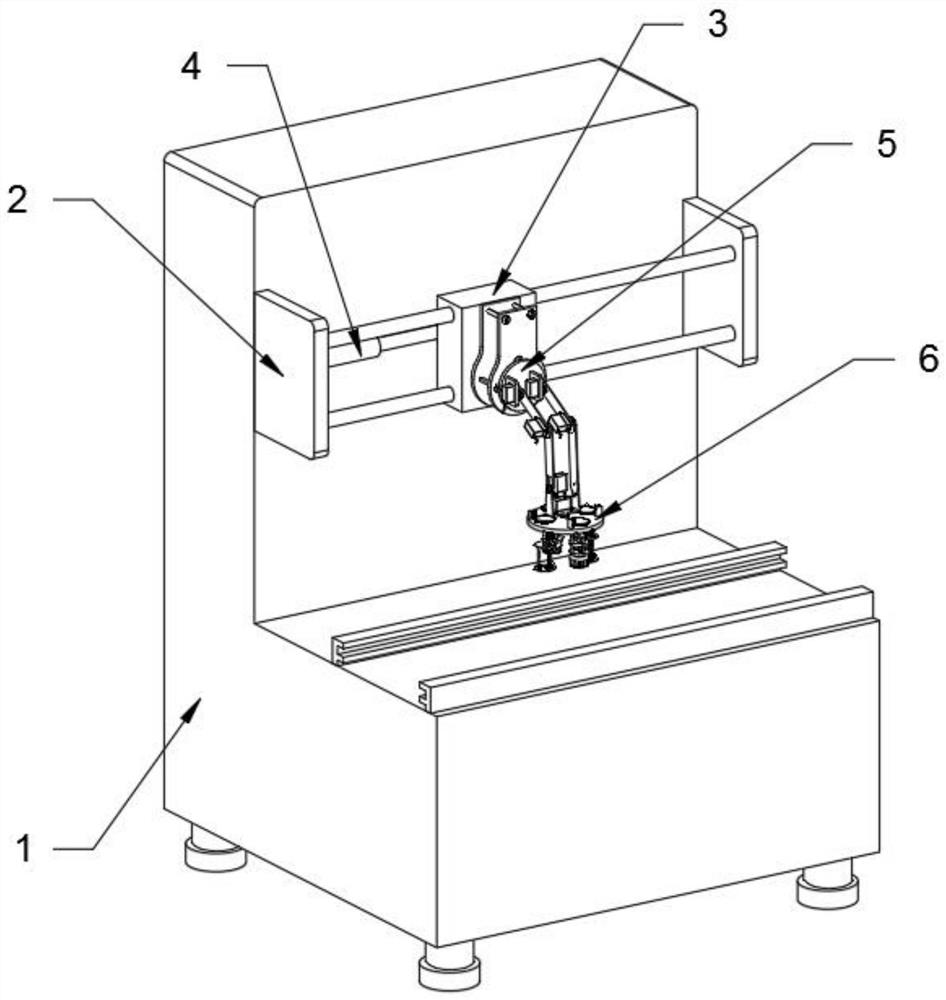

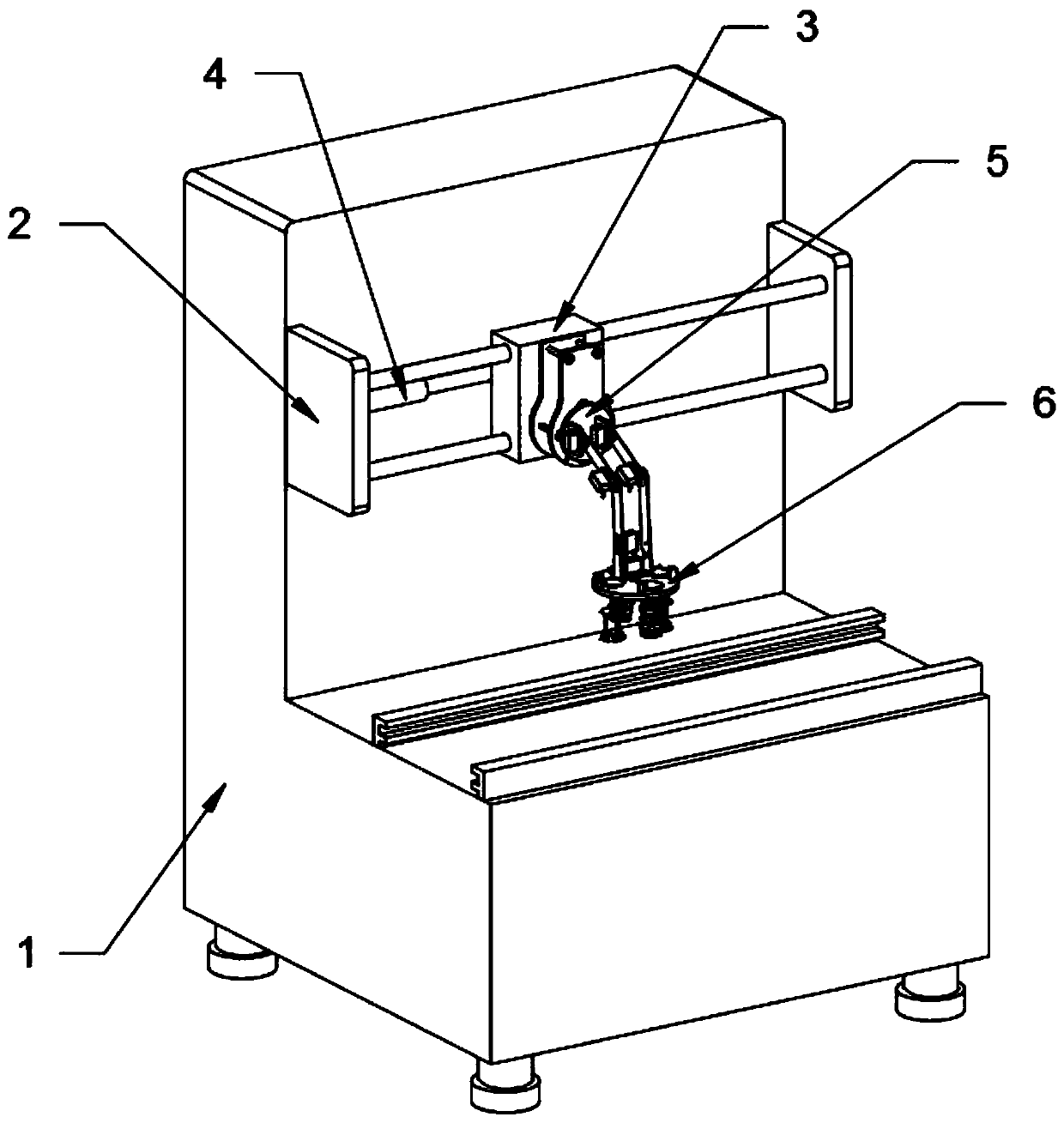

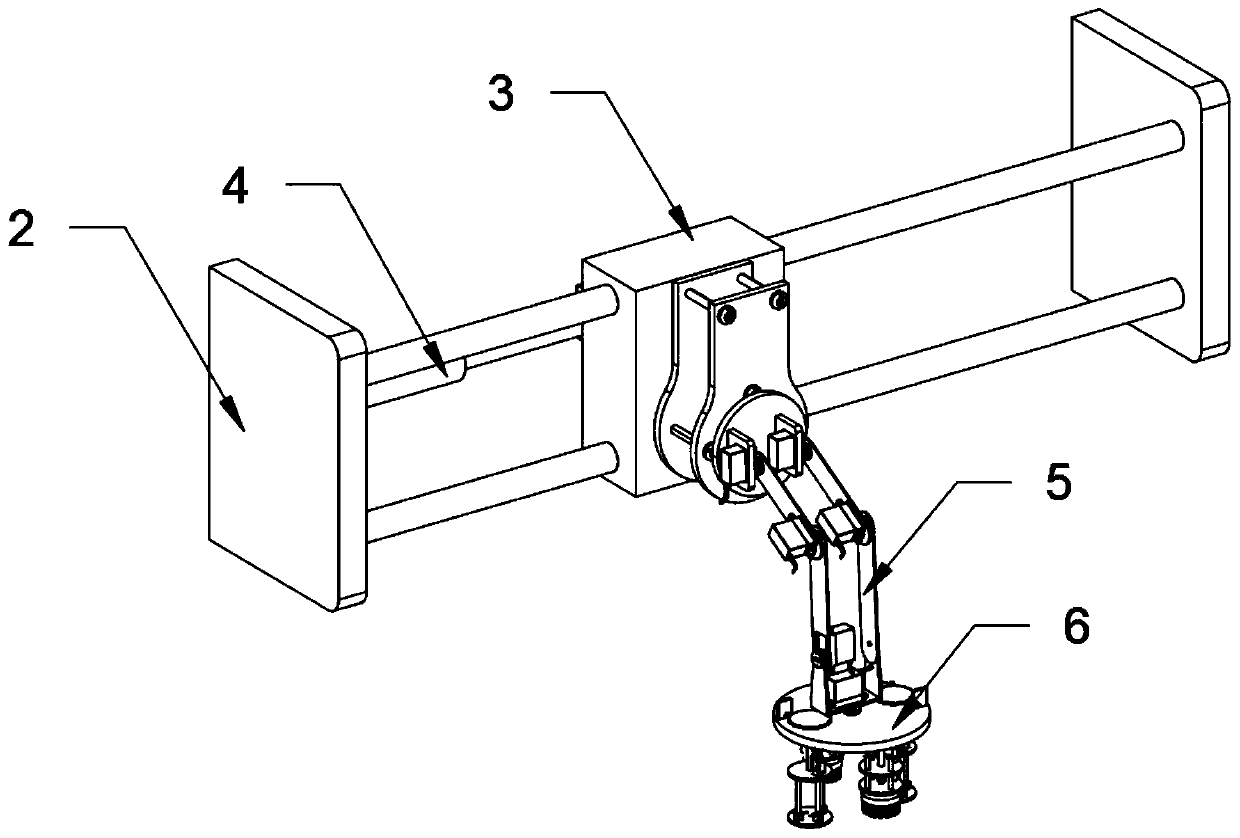

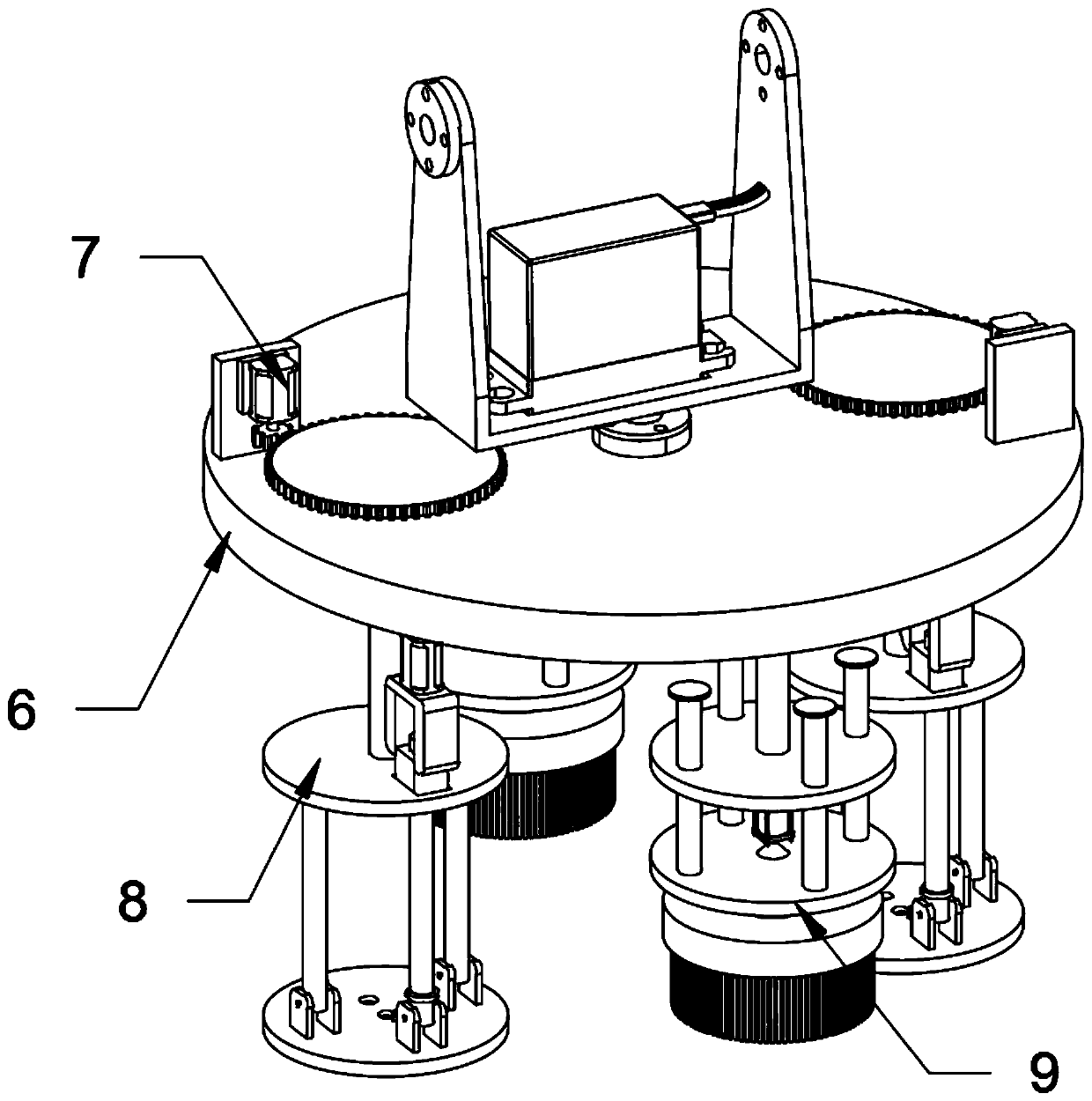

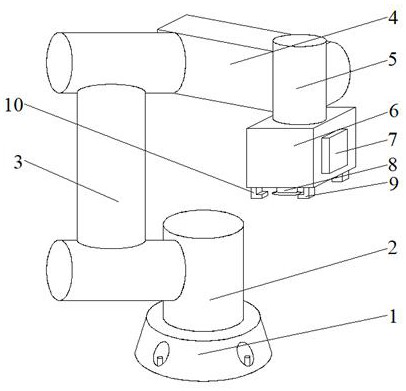

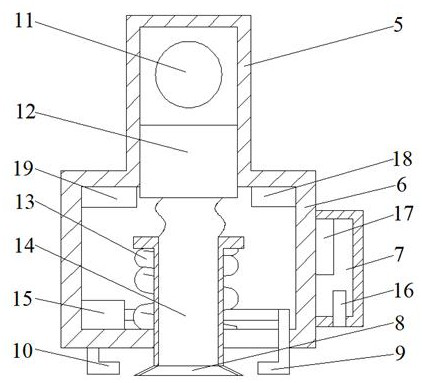

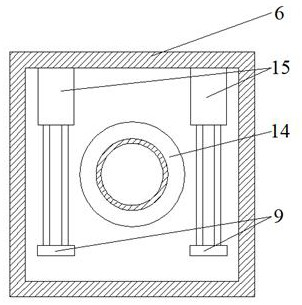

Artificial intelligence robot mounting device

InactiveCN112338949AExpand the scope of workIncrease flexibilityGripping headsArmsElectrical and Electronics engineeringMechanical engineering

The invention discloses an artificial intelligence robot mounting device. The artificial intelligence robot mounting device comprises a base, a rotary base, a supporting arm, a cross beam, an angle adjusting module, a main body, a positioning device, a suction cup, movable clamping blocks, fixed clamping blocks, a spring, an air suction pipeline, a camera, a storage module, a processing module anda control module; and the rotary base is arranged at the top end of the base, the supporting arm is arranged on one side of the rotary base, the cross beam is arranged at the top end of the supporting arm, the angle adjusting module is arranged at one end of the cross beam, the body is arranged at the bottom end of the angle adjusting module, the suction cup, the movable clamping blocks and the fixed clamping blocks are arranged at the bottom end of the body, the air suction pipeline is arranged at the top end of the suction cup, and the spring is arranged outside the air suction pipeline. According to the artificial intelligence robot mounting device, when the suction cup cannot suck an object, the object can be grabbed through the movable clamping blocks and the fixed clamping blocks, so that the working range of a robot is expanded; and the angle adjusting module is designed, the angle needed by equipment installation is conveniently adjusted, and the flexibility of the robot is improved.

Owner:CHANGCHUN GUANGHUA UNIV

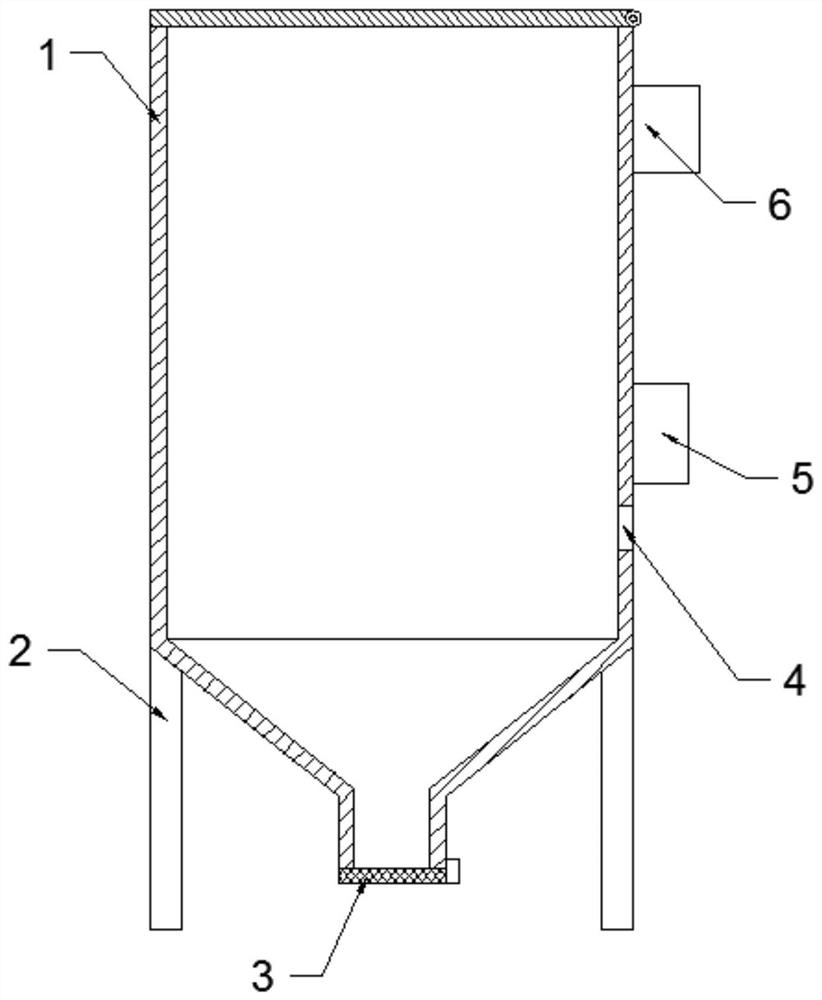

Automatic detection device for material shortage of hopper

The invention discloses a hopper material shortage automatic detection device in the technical field of automatic detection, the hopper material shortage automatic detection device comprises a hopper and an alarm system, the hopper is provided with a detection hole, the distance between the detection hole and the bottom of the hopper is 3-10cm, the alarm system comprises a controller and a sensor, the sensor is arranged in the detection hole, and the detection surface of the sensor faces the interior of the hopper; the controller is fixedly connected to the hopper, and the sensor is in electric signal connection with the controller; the controller is connected with an alarm through electric signals, and the alarm is fixedly connected to the hopper. According to the scheme, the sensor and the alarm are arranged in the hopper, when raw materials in the hopper are about to be used up, the alarm gives out an alarm, an operator is lifted to add the raw materials, and the situation that the production progress is affected due to material shortage in the equipment running process is avoided.

Owner:遵义群建塑胶制品有限公司

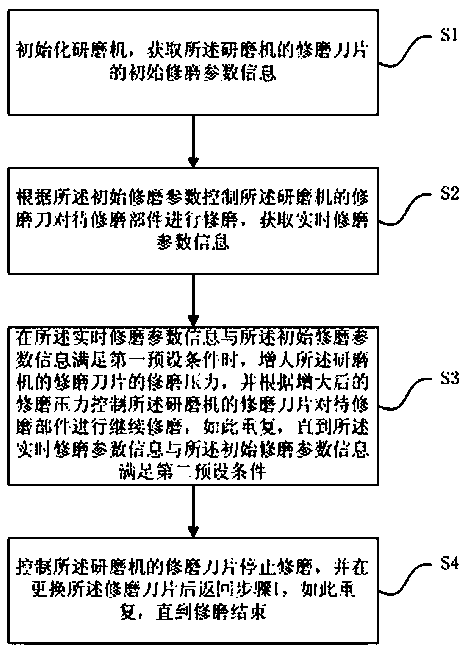

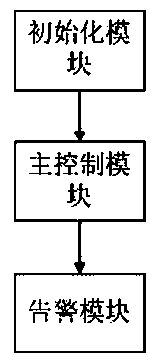

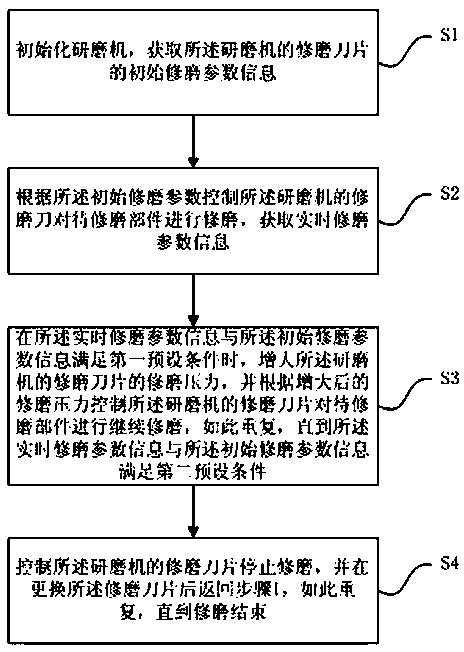

A robot grinding pressure control method, system, storage medium and equipment

Owner:DIGITAL DIE STAMPING TECH WUHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com