Patents

Literature

100results about How to "Realize quality inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beef quality multi-parameter simultaneous detection method by multichannel near-infrared spectroscopy

ActiveCN102519906AInformativeEasy to operateColor/spectral properties measurementsPhysicsWater content

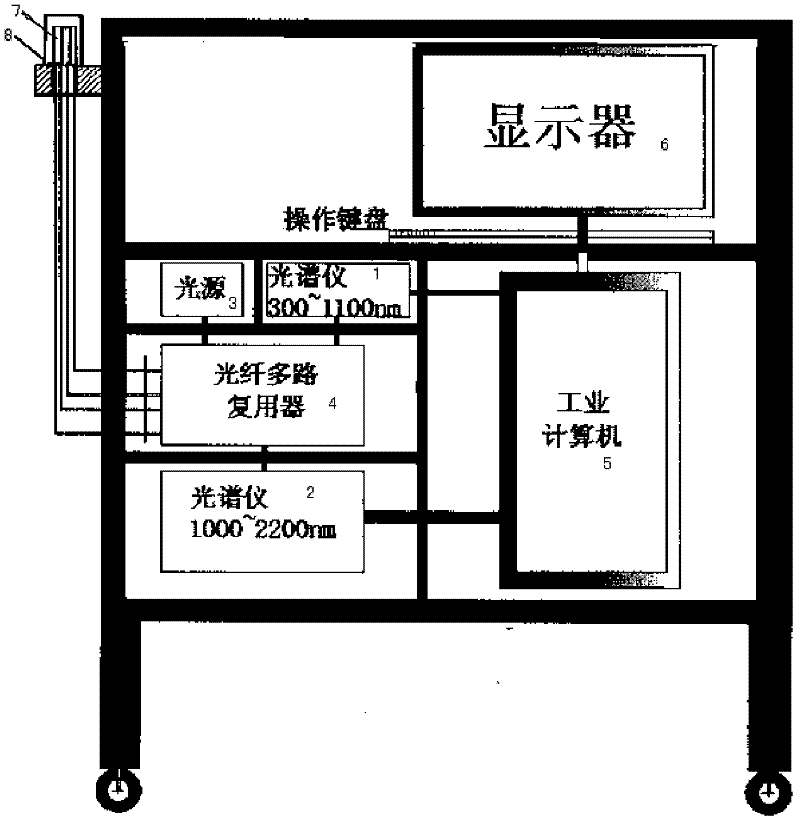

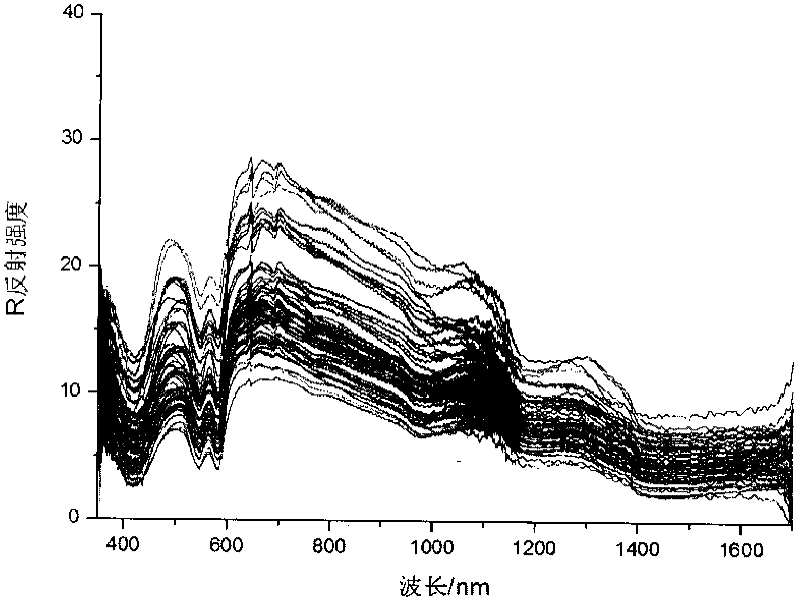

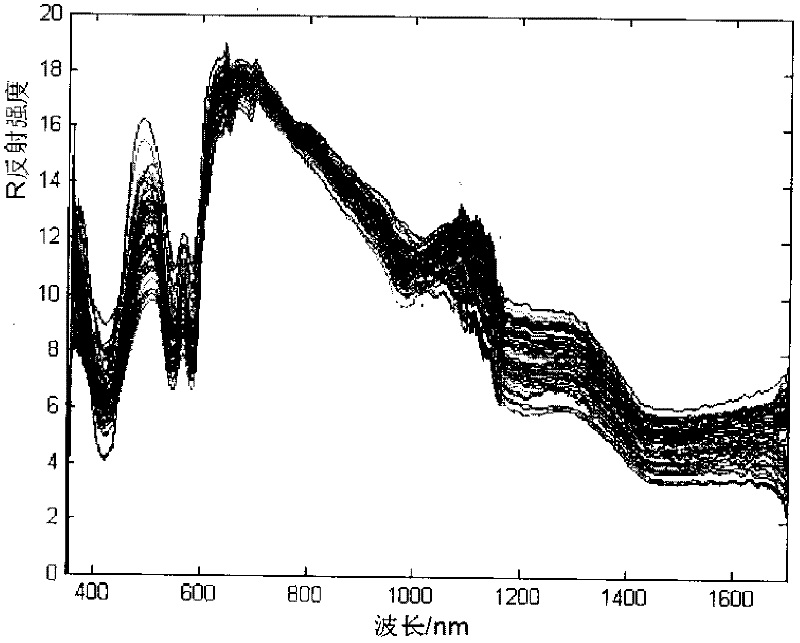

The invention discloses a beef quality multi-parameter simultaneous detection method by multichannel near-infrared spectroscopy, belonging to the rapid nondestructive detection range of beef quality. The method comprises the following steps: first, arranging a spectral detection system comprising an 8-channel fiber multiplexer, two spectrometers with different wavelength ranges and probe units ina movable control cabinet, wherein the 8-channel fiber multiplexer is respectively connected with the spectrometers and the probe units; embedding in a production line technology to carry out on-linedetection to obtain optimum spectra data, wherein the quality detection of carcass and cut meat can be simultaneously satisfied; establishing a calibration prediction model, evaluating model effects by using relative analytical errors, carrying out model analysis on a large number of sample experimental data, respectively establishing prediction models of tenderness and water content to obtain a predicted value of each index, and then plugging the obtained predicted values into a beef multi-parameter comprehensive quality evaluation model which is established based on the detected indexes to obtain a final meat grade. According to the invention, the spectral information in the visible near-infrared band is collected, the information is abundant, the detection indexes have extensibility, and the method can be suitable for the requirement of production line detection.

Owner:CHINA AGRI UNIV

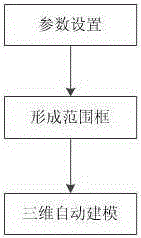

Batch type refined three-dimensional modeling method of building frame model

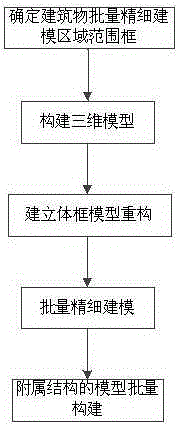

The invention, which belongs to the technical field of model construction, discloses a batch type refined three-dimensional modeling method of a building frame model. The method comprises the following steps: determining a range frame of a batch type refined modeling region of a building; constructing a three-dimensional model; establishing a frame model index; and constructing a model of a batch type refined modeling accessory structure. According to the method, a BSP building model reconstruction method under a DLG building outer contour constraint is put forward; and with the high-plane precision of a DLG, a defect of low precision of a point cloud boundary is overcome, so that strict matching of the main contour of the frame model with the outer contour of the DLG can be realized. On the basis of a one-to-one correspondence relationship among a building DLG base map, a building point type in a range, and a generated model, batch type refined modeling and quality checking of buildings in a large area can be realized and a well-developed production and quality checking working flow can be formed. A model space matching and duplicating method is put forward and base elevation and precise orientation information of the model can be obtained automatically, so that the precise modeling efficiency can be improved.

Owner:星际空间(天津)科技发展有限公司

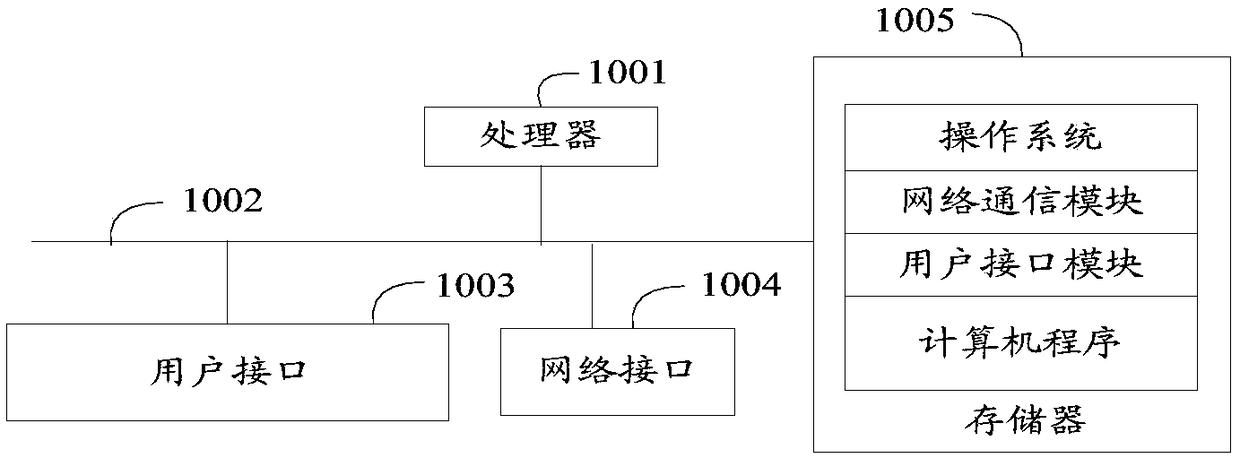

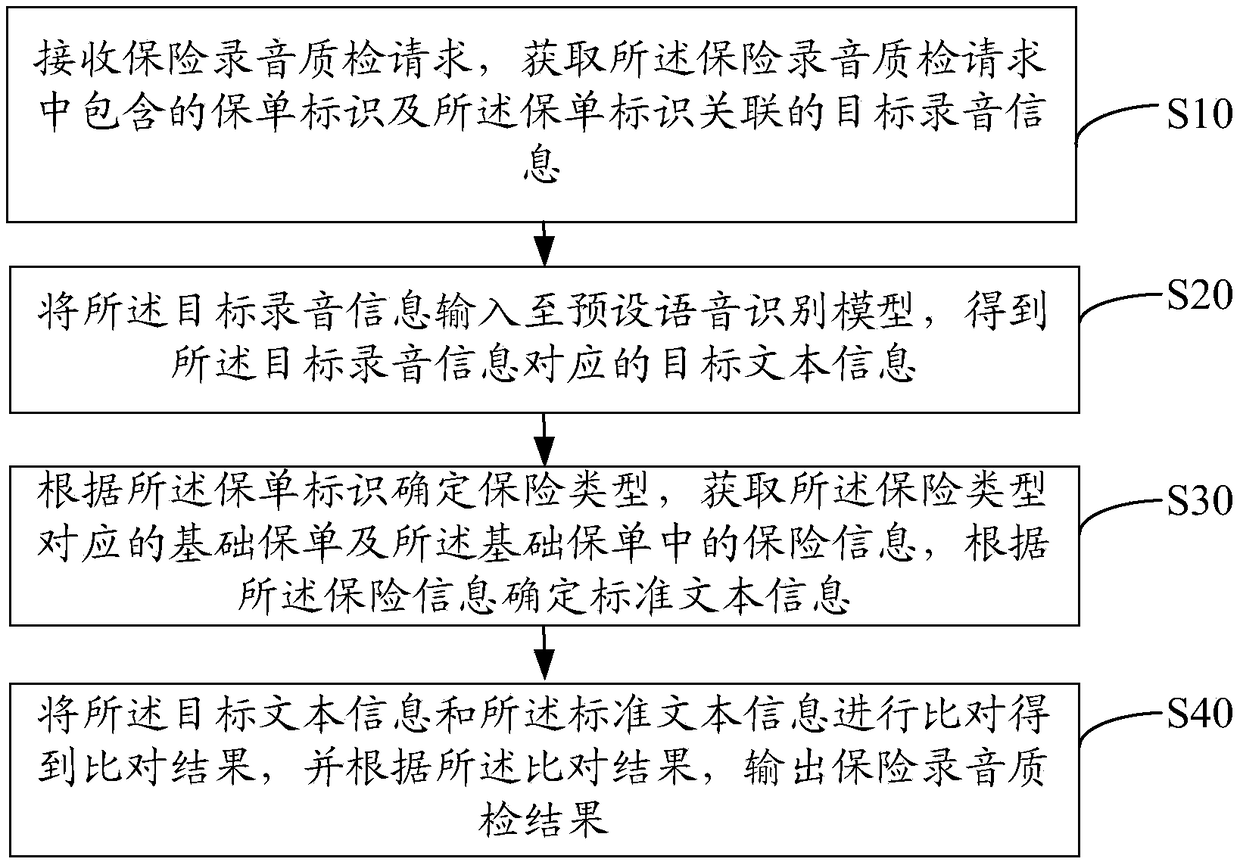

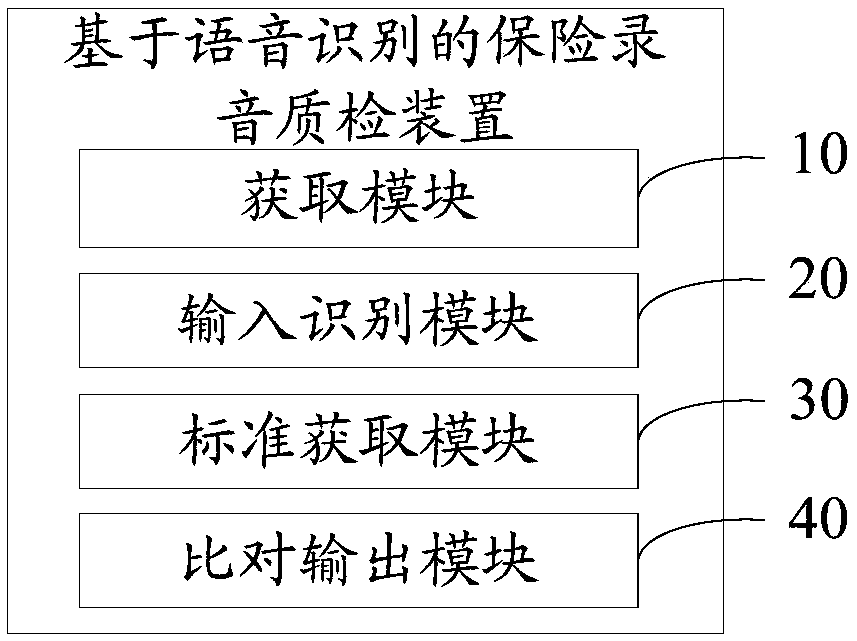

Insurance recording quality inspection method, device and equipment based on voice recognition and medium

ActiveCN109389971AImprove efficiencyImprove accuracyFinanceSemantic analysisTarget textSubvocal recognition

The invention discloses an insurance recording quality inspection method based on voice recognition. The method comprises a step of receiving an insurance recording quality inspection request and obtaining a policy identification included in the insurance recording quality inspection request and target recording information associated with the policy identification, a step of inputting the targetrecording information into a preset voice recognition model to obtain target text information corresponding to the target recording information, a step of determining an insurance type according to the policy identification, obtaining a basic policy corresponding to the insurance type and insurance information in the basic policy and determining standard text information according to the insuranceinformation, and a step of comparing the target text information and the standard text information to obtain a comparison result and outputting an insurance recording quality inspection result according to the comparison result. The invention also discloses an insurance recording quality inspection device and equipment based on voice recognition and medium. The insurance recording quality inspection is efficiently and automatically performed through the voice recognition mode.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

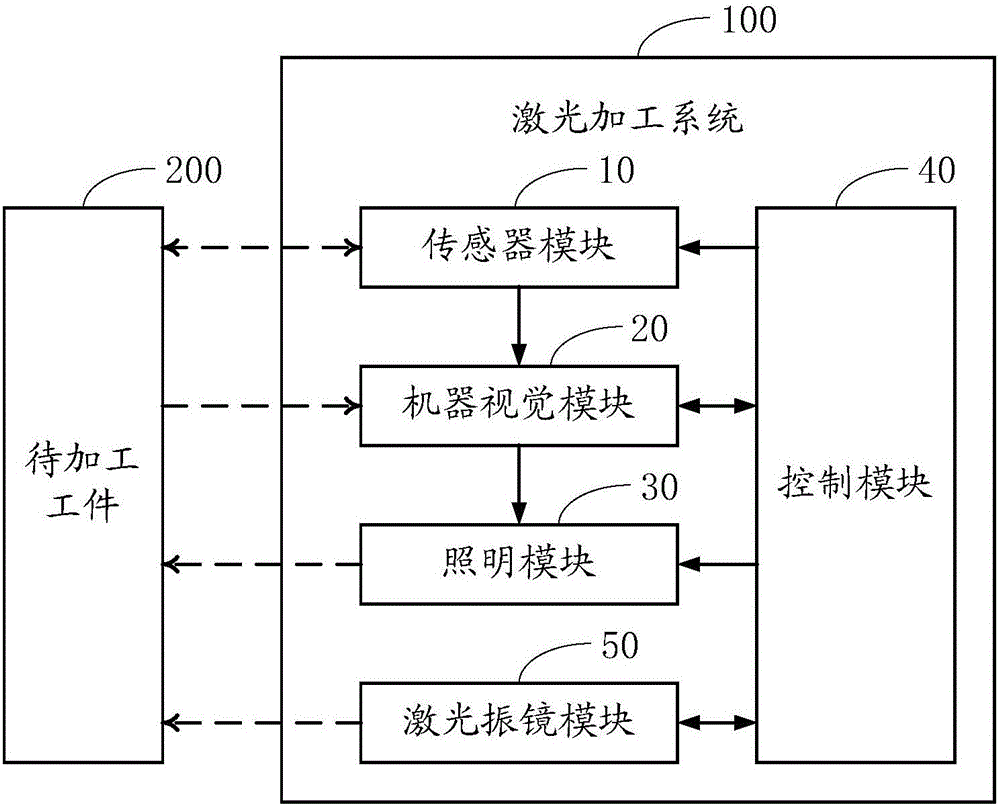

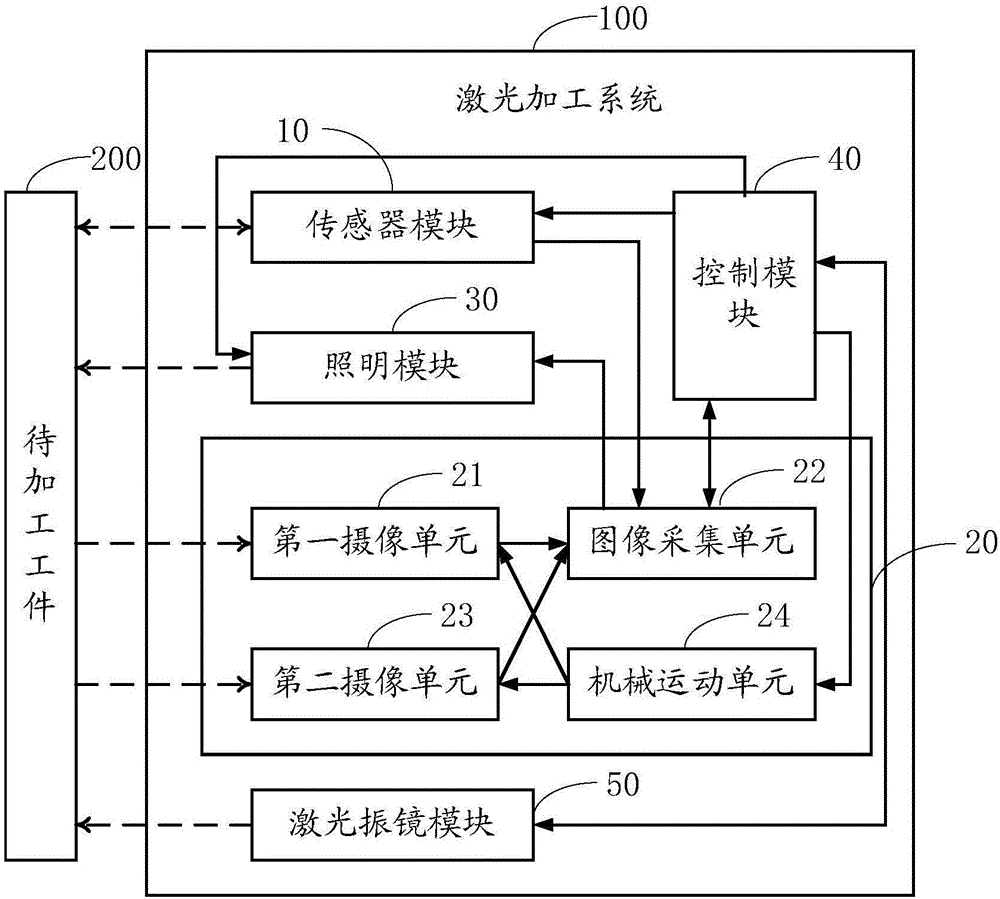

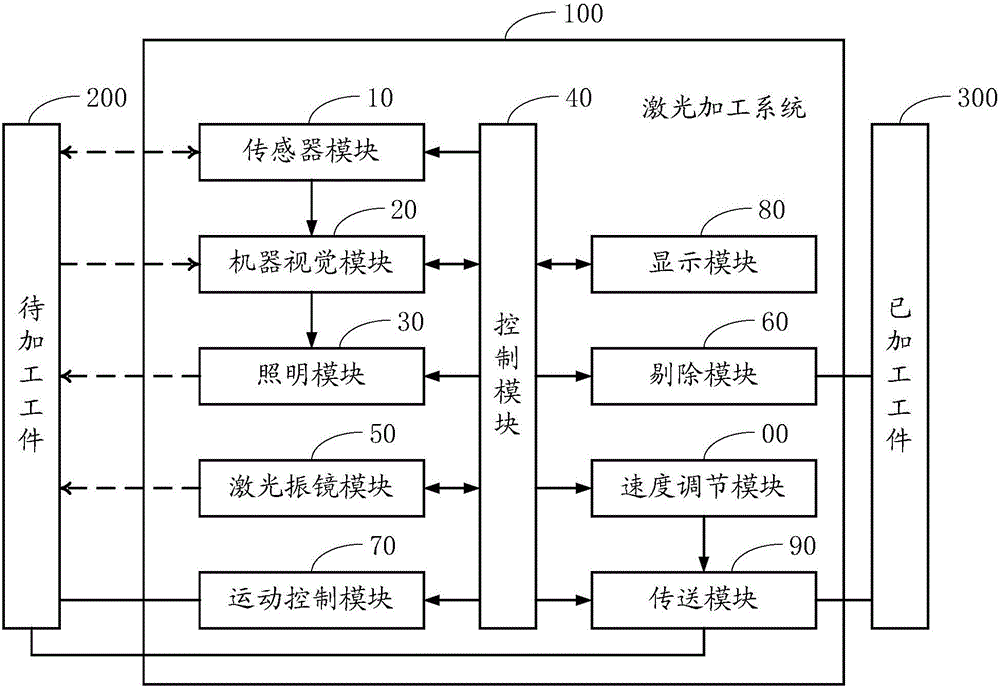

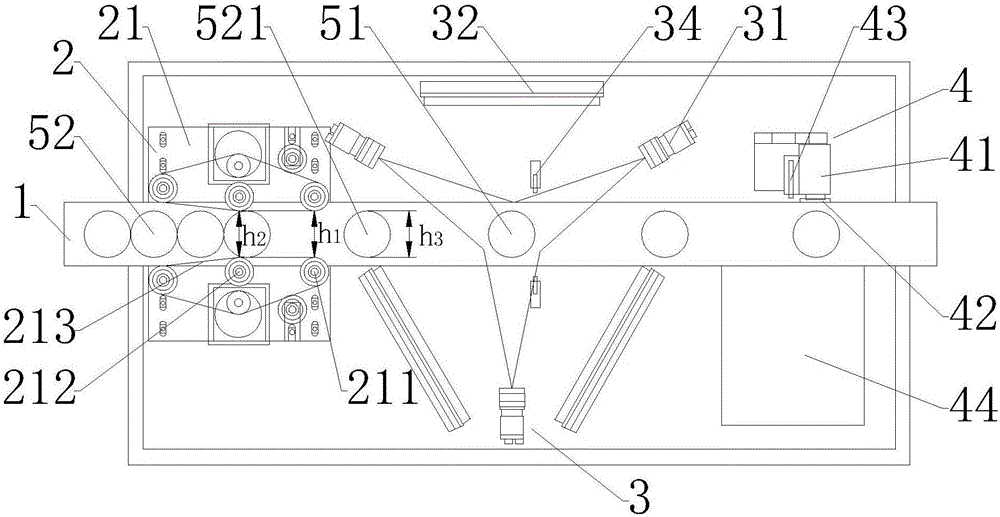

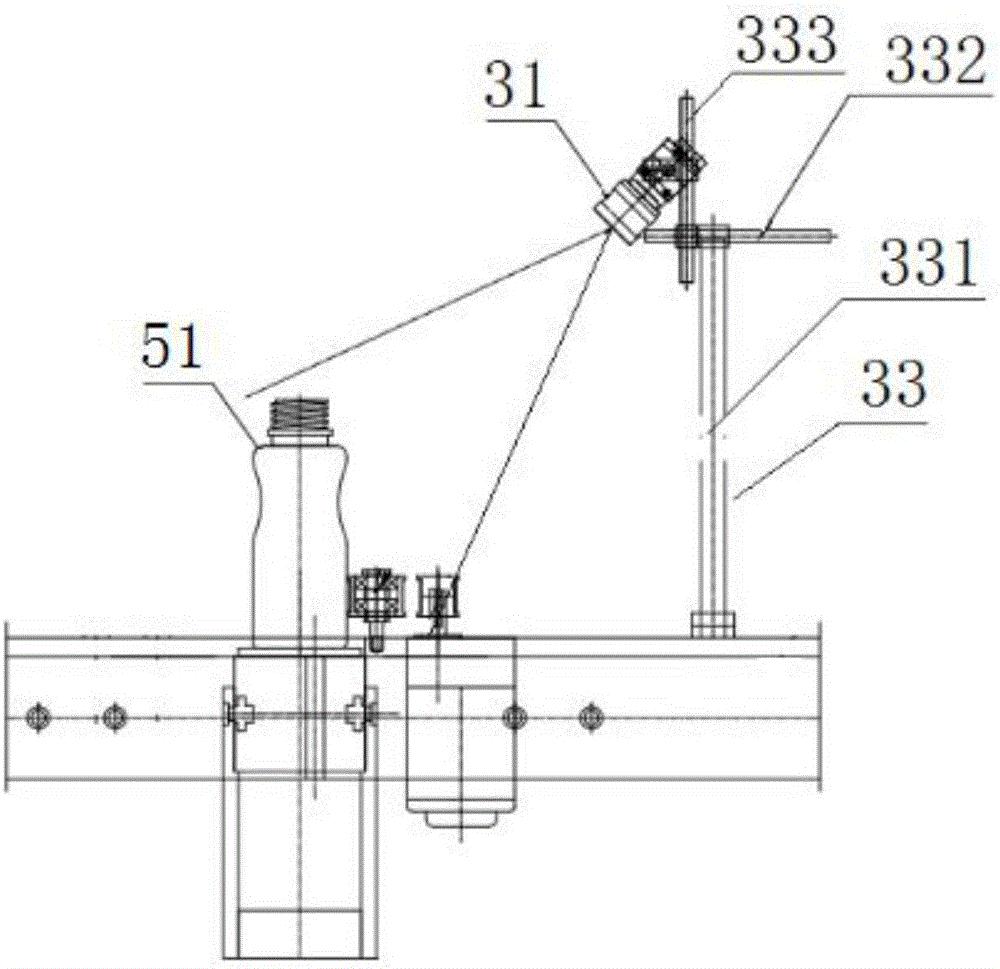

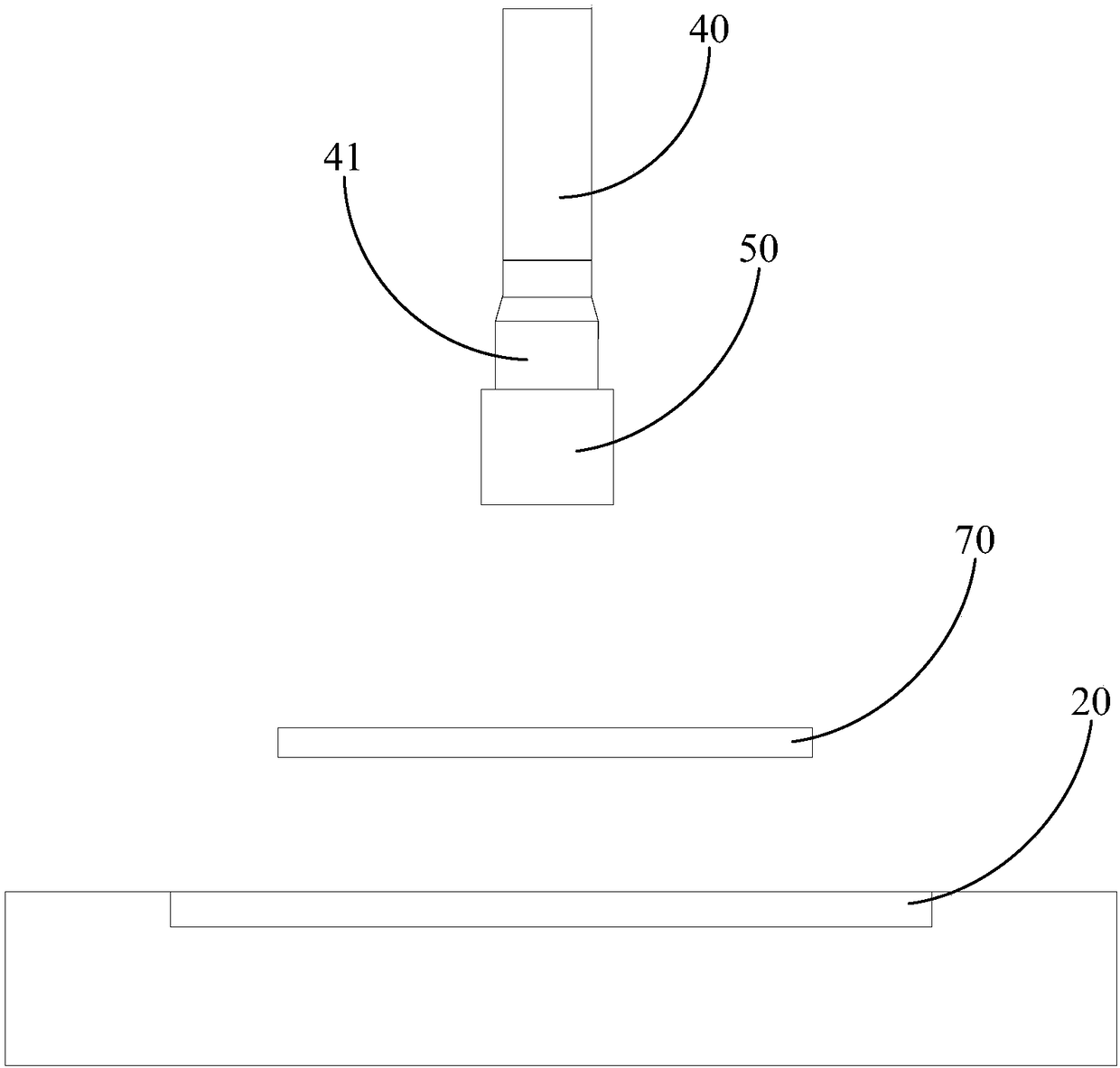

Machine vision-based laser processing system and machine vision-based laser processing method

ActiveCN106680286ARealize quality inspectionImprove quality and efficiencyImage analysisOptically investigating flaws/contaminationMachine visionGalvanometer

The embodiment of the invention provides a machine vision-based laser processing system and a machine vision-based laser processing method. The machine vision-based laser processing system comprises a sensor module, a machine vision module, an illumination module, a control module and a laser galvanometer module. According to the machine vision-based laser processing system provided by the embodiment of the invention, image data of a to-be-processed workpiece and image data of a processed workpiece can be respectively obtained through machine vision, and the image data can be sent to the control module for analytical processing, so that existence detection and location on the to-be-processed workpiece can be completed online, and the laser galvanometer module is enabled to quickly move to a designated position for laser processing; meanwhile, quality detection on the processed workpiece can be realized, the location accuracy is high, the speed is fast, and the processing quality and the processing efficiency of laser processing products can be effectively increased.

Owner:深圳市佳康捷科技有限公司

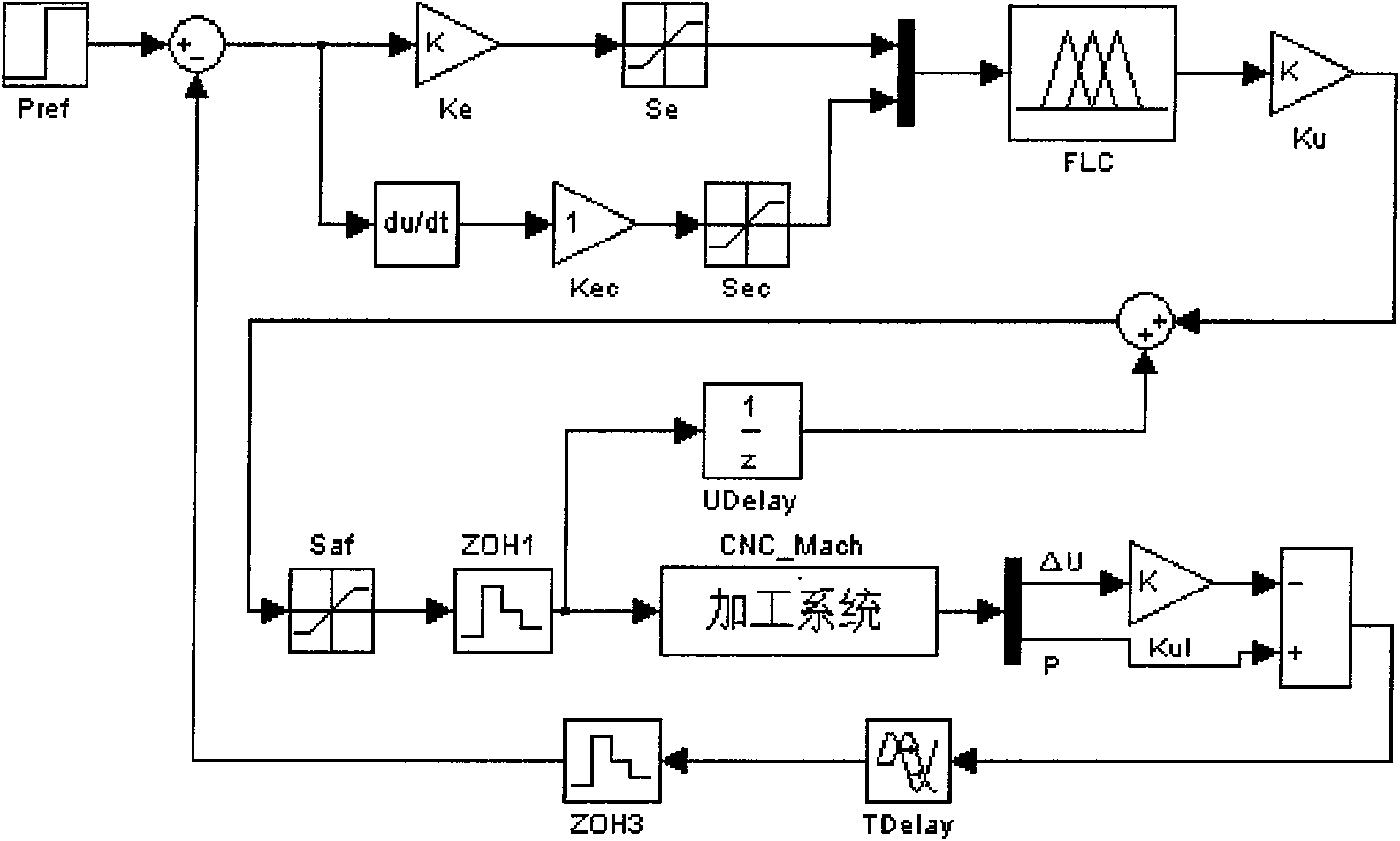

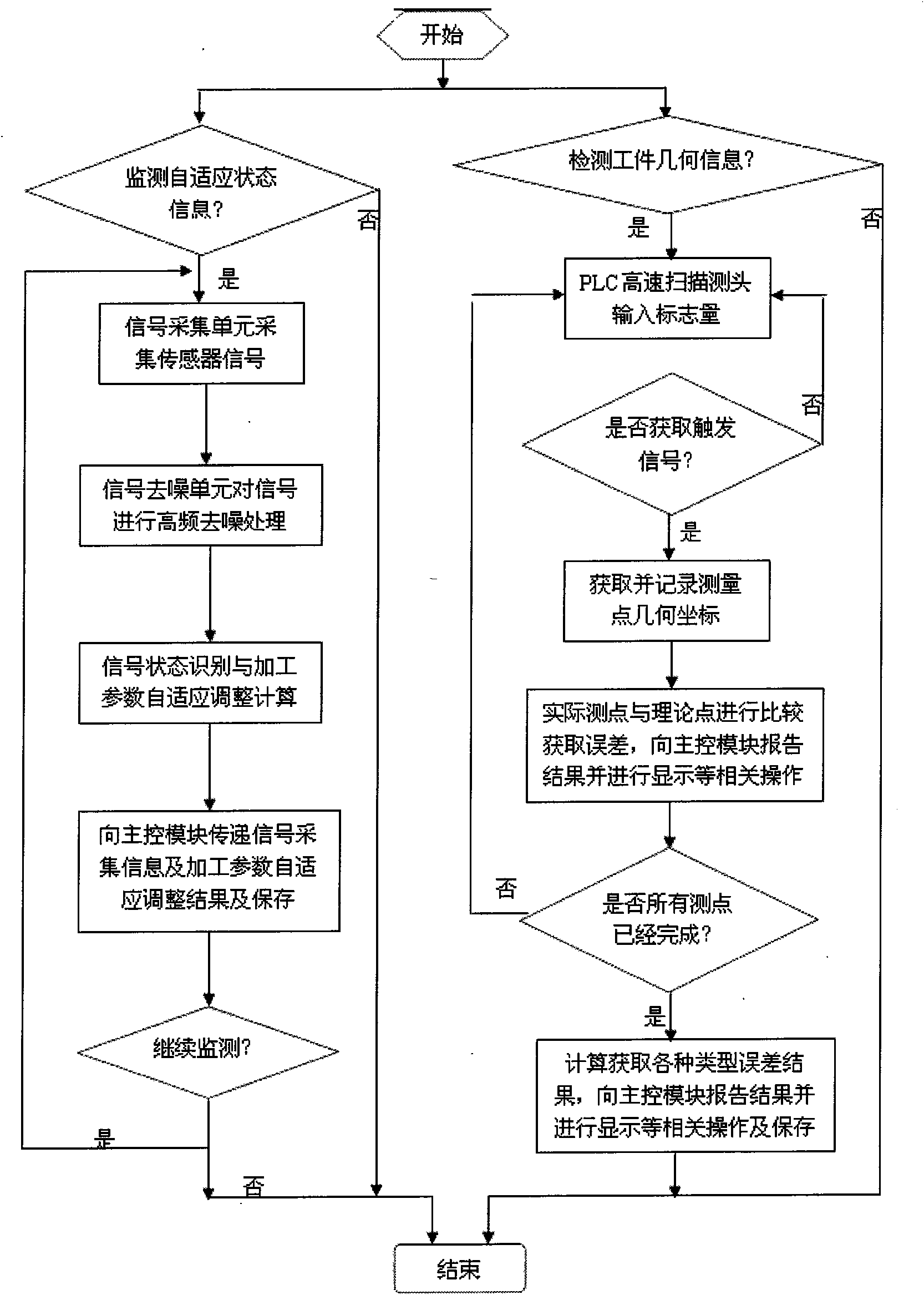

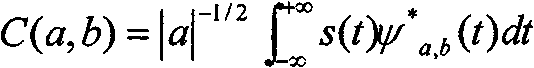

Monitoring method with processing self-adapting function and on-machine quality detection

InactiveCN101571712ARealize quality inspectionReduce the number of card loadingProgramme controlComputer controlPower sensorClosed loop feedback

The invention belongs to the technical field of numerical control of electromechanical integration, and relates to a monitoring method with processing self-adapting function and on-machine quality detection. The method comprises the following steps: (1) acquiring the machine tool status signals through a power sensor and a voltage sensor; (2) carrying out the high frequency signal denoising treatment of the acquired data through a wavelet method to obtain the treated power and voltage signals; (3) taking the variable delta af of feed speed af as a systematic adjustment variable and realizing the closed loop feedback fuzzy control of the machining process; and (4) when the procedure of needing checking the geometric information of a workpiece is completed, acquiring the measuring point information, evaluating the error of the machined workpiece, taking the error evaluation data as the information source base of adjustments in the subsequent procedures, and carrying out the self-adapting optimization adjustment of the machining process. The method realizes the self optimization of the numerical program; and the numerical control system can acquire the shape and position error information of the workpiece in time, thereby facilitating the parameter adjustment of the subsequent procedures.

Owner:TIANJIN UNIV

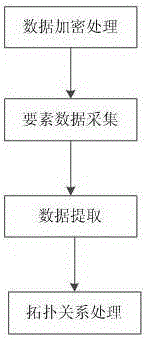

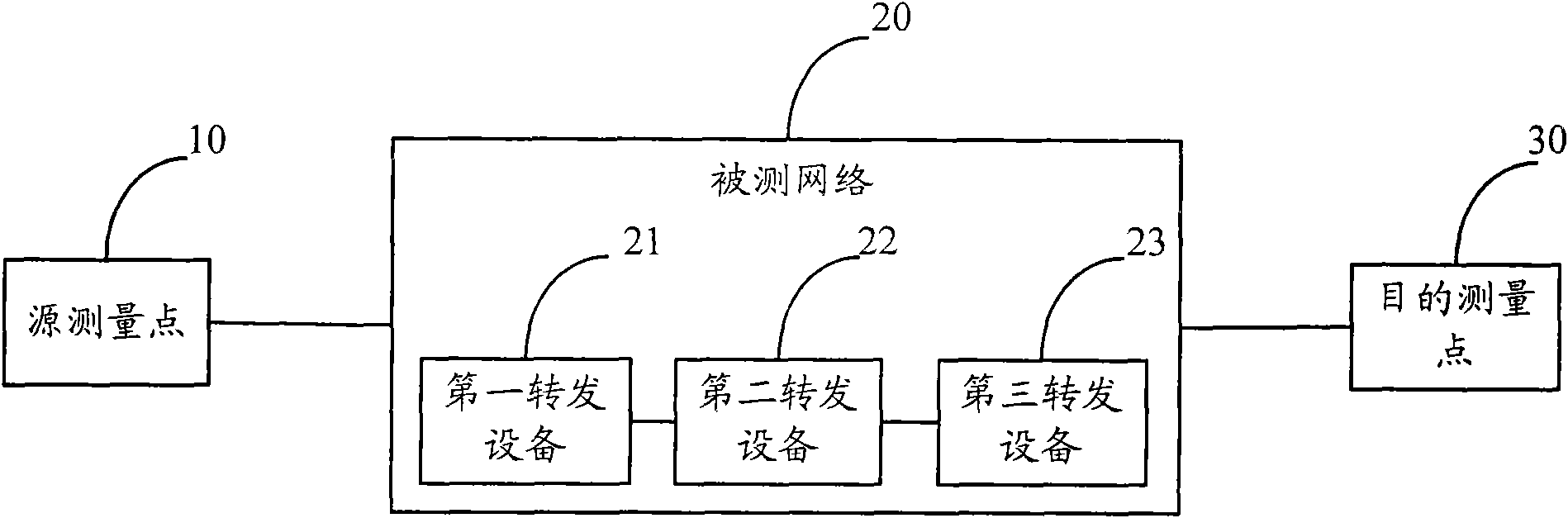

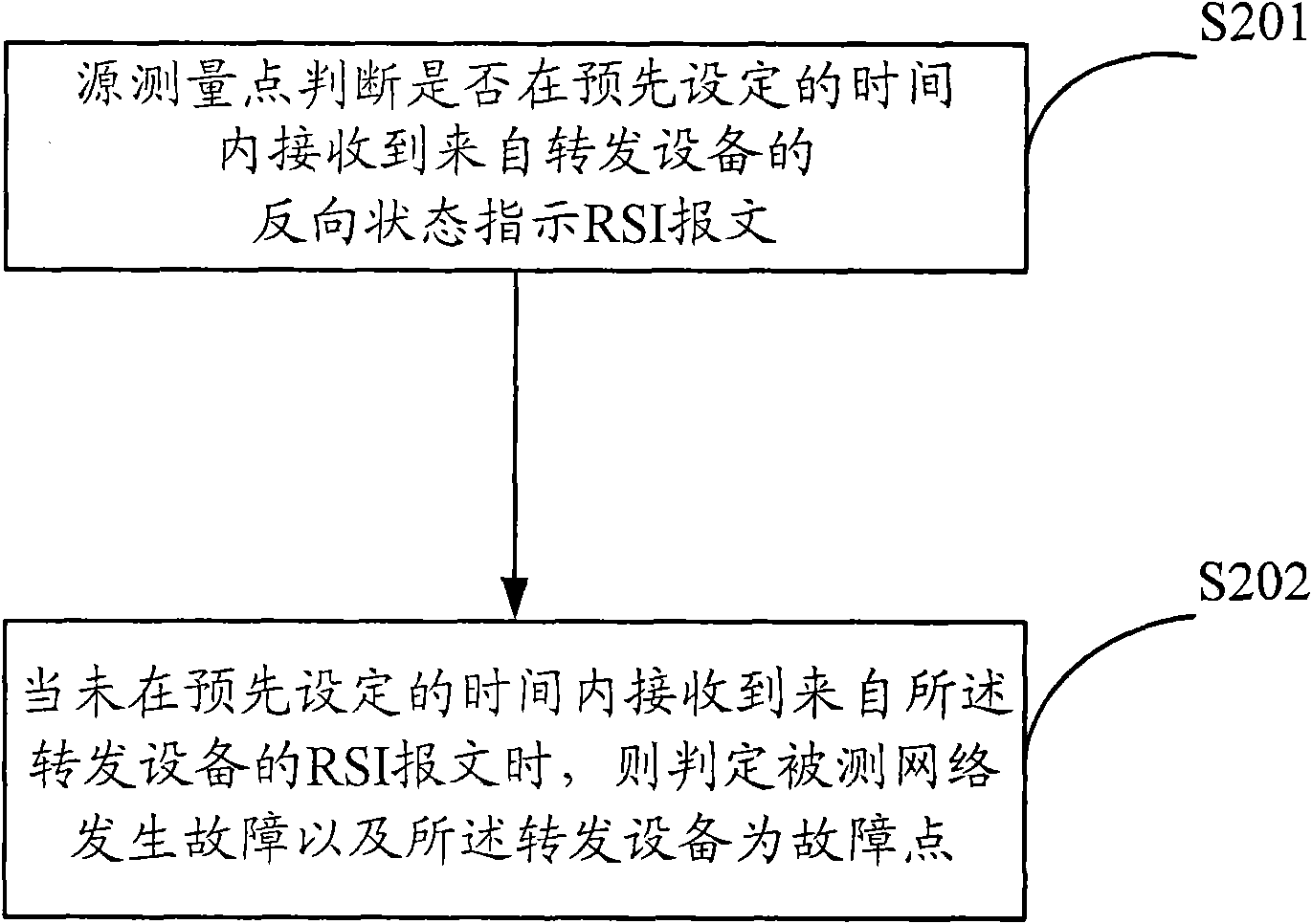

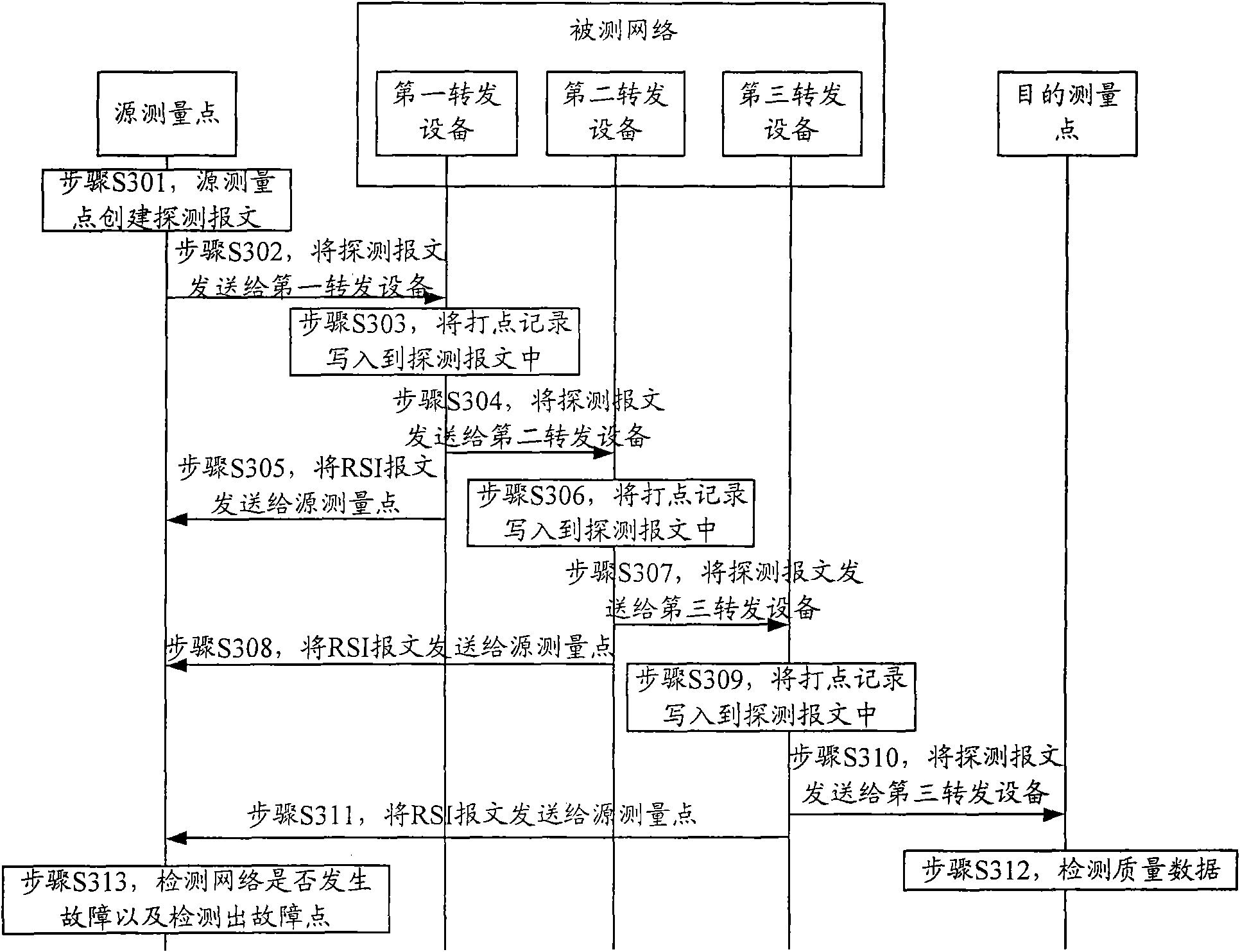

Method, system and device for detecting and positioning network failure

InactiveCN101640617ARealize quality inspectionData switching networksWireless communicationReal-time computing

The embodiment of the invention discloses a method, a system and a device for detecting and positioning a network failure. The method comprises the following steps that: a source measuring point determines whether a reverse status indicating RSI message from forwarding equipment is received within the preset time or not; when the RSI message from the forwarding equipment within the preset time isnot received, the source measuring point determines that a detected network generates the failure and the forwarding equipment is a failure point. The embodiment of the method can realize quality detection of end-to-end of a network and network piecewise links, detect whether the network generates the failure or not, and position the failure point when the network generates the failure.

Owner:HUAWEI TECH CO LTD

Machine vision-based 3D printing forming quality detection system and method

PendingCN107941808AQuick checkImprove compatibilityOptically investigating flaws/contaminationThe InternetEngineering

The invention discloses a machine vision-based 3D printing forming quality detection system and method. A rotary platform is mounted on a workpiece placement platform, a 3D printed product is placed on the rotary platform, an image acquisition device is connected to an upper computer through a communication device, a backlight is arranged below the workpiece placement platform, the rotary platformcomprises an upper plate and a lower plate parallel to the upper plate, the bottom end of a center shaft is fixedly connected to the center of the lower plate, the center shaft is sleeved by a surface bearing, the surface bearing is sandwiched between the upper and lower plates, and multiple rolling parts are uniformly installed between the edges of the upper and lower plates in intervals. The method comprises acquiring surface images of a 3D printed finished product through an area-array camera, inputting an image capture card into the upper computer, carrying out image pre-processing, and analyzing the images to detect contour defects or surface defects. The system and method can realize fast detection of the quality of the 3D printed finished product, have a high detection precision and improve the qualified rate of the workpiece.

Owner:CHINA JILIANG UNIV

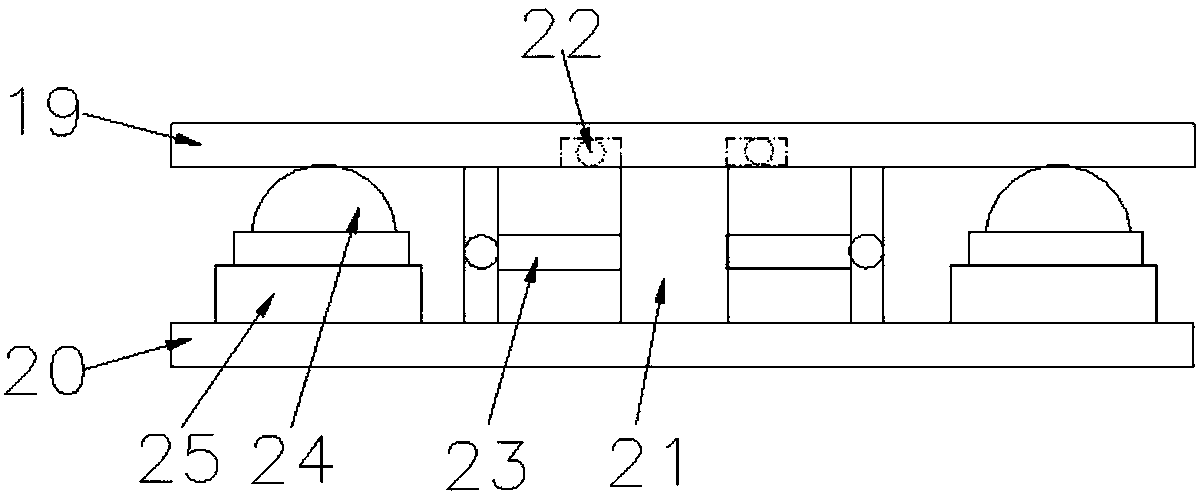

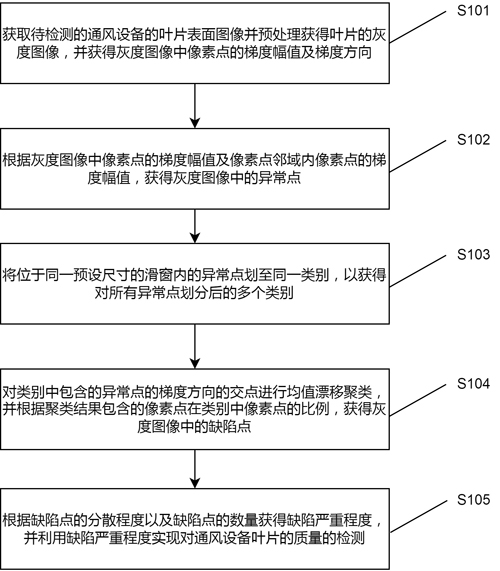

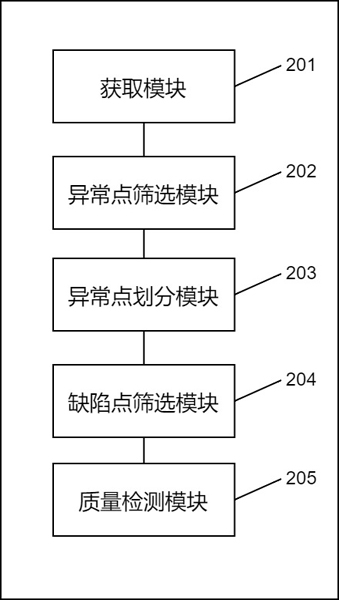

Ventilation equipment blade quality detection method, device and system based on image processing

ActiveCN114359274ARealize quality inspectionRealize detectionImage analysisCharacter and pattern recognitionImaging processingMedicine

The invention discloses a ventilation equipment blade quality detection method, device and system based on image processing, and relates to the field of artificial intelligence. The method mainly comprises the steps that a blade surface image of ventilation equipment to be detected is acquired and preprocessed to obtain a gray level image of a blade; obtaining an abnormal point in the gray level image according to the gradient magnitude of the pixel point in the gray level image and the gradient magnitude of the pixel point in the pixel point neighborhood; dividing the abnormal points in the sliding windows with the same preset size into the same category so as to obtain a plurality of categories after dividing all the abnormal points; carrying out mean shift clustering on intersection points of the gradient directions of the abnormal points contained in the category, and obtaining defect points in the grayscale image according to the proportion of pixel points contained in a clustering result in pixel points in the category; and obtaining the defect severity according to the dispersion degree of the defect points and the number of the defect points, and detecting the quality of the ventilation equipment blade by using the defect severity.

Owner:布鲁奇维尔通风设备启东有限公司

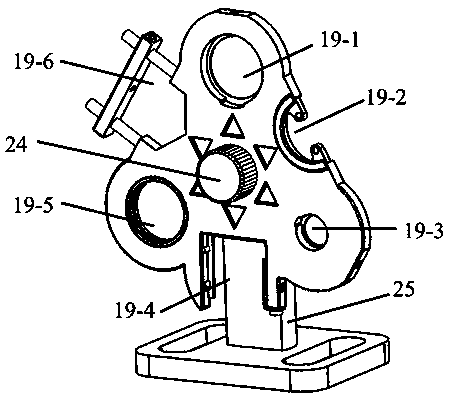

Circumferential wave guide energy converter with adjustable incident angle

ActiveCN101625337ARealize quality inspectionSolve the technical problems of comprehensive inspectionAnalysing solids using sonic/ultrasonic/infrasonic wavesEnergy converterPower station

The invention discloses a circumferential wave guide energy converter with an adjustable incident angle for realizing ultrasonic testing of the whole tube of the each small diameter tube of various types of power station boilers on a smaller contact surface. A piezoelectric wafer of the energy converter is stuck and fixed on a slide block; the slide block can move along the arc surface of a transparent wedge block; the transparent wedge block matches with a match block, so that ultrasonic wave rectilinearly propagates in a organic glass before propagating into a tube to be tested, and incidence point thereof is just at the symmetric point of the arc inner surface of the match block. By adjusting the incident angle of the ultrasonic wave, the incident ultrasonic wave is refracted on the outer interface of the small tube to be tested, regular polygonal ultrasonic wave preparation channel is formed in a metal medium, and under the state of no defect, the ultrasonic wave returns to the energy converter at the incidence point by the means that the perimeter of the regular polygon is taken as a single beam path, and is received. The energy converter solves the technical problem that a heating surface tube panel can not be completely tested with the ultrasonic technology on the spot.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

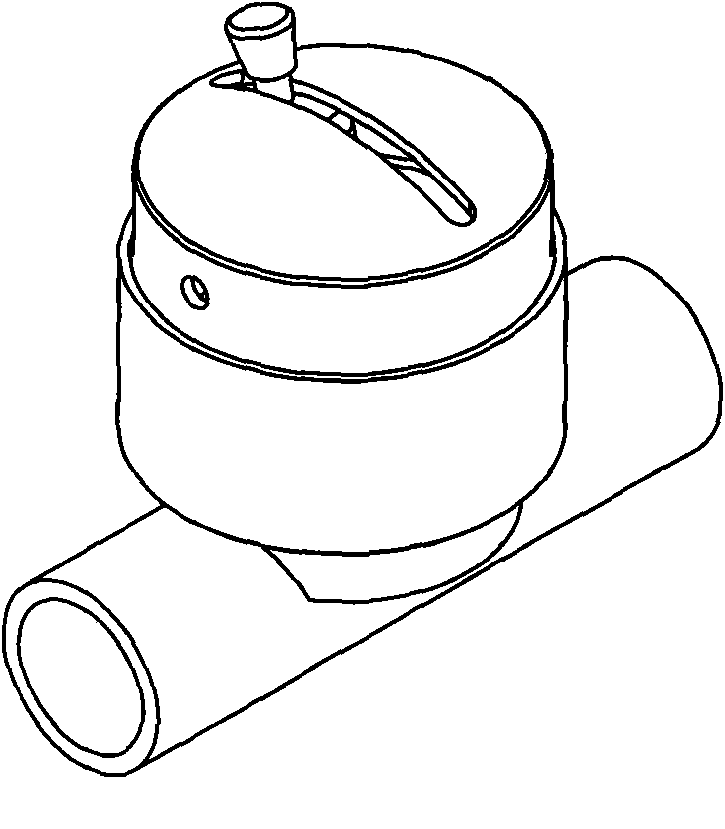

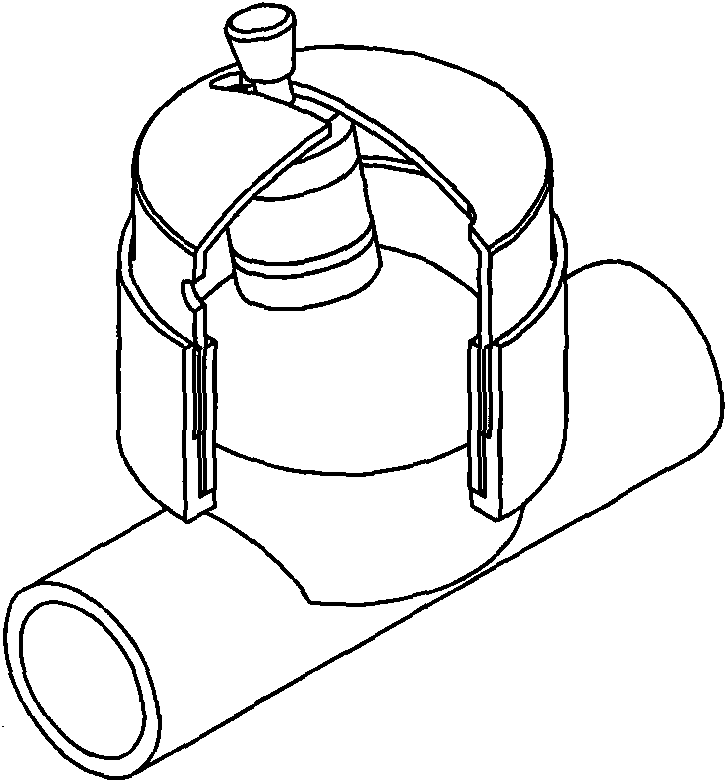

Quality visual detection system for plastic bottles

InactiveCN106706654AAchieve one-by-one separationRealize all-round image acquisitionOptically investigating flaws/contaminationEngineeringVisual perception

The invention relates to a quality visual detection system for plastic bottles. The quality visual detection system comprises a detection box and a server; a conveying guide rail, a separating mechanism and a detection mechanism are arranged in the detection box; the separating mechanism comprises two transmission parts, and the two transmission parts are used for separating the to-be-detected plastic bottles one by one to orderly enter a detection station; the detection mechanism comprises three cameras and a light source, and the three cameras are arranged on the two sides of the conveying guide rail in the shape of a regular triangle. The quality visual detection system provided by the invention has the benefits that as the separating mechanism is arranged, the next to-be-detected plastic bottle can be driven to move forwards; meanwhile, the distance between the next to-be-detected plastic bottle and the detected plastic bottle can be controlled, so that the influence on the accuracy of detection results is avoided, and the problem of slower detection speed is solved; the quality visual detection system provided by the invention can also realize the all-round image collection of the detected plastic bottles, so that the detection results are more reliable.

Owner:WUHAN EASY VIEW SCI & TECH CO LTD

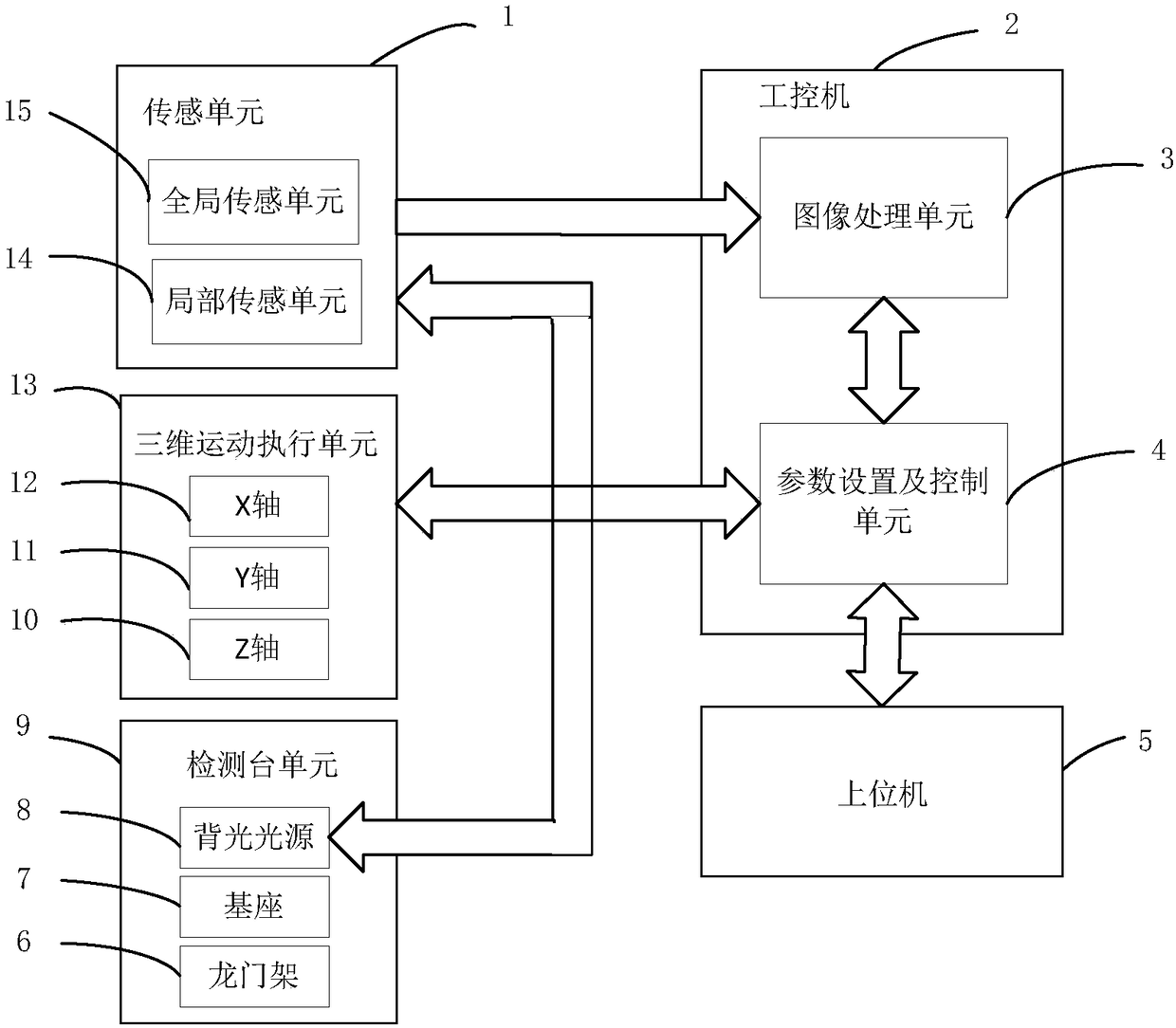

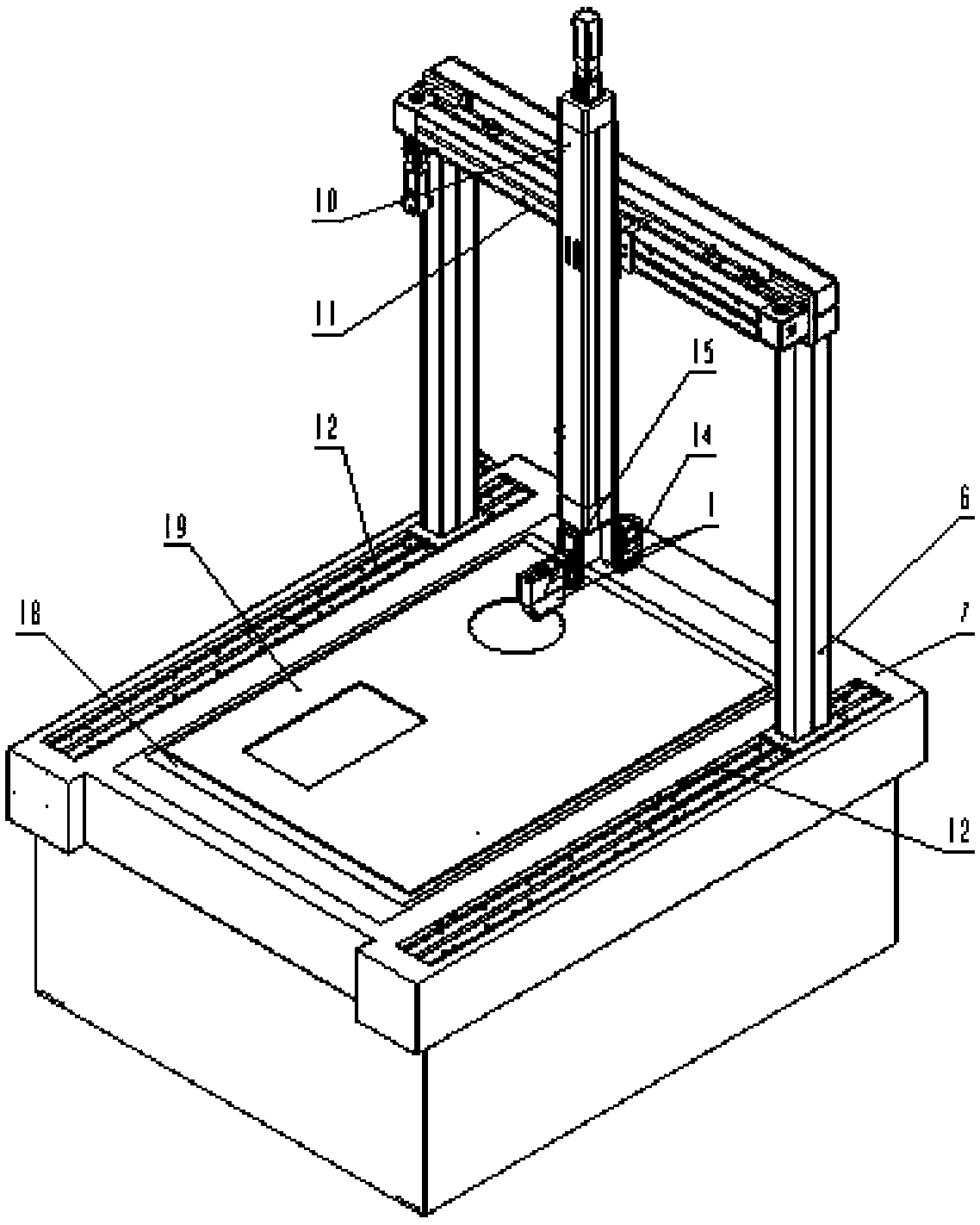

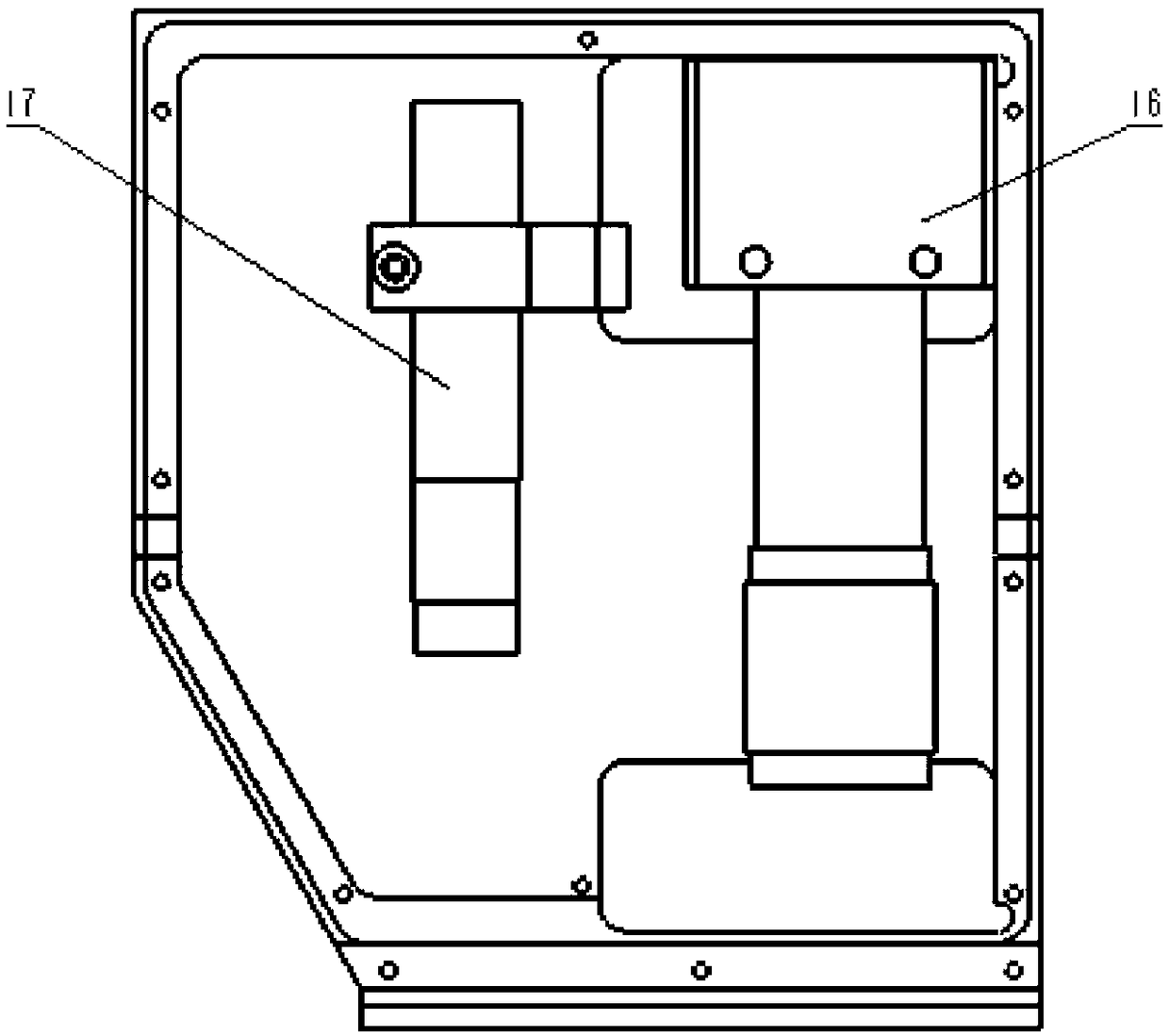

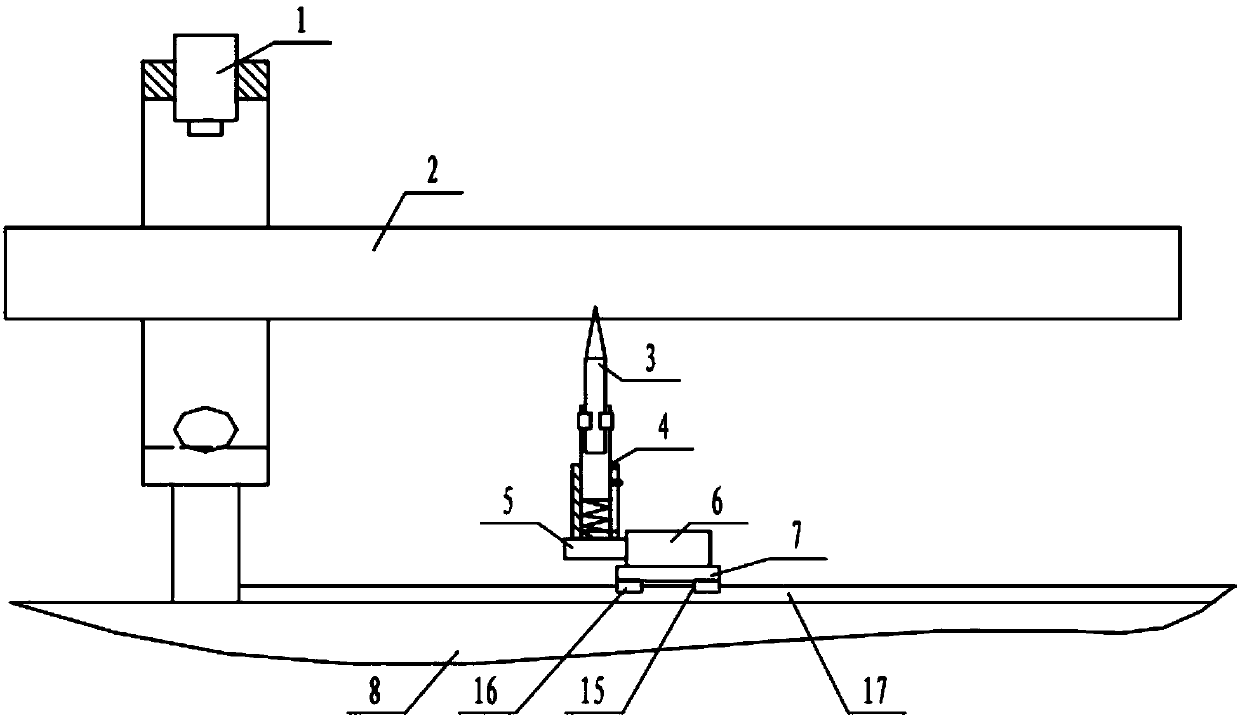

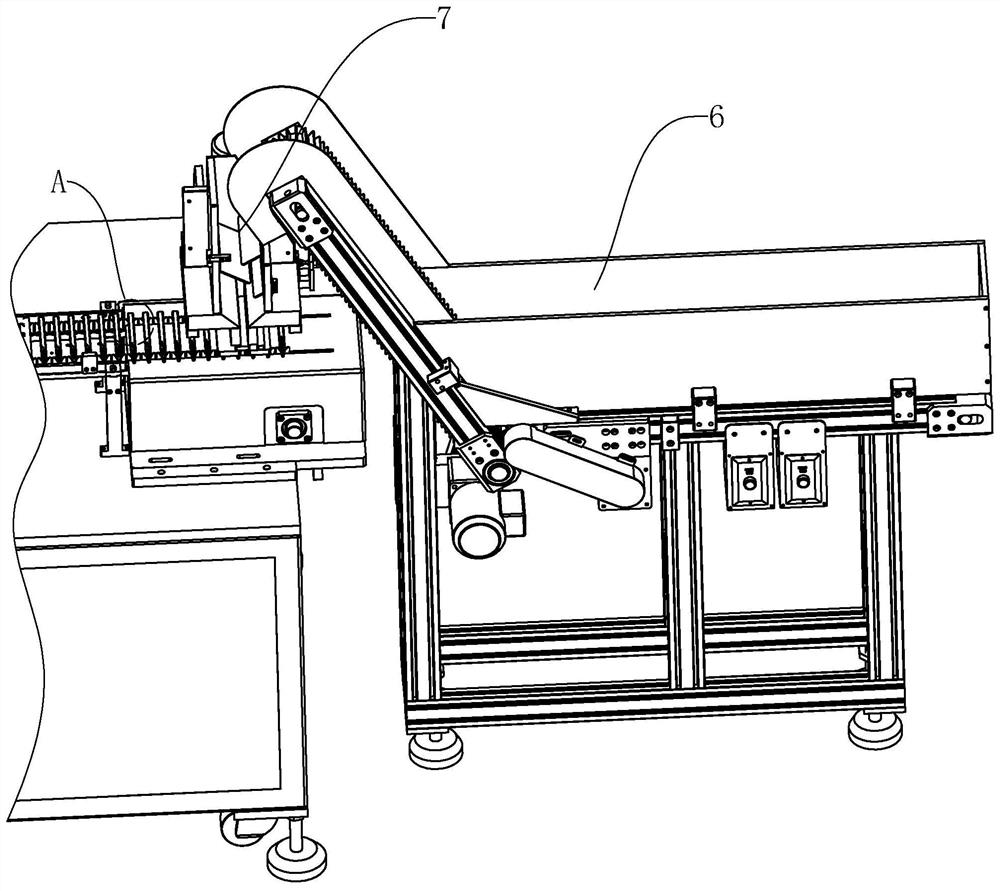

Automatic detection device and method of geometric quality of arge-sized thin-plate metal workpiece

InactiveCN108489394ANot limited by sizeRealize quality inspectionUsing optical meansImaging processingLocal sequence

The invention relates to an automatic detection device and method of the geometric quality of a large-sized thin-plate metal workpiece. An overall image and a distance of a thin-plate workpiece are collected at a detection position and the collected image and distance information are transmitted to an image processing unit; the image processing unit obtains the number of processing holes and central positions of all holes, identifies arc and segment pixels, determines the pixel types and the numbers of all types of pixels, and calculates workpiece thickness information; if the hole number, theworkpiece thickness and the hole types meet requirements, a local sensing unit collected a workpiece sequence image and transmits the image to the image processing unit; the image processing unit processes a local sequence image and identifies dimension information and position information of the obtained pixels; and if the pixel dimensions and positions meet requirements, a detection result is outputted. According to the invention, the original image of a to-be-detected workpiece is collected and obtained by means of macro-micro combination and quality detection of the large-sized workpieceis realized; the detection precision is ensured; the restriction on the workpiece dimension is eliminated; and the detection range and the detection precision are improved.

Owner:SHENYANG JIANZHU UNIVERSITY

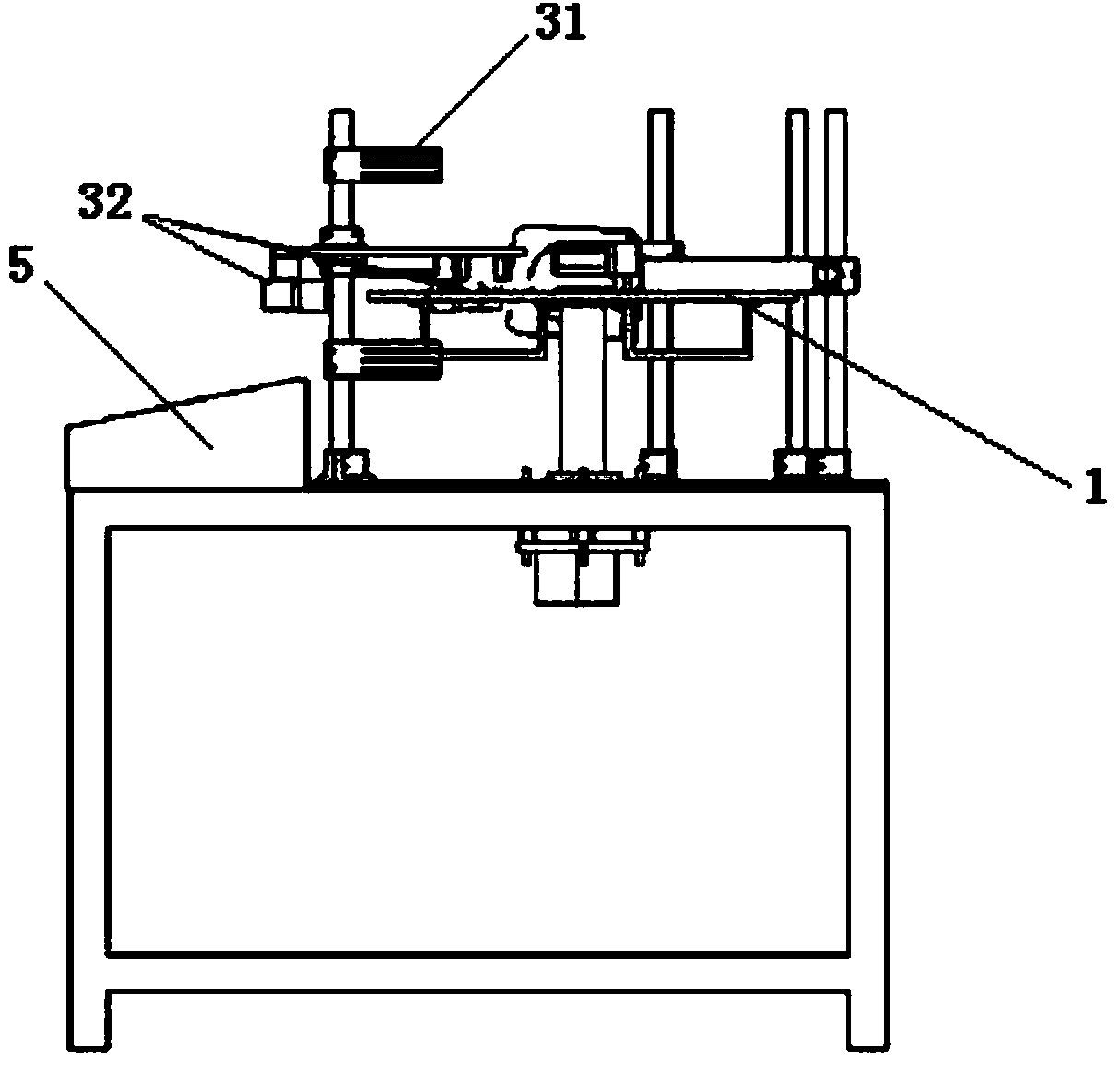

Rubber plug quality detection device and method

InactiveCN104315977ARealize comprehensive automatic quality inspectionReliable RejectionImage analysisOptically investigating flaws/contaminationDisplay devicePersonal computer

The invention discloses a rubber plug quality detection device and method. The detection device at least comprises a uniform speed rotating platform, a detection position, a focus-fixing camera, a photoelectric switch, a light source, an industrial personal computer, a display device and a defective good processing device. Rubber plugs to be detected are conveyed to the detection position through the uniform speed rotating platform. When the photoelectric switch identifies that the rubber plugs to be detected are in the detection position, five focus-fixing cameras are triggered to conduct multi-angle shooting on the rubber plugs to be detected, the rear industrial personal computer conducts radius detection processing, roundness detection processing, trimming condition detection processing, thickness detection processing, impurity pot detection processing and other detection processing on the shot and collected rubber plug images, and data statistics, storage and display transmission are conducted on the detected results; the detected defective goods are removed. By means of the rubber plug quality detection device and method, comprehensive automatic quality testing, quality detection, result display and removal processing are finished in one detection device, the precision is high, the speed is high, efficient and reliable functions are achieved, the production cost is low, and the defects generated by manual detection are overcome.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

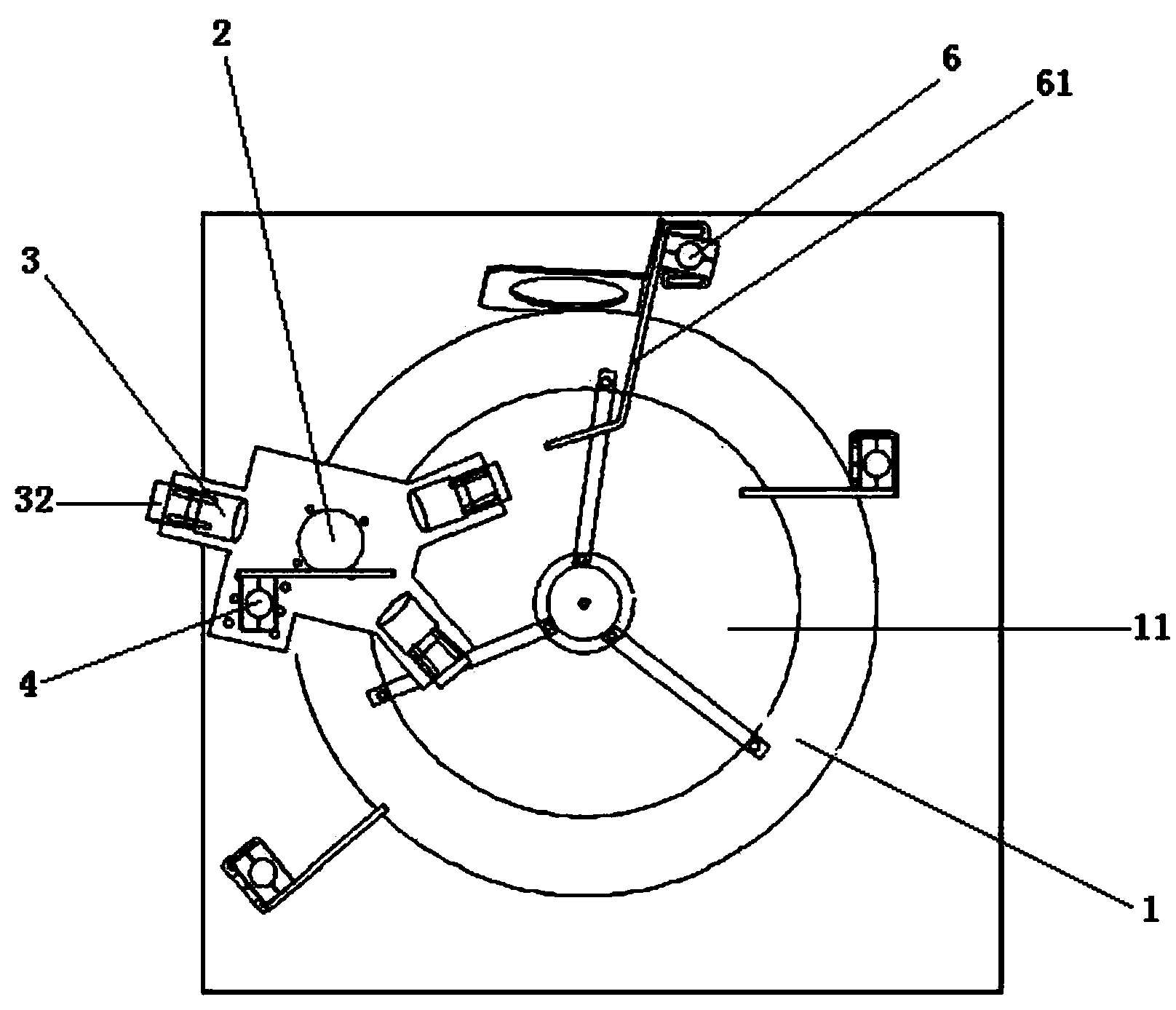

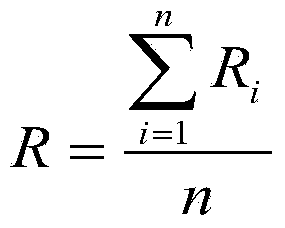

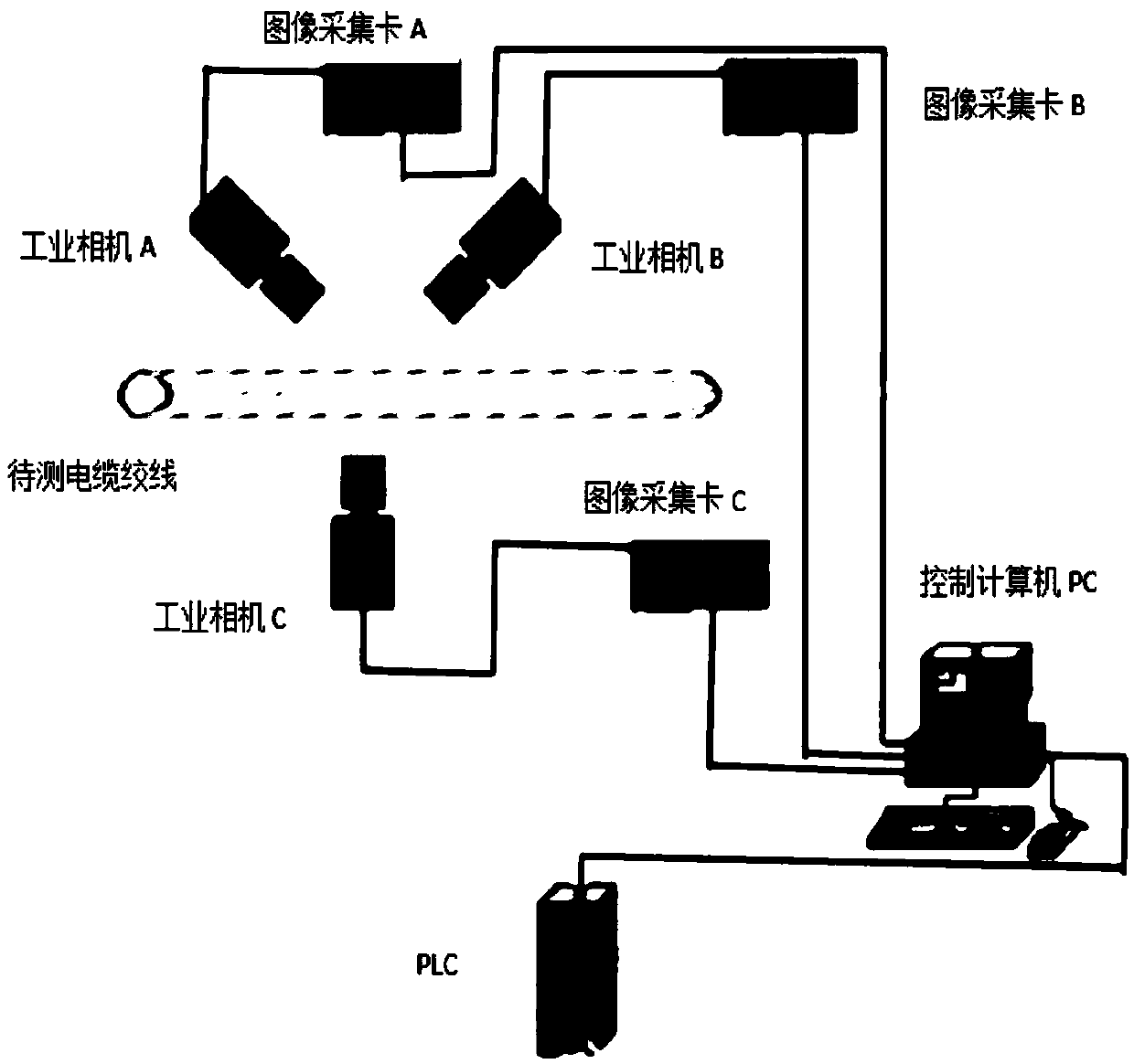

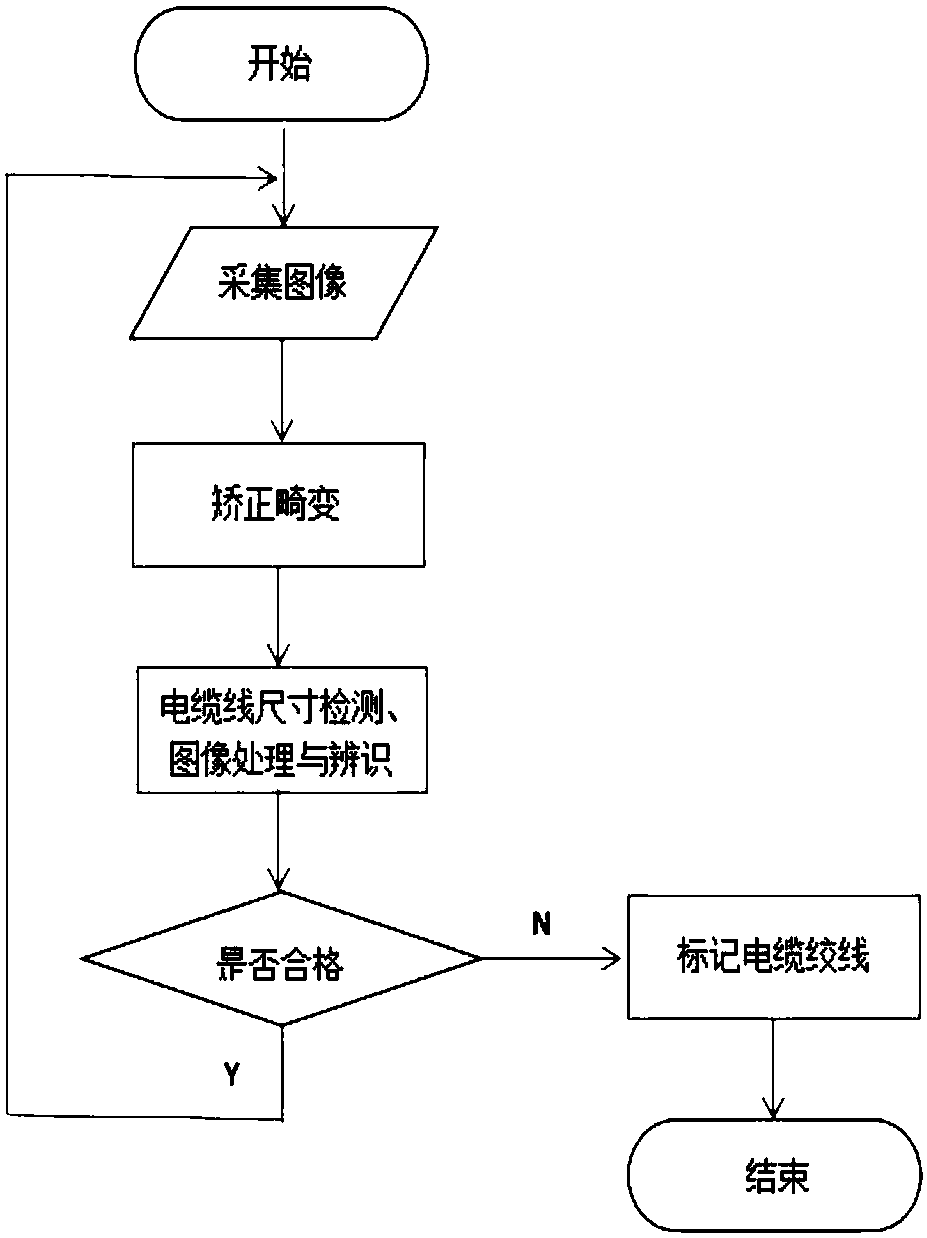

Twisted cable quality detection system based on machine vision and detection method for same

PendingCN107703148AAvoid scratchesImprove detection efficiencyOptically investigating flaws/contaminationUsing optical meansImaging processingMachine vision

The invention discloses a twisted cable quality detection system based on machine vision and a detection method for same. The system includes an image collection module, an image processing and identifying module, and a marking and positioning module. The signal receiving end of the image processing and identifying module is connected to the image collection module while a control end is connectedto the marking and positioning module. The image processing and identifying module is used for processing, identifying and size-detecting the collected image; the image collection module is used forcollecting an image of the twisted cable on line; the marking and positioning module is used for positioning and marking an unqualified twisted cable. The system can achieve on-line quality detectionand defect marking of the twisted cable, can greatly improve detection efficiency and avoid human influence, greatly reduces error, is more accurate in detection and avoids influence on production schedule due to detection. The detection is free of contact between hands and equipment and the twisted cable, so that damage on the twisted cable and injury on hands are avoided. The system is safer tooperate.

Owner:GUIZHOU UNIV

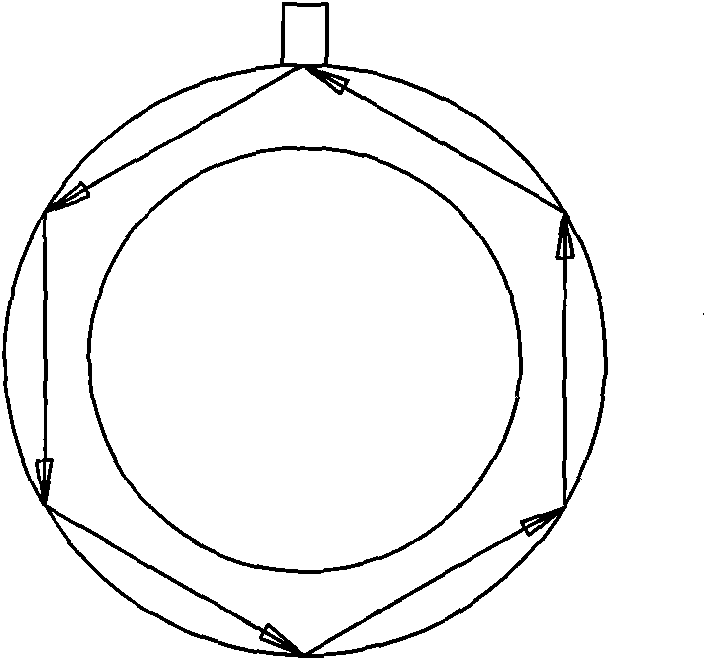

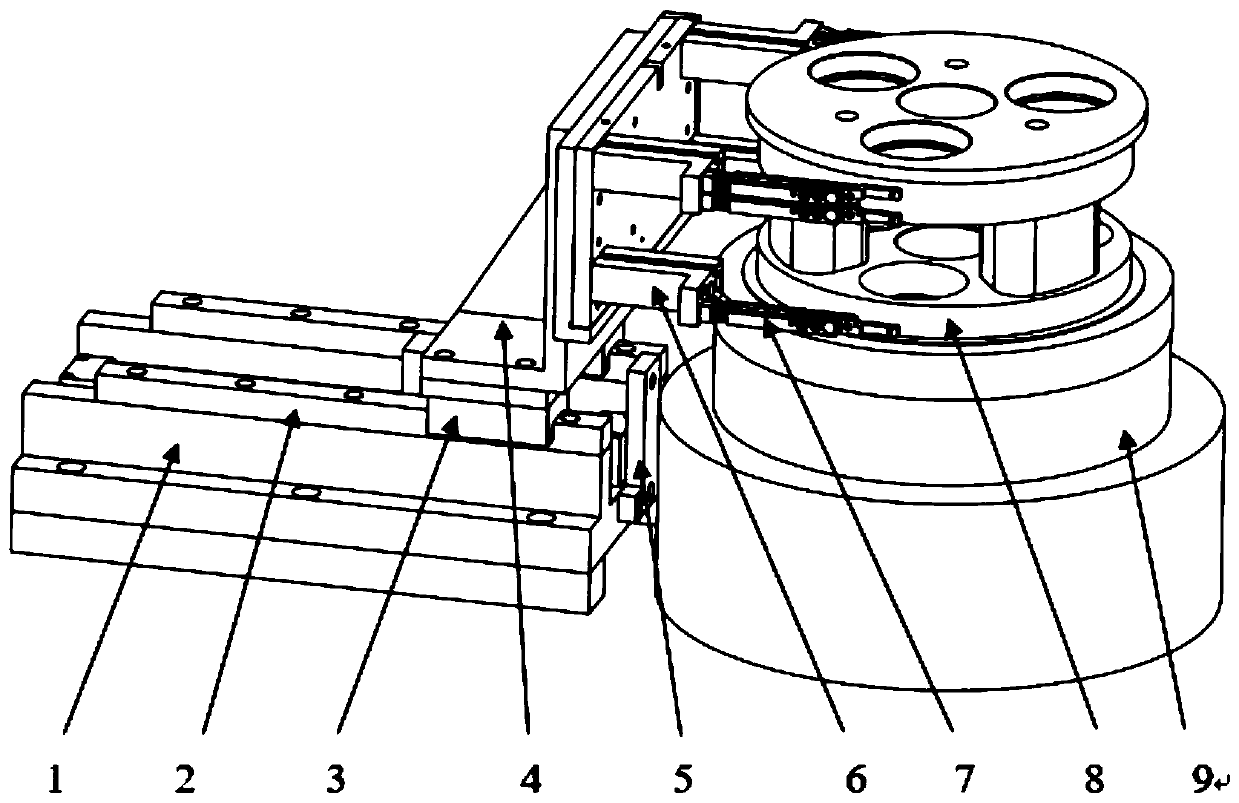

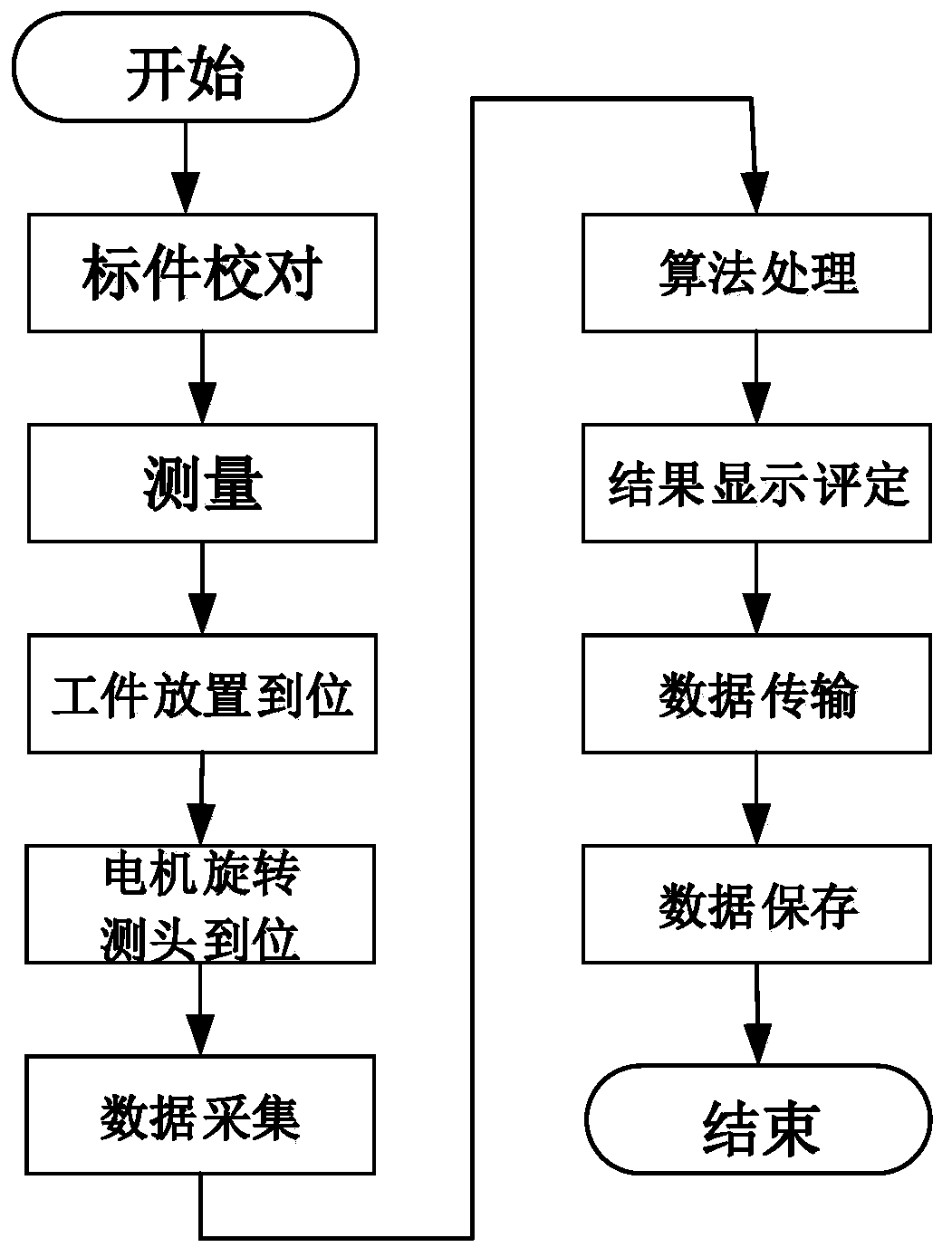

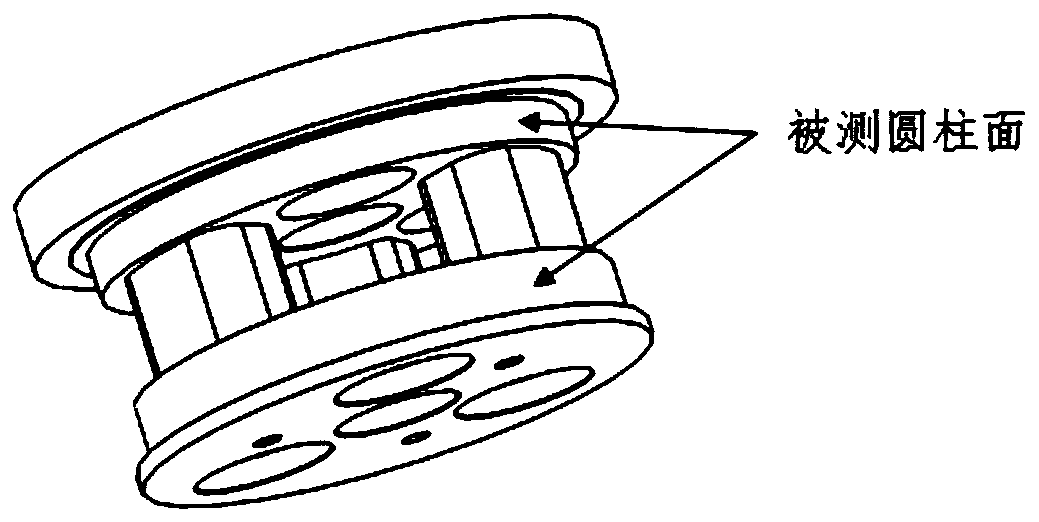

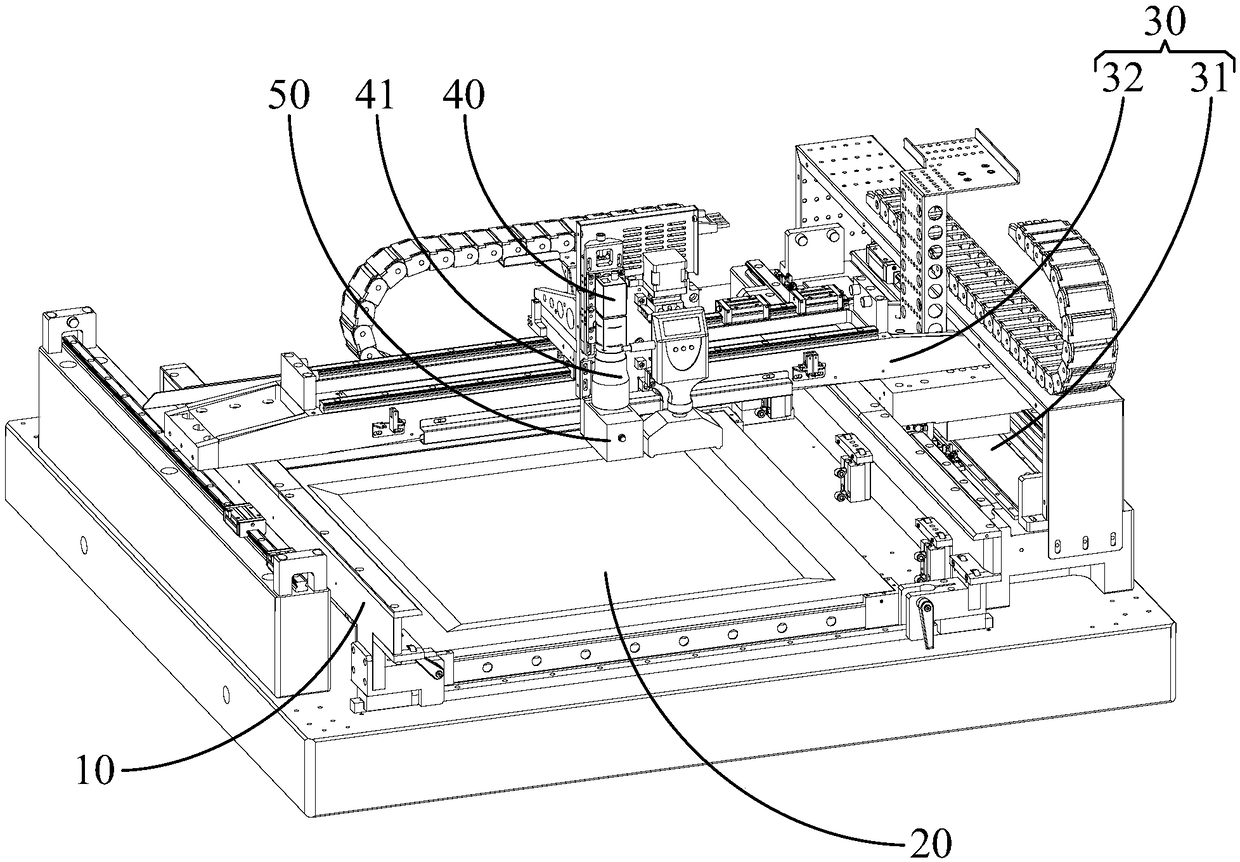

Multi-element cylindrical surface detection device based on concentric circular mesh traversal optimization and method

ActiveCN109780965ARealize quality inspectionGuaranteed to workMechanical counters/curvatures measurementsMechanical diameter measurementsCircular surfaceMeasurement precision

The invention discloses a multi-element cylindrical surface detection device based on concentric circular mesh traversal optimization and method. Dynamic rotary scanning measurement is adopted, threesections are measured on the outer circle of a planet carrier, and the diameter of each section is provided with a sensor; a workpiece is positioned on a precision rotary platform for high-precision rotary positioning on a measured piece; a left measurement part is driven by a cylinder guide rail to enter a measurement position through a control motor, the sensor probe thus arrives at the measurement position, and precise positioning during the automatic measurement process is realized; the workpiece rotates slowly on the precision rotary platform, each time when the workpiece rotates for a certain angle, the sensor acquires a group of data, and by using the data measured and obtained by the sensor, according to an evaluation algorithm involved in the invention, the outer diameter, the roundness and the cylindricity of the outer circle of the planet carrier are calculated. The measurement precision and the measurement efficiency are improved, quality detection on the cylindrical surface of the planet carrier in a production line can be realized, efficient work of the production line is ensured, and precise measurement and evaluation on multiple elements of the outer circular surface are realized.

Owner:XI AN JIAOTONG UNIV

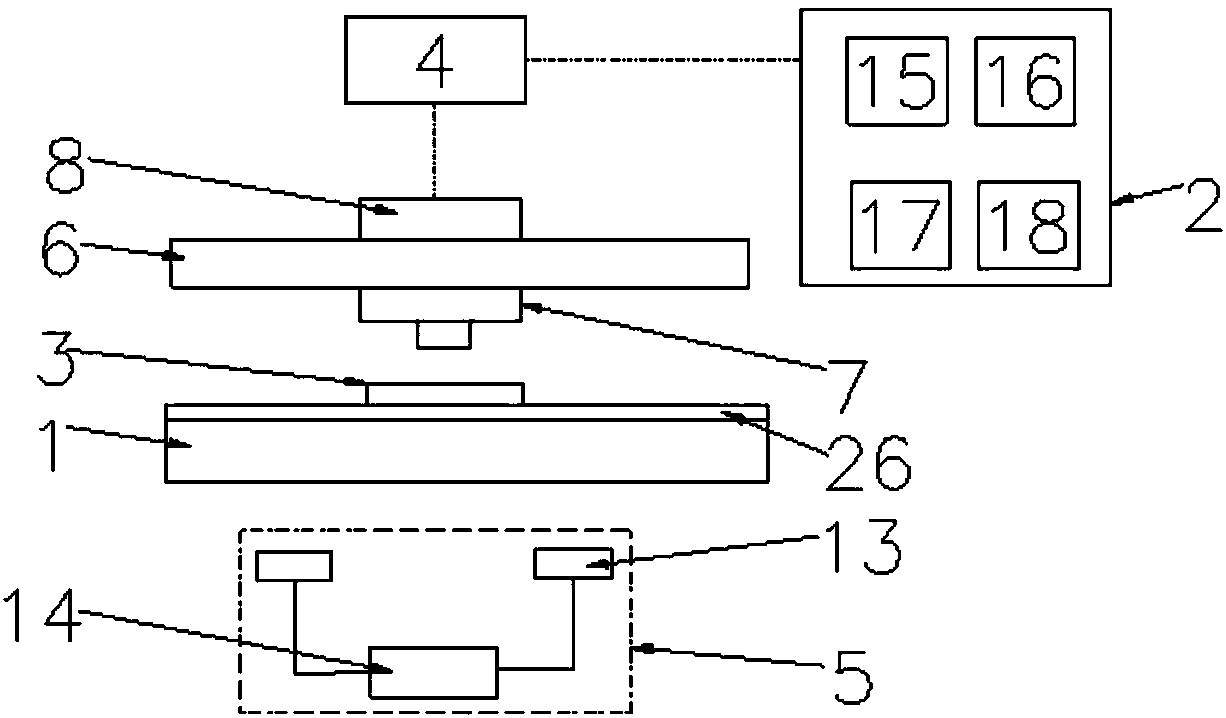

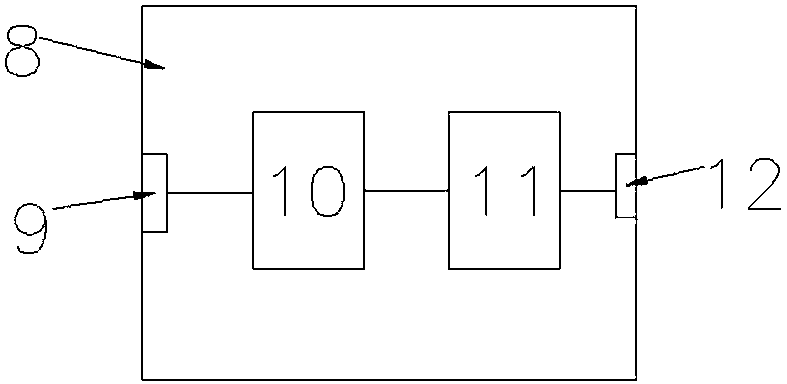

Visual detection device and method for wire rods without tension constraint

InactiveCN105445285ASame resolutionRealize surface quality inspectionMaterial analysis by optical meansCamera imageMachine vision

The invention relates to the field of machine vision technology, in particular to a surface quality detection device and method for tubes, rods and wire rod products in the iron and steel industry without tension constraint. The visual detection device for wire rods without tension constraint includes a plurality of cameras (1) mounted on a sliding guide rail (3), the sliding guide rail (3) is fixed on a fixed plate (4) and is circumferentially distributed along the periphery of a hollow guide slot (2), when a detected wire rod (5) passes through the hollow guide slot, the cameras image the outer surface of the wire rod, the imaging distances between the cameras and the detected wire rod are equal; and when the wire rod specification changes, cameras perform position adjustment along the sliding guide rail to keep the imaging distances between the cameras and the detected wire rod equal. The device and the method provided by the invention can realize automatic adjustment of camera imaging distance so as to achieve focusing, thus ensuring clear imaging of the detection system under the circumstance of constant resolution.

Owner:BAOSHAN IRON & STEEL CO LTD

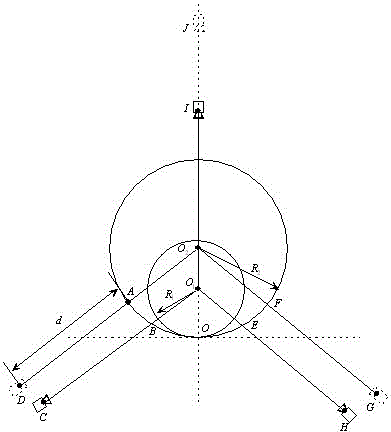

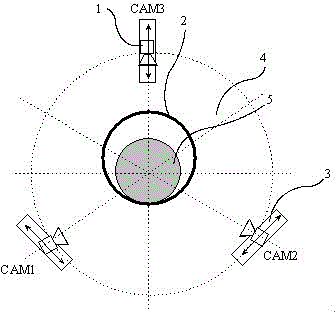

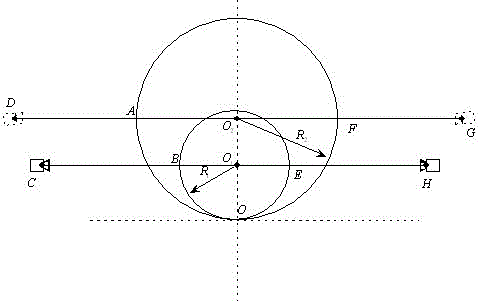

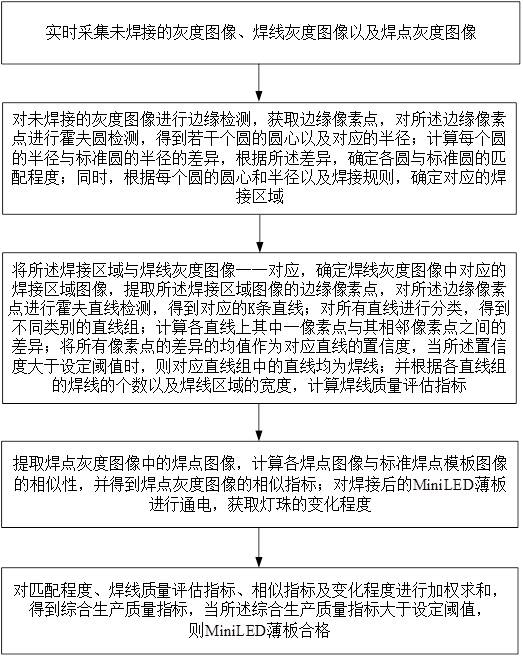

Production quality detection method for full-automatic connection of MiniLED sheets

ActiveCN114723758ARealize quality inspectionMonitor qualityImage analysisCharacter and pattern recognitionThin slabManufacturing line

The invention relates to the field of image processing, in particular to a production quality detection method for a Mini LED thin plate full-automatic connection line, which comprises the following steps of: acquiring an unwelded gray scale image, a welding line gray scale image and a welding spot gray scale image in real time; the method comprises the following steps: acquiring the matching degree of each circle and a standard circle in an unwelded grayscale image; according to the circle center and the radius of each circle and the welding rule, a corresponding welding area is determined; determining a bonding wire in the corresponding welding area image in the bonding wire gray level image, and calculating a bonding wire quality evaluation index; meanwhile, calculating a similarity index of each welding spot image and a standard welding spot template image and obtaining a change degree of the lamp bead; and performing weighted summation on the matching degree, the bonding wire quality evaluation index, the similarity index and the change degree to obtain a comprehensive production quality index, and judging whether the MiniLED thin plate is qualified or not. According to the scheme, the quality of the technological process of the whole production line can be monitored, and therefore quality detection of the MiniLED thin plate is achieved.

Owner:惠州威尔高电子有限公司

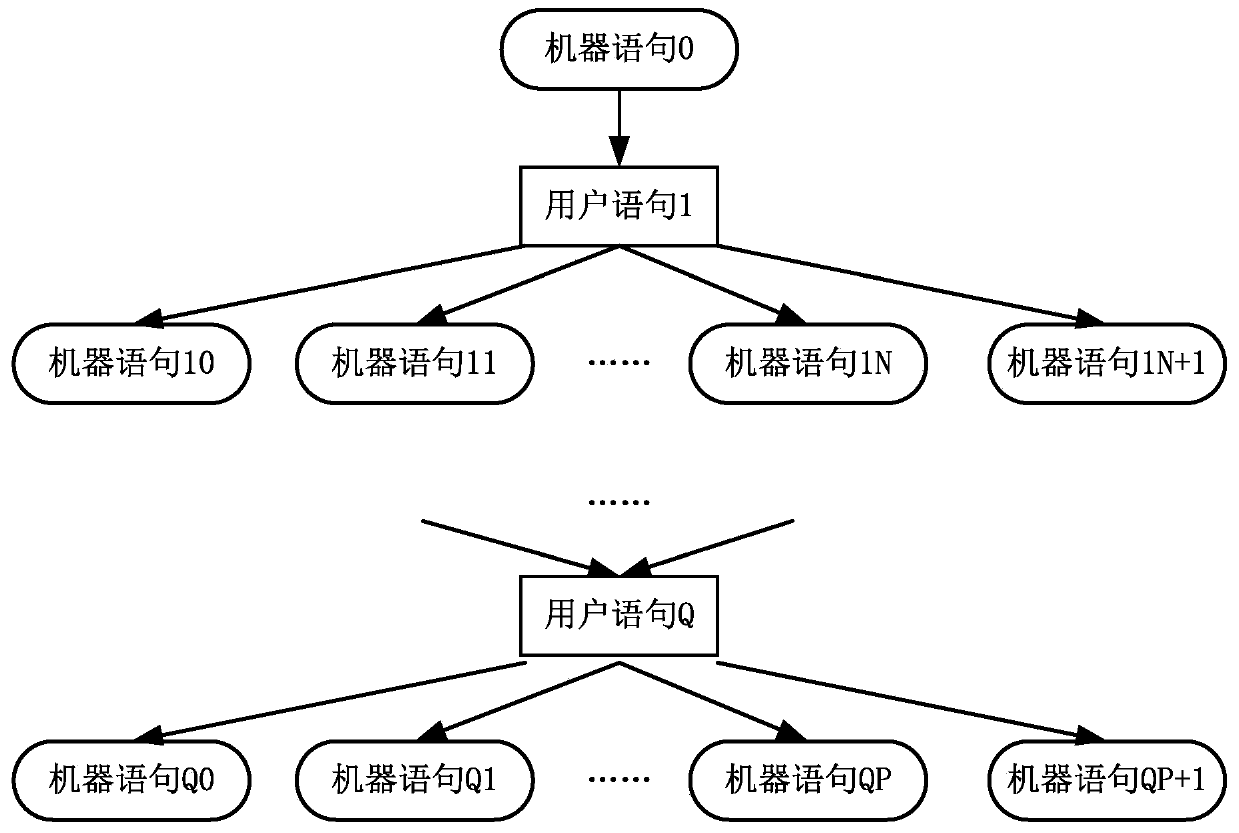

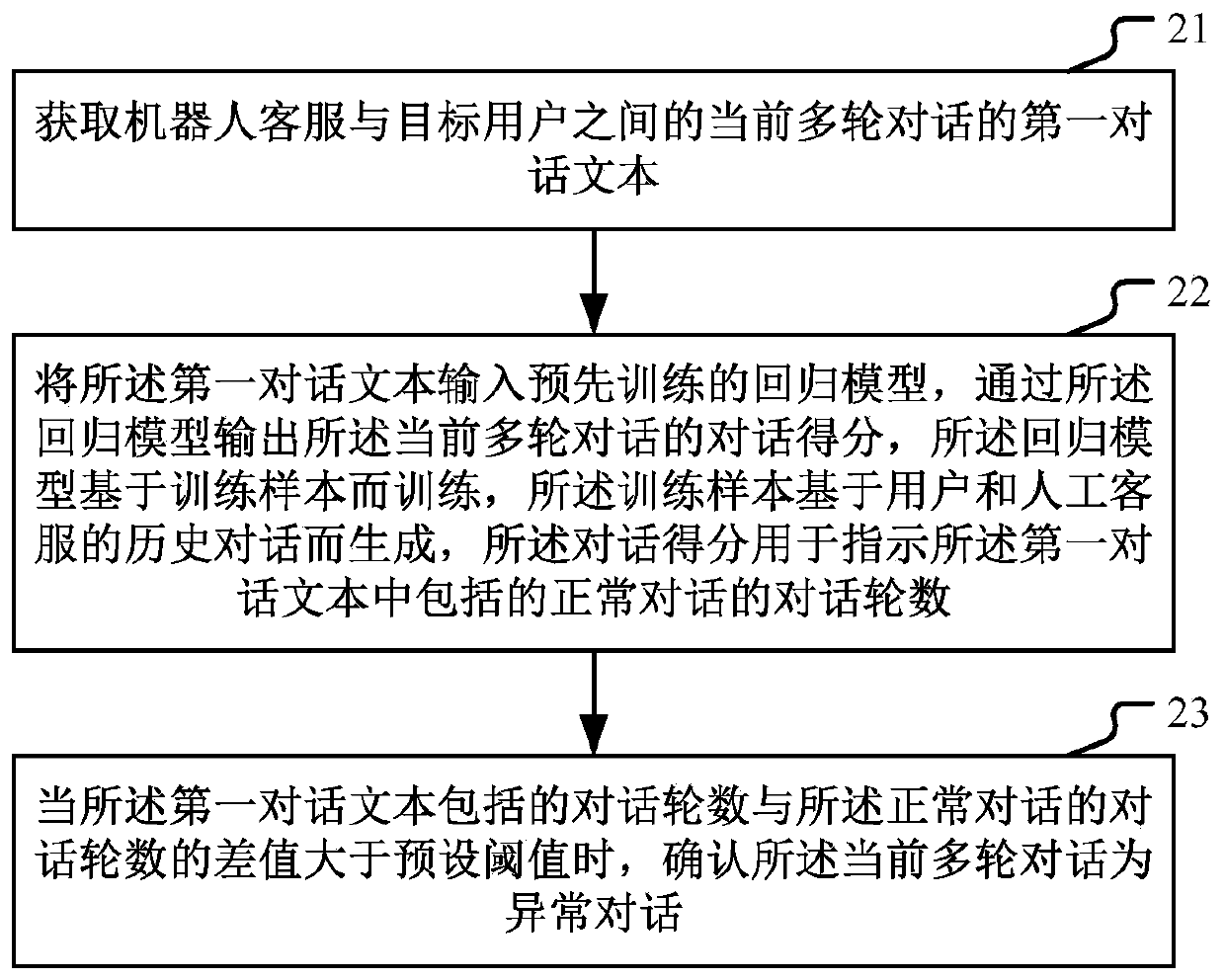

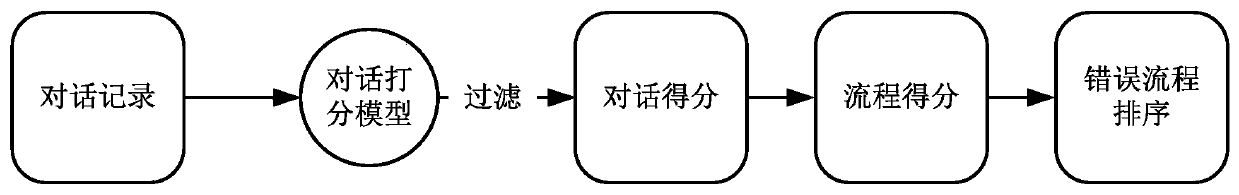

Quality inspection method and device for multiple rounds of conversations in robot customer service guidance conversations

InactiveCN110765249ARealize quality inspectionDigital data information retrievalSpecial data processing applicationsText entryEngineering

The embodiment of the invention provides a quality inspection method and device for multiple rounds of conversations in robot customer service guidance conversations. The method comprises the steps ofacquiring a first conversation text of the current multiple rounds of conversations between robot customer service and a target user; inputting the first dialogue text into a pre-trained regression model, outputting a dialogue score of the current multi-round dialogue through the regression model, with the regression model being trained based on a training sample, the training sample being generated based on historical dialogues of a user and an artificial customer service, the dialogue score being used for indicating the number of dialogue rounds of a normal dialogue included in the first dialogue text; and when the difference between the number of dialogue rounds included in the first dialogue text and the number of dialogue rounds of the normal dialogue is greater than a preset threshold, determining that the current multi-round dialogue is an abnormal dialogue. Quality inspection of multiple rounds of conversations in robot customer service guidance conversations can be efficiently realized.

Owner:ALIPAY (HANGZHOU) INFORMATION TECH CO LTD

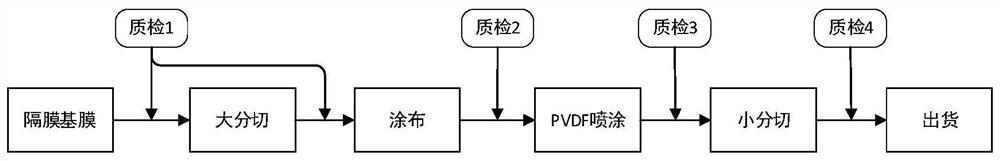

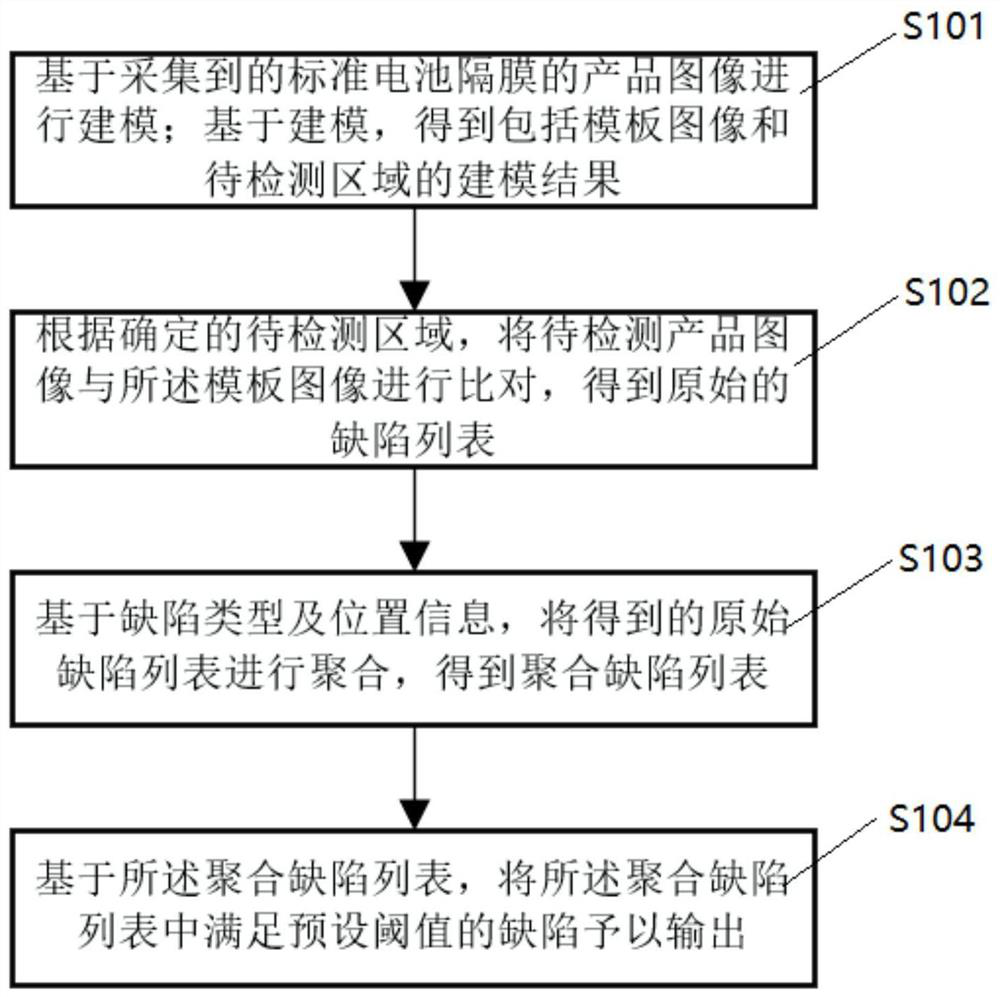

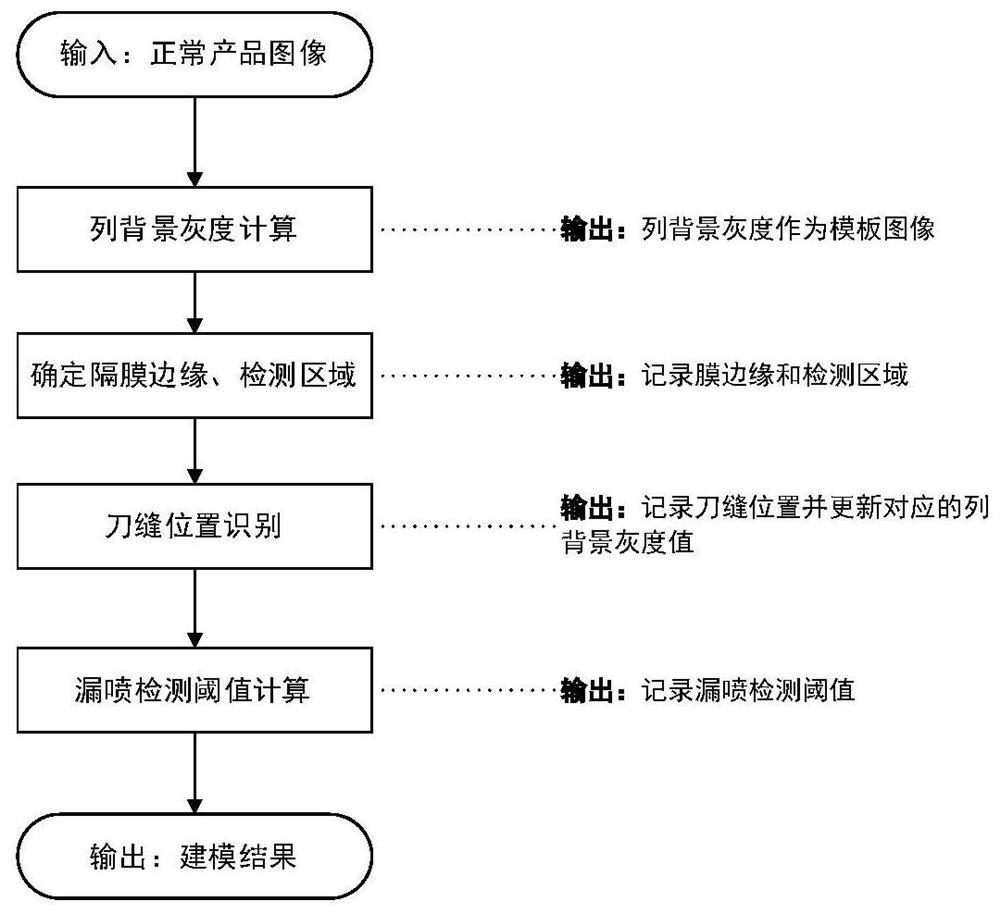

Battery diaphragm surface defect detection method and system

ActiveCN113030093ARealize quality inspectionEfficient and fast detectionOptically investigating flaws/contaminationAlgorithmBattery cell

The invention discloses a battery diaphragm surface defect detection method. The method comprises the following steps of: modeling an acquired product image of a standard battery diaphragm; based on the modeling, obtaining a modeling result comprising a template image and a to-be-detected area; according to the determined to-be-detected area, comparing the to-be-detected product image with the template image to obtain an original defect list; based on defect types and position information, aggregating the obtained original defect list to obtain an aggregated defect list; and based on the aggregated defect list, outputting defects meeting a preset threshold in the aggregated defect list. According to the structural design of the method, the surface defects of a battery diaphragm can be efficiently and quickly detected; the method has the advantages of high efficiency, low cost, high accuracy, and can effectively detect the defects such as coating missing and spraying missing. In addition, the invention also discloses a battery diaphragm surface defect detection system.

Owner:BEIJING LUSTER LIGHTTECH

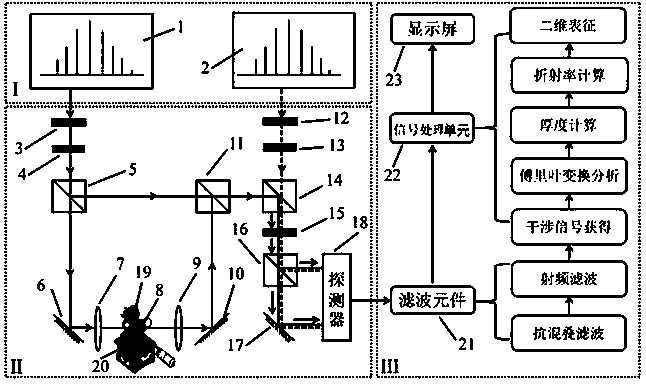

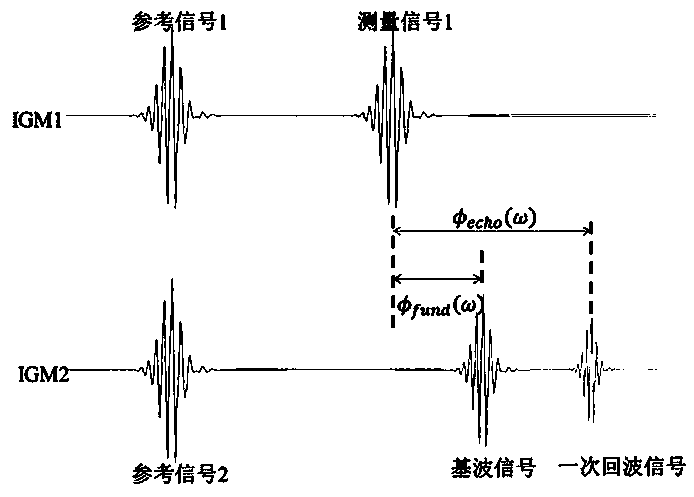

Optical lens quality detection system and method based on double-optical-comb interference measurement method

ActiveCN111351640AAchieving 2D representationRealize quality inspectionTesting optical propertiesRefractive indexLight beam

The invention belongs to the technical field of optical precision measurement, and discloses an optical lens quality detection system and method based on a double-optical-comb interference measurementmethod, and the system comprises a light source system, an interference measurement system, and a signal processing system. The light source system comprises a first optical frequency comb and a second optical frequency comb and is used for generating two beams of laser of which the repetition frequency meets a heterodyne beat frequency condition; in the interference measurement system, an outputsignal of a first optical frequency comb is divided into a measurement light beam and a reference light beam, and the measurement light beam coincides with the reference light beam after entering a to-be-measured optical lens; the superposed measurement light beam and reference light beam are superposed with the output light beam of the second optical frequency comb again and then are divided into two beams which are respectively detected by two detection windows of the detector; and the signal processing system is used for calculating the thickness and the refractive index of the to-be-measured optical lens according to the detection signal of the detector. The thickness and the refractive index of the glass lens can be measured at the same time, and two-dimensional characterization of the glass lens is achieved.

Owner:SHANXI UNIV

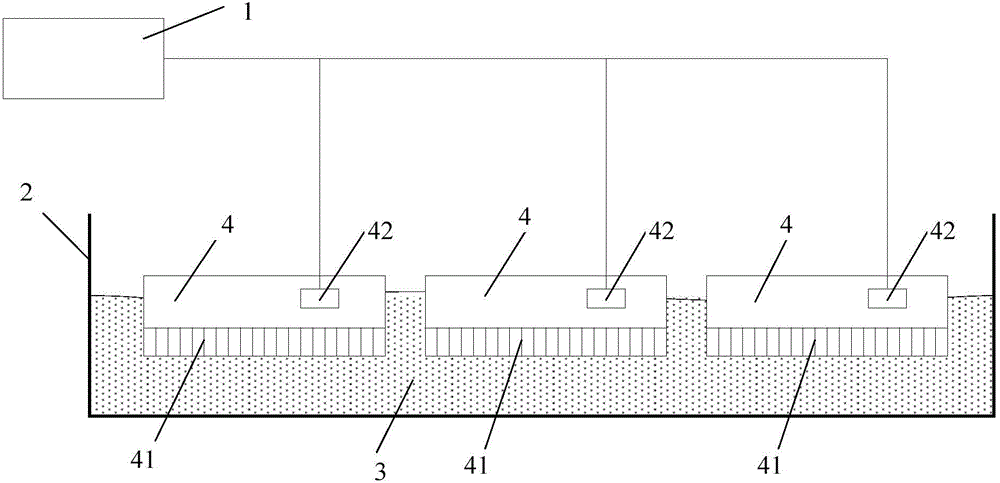

Circuit board detection system

InactiveCN106291333ARealize quality inspectionReduce testing costsElectronic circuit testingVoltageControl unit

The invention provides a circuit board detection system. The electrodes of a region to be bound of a circuit board to be tested are immersed in a test solution and are conducted by using a conductive property of the test solution. Test voltage is sent to the control unit of the circuit board to be tested to detect the impedance between the two adjacent electrodes in the region to be bound of the circuit board to be tested. According to the impedance detection value between the two adjacent electrodes in the region to be bound of the circuit board to be tested and the conductivity of the test solution, whether the circuit board to be tested is qualified is determined. On the one hand, the quality of the circuit board to be tested can be detected without a need to match a dedicated test circuit board to the circuit board to be tested anymore, thereby reducing the testing cost of circuit board. On the other hand, the conduction of the electrodes can be guaranteed as long as the electrodes of the region to be bound of the circuit board to be tested are immersed in the test solution, the electrodes are not required to correspond to one another one by one, thereby improving detection efficiency.

Owner:BOE TECH GRP CO LTD +1

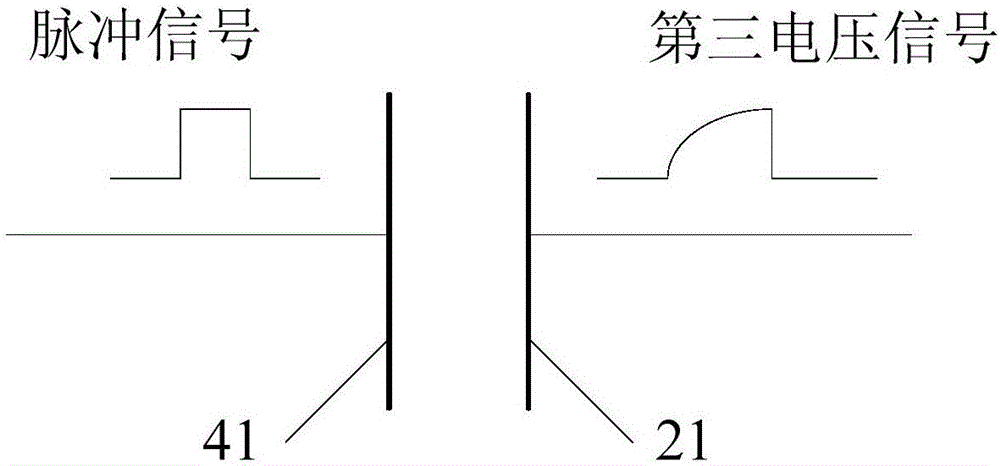

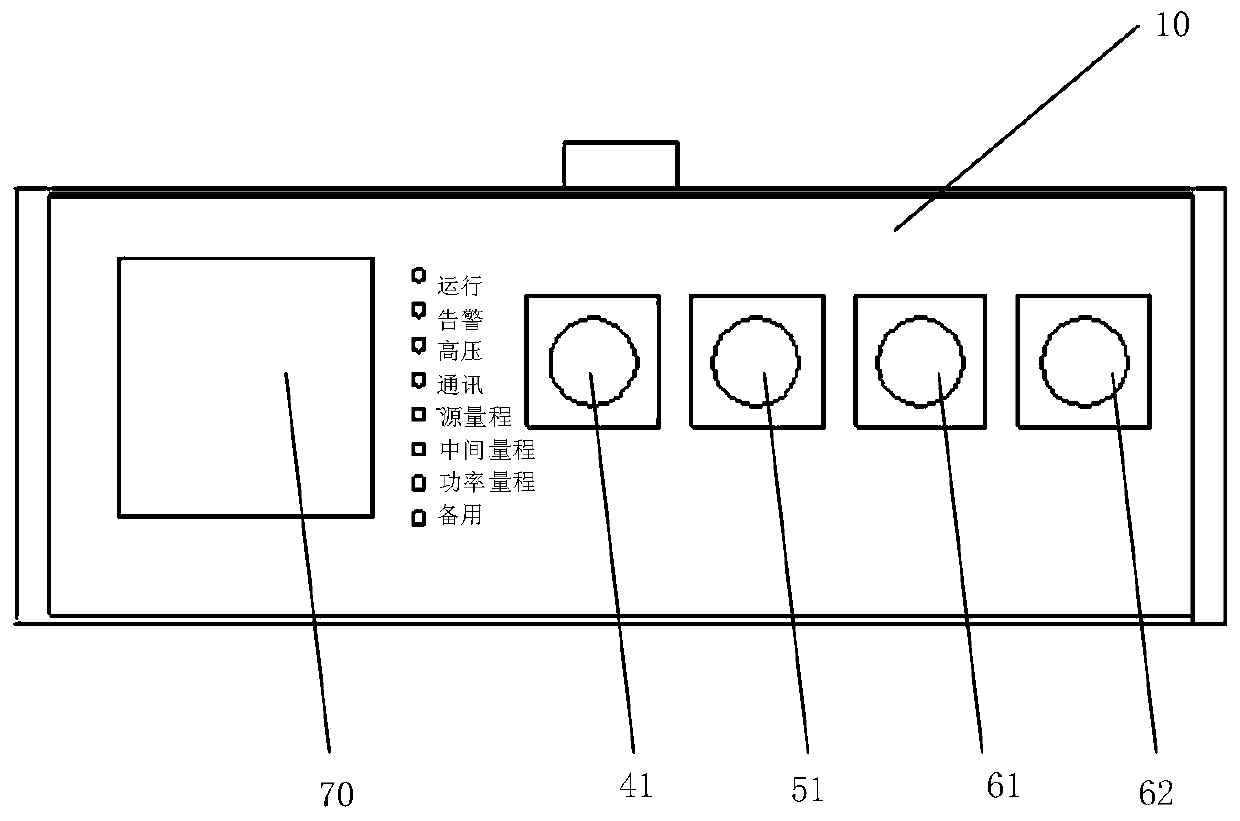

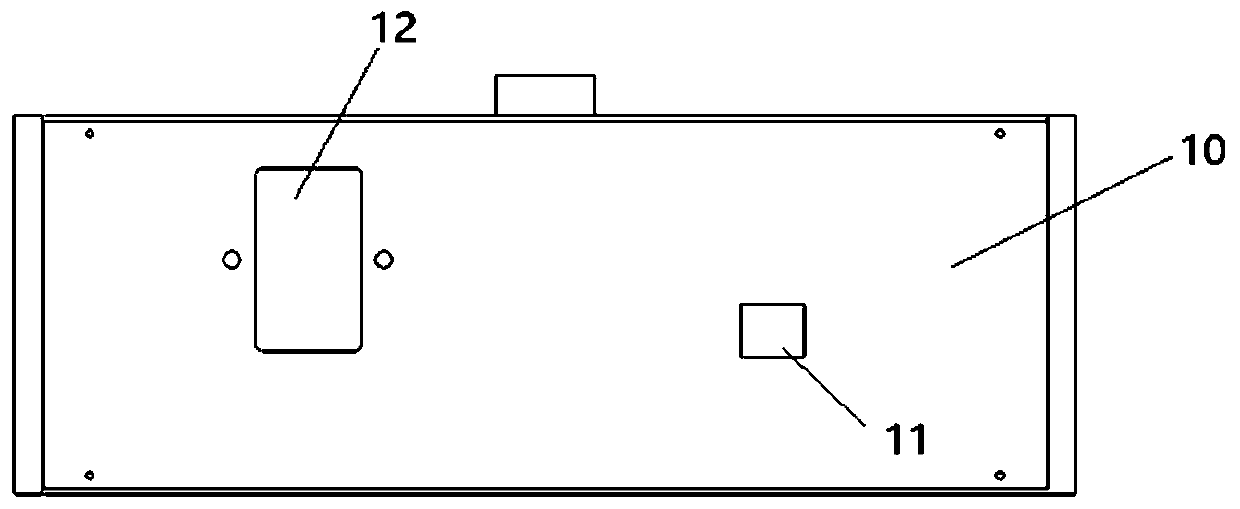

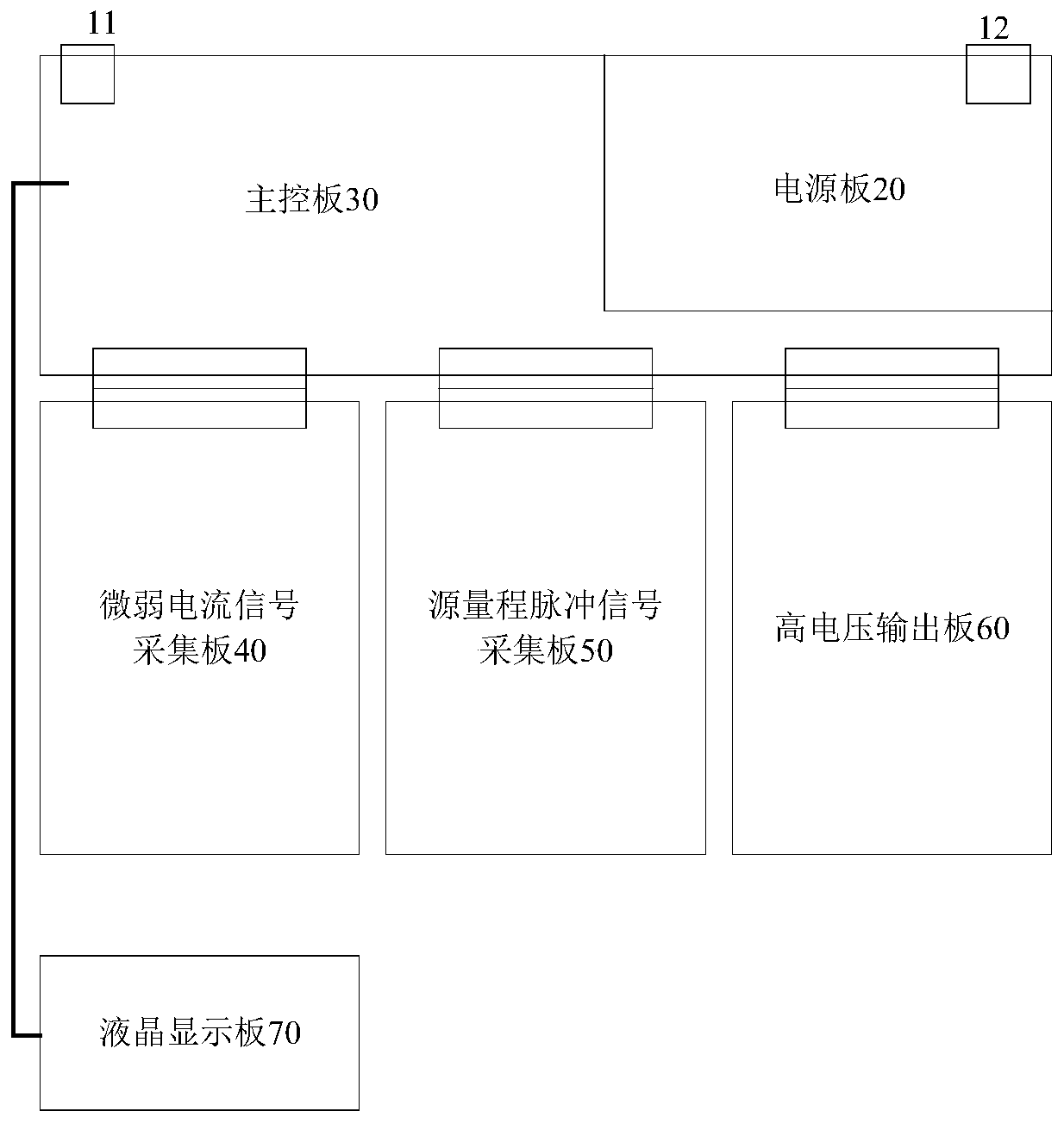

Portable nuclear instrument system signal detection and fault positioning device

InactiveCN111077487AGuaranteed Signal AccuracyMiniaturizationAltering measuring range circuitsMeasurement using digital techniquesComputer hardwareDisplay board

The invention provides a portable nuclear instrument system signal detection and fault positioning device. The device comprises a shell, a power supply board, a main control board, a weak current signal acquisition board, a source range pulse signal acquisition board, a high voltage output board and a liquid crystal display board, wherein an accommodating cavity is formed in the shell; the power supply board, the main control board, the weak current signal acquisition board, the source range pulse signal acquisition board and the high voltage output board are all placed in the accommodating cavity; the liquid crystal display panel is fixed on the surface of the shell, and the power panel, the weak current signal acquisition board, the source range pulse signal acquisition board, the high voltage output board and the liquid crystal display panel are all electrically connected with the main control board; the weak current signal acquisition board, the source range pulse signal acquisition board and the high voltage output board are provided with corresponding HN terminals; and the HN terminal is arranged on the surface of the shell. According to the invention, when an abnormal signaloccurs, a fault section can be troubleshot through a segmentation test function of the device, so that troubleshooting and positioning are realized.

Owner:中广核工程有限公司 +2

Automatic quality classification system and method of wheat grains

ActiveCN103934214AAutomatic Grading FastRealize quality inspectionMaterial analysis by optical meansSortingNon destructiveSpectrum analyzer

The invention discloses an automatic quality classification system and method of wheat grains, the method is as follows: a plurality of storage bins respectively used for storing wheat grains of multiple levels are arranged; when the wheat grains are conveyed by conveying equipment, a near infrared spectrum analyzer is used to detect quality characteristic information of the wheat grains which is to-be-put in a storage and is loaded in the conveying equipment, the quality characteristic information is sent to a control device which judges the level of the wheat grains to-be-put in the storage based on the quality characteristic information and generates control instructions for instructing the conveying equipment to convey the wheat grains to-be-put in the storage to the storage bins with corresponding levels; and the conveying equipment conveys the wheat grains to-be-put in the storage into the storage bins with corresponding levels based on the control instructions. The automatic quality classification system and method realize the automatic, rapid, non-destructive quality classification of the wheat grains.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Quality detection method for kidney-replenishing and wind-dispelling climacterium mixture

ActiveCN104950068ARealize quality inspectionGuaranteed stabilityComponent separationAngelica Sinensis RootSaposhnikovia

The invention discloses a quality detection method for a kidney-replenishing and wind-dispelling climacterium mixture. The kidney-replenishing and wind-dispelling climacterium mixture comprises the following raw materials in weight part: 114-132 parts of prepared rehmannia root, 114-132 parts of rhizoma curculiginis, 114-132 parts of Chinese yam, 114-132 parts of cornus officinalis, 114-132 parts of epimeddium, 114-132 parts of morinda officinalis, 114-132 parts of Chinese taxillus twig, 114-132 parts of glossy privet fruits, 114-132 parts of herba ecliptae, 95-110 parts of angelica sinensis, 94.5-99 parts of cassia twigs, 94.5-99 parts of radix angelicae pubescentis, 95-99 parts of divaricate saposhnikovia roots, 31.5-33 parts of asarum sieboldii, and 57-66 parts of licorice. The quality detection method comprises the steps of detecting the characters of the mixture; identifying the mixture, including the TLC identification on cornus officinalis; inspecting the relative density and the pH value of the mixture; and determining the content, including the content determination of epimeddium. The quality detection result of the mixture shows that, the mixture is in the form of a slightly fragrant and slightly bitter dark-brown liquid containing a small amount of sediments. The relative density of the mixture is 1.10-1.20 and the pH value of the mixture is 3.5-5. With the above method as a standard for detecting the kidney-replenishing and wind-dispelling climacterium mixture, the stability of the preparation can be better ensured, so that the curative effect of the mixture is ensured.

Owner:贵州中医药大学第二附属医院

Full-quantity real-time automatic service quality inspection system and method

InactiveCN111147669AEasy to detectRealize quality inspectionSpecial service for subscribersSupervisory/monitoring/testing arrangementsService qualityReal-time computing

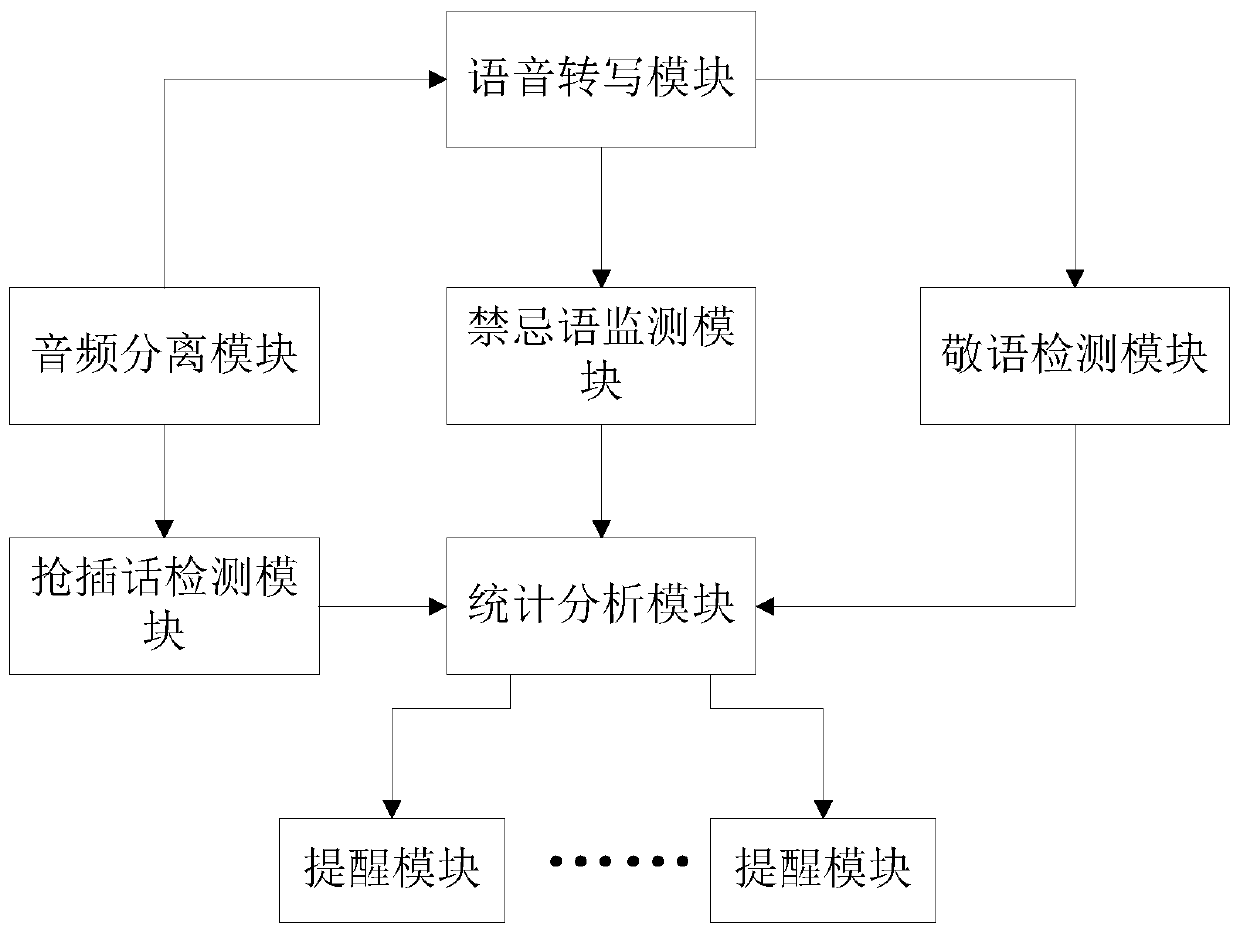

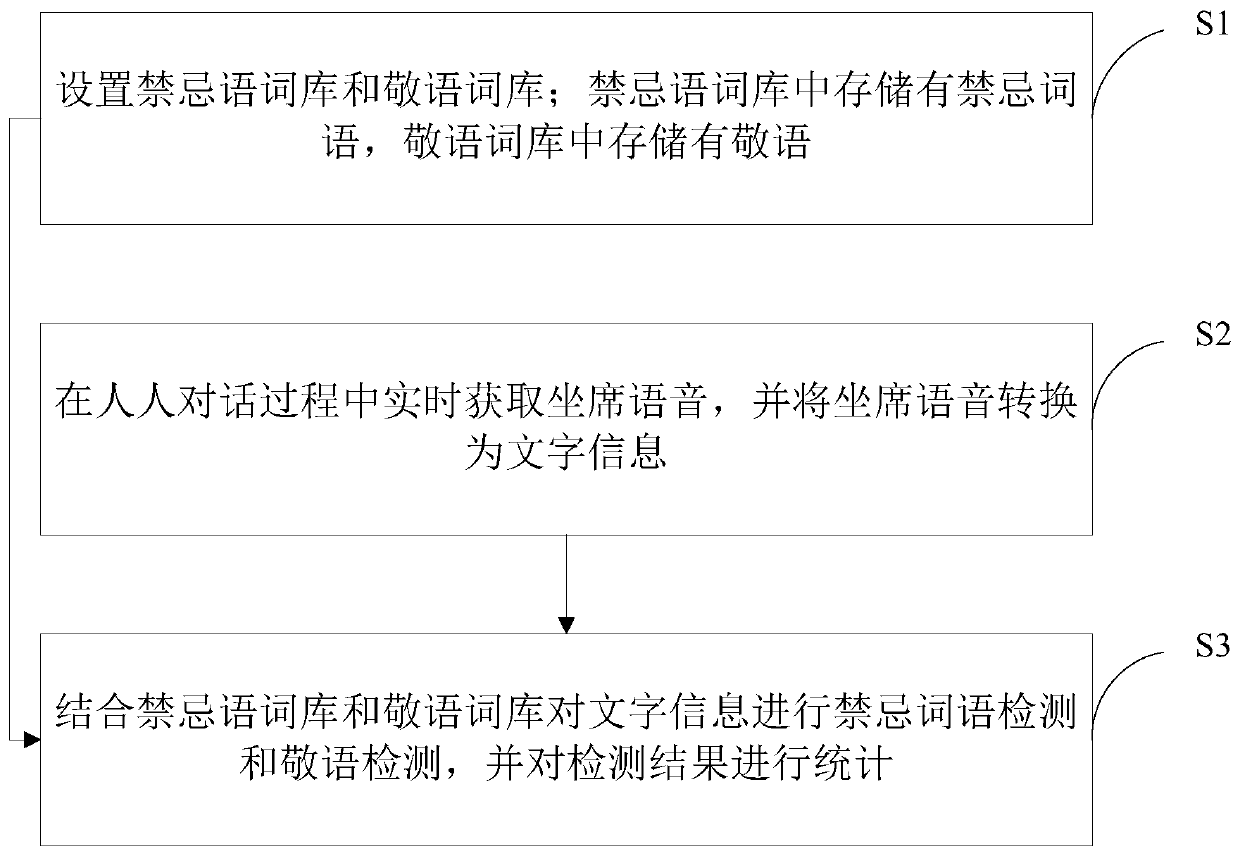

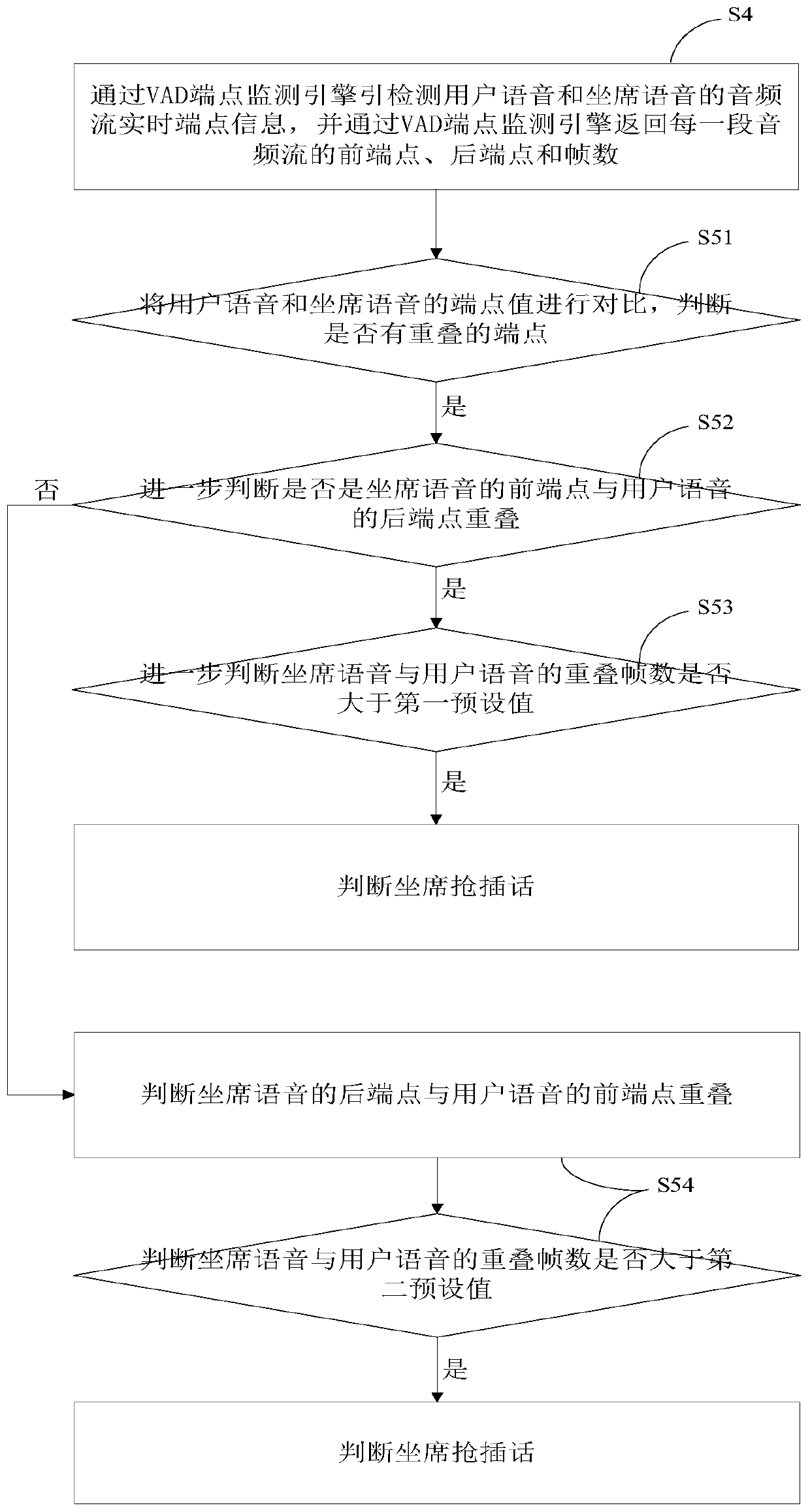

The invention provides a full-quantity real-time automatic service quality inspection system. The system comprises an audio separation module, an interruption detection module, a voice transliterationmodule, a tabu language monitoring module, a honorific detection module and a statistical analysis module. According to the full-quantity real-time automatic service quality inspection system provided by the invention, through audio separation, voice writing, word detection and interruption detection, voice flow information of human-to-human conversation is captured in real time and role separation is carried out, quasi-real-time voice transliteration and quality inspection are realized, and particularly, online detection and comprehensive quality inspection of customer service calls are realized.

Owner:科讯嘉联信息技术有限公司

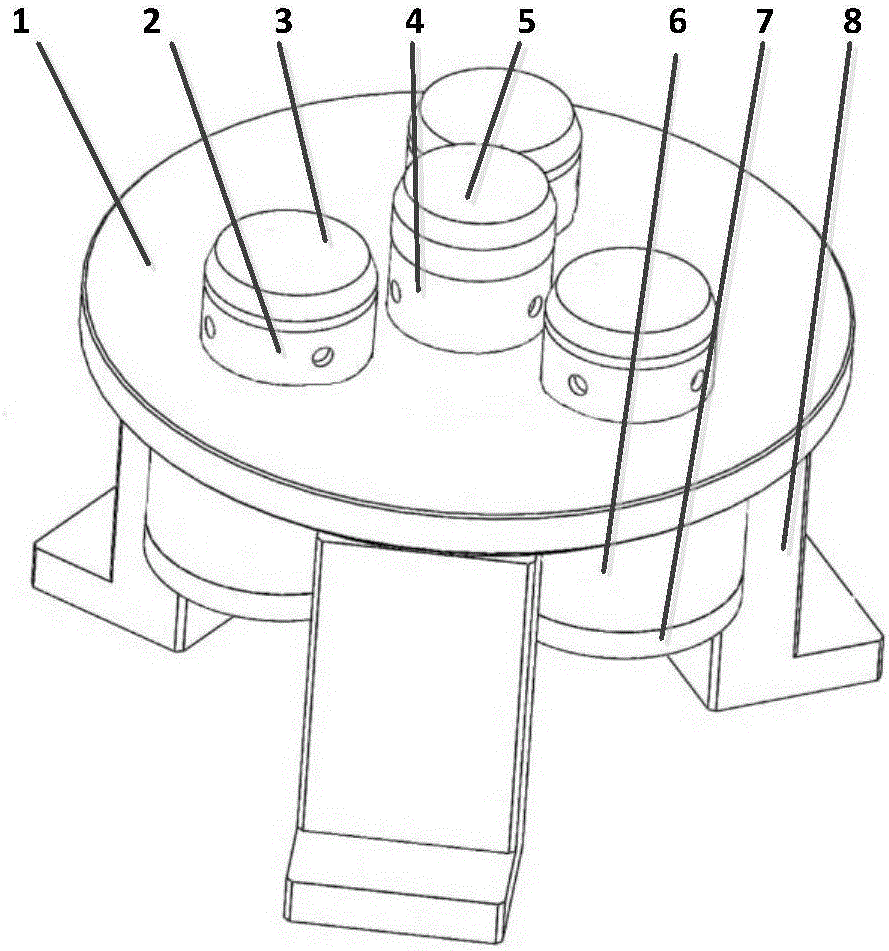

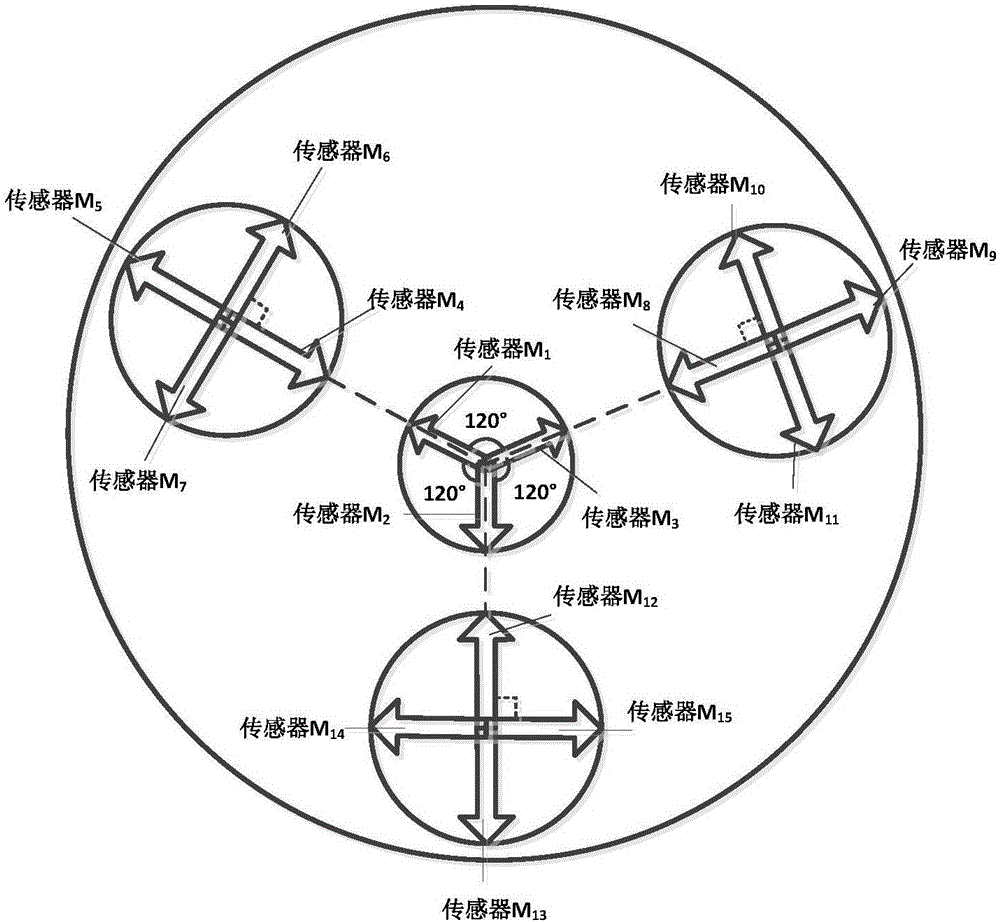

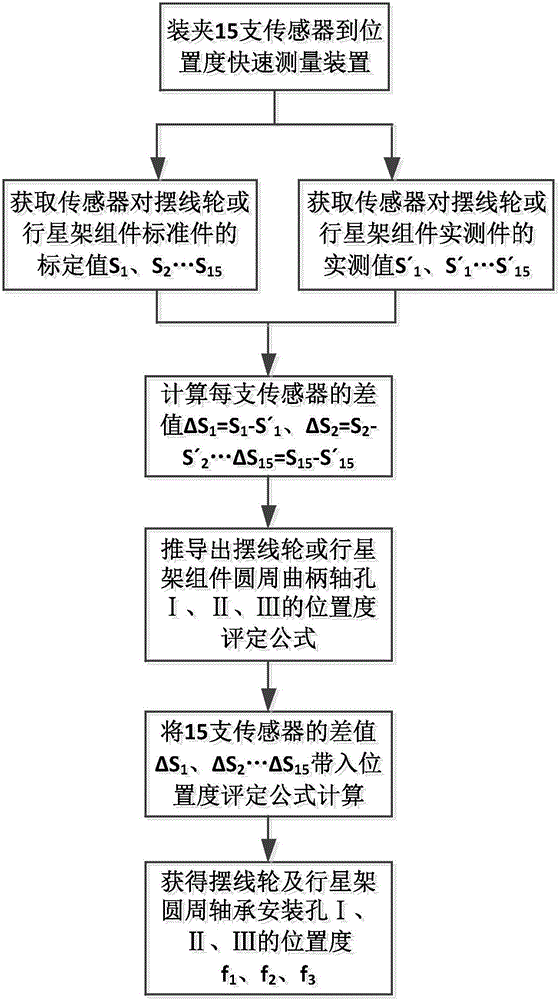

Location degree quick detection device and measuring method

InactiveCN105806282ARealize quality inspectionGuaranteed to workMeasurement devicesMeasurement pointEngineering

The invention provides a location degree quick detection device and measuring method.The device comprises a substrate.The substrate is connected with a center guide sleeve and three circumferential guide sleeves evenly distributed along the circumference with the center guide sleeve as the circle center.First sensor probe holes are formed in the circumference of the center guide sleeve at the interval of 120 degrees, second sensor probe holes are formed in the circumference of each circumferential guide sleeve at the interval of 90 degrees, and the axis directions of the circle centers of two second sensor probe holes are consistent with the axis directions of the circle centers of the corresponding first sensor probe holes.During measuring, deviation between a standard element, center holes of measured pieces and installation holes of circumferential crankshafts can be obtained by obtaining data of 15 measuring points of the center holes of cycloidal gears or planetary frames and the installation holes of the circumferential crankshafts, and the distance between ideal positions and actual positions of the circle centers of the installation holes of the three circumferential crankshafts is calculated through coordinate translation.The location degree is obtained through derivation.According to the device and method, detection of a quality detection center is not needed, and efficient work of a production line is guaranteed.

Owner:XI AN JIAOTONG UNIV

Quality check method of children's granules for clearing heat from throat

InactiveCN106442843ARealize quality inspectionGuaranteed stabilityWeighing by removing componentComponent separationPeppermintsQuality check

The invention discloses a quality check method of children's granules for clearing heat from throat. 1000g of the children's granules are prepared from the following crude drugs by quantity parts: 390.6g of mulberry leaves, 390.6g of radix isatidis, 260.4g of rhizoma belamcandae, 260.4g of radix scrophulariae, 260.4g of liquorice, 2.5mL of dementholized peppermint oil and 433-550g of soluble starch. The quality check method of the children's granules for clearing heat from throat comprises the following items: character: the product is the granules, is claybank to tawny and has fragrant smell and slightly sweet and slightly bitter taste; identification: a thin layer chromatography is adopted for identification; check: the check complies with the following various relevant provisions for the granules (Chinese Pharmacopoeia (General Principles 0104)); determination of extract: the determination comprises content determination of dilute ethanol extract; content determination: the content determination comprises content determination of tectoridin. The method is taken as a standard for checking the children's granules for clearing heat from throat, so that the stability of the preparation can be excellently ensured, thereby ensuring the curative effect of the preparation.

Owner:贵州中医药大学第二附属医院

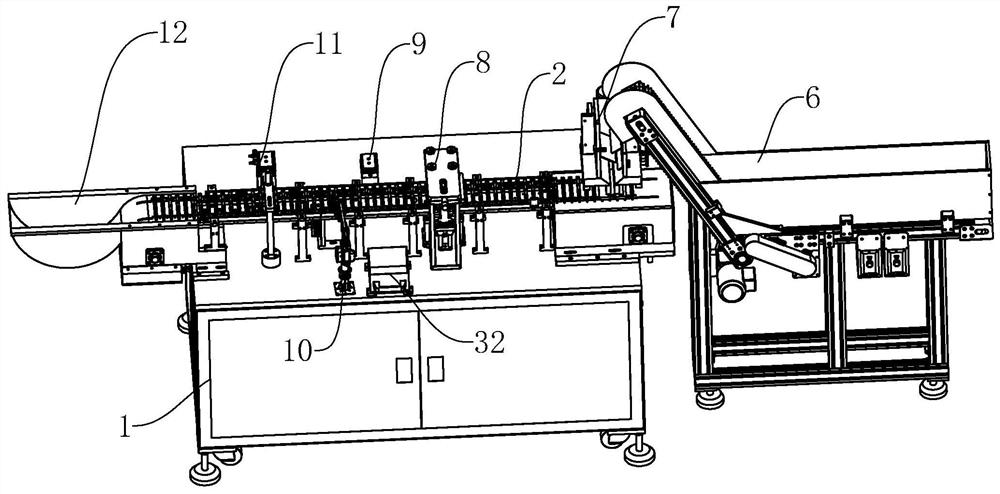

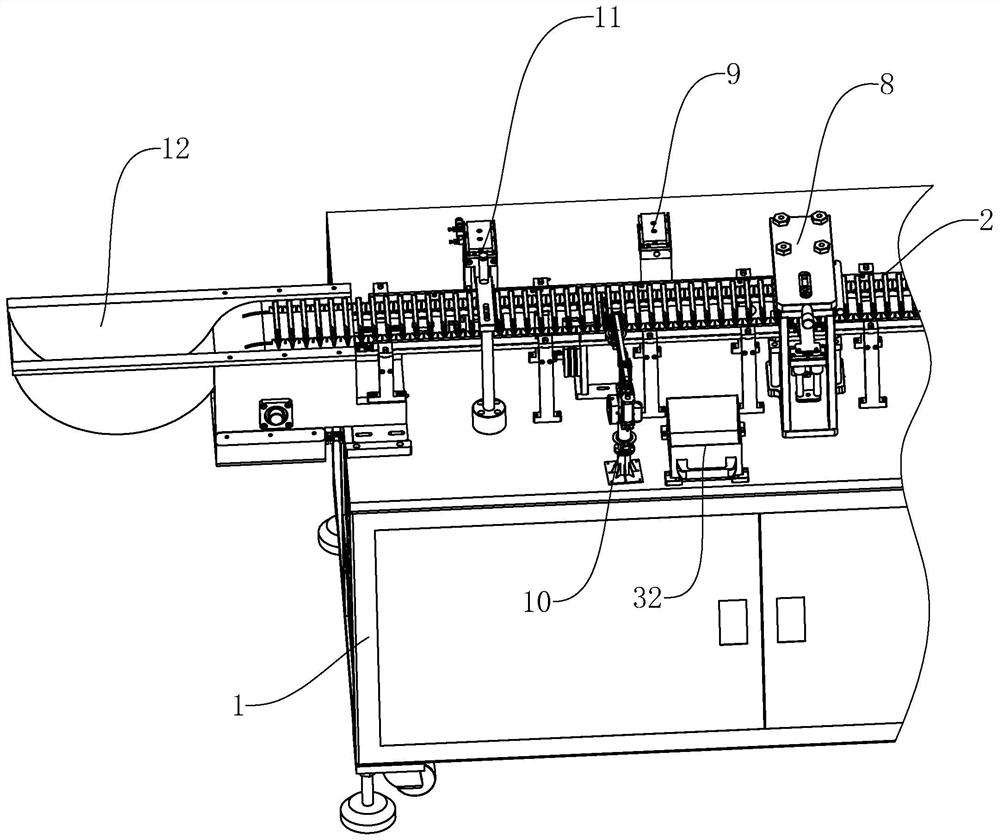

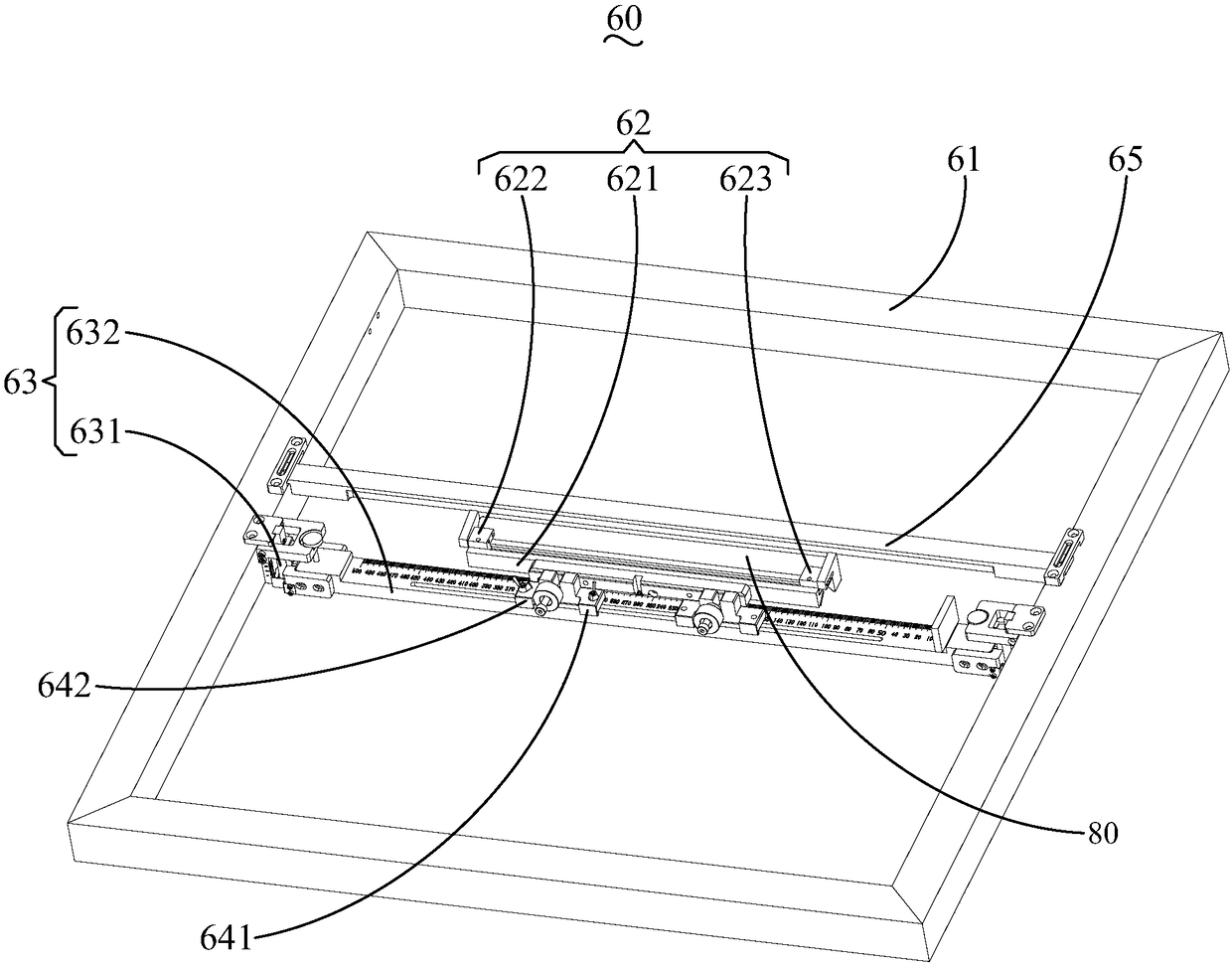

Medical needle cylinder processing equipment and processing method

InactiveCN113580748ARealize scale printingRealize quality inspectionHollow article cleaningRotary pressesControl cellPrinting press

The invention discloses medical needle cylinder processing equipment and a processing method. The medical needle cylinder processing equipment comprises a rack and a conveying chain arranged on the rack, clamping blocks are distributed on the two sides of the inner wall, in the length direction, of the conveying chain at equal intervals, the rack is sequentially provided with a feeding frame, a material blocking mechanism, a printing mechanism, a CCD detection assembly, a sorting mechanism, a cleaning mechanism and a storage box in the conveying direction of the conveying chain, needle cylinders are conveyed into the material blocking mechanism through the feeding frame and output one by one through the material blocking mechanism, the printing mechanism conducts scale printing on all the passing needle cylinders, the CCD detection assembly is used for monitoring each passing needle cylinder, if the CCD detection assembly monitors that printing on the surfaces of the needle cylinders is abnormal, a control unit starts the sorting mechanism to screen the unqualified needle cylinders and pick the unqualified needle cylinders into a sorting box on one side of the rack, and qualified products are conveyed into the storage box through the conveying chain. The equipment is high in automation degree and convenient to process, and the product processing quality is guaranteed.

Owner:WENZHOU CENT HOSPITAL

Cutting edge and formed hole imaging detector

PendingCN108613986ARealize quality inspectionOptically investigating flaws/contaminationCcd cameraCharge couple device

The invention discloses a cutting edge and formed hole imaging detector, comprising: a base; a discharge rack arranged on the base and used for holding an object under test; a lighting component arranged on the base and positioned below the object under test, wherein the lighting component is used for facing the object under test; a moving device; a CCD (charge coupled device) camera arranged on the base, wherein the CCD camera is arranged on the moving device and positioned above the object under test, the moving device drives the CCD camera to move such that the CCD camera acquires an imageof the object under test; a processor connected with the CCD camera and used for receiving and analyzing the image output by the CCD camera. The cutting edge and formed hole imaging detector for detecting quality of the periphery of a formed hole or quality of a cutting edge of a tool is provided herein.

Owner:SHENZHEN SUNMENTA ELECTRONICS

Method for identification and systematic classification of citrus variety based on 21 characteristic component content

ActiveCN107917982ARealize quality inspectionRealize monitoringComponent separationCHEMISTRY METHODSStandard samples

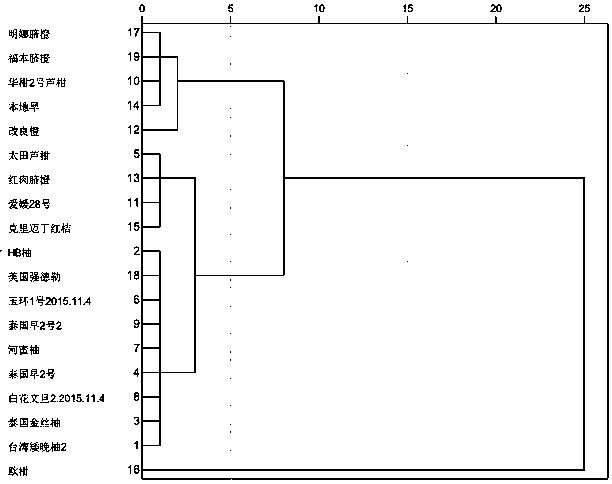

The invention belongs to the filed of analytical chemistry, particularly relates to a method for the identification and systematic classification of citrus variety based on 21 characteristic componentcontent. The method comprises the following steps: selecting citrus standard samples, measuring the contents of 17 characteristic components in the standard samples and the percent ratio of the content of 4 organic acids to the content of the total acid, utilizing the content and percent ratio as indexes to build a sample matrix, applying a principal component analysis method and a clustering methodology method, selecting the chemical component with largest weight in principal component as a distinguishing factor, utilizing the distinguishing factor as an independent variable, calculating thesquared euclidean distance among the citrus standard samples with the same variety, obtaining the squared euclidean distance range of the standard samples, measuring the characteristic component content of the distinguishing factor of samples to be measured, respectively calculating the squared euclidean distance range of the characteristic component content of the distinguishing factor of samples to be measured and the citrus standard samples and judging the variety of samples to be measured. The method can realize the effective distinguishing among different citrus variety, especially amongpomelo, citrus reticulate and orange and the like, and is an objective and reliable method for citrus classification.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

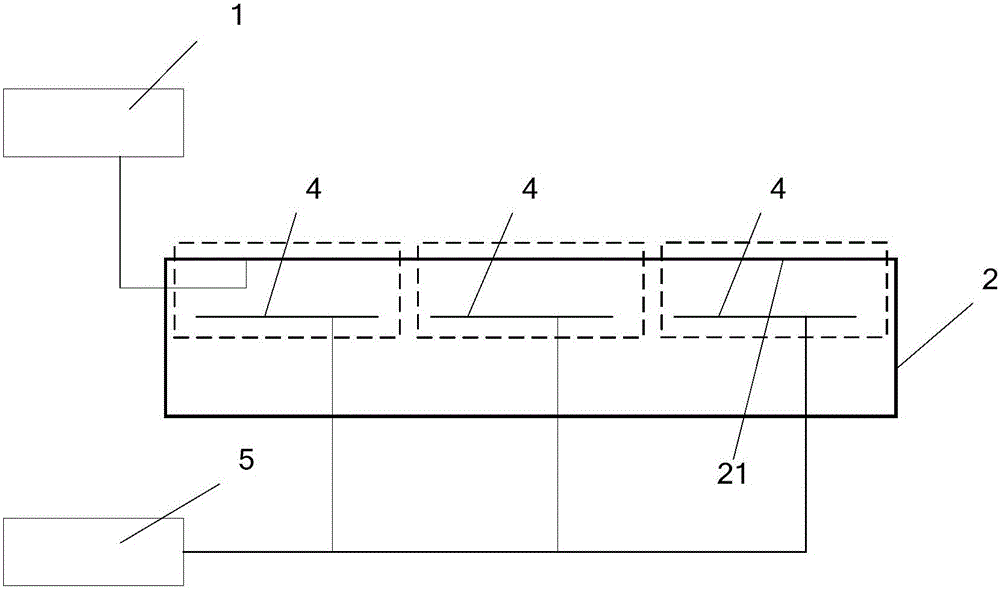

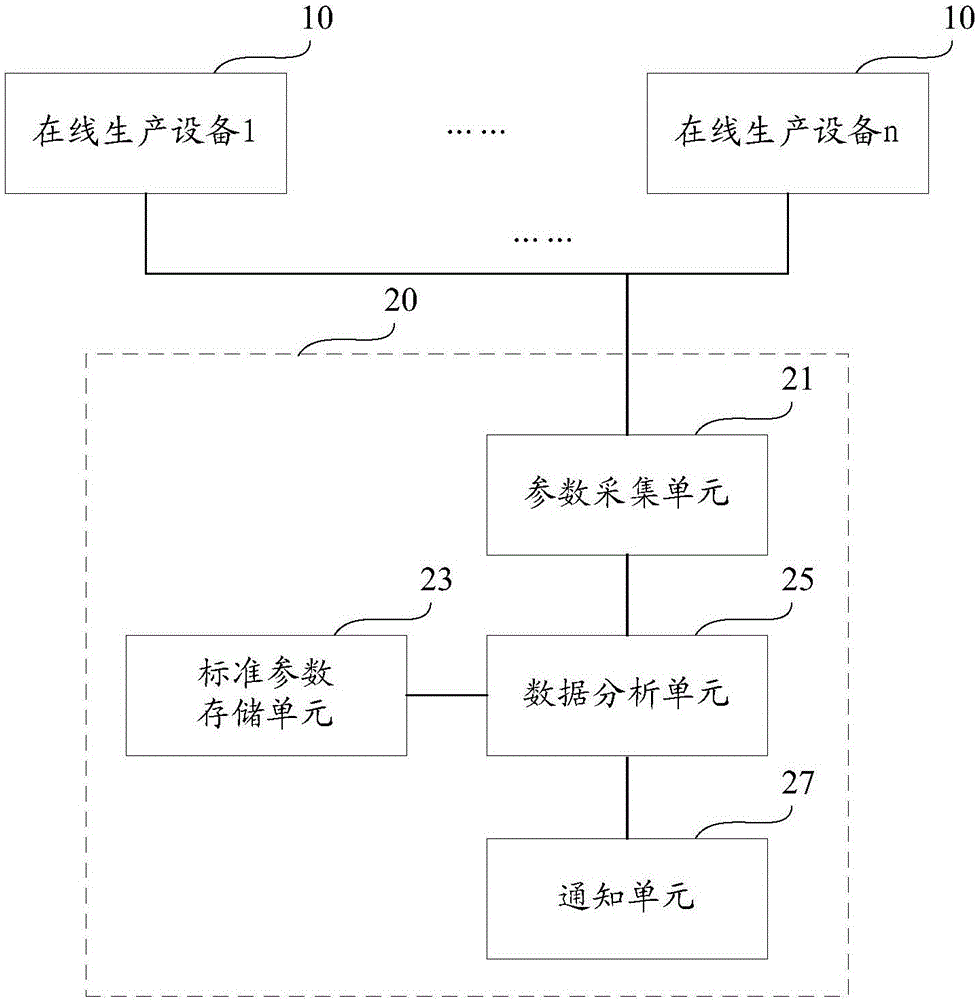

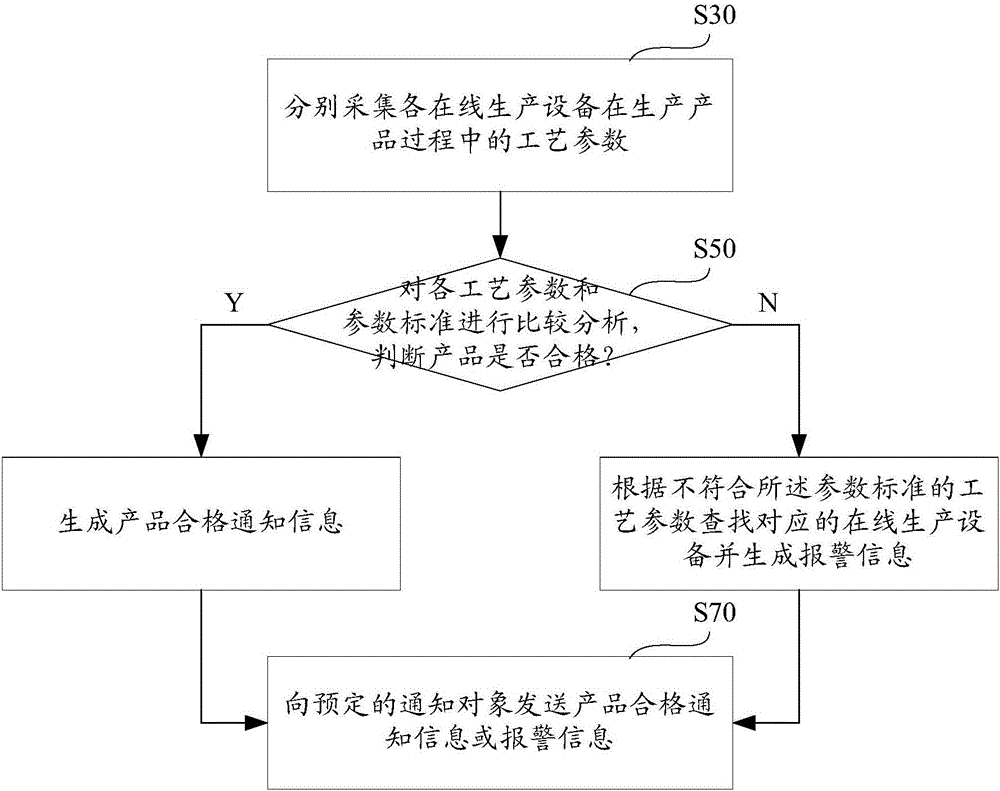

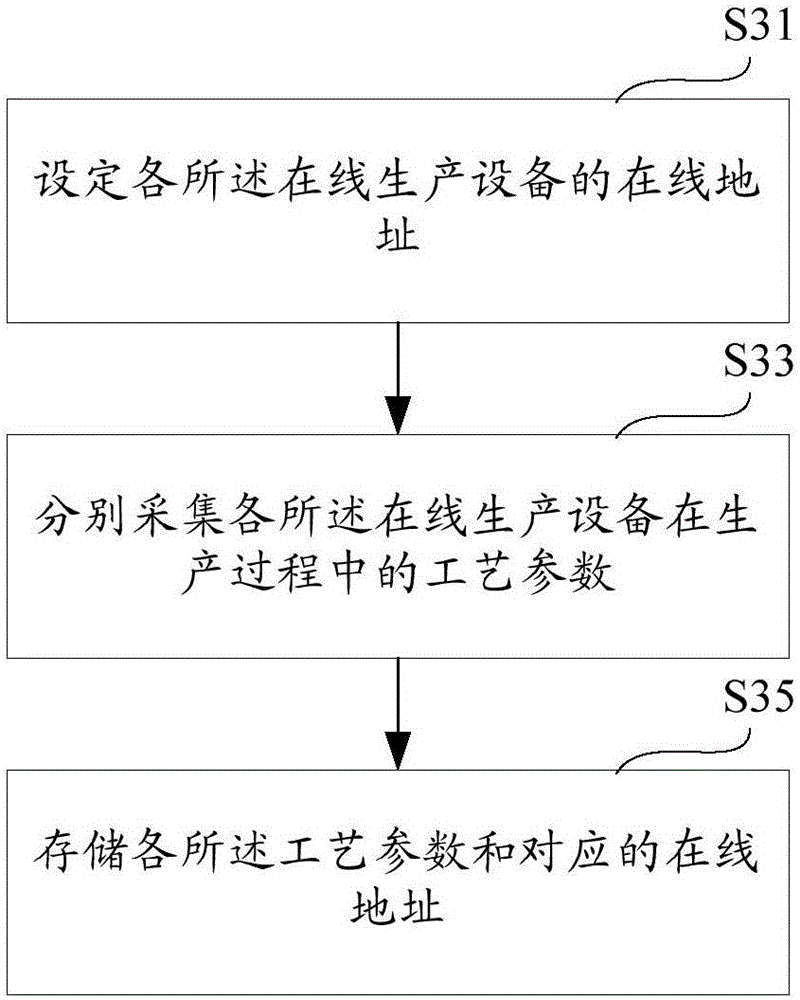

On-line production quality inspection system and method

ActiveCN106681204AFind in timeRealize quality inspectionProgramme controlComputer controlProduction qualityData analysis

The invention provides an on-line production quality inspection system and method. The system comprises: a parameter collection unit, which collects technological parameters of on-line production devices during product production; a standard parameter storage unit, which stores quality indexes of qualified products; a data analysis unit, which compares and analyzes the technological parameters and the quality indexes to determine whether products are qualified, generates product qualifying notice information, and searches corresponding on-line production devices and generates alarming information according to the technological parameters that do not meet the quality indexes; and a notification unit, which sends the product qualifying notice information or the alarming information to predetermined notice objects. The technological parameters are collected, the technological parameters and the prestored quality indexes are compared and analyzed, and thus quality detection of on-line production is realized. Moreover, the corresponding on-line production devices are searched according to the technological parameters that do not meet the quality indexes, and the alarming information is generated and sent. In this way, the production devices with problems can be found in time.

Owner:GUANGDONG WEIDA INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com