Monitoring method with processing self-adapting function and on-machine quality detection

An adaptive and functional technology, applied in the direction of adaptive control, computer control, program control, etc., can solve problems such as process processing troubles, occupying invalid time, affecting processing efficiency, etc., so as to reduce the number of card installations and enhance system integration The effect of expanding the function and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

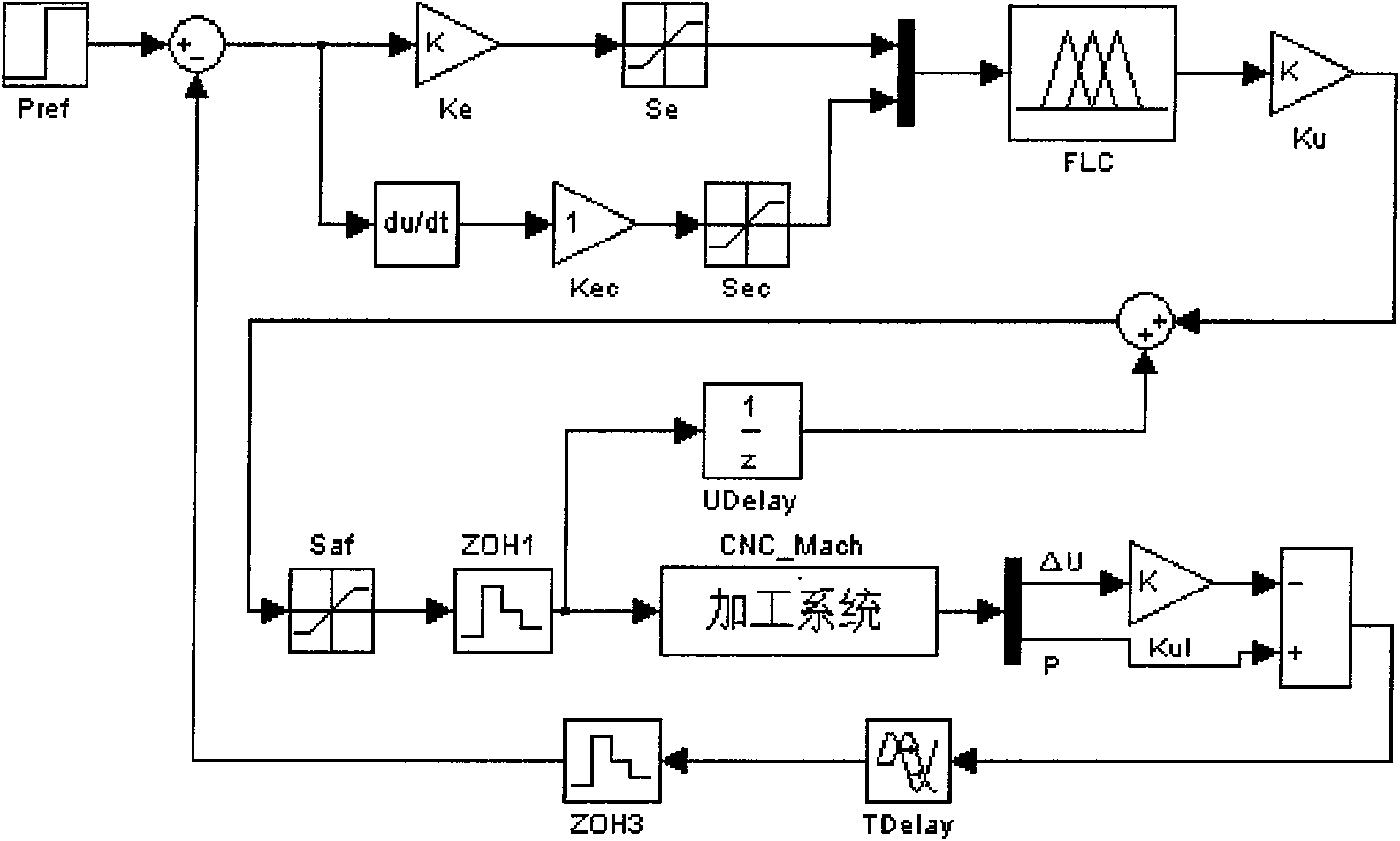

[0014] Hereinafter, the present invention will be described in detail by taking the intelligent numerical control system with integrated self-optimization function constructed according to the monitoring method of the present invention as an example.

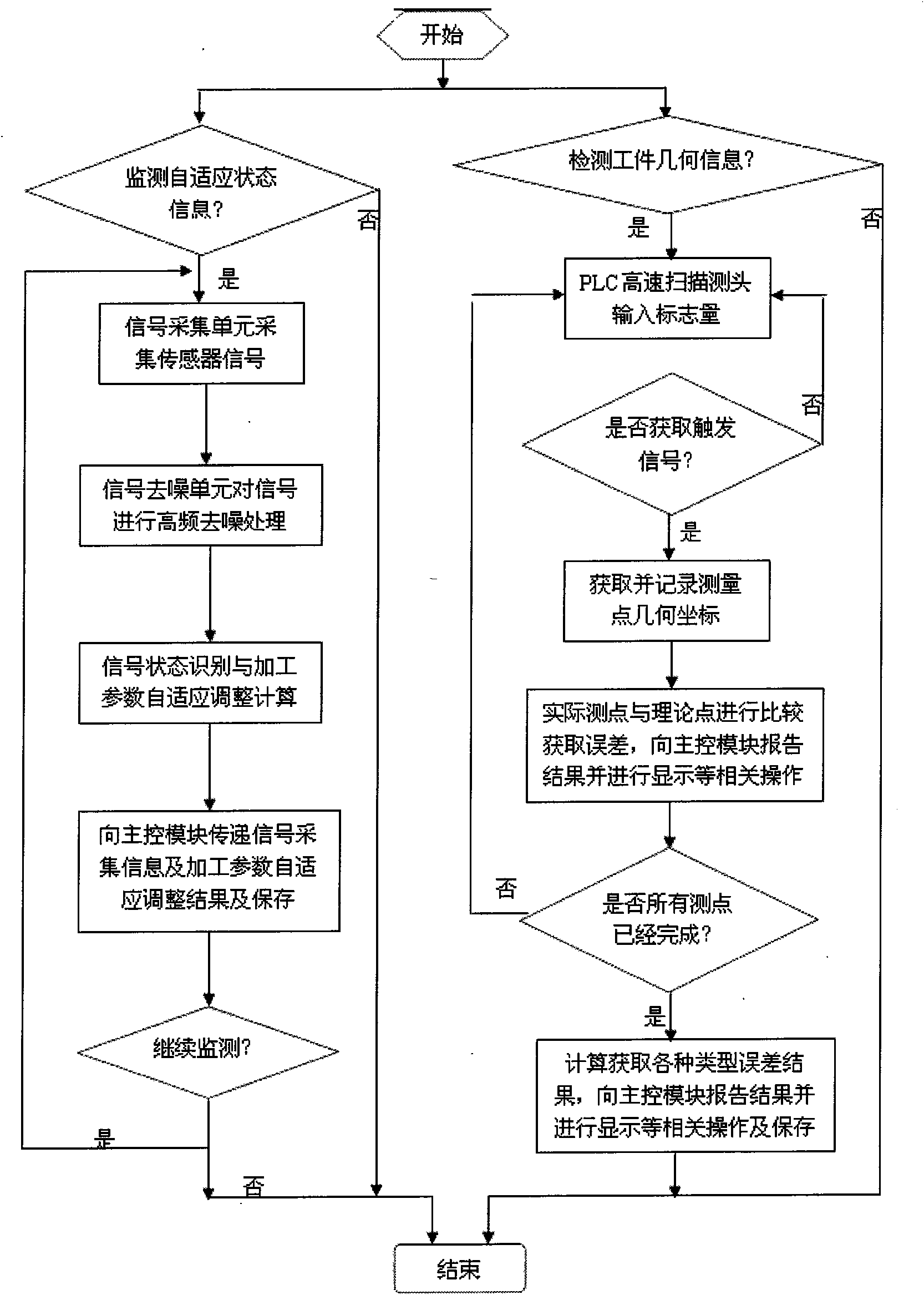

[0015] The numerical control system of the embodiment of the present invention is mainly composed of a main control module, a motion control module, a communication module, a processing adaptive module, and an on-machine quality detection module. The system basic module includes the following three items: main control module, motion control module and communication module. The specific structure of the basic module is as follows:

[0016] (1) Main control module

[0017] This module is mainly for the overall control and coordination of the system. Including system initialization, parameter management, global data management, overall task coordination, human-computer interaction management, motion program error detection, machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com