Location degree quick detection device and measuring method

A detection device and technology of position degree, which is applied in the field of rapid detection device of position degree, can solve the problems such as the complexity of flat-panel coordinate measurement, the inability to judge the direction, and the long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

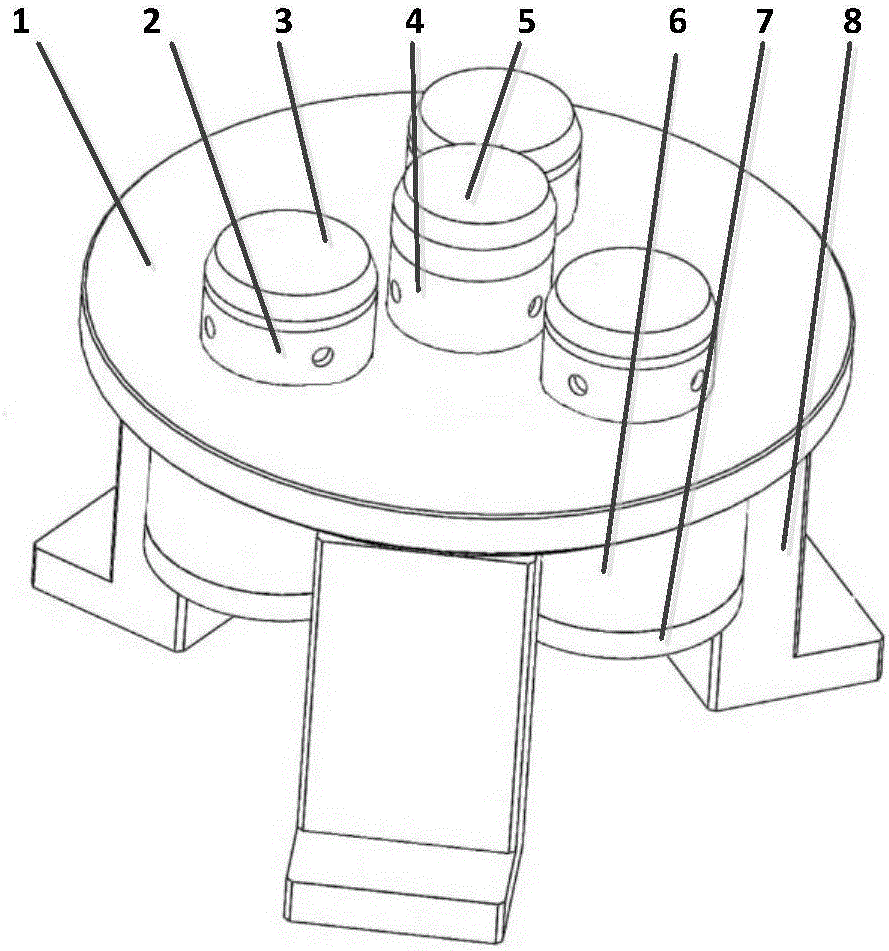

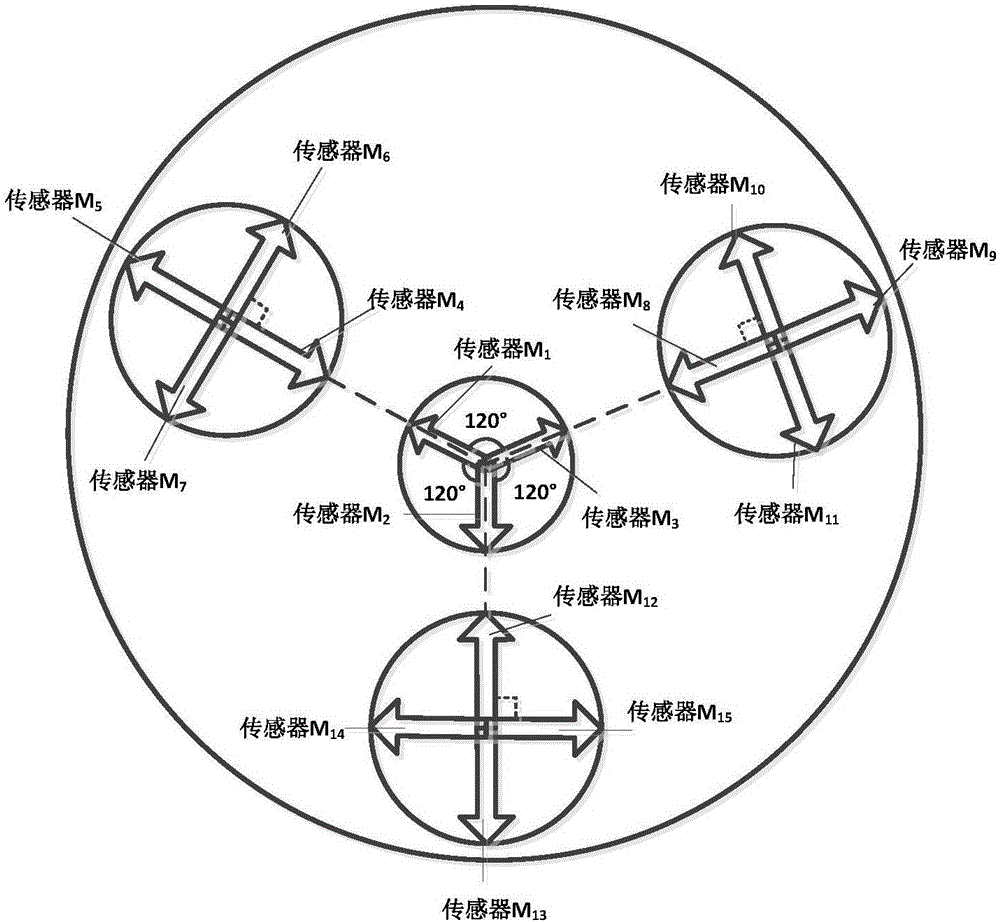

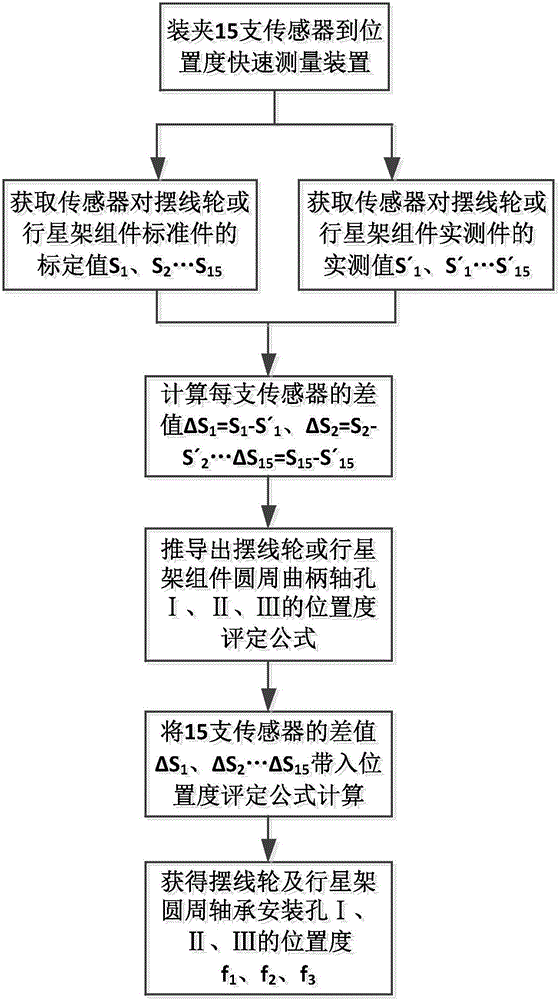

[0043] refer to figure 1 with figure 2 , a rapid position detection device, comprising a base plate 1, the base plate 1 is supported and fixed by three brackets 8, a central guide sleeve 4 and three center guide sleeves 4 are connected to the base plate 1, and the circumference is evenly distributed. The same circumferential guide sleeve 2, the central guide sleeve 4 and the circumferential guide sleeve 2 are all fixed on the base plate 1 through the spacer 6 and the sensor seat 7, and the circumference of the central guide sleeve 4 has an identical position in every 120° direction. The first sensor probe hole of each circumferential guide sleeve 2 has a completely identical second sensor probe hole in the direction of every 90°, wherein the axis direction of the center of the two second sensor probe holes is the same as The axis direction of the center of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com