Automatic detection device and method of geometric quality of arge-sized thin-plate metal workpiece

An automatic detection device, a technology of sheet metal, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems of limited detection workpiece size, high measurement accuracy requirements, large measurement size, etc., to improve the detection range and detection accuracy. , Improve production efficiency and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

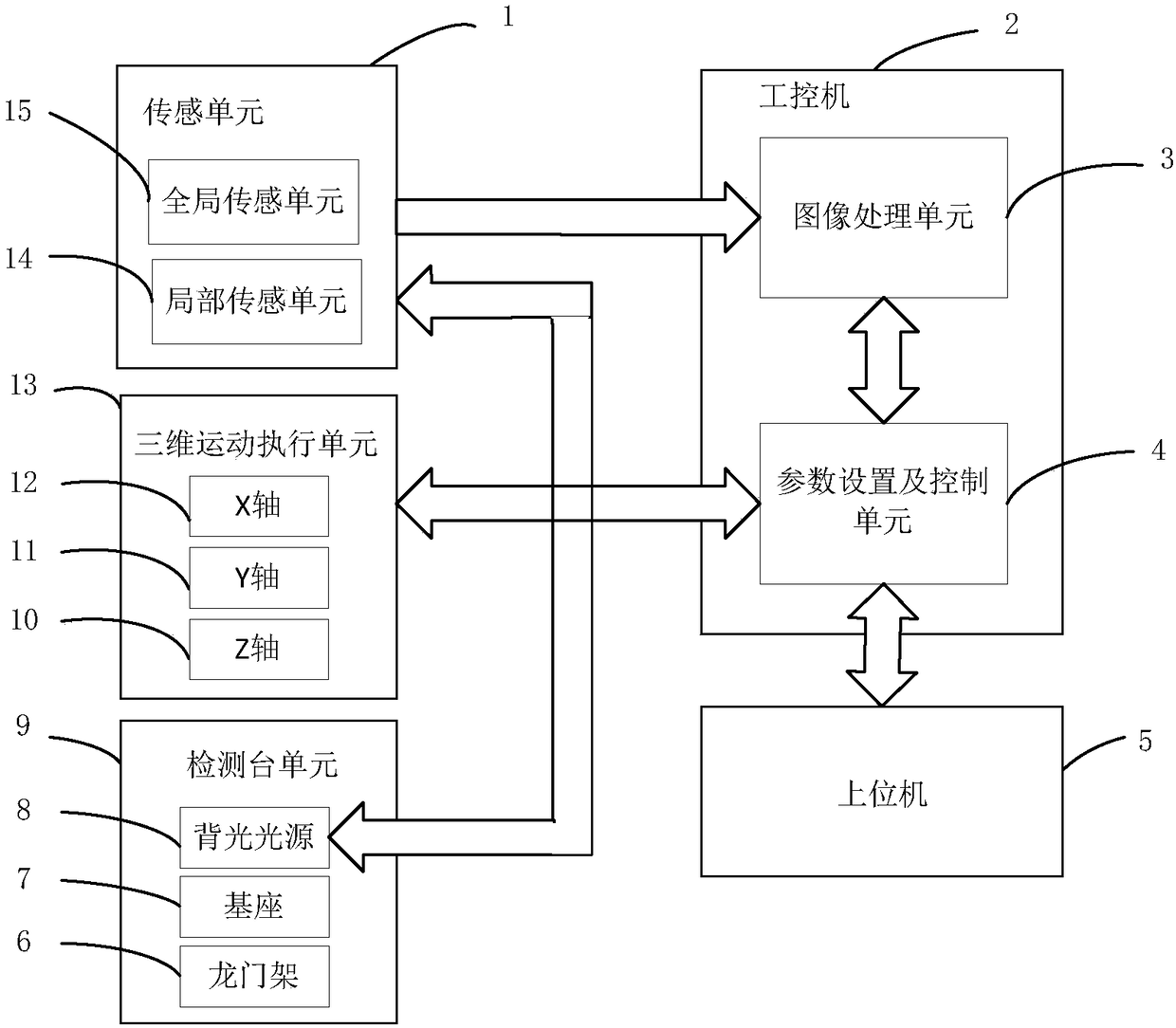

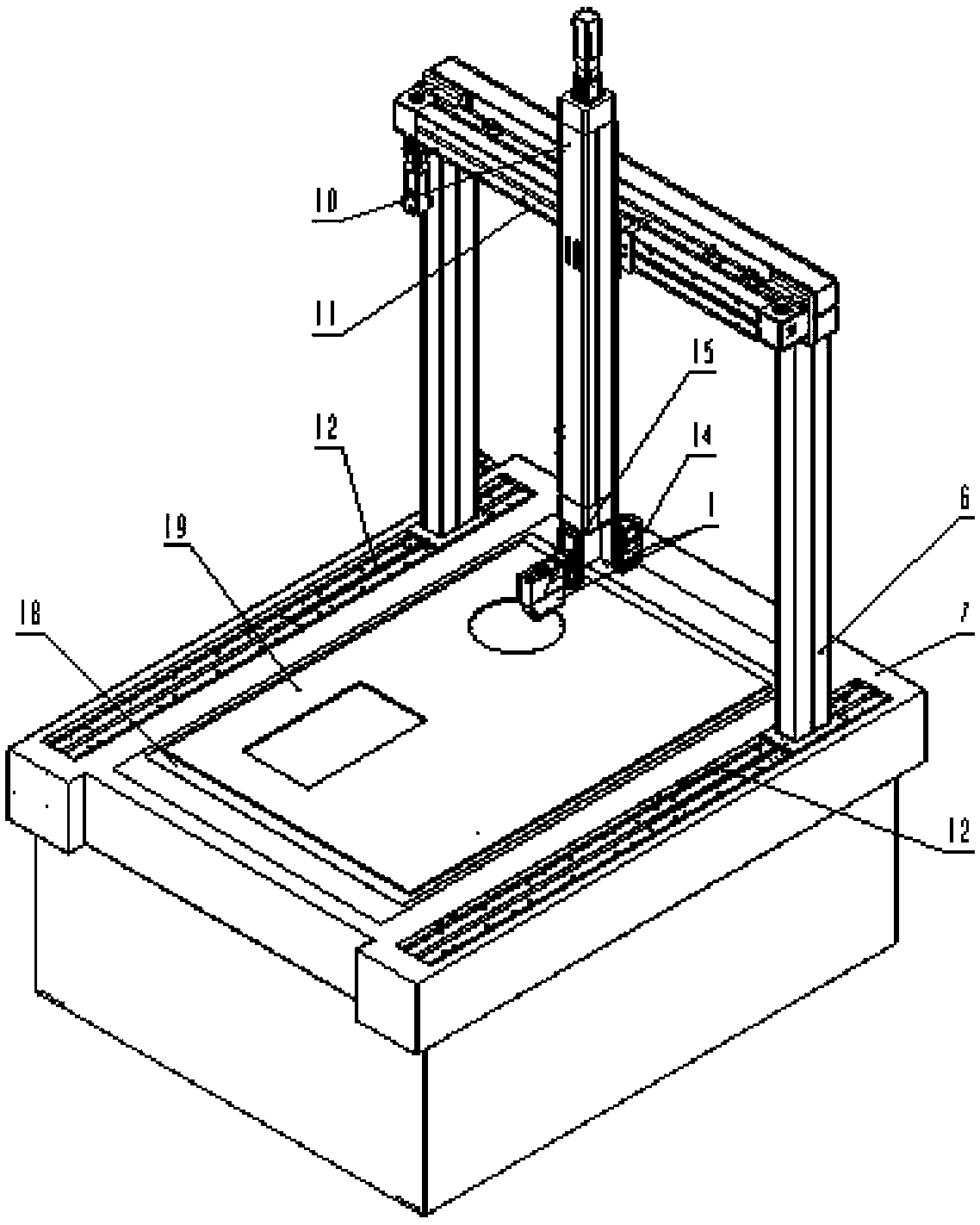

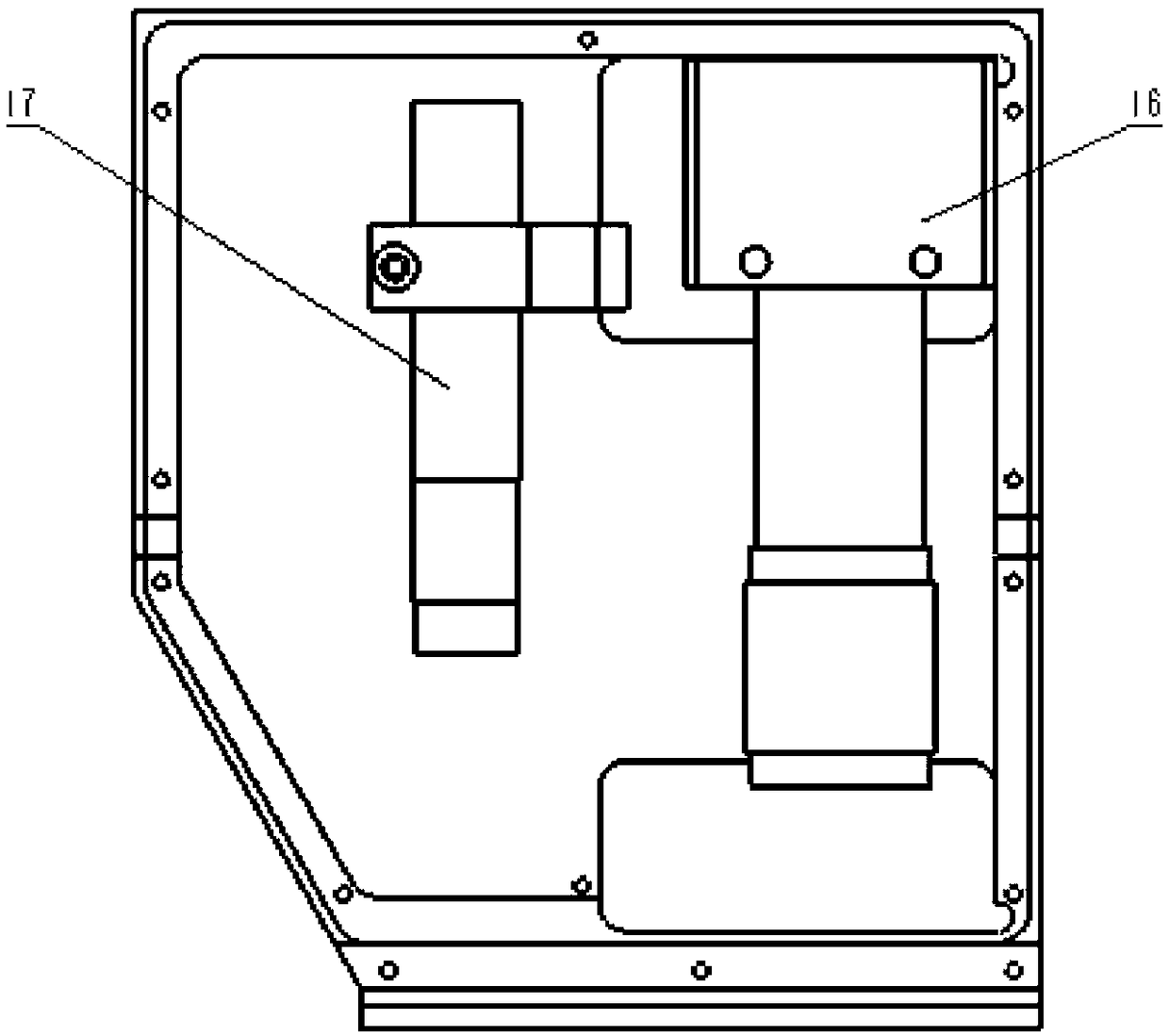

[0049] like Figure 1~2 As shown, the present invention is an automatic detection device for the geometric quality of a large-sized thin-plate metal workpiece, including: a detection table unit 9, a three-dimensional motion execution unit 13, and a sensing unit 1, wherein the upper surface of the detection table unit 9 is placed on the thin-plate workpiece to be measured 19. The three-dimensional motion execution unit 13 is installed above the detection table unit 9 , and the sensing unit 1 is installed on the three-dimensional motion execution unit 13 to collect the original image of the thin-plate workpiece 19 to be tested and transmit it to the industrial computer 2 .

[0050] The industrial computer receives the original image collected by the sensing unit 1 for processing, and outputs the detection result of the geometric quality of the workpie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com