Fuel vaporizing combustion device with high firepower and long service life

A technology with a long service life of a combustion device, applied to burners, lighting and heating equipment, etc., can solve the problems of parts damage, low device service life, poor heat dissipation performance of the device, etc., to achieve low noise, extended service life, and increased heating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

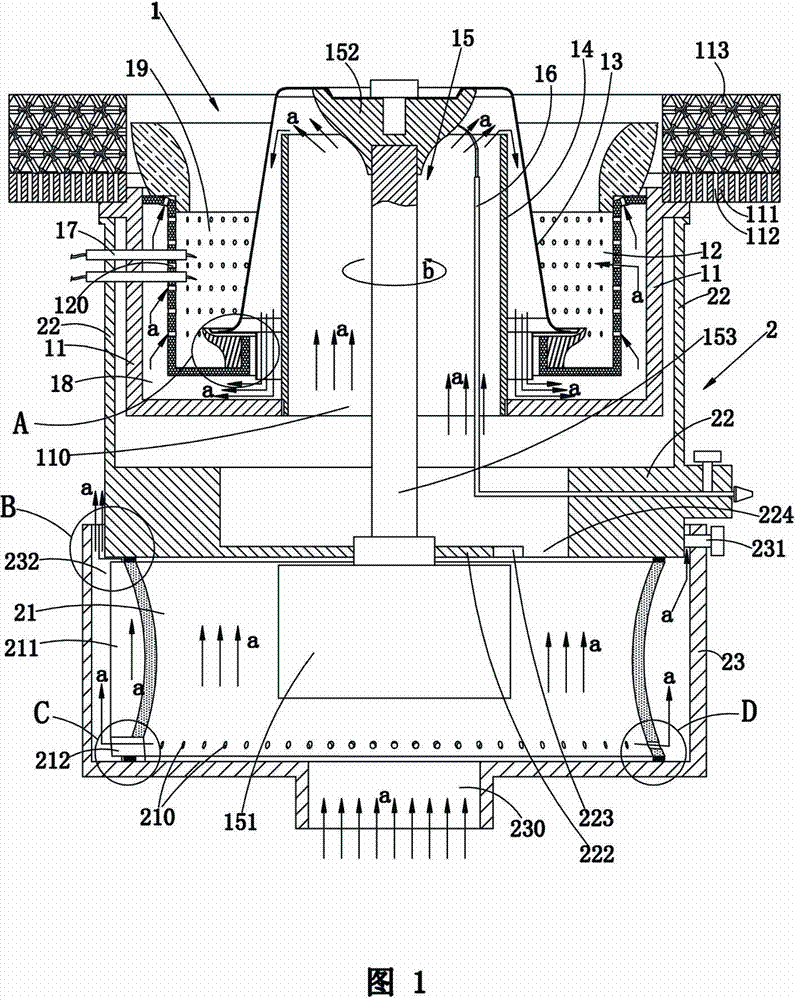

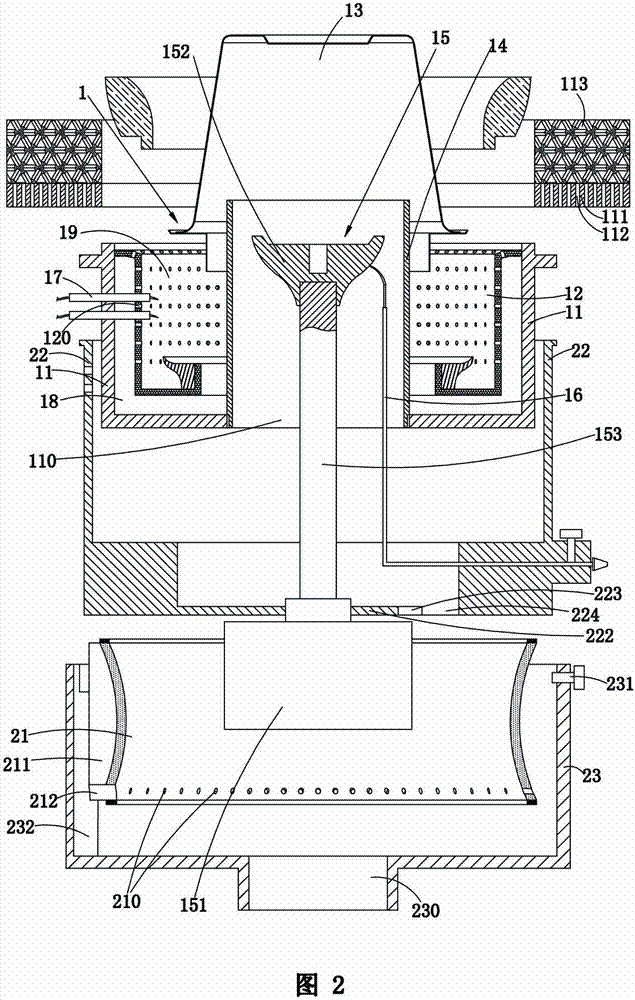

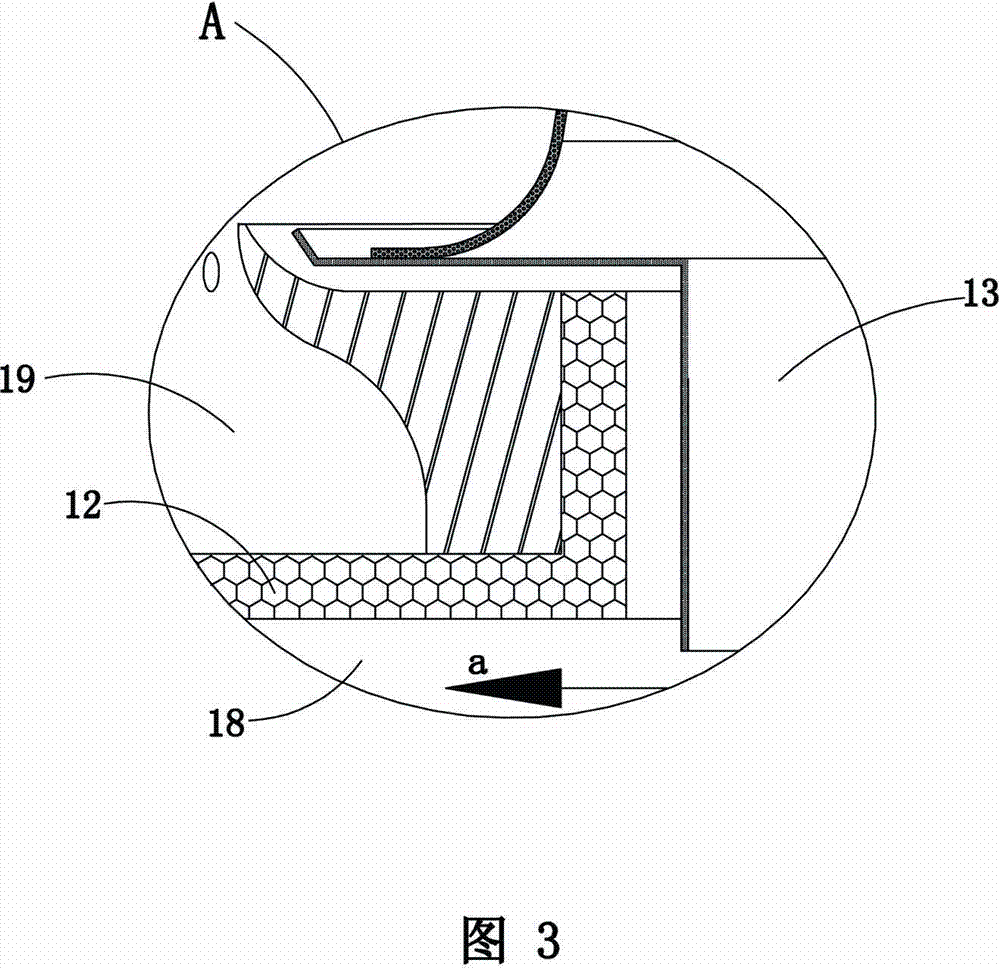

[0026] refer to figure 1 , figure 2 , Figure 6 , Figure 7 , a fuel oil vaporization combustion device with strong firepower and long service life, which includes a combustion part 1 and a heat dissipation mechanism 2. The heat dissipation mechanism 2 includes a shunt ring 21 and an upper shell 22 and a lower shell 23 with open tops. The bottom of the lower casing 23 is provided with an air inlet 230 for communicating with the fan, the splitter ring 21 is assembled in the lower casing 23, and the bottom surface of the upper casing 22 is connected to the top surface of the splitter ring 21 and assembled in the lower casing 23 , the combustion part 1 is assembled in the top of the upper casing 22 in communication with the air inlet 230 . Continue to refer to figure 1 , figure 2 , Figure 7 The inner diameter r1 of the middle part of the splitter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com