A circulating fluidized bed reaction device for alkane dehydrogenation-cracking to olefins

A cracking reaction and reaction device technology, applied in the field of circulating fluidized bed reaction devices, can solve the problem of high energy consumption for separation, and achieve the effects of low reaction temperature, convenient equipment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

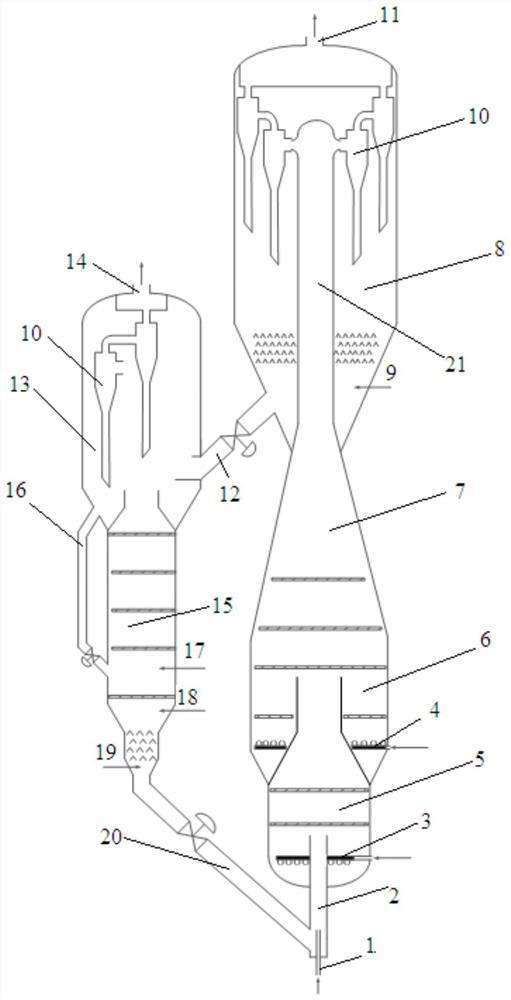

[0090] This embodiment refers to the attached figure 1 As shown, the alkane catalytic dehydrogenation-cracking reaction device for producing olefins provided by this application is used in conjunction with the catalyst regeneration device. These two sets of devices can be used separately, and respectively used in combination with other reaction devices or catalyst regeneration devices in the prior art.

[0091] The reaction device for producing alkenes by catalytic dehydrogenation-cracking of alkanes includes a catalytic dehydrogenation-cracking reactor and a settling section 8 of the reactor, and the settling section 8 of the reactor is located at the upper part of the reactor. Wherein, the reactor includes a diameter-reducing section 7, a dehydrogenation dense-phase reaction section 6, and a cracking reaction section 5, the diameter-reducing section 7 is located above the dehydrogenation dense-phase reaction section 6, and the cracking reaction section 5 is located at the de...

Embodiment 2

[0106] Compared with Embodiment 1, this embodiment is in that the dilute phase delivery section of the reactor is connected with the cyclone 10 in the settler in a socket type. This connection method can quickly separate the catalyst from the oil and gas, which is not only beneficial to reduce the secondary reaction of olefins generated by dehydrogenation, but also reduces the partial pressure of oil and gas in the settler, which can effectively avoid coking in the settler.

experiment example 1

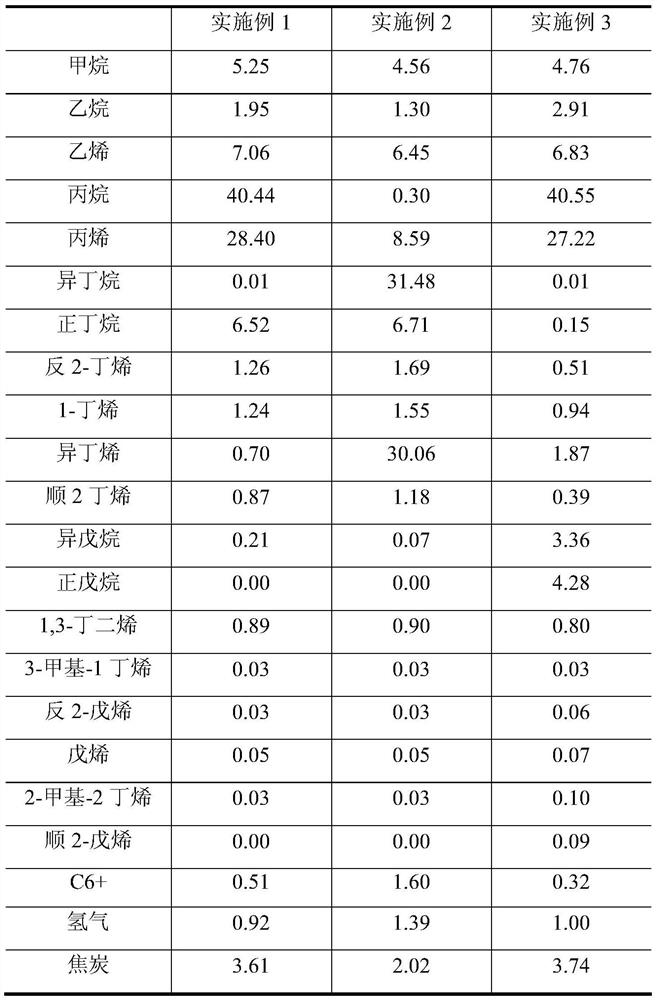

[0108] Pure n-butane is used as the raw material for dehydrogenation cracking, and pure propane is used as the raw material for dehydrogenation, and the mass ratio of the two feeds is 1:2. The catalyst is a non-precious metal environment-friendly catalyst produced according to ZL 2011 1012 3675.1. Experimental Examples 2-3 also all used this catalyst.

[0109] The average temperature of the dehydrocracking zone is controlled at 700°C, the average residence time of oil and gas in the dehydrocracking zone is 5s, and the superficial gas velocity of oil and gas under the actual reaction conditions in this zone is 1.7m / s.

[0110] The average temperature of the dehydrogenation zone is controlled at 600°C, the pressure of the settling section of the reactor (in terms of hydrocarbon partial pressure) is 0.042MPa, and the average residence time of oil and gas (including dehydrogenation cracked oil and gas) in the dehydrogenation zone is 8s. The superficial gas velocity under the actu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com