Fully-perforated microwave absorbing material and preparation method thereof

A microwave-absorbing material and fully open-hole technology, which can be used in radiation-absorbing coatings, polyurea/polyurethane coatings, chloroprene homopolymer coatings, etc., and can solve problems such as large environmental pollution and microwave absorption performance not listed , to achieve the effects of less environmental pollution, flexible implementation, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

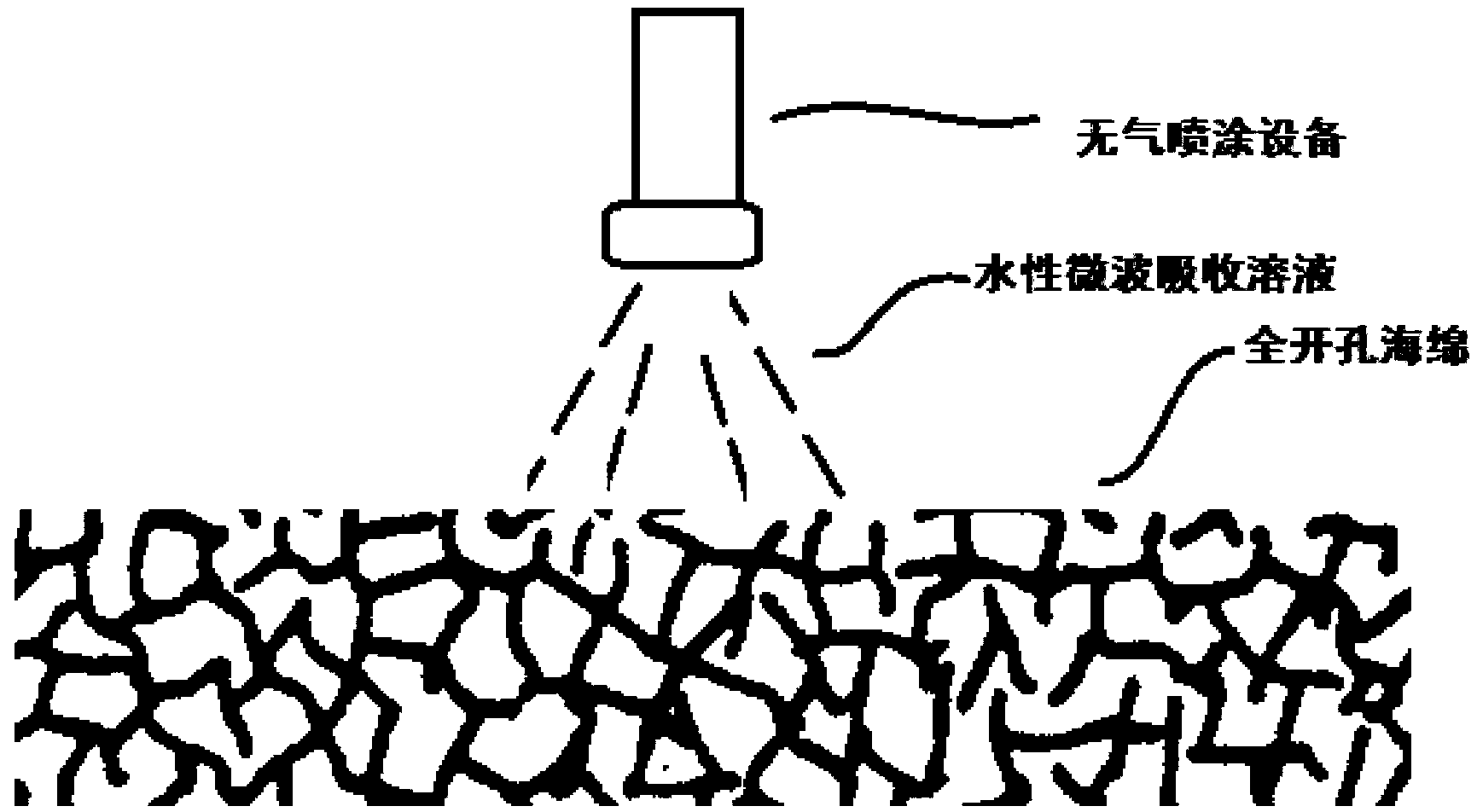

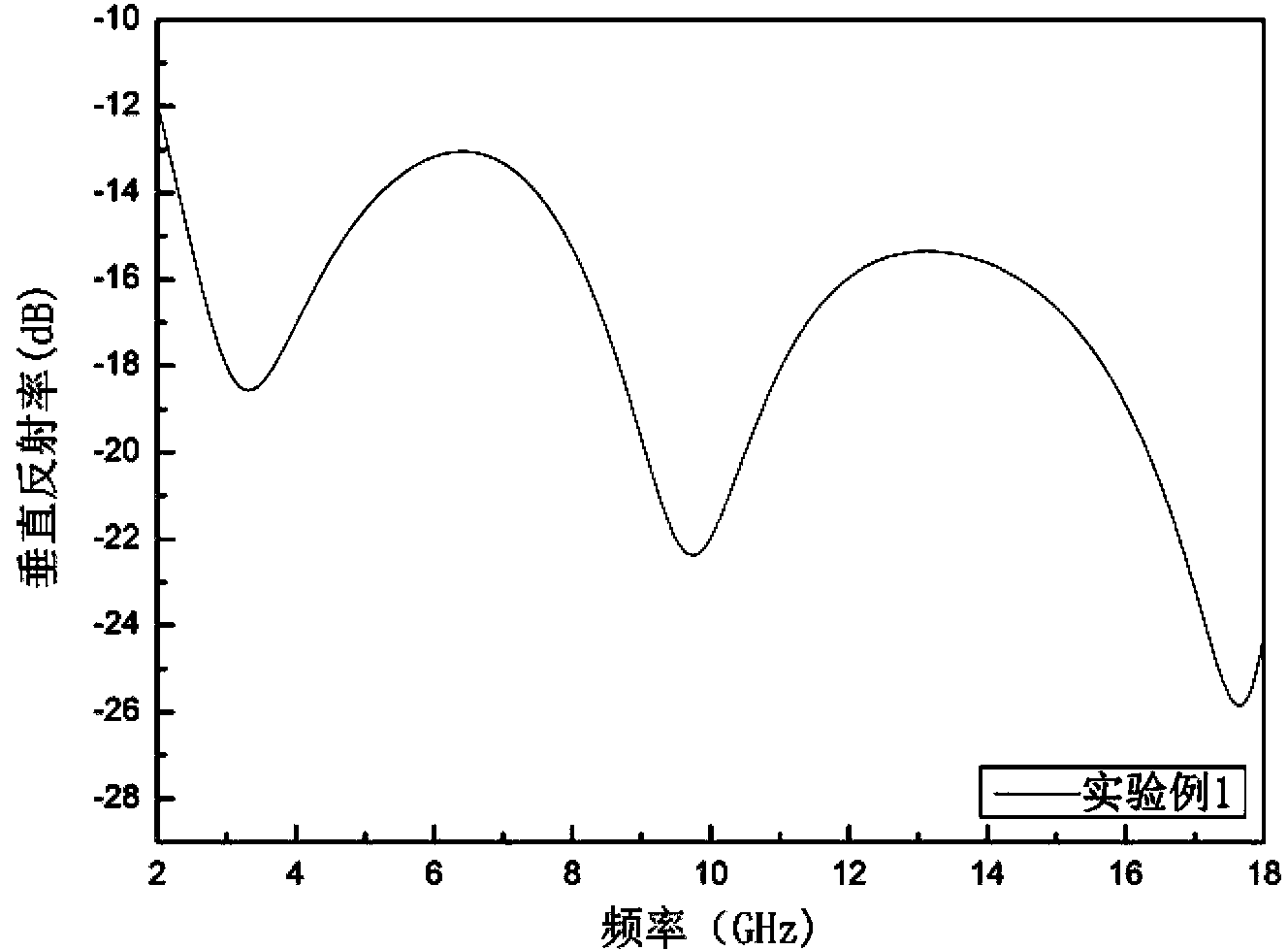

[0023] Weigh 690g of water and 11g of dispersant N into a plastic container, set the speed at 500RPM, and disperse evenly with an F-0.4 high-speed disperser. Then add 42g of conductive carbon black, 15g of barium titanate, 4g of silicon dioxide, 15g of tetrabromobisphenol A, and 5g of antimony trioxide in sequence, adjust the rotation speed to 1500RPM, and disperse for 20min to form a conductive paste. Import the conductive paste into the LKS-21 vertical sand mill, and the sanding time is 30min. After sanding, the conductive slurry is filtered with a 300-mesh stainless steel gauze, and 217gPU-113 water-based polyurethane binder (solid content 35%), 1g silver-plated T3 conductive copper powder (300 mesh) is added, and the F-0.4 high-speed disperser Disperse for 25 minutes to make an aqueous microwave absorbing solution. Take a square fully-opened sponge with a thickness of 2 cm and a side length of 50 cm, with a pore diameter of 0.3-0.5 cm and a pore density of 5-8 per square ...

Embodiment 2

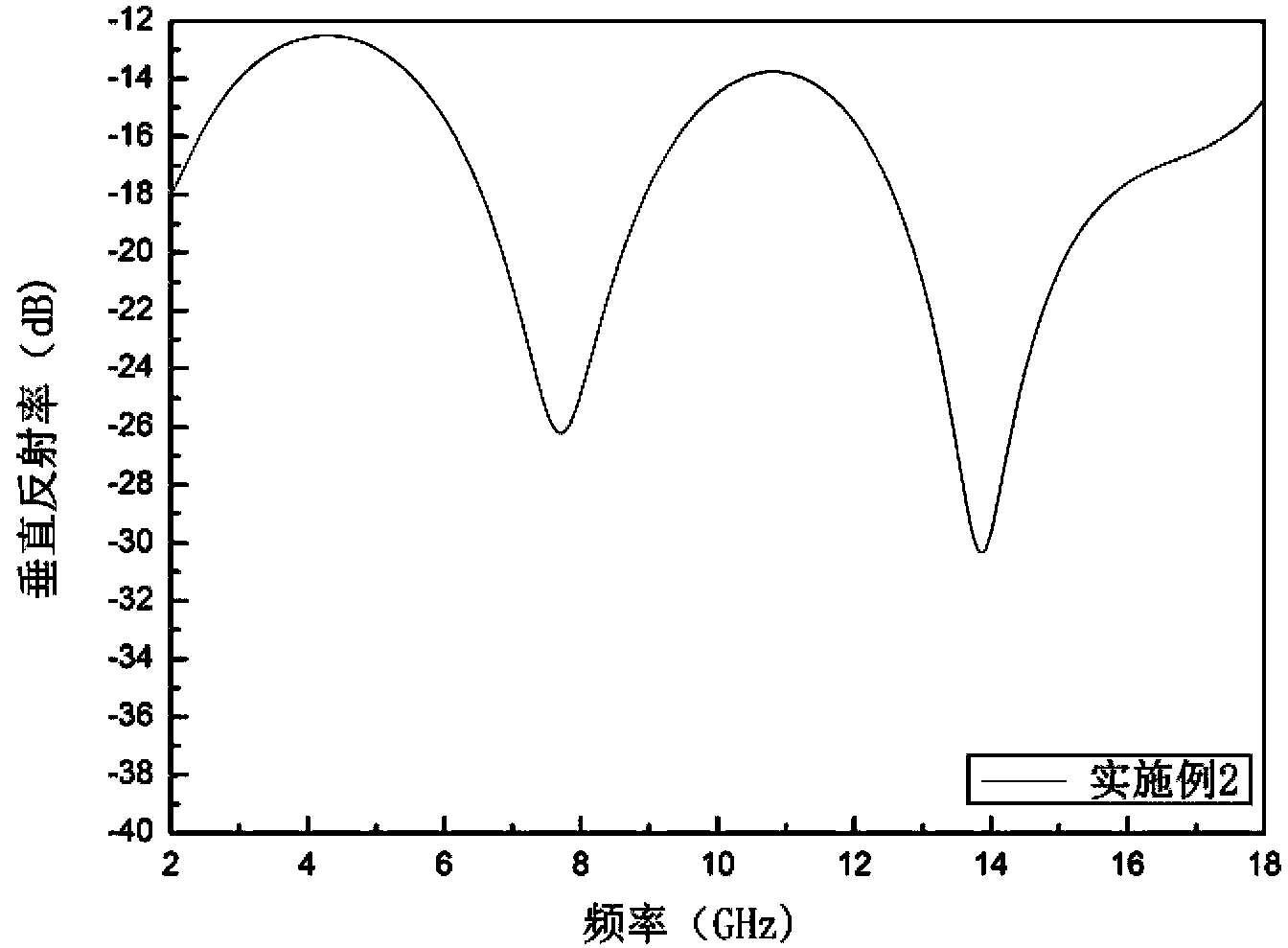

[0025] Weigh 668g of water and 11g of dispersant N into a plastic container, set the speed at 500RPM, and disperse evenly with an F-0.4 high-speed disperser. Then add 42g of conductive carbon black, 32g of barium titanate, 8g of silicon dioxide, 15g of tetrabromobisphenol A, and 5g of antimony trioxide in sequence, adjust the rotation speed to 1500RPM, and disperse for 20min to form a conductive paste. Import the conductive paste into the LKS-21 vertical sand mill, and the sanding time is 30min. After sanding, the conductive slurry is filtered with 300-mesh stainless steel gauze, and 217gPU-113 water-based polyurethane binder (solid content 35%), 2g silver-plated T3 conductive copper powder (300 mesh) are added, and the powder is mixed in the F-0.4 high-speed disperser Disperse for 25 minutes to make an aqueous microwave absorbing solution. Take a square fully-opened sponge with a thickness of 2 cm and a side length of 50 cm, with a pore diameter of 0.3-0.5 cm and a pore dens...

Embodiment 3

[0027] Weigh 633g of water and 11g of dispersant N into a plastic container, set the speed at 500RPM, and disperse evenly with an F-0.4 high-speed disperser. Then add 42g of conductive carbon black, 65g of barium titanate, 9g of silicon dioxide, 15g of tetrabromobisphenol A, and 5g of antimony trioxide in sequence, adjust the rotation speed to 1500RPM, and disperse for 20min to form a conductive paste. Import the conductive paste into the LKS-21 vertical sand mill, and the sanding time is 30min. After sanding, the conductive slurry is filtered with a 300-mesh stainless steel gauze, and 217g of PU-113 water-based polyurethane binder (solid content 35%) and 3g of silver-plated T3 conductive copper powder (300 mesh) are added, and dispersed at F-0.4 at high speed Disperse by machine for 25 minutes to make an aqueous microwave absorbing solution. Take a square fully-opened sponge with a thickness of 2 cm and a side length of 50 cm, with a pore diameter of 0.3-0.5 cm and a pore de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com