Visual detection device and method for wire rods without tension constraint

A visual inspection device and tension-free technology, which is applied in measurement devices, material analysis, material analysis by optical means, etc., can solve problems such as not taking into account, ensure consistent imaging resolution, realize surface quality inspection, and realize surface quality inspection. The effect of visual inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

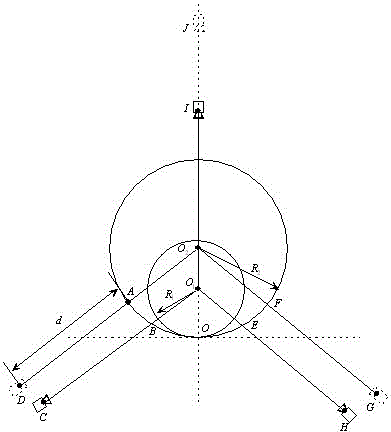

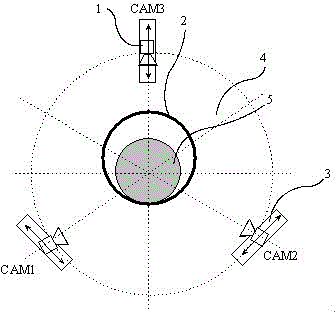

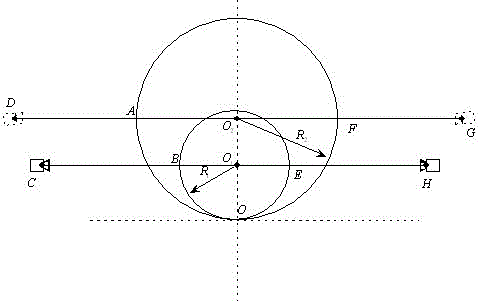

[0031] see Image 6 with Figure 14 , a device for visual detection of wire rods under no tension constraints, including several cameras 1, the cameras 1 are installed on the sliding guide rail 3, the sliding guide rail 3 is fixed on the fixed plate 4, and the sliding guide rail 3 is along the circumference of the hollow guide groove 2. Distribution, when the detected wire 5 passes through the hollow guide groove 2, each camera 1 images the outer surface of the wire 5, and the cameras 1 are evenly arranged on a circle centered on the outer circular center of the cross-section of the detected wire 5, and the cameras 1 The imaging distance is equal to the detected wire 5; when the specification of the wire 5 changes, the position of the camera 1 is adjusted along the sliding guide rail 3 to keep the imaging distance between the camera and the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com