Twisted cable quality detection system based on machine vision and detection method for same

A detection system and machine vision technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as damage to cable strands, affect production progress, and inaccurate detection, so as to avoid head-on damage, convenient and quick installation, and accurate detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

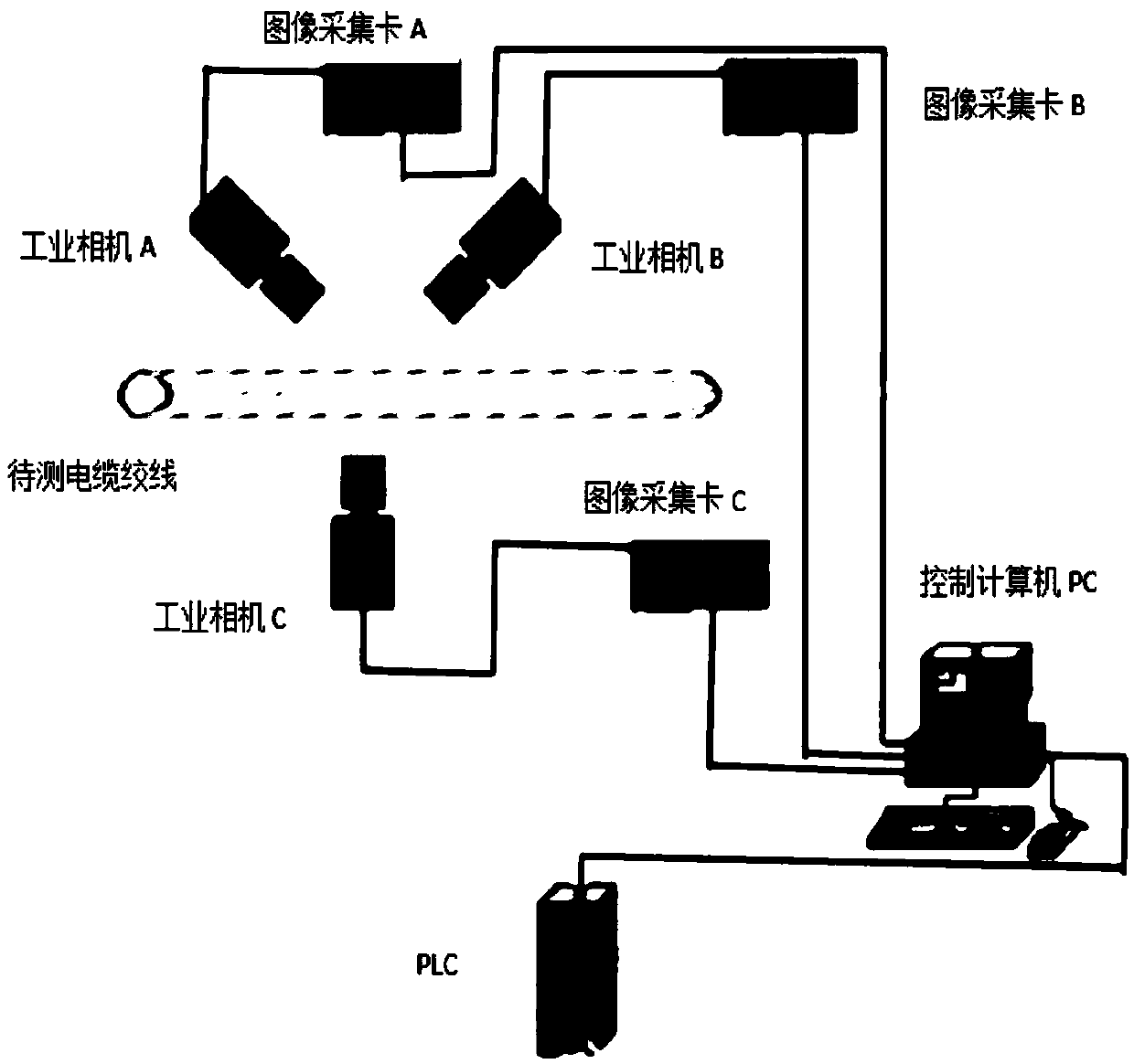

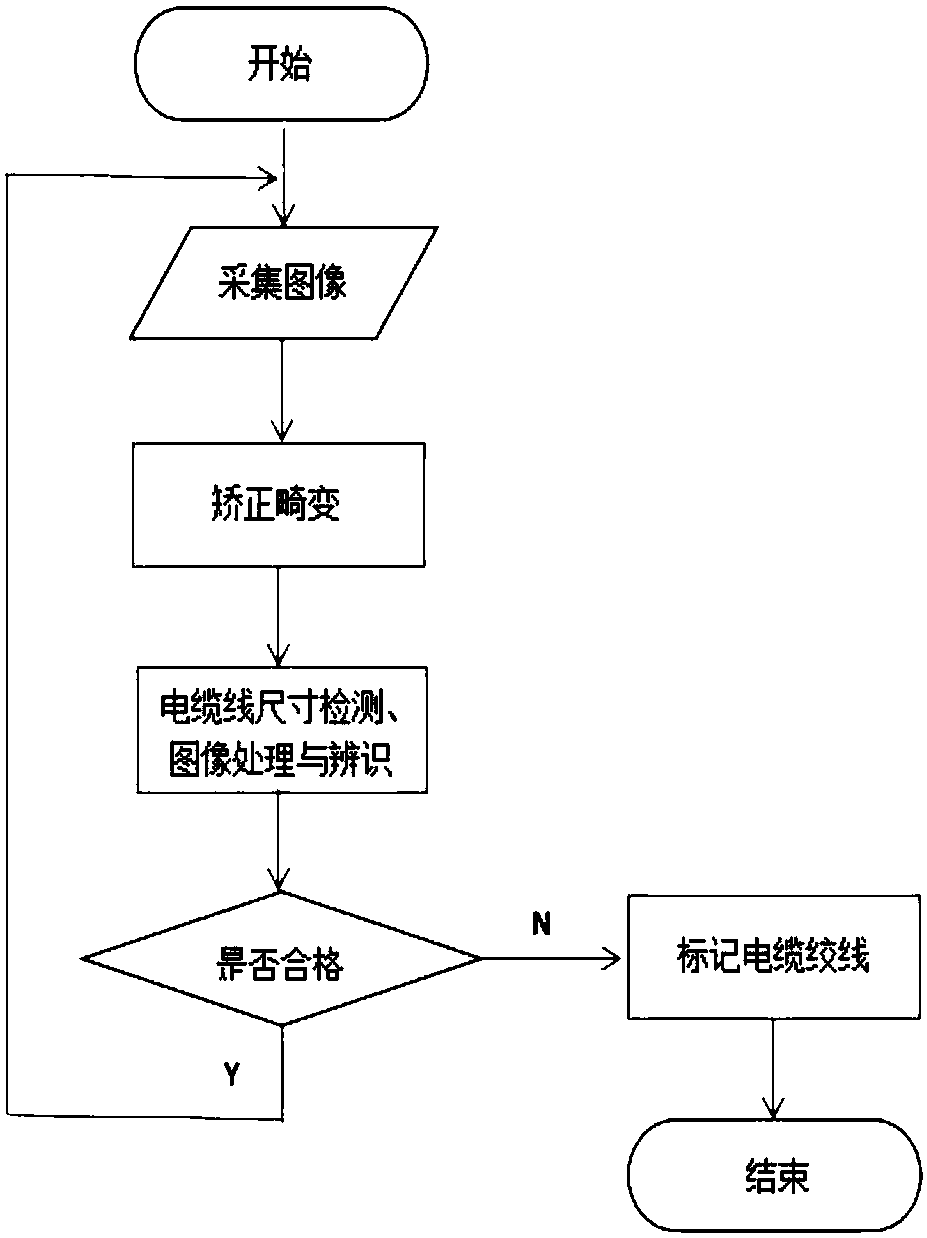

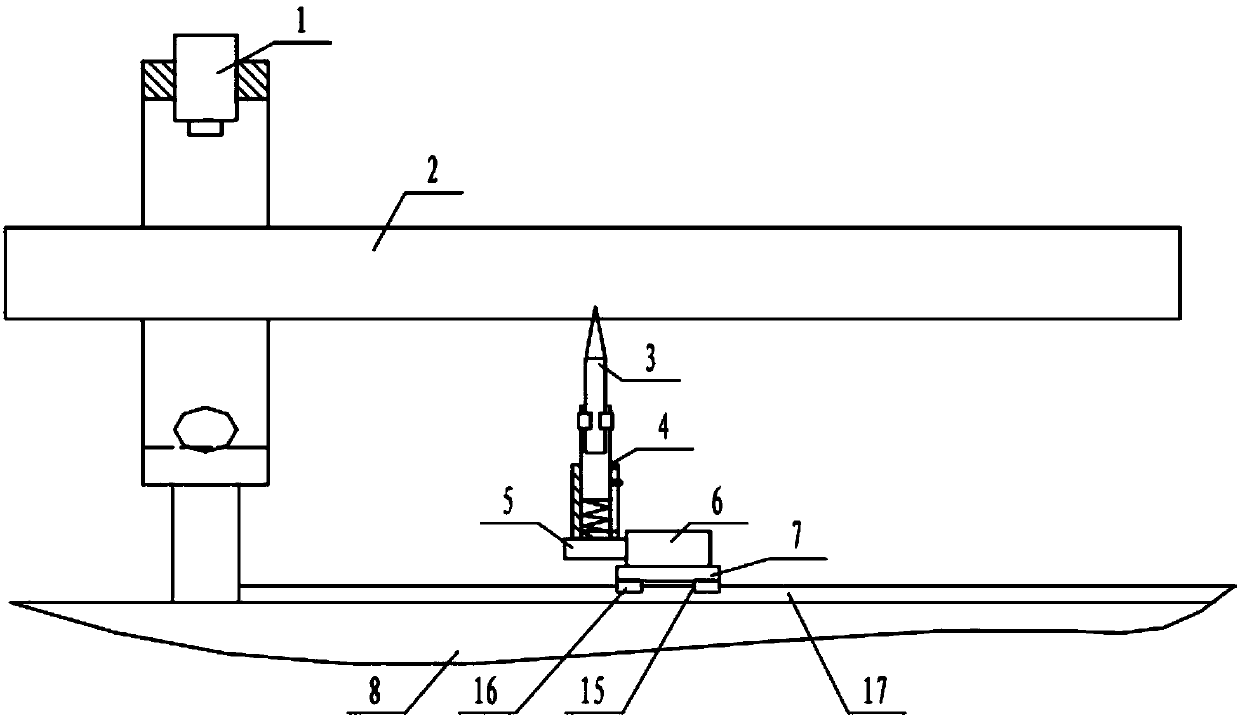

[0042] Embodiment 1: as Figure 1-Figure 7 As shown, a cable strand quality inspection system based on machine vision includes an image acquisition module, an image processing and identification module, and a marker positioning module. The signal receiving end of the image processing and identification module is connected to the image acquisition module, and the control end is connected to the marker positioning module. module, the image processing and identification module is used to process, identify and measure the collected images, the image acquisition module is used for online acquisition of cable strand images, and the marking and positioning module is used to locate and mark unqualified cable strands.

[0043] Preferably, the above-mentioned image processing and recognition module adopts a control computer PC.

[0044] Preferably, the above-mentioned image acquisition module includes an industrial camera 1 and an image acquisition card connected to the industrial camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com