Comprehensive inspection tool for simulating component assembly position relation structure

A technology of parts assembly and comprehensive inspection tools, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of three-coordinate detection failing to meet production requirements, long detection time, delaying production progress, etc., and shortening the three The effect of coordinate detection time, reduction of three-coordinate detection cost, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

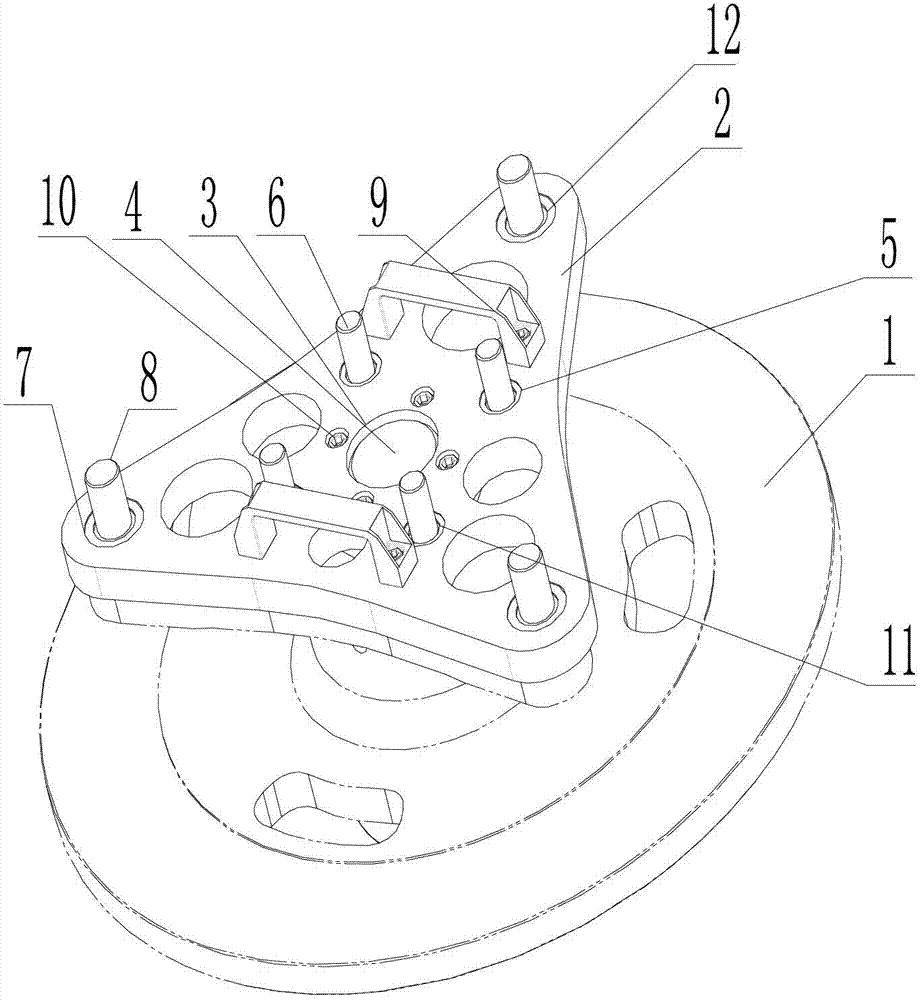

[0018] Such as figure 1 As shown, a comprehensive inspection tool for simulating parts assembly position relationship structure according to the present invention includes a base 1, a inspection tool body 2 is arranged above the base 1, and a large Locating pin hole 3, is provided with big locating pin 4 in described big locating pin hole 3, is provided with four fixed locating pin holes 5 around described big locating pin 4, in described fixed locating pin hole 5 A fixed positioning pin 6 is provided inside, and a movable positioning pin hole 7 is provided on each corner of the inspection tool body 1, and a movable positioning pin 8 is arranged in the movable positioning pin hole 7; A handle 9 is provided beside the fixed positioning pin 6; there are two handles 9; the large positioning pin 4 is fixedly connected with the inspection tool body 2 throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com