Concrete surface brick forming device capable of achieving rapid mold replacement

A technology for forming concrete and bricks, which is applied in unloading devices, supply devices, ceramic molding machines, etc., and can solve problems such as scratches on concrete surface bricks and inconvenient mold replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

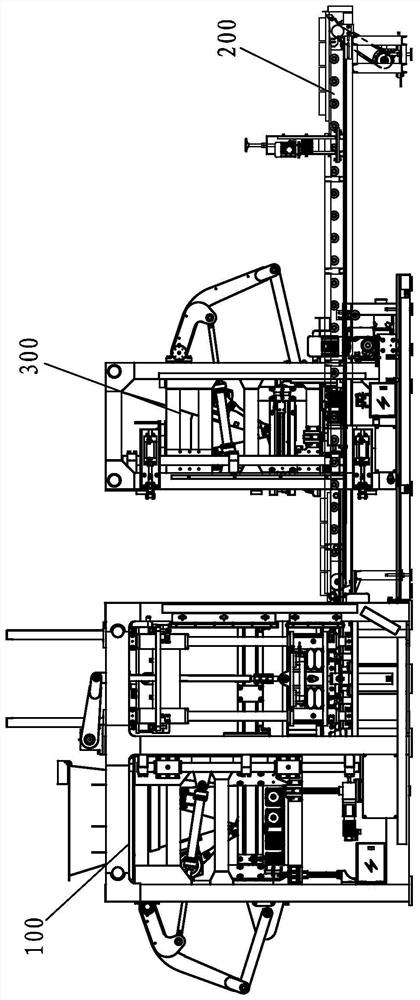

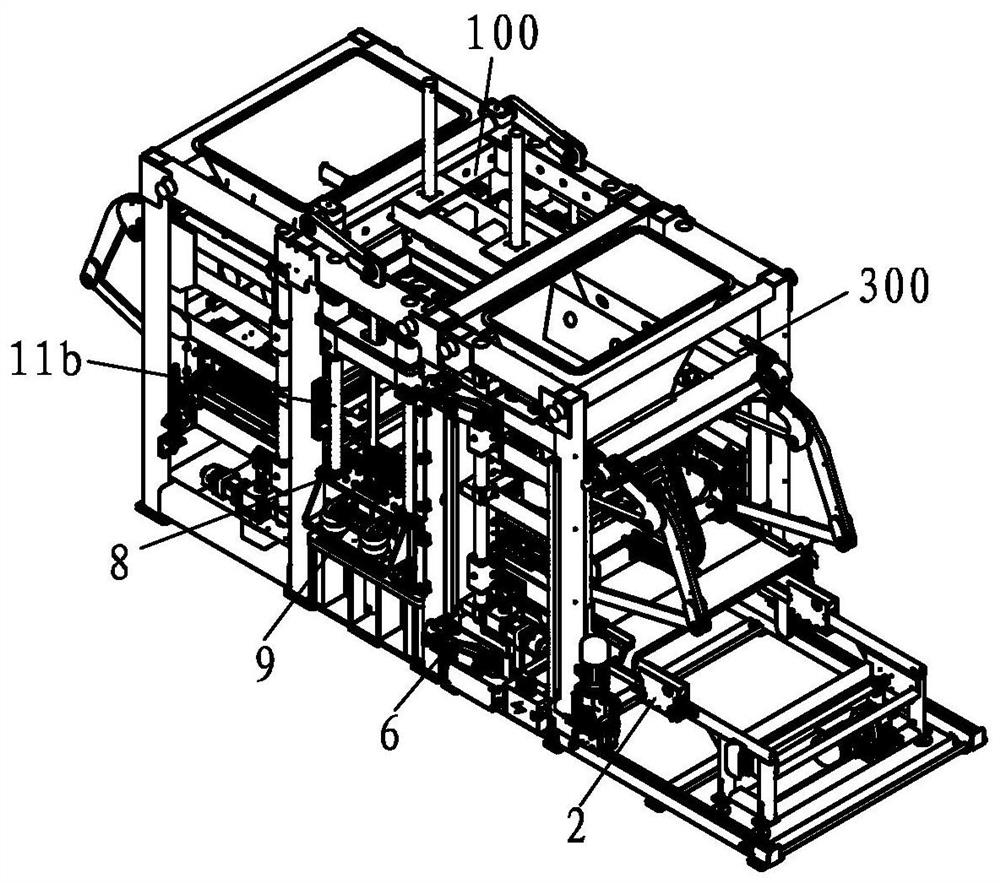

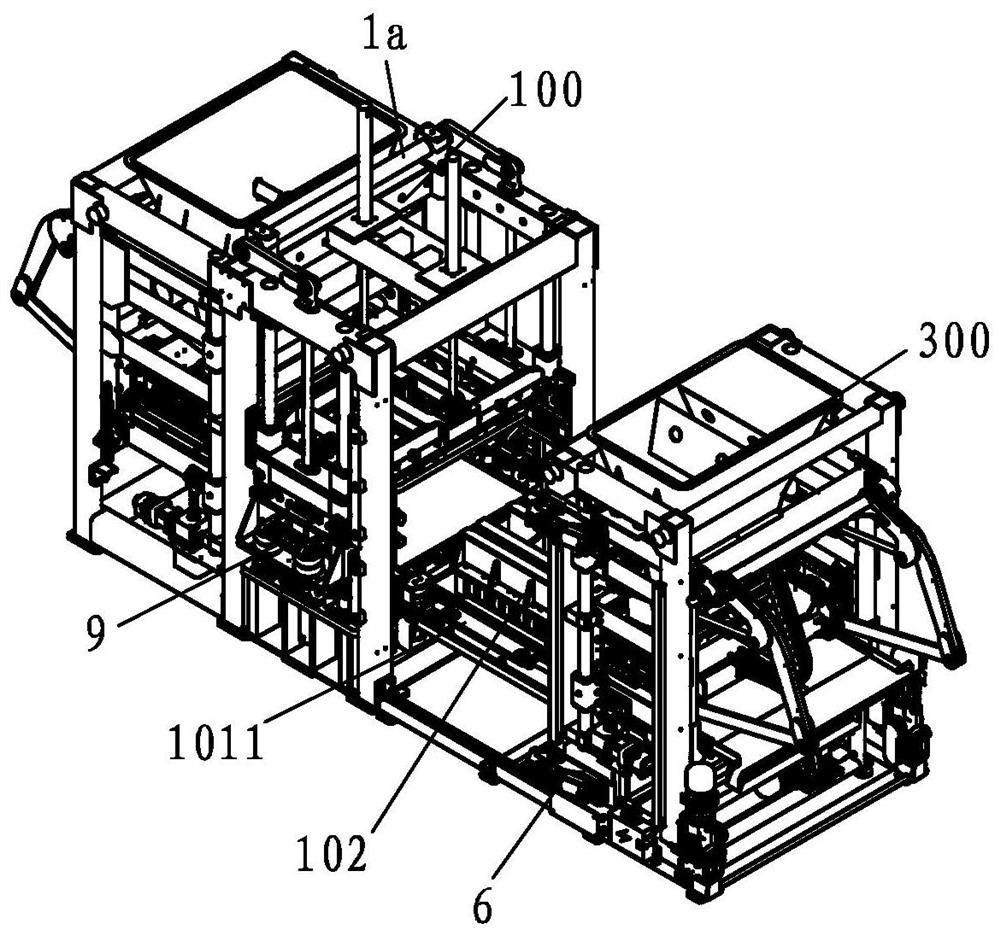

[0066] see Figure 1 to Figure 25 As shown, a preferred embodiment of a quick-change mold-changing concrete facing brick forming device of the present invention includes a forming machine main frame 100, and is fixed at the discharge end of the forming machine main frame 100 for conveying the formed concrete facing bricks. The brick feeder 200 and the fabric machine 300 that can be arranged on the discharge end of the main machine 100 of the forming machine for distributing fabrics in the mold frame 101 of the main machine 100 can be moved; Below the fabric pallet 301; the fabric machine 300 includes a jacking mechanism 1 fixedly arranged below the fabric pallet 301 for driving the fabric pallet 301 to lift; the two sides of the brick feeder 200 A mold transfer mechanism 2 for transferring the mold from the inside of the molding machine main body 100 to the outside or transferring the mold from the outside to the inside of the molding machine main body 100 is provided. Wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com