Collaborative manufacturing support system and method

A technology of collaborative manufacturing and supporting methods, applied in the direction of manufacturing computing systems, instruments, commerce, etc., can solve problems that affect product manufacturing, affect the production work of manufacturing enterprises, and affect the process of collaborative manufacturing, so as to ensure production progress and save training cost, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

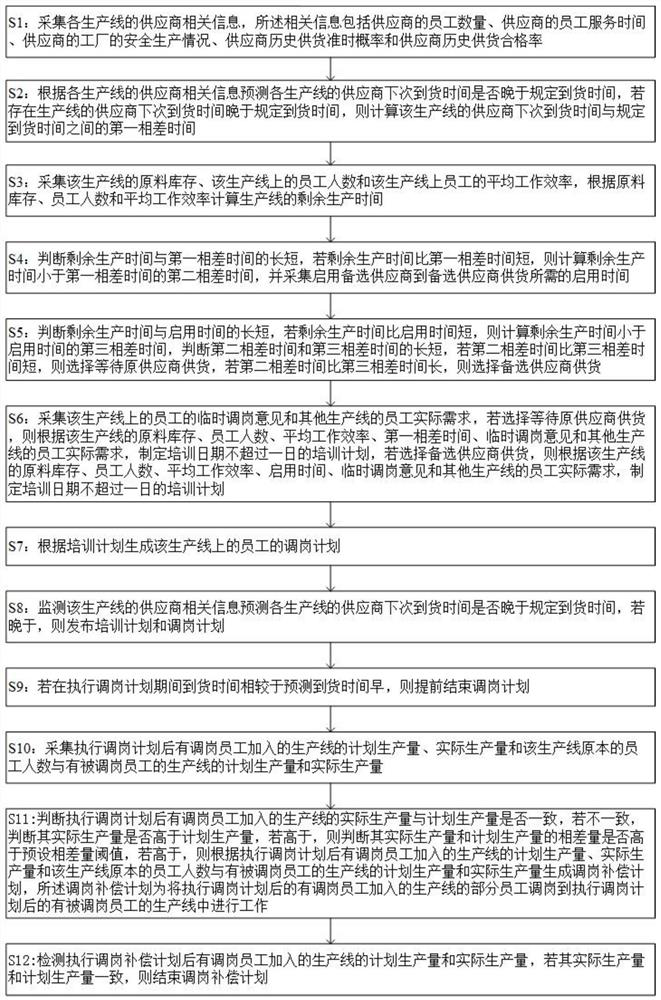

[0064] The embodiment is basically as attached figure 1 Shown: a collaborative manufacturing support method, including the following:

[0065] S1: Collect supplier-related information for each production line, the relevant information includes the number of employees of the supplier, the service hours of the employees of the supplier, the safety production situation of the supplier's factory, the on-time probability of the supplier's historical supply and the supplier's historical supply. Goods qualification rate; the number of employees of the supplier, the service hours of the employees of the supplier and the safe production situation of the supplier's factory can be obtained through crawlers, and the on-time probability of the supplier's historical supply and the qualified rate of the supplier's historical supply can be obtained Retrieval from memory at the factory;

[0066] S2: Predict whether the next arrival time of the suppliers of each production line is later than the...

Embodiment 2

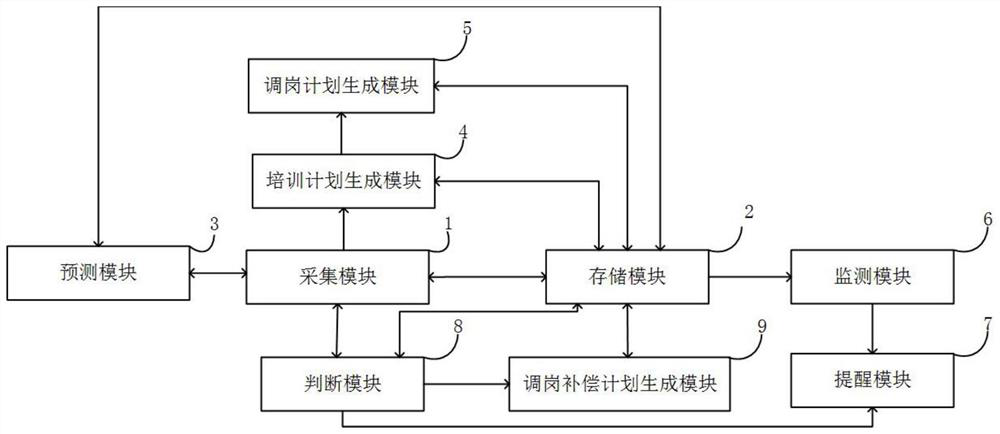

[0081] Embodiment two is basically as figure 2 As shown, a collaborative manufacturing support system is applied to a server, including an acquisition module 1, a storage module 2, a prediction module 3, a training plan generation module 4, a job transfer plan generation module 5, a monitoring module 6, a reminder module 7, and a judgment module 8 and post transfer compensation plan generation module 9;

[0082] The collection module 1 is used to collect supplier-related information of each production line on the terminal equipment, and the relevant information includes the number of employees of the supplier, the service hours of the employees of the supplier, the safety production situation of the supplier's factory, the supplier's The on-time probability of historical supply and the qualification rate of supplier historical supply are sent to the forecasting module 3 and the storage module 2; the collection module 1 can use crawlers to obtain from the supplier's website an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com