Patents

Literature

154results about How to "Guarantee the production progress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

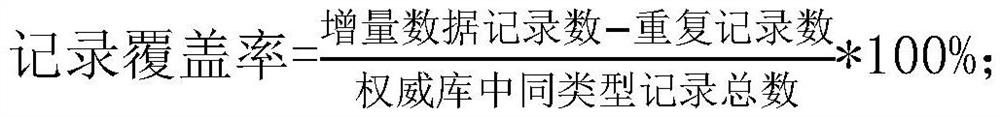

Tool and method for assembling spindle head and center pull rod of gas turbine

ActiveCN101633113ARealize localized assemblySimple structureMetal working apparatusEngineeringScrew thread

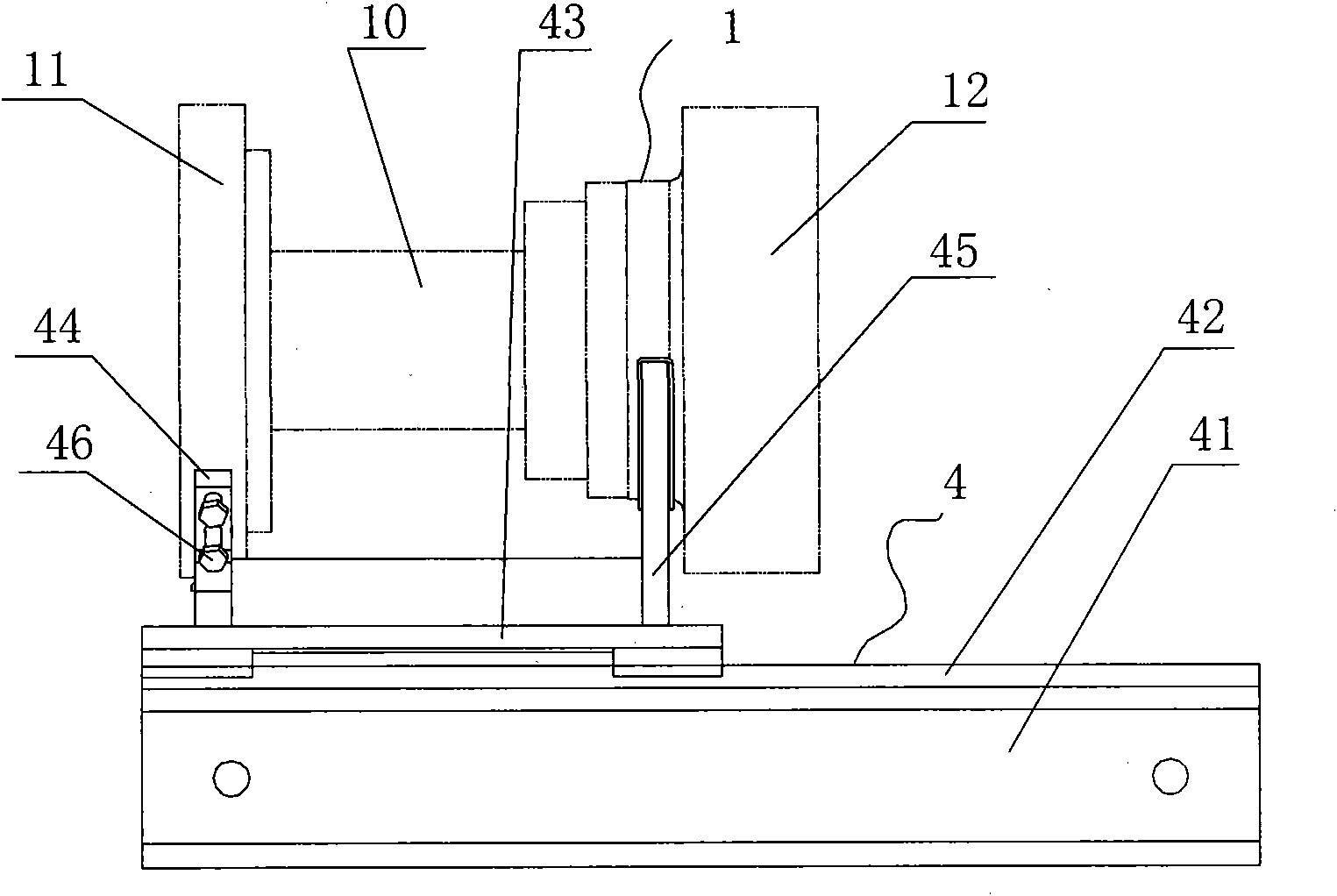

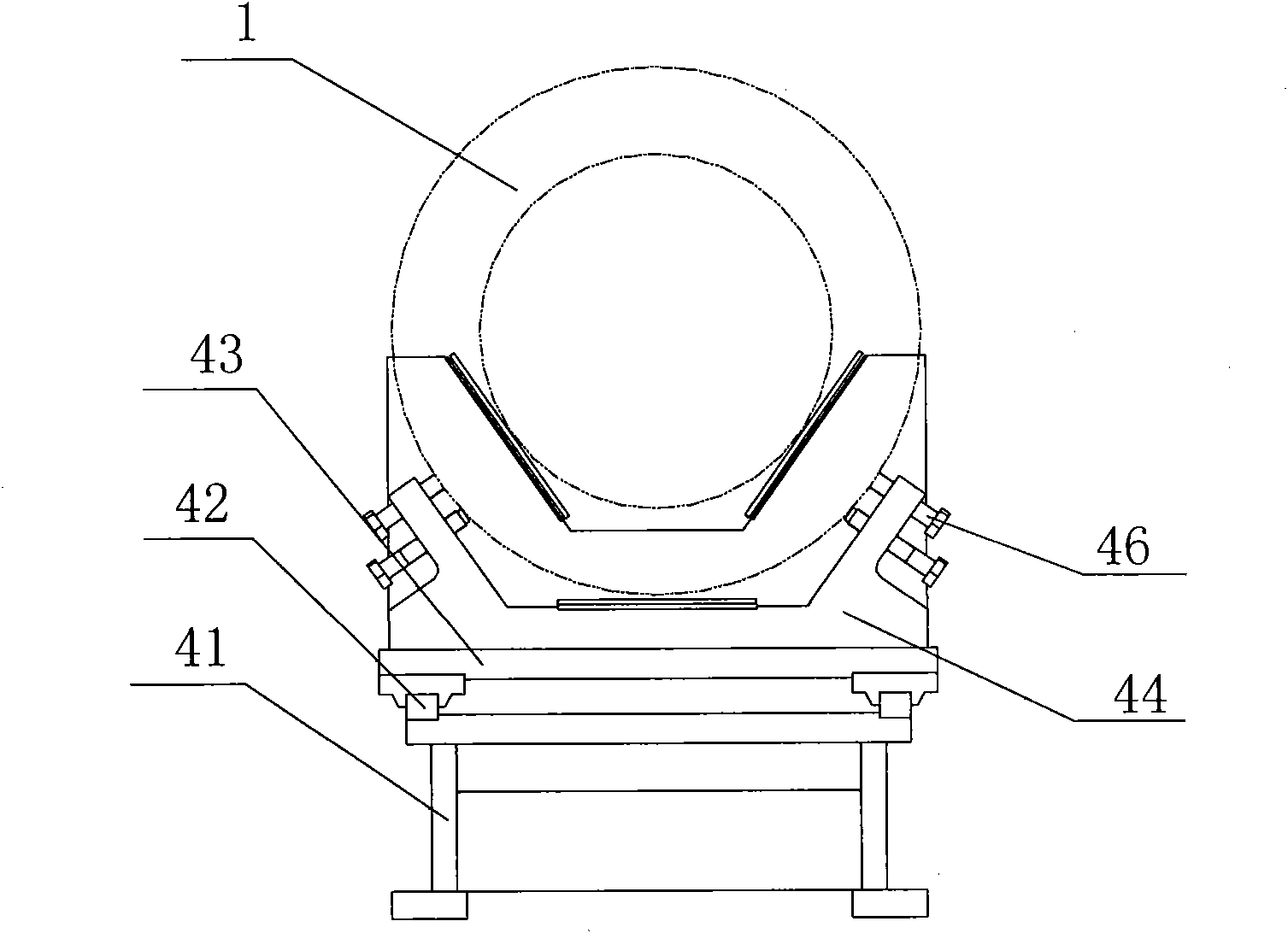

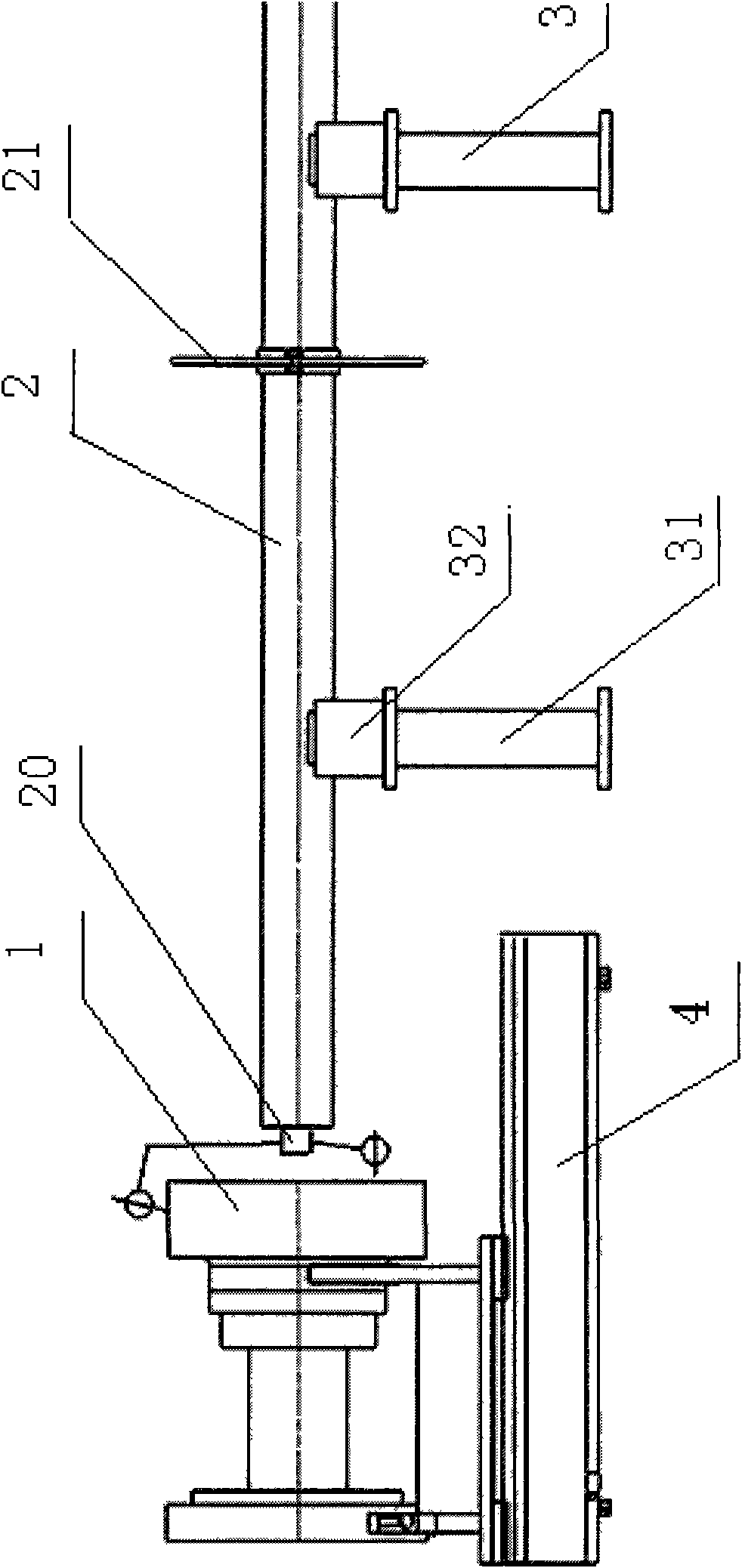

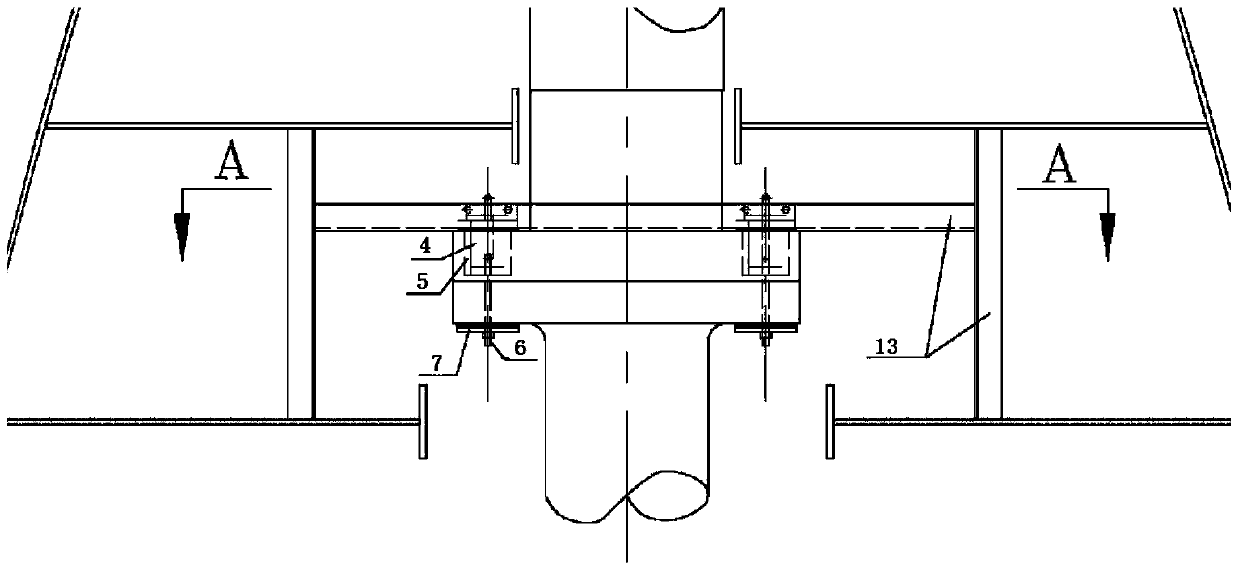

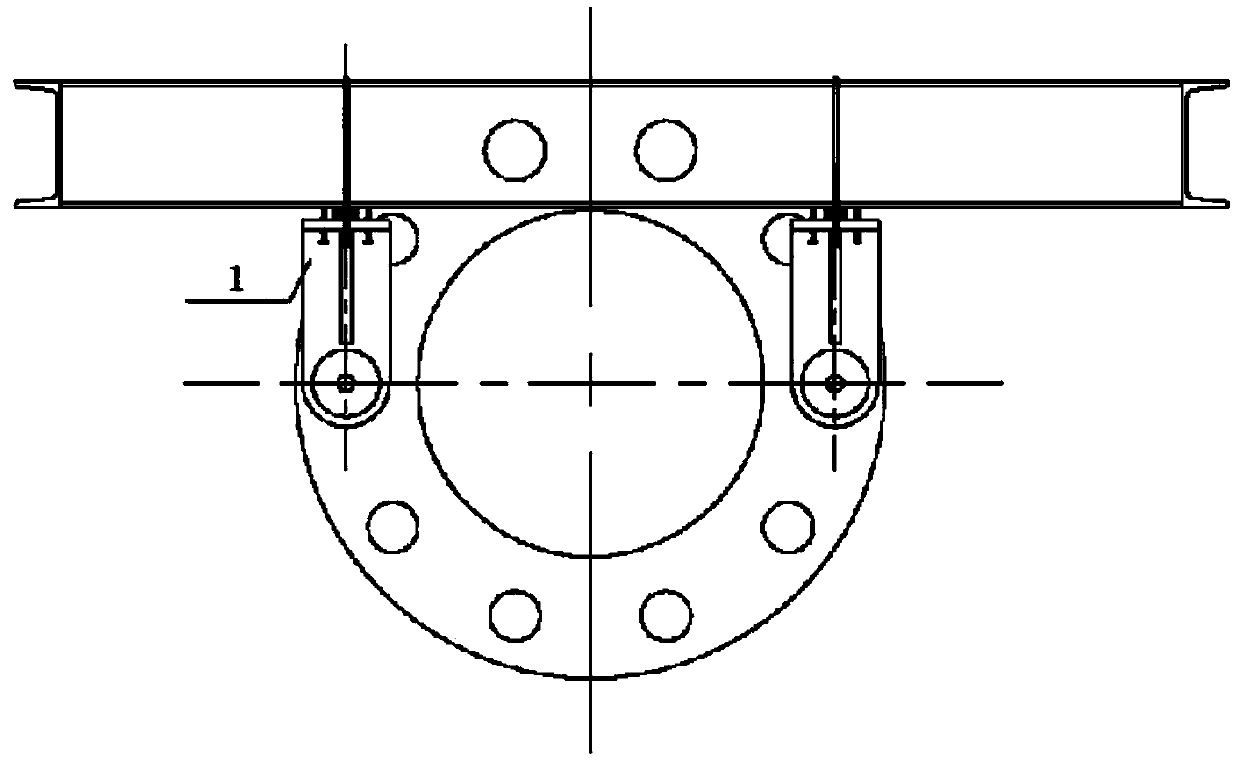

The invention discloses a tool for assembling a spindle head and a center pull rod of a gas turbine, wherein the spindle head is provided with a bearing guard, and a clutch and a step-type joint part provided with a threaded bland hole arranged on the head and the tail of the bearing guard respectively, and the head of the center pull rod is provided with a threaded section matched with the threaded blind hole of the joint part of the spindle head. The tool comprises a plurality of roller wheel supporting frames for up-bearing the center pull rod and a spindle head supporting frame, wherein the spindle head supporting frame comprises a bed body, a pair of linear guide rails axially arranged on the bed body, a dragging plate arranged on the bed body and capable of moving forwards and backwards along the linear guide rails, V-shaped lug supports arranged on the dragging plate in tandem and pushing screws at least arranged on two sides of one of the V-shaped lug supports; and the head clutch of the spindle head is supported on the V-shaped lug support at the front end of the dragging plate, while the joint part at the tail of the spindle head is supported on the V-shaped lug support at the rear end of the dragging plate. The invention also discloses a method for assembling the spindle head and the center pull rod of the gas turbine, which is carried out on the assembling tool.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

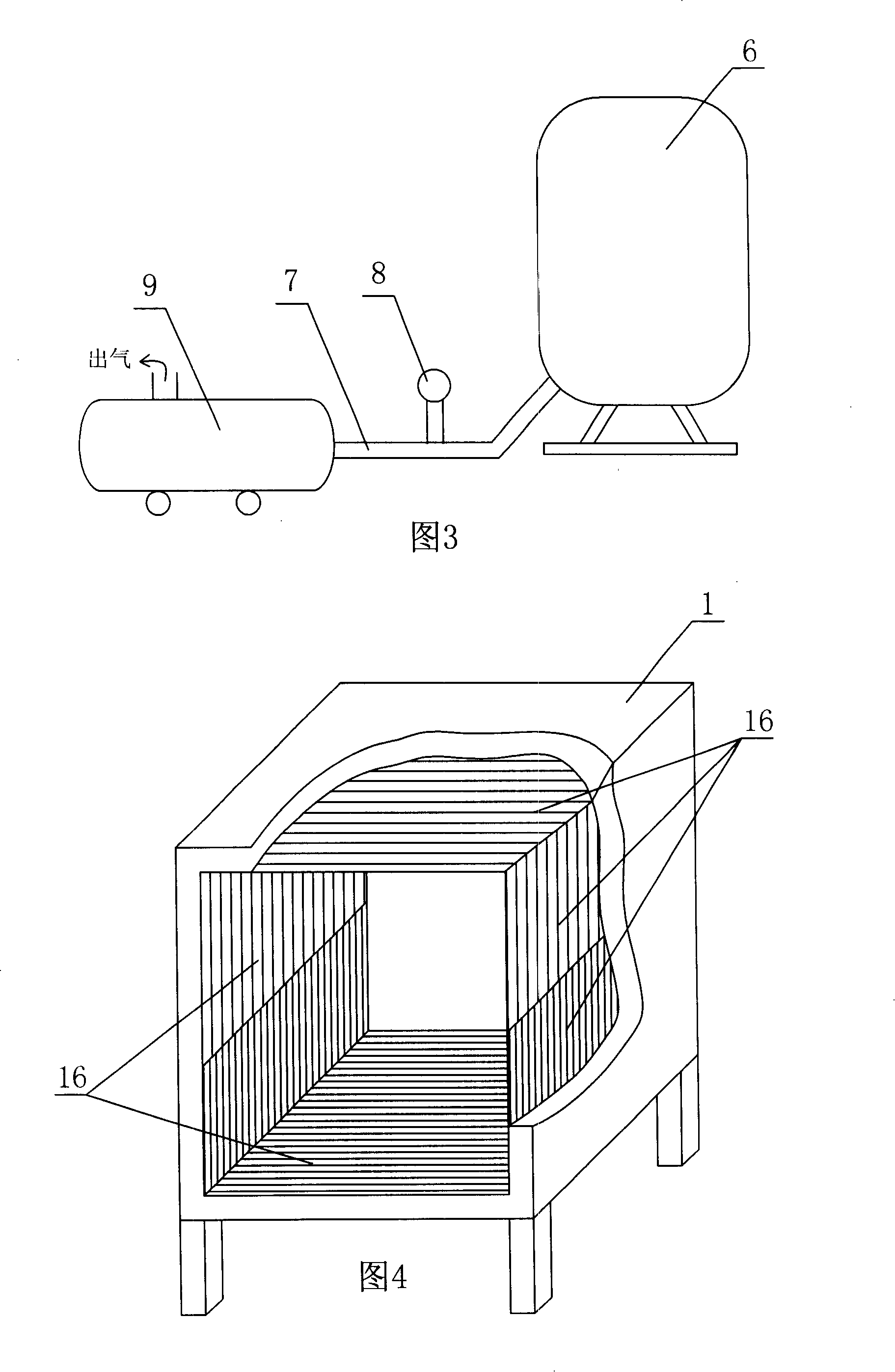

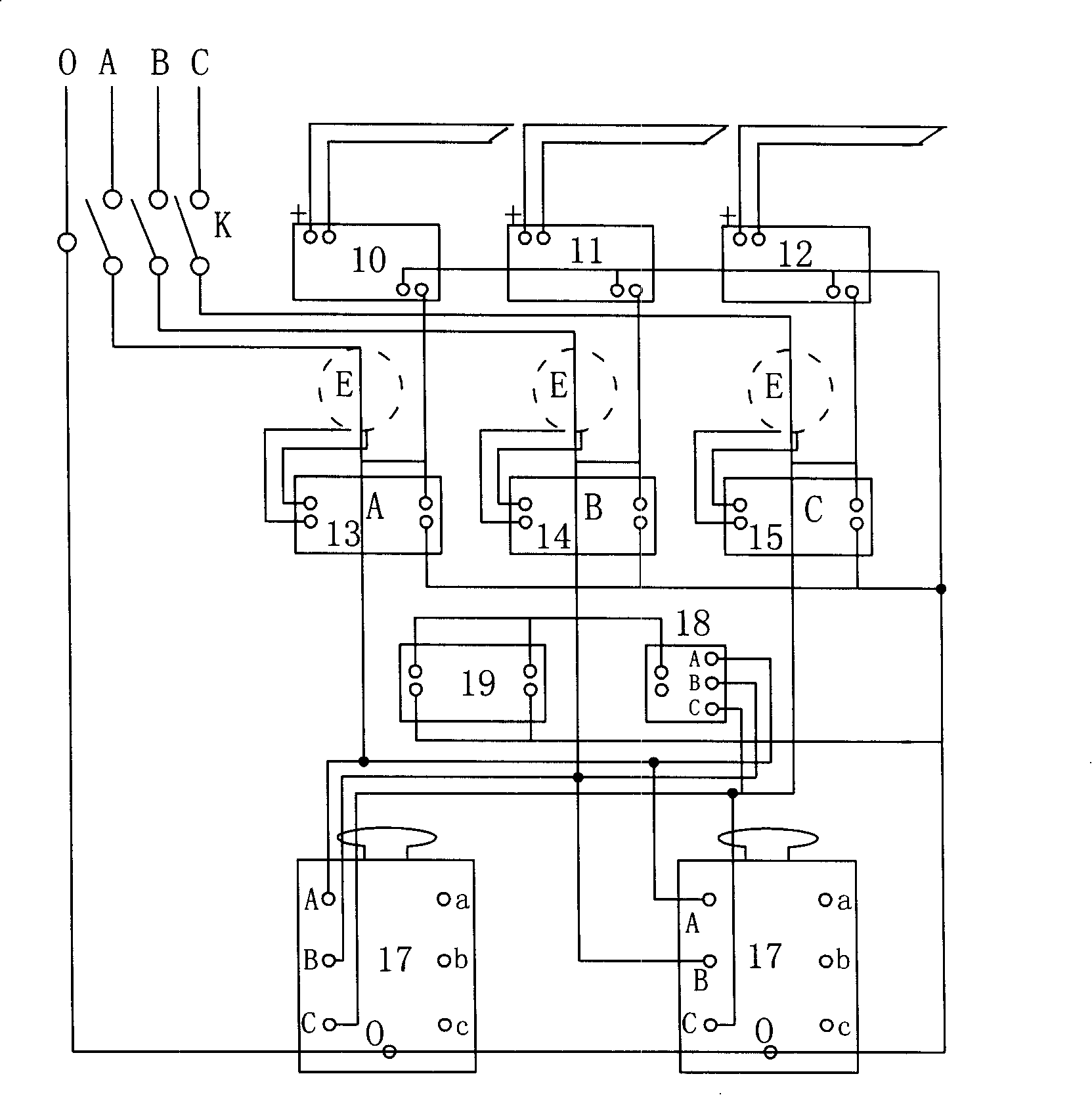

Activation furnace for producing and reproducing activation block absorbent charcoal

InactiveCN101219786AAccurately spot heating faultsHeating fault foundOther chemical processesDisplay deviceBiological activation

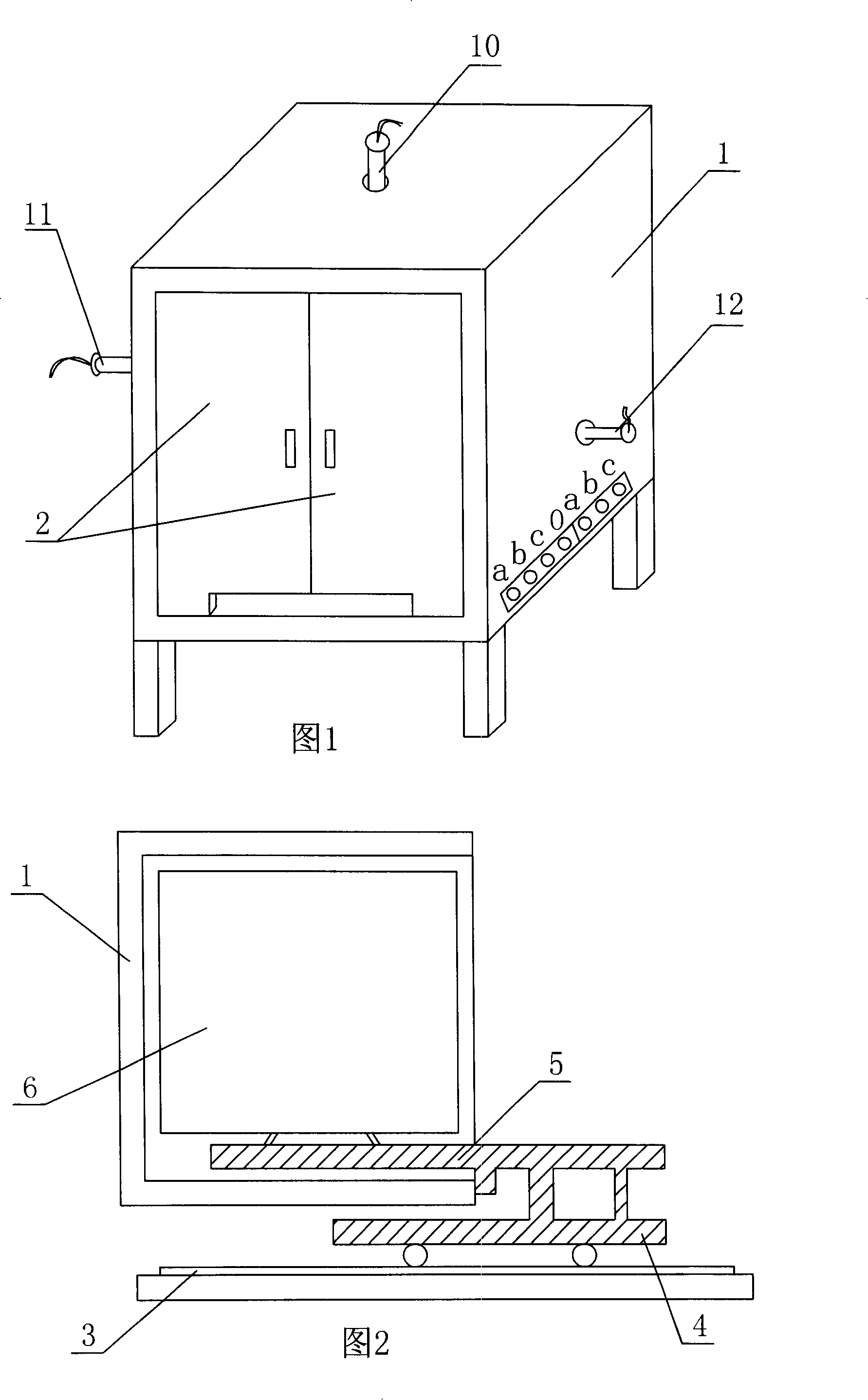

The invention discloses an activating furnace for producing, regenerating and activating block shaped active carbon; the invention is provided with a closed furnace body which has a furnace door at the front part; the furnace body is provided with an insulating layer; the invention also comprises a kiln car moving on a track; the kiln car is provided with an upper layer bracket which enters or exits a cavity of the furnace body from the lower part of the furnace door; a closed metal container which is provided with a closed door is arranged on the bracket; a cavity of the closed metal container is communicated with a suction inlet of a vacuum pump outside the furnace body through a communicating pipe; the top of the furnace body, an upper part of a side, a lower part of another side are respectively provided with temperature sensors which measure temperature of corresponding parts inside the furnace respectively; signals lines of each temperature sensor are connected with corresponding digital temperature displayers; a top surface, a left side and a right side of the furnace cavity are provided with electro thermal wires of which the electricity is provided by a three-phase power through a three-phase voltage regulator of contact type; a power circuit of each phase is connected in series with a digital circuit meter. The invention can meet the technical requirements of producing, regenerating and activating the block typed active carbon, and thus becomes an indispensable production device for producing, regenerating and activating the block typed active carbon.

Owner:长沙文象环保科技有限公司

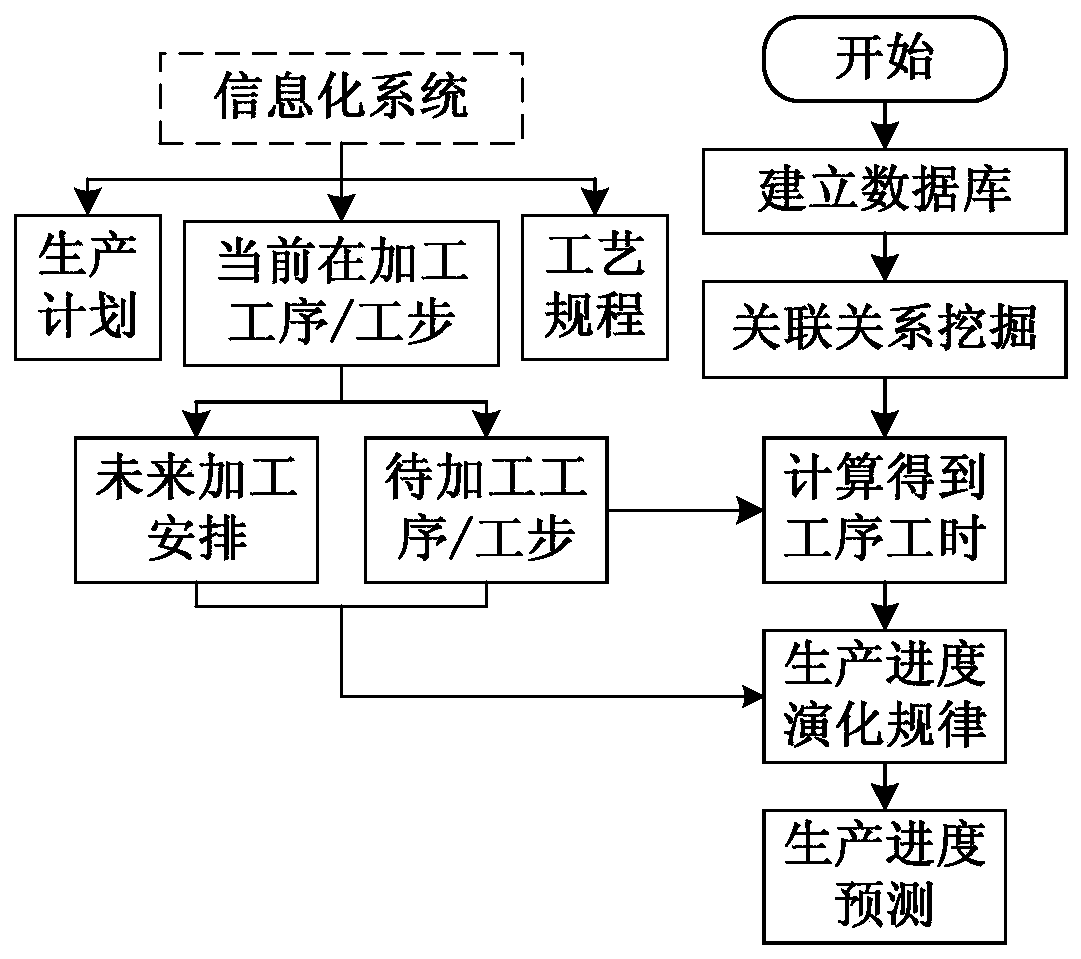

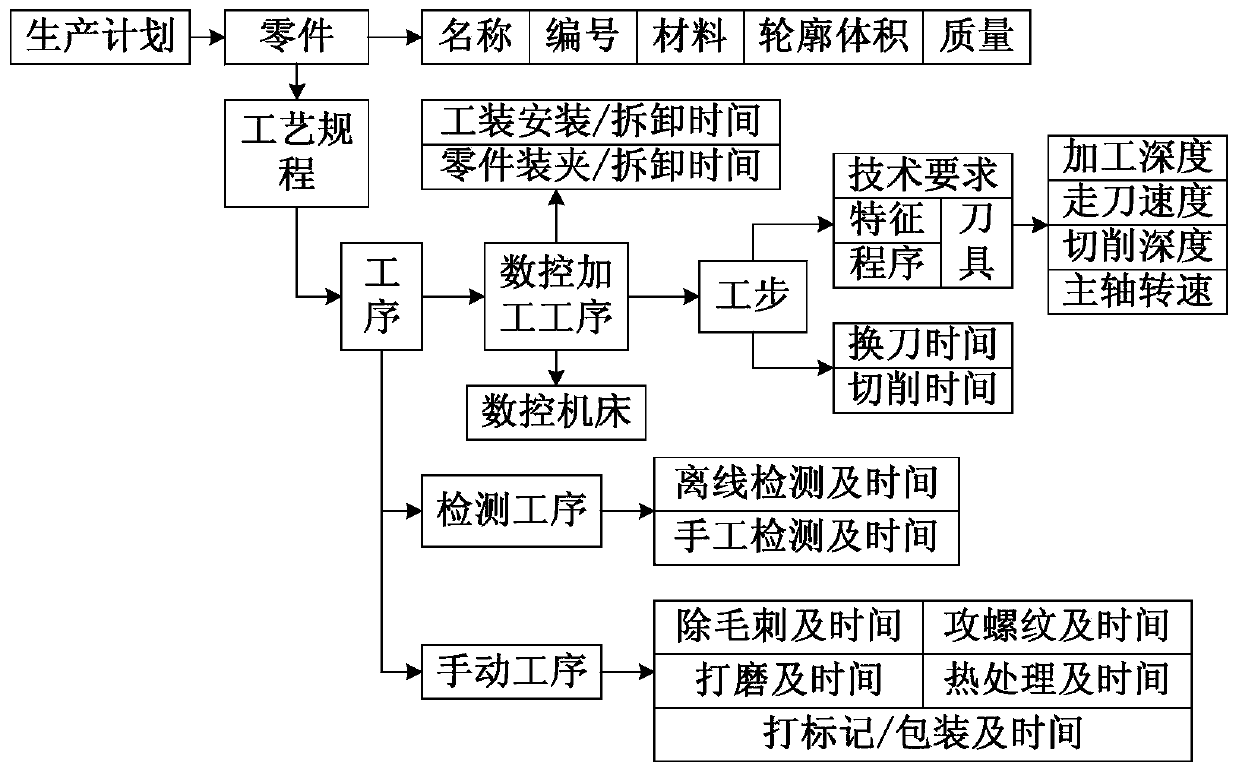

Production schedule prediction method and system based on data mining

ActiveCN110414727ASolve choice problemsIn line with reality and feasibilityDigital data information retrievalForecastingProduction schedulePrediction algorithms

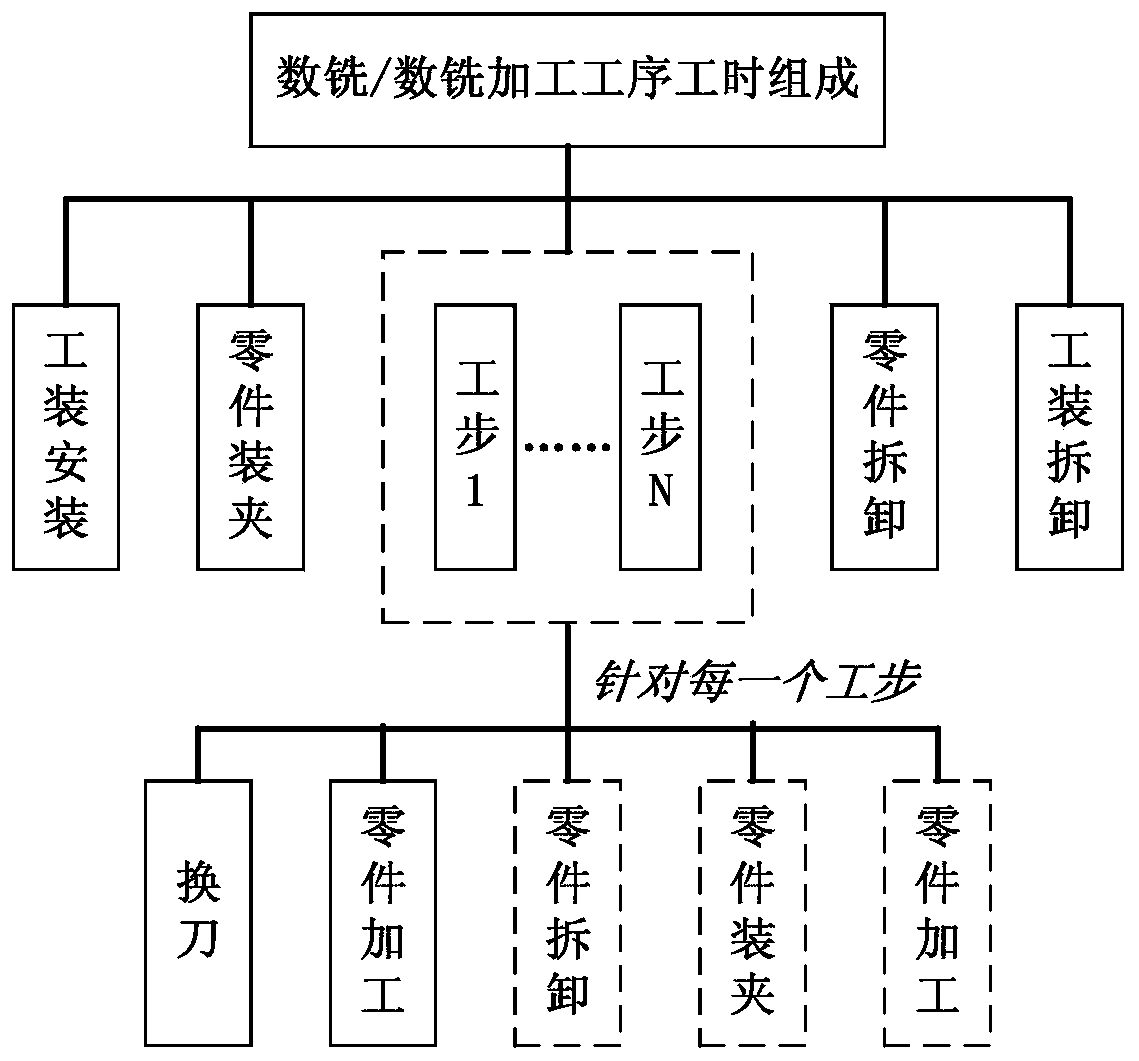

The invention discloses a production schedule prediction method and system based on data mining, and belongs to the technical field of automation. The method comprises the following steps of establishing a database, and storing historical data of part machining and workshop resource data; based on the historical data and a prediction algorithm, calculating a function relationship between the partmachining working hours and the working hour influence parameters; receiving a part production plan and a part technological procedure on the basis of the current part machining process and step to obtain a man-hour influence parameter of the current part machining process and a to-be-machined process; calculating the working hours of all current to-be-machined procedures of the machined parts; and calculating the machining starting time and the machining ending time of all the to-be-machined processes of the current machined parts to predict the production progress of the parts. On the basisof obtaining the calculation functions of all the working procedures and working hours of the machining workshop, the part production schedule calculation method under different machining states is provided, and a basis is provided for accurately predicting the part production schedule.

Owner:中国航天系统科学与工程研究院

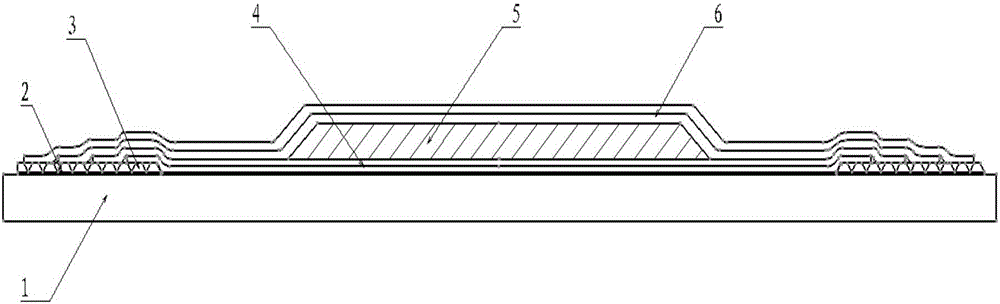

Method for preventing honeycomb from sliding

The invention belongs to the technical field of composite manufacturing and relates to a method for preventing a honeycomb from sliding. An anti-slide band is pasted to a tool and is made from a high-friction material. The periphery of each layer of prepreg cloth is closely attached to the friction band, and during the part curing process, the relative position of each layer of the prepreg cloth is ensured through the anti-slide band, so that relative motion of an upper skin prepreg of a sandwich structure and a lower skin prepreg of a sandwich structure is prevented, and the honeycomb is prevented from sliding. The anti-slide band method does not need to change the curing mode of materials and has no special limit to the materials, so that the method is suitable for various prepreg materials. In addition, the operation method is simple and convenient and easy to realize. The sliding problem of the honeycomb in the curing process is effectively solved, and the position and size of a formed part honeycomb meet the requirement of a design drawing.

Owner:HARBIN

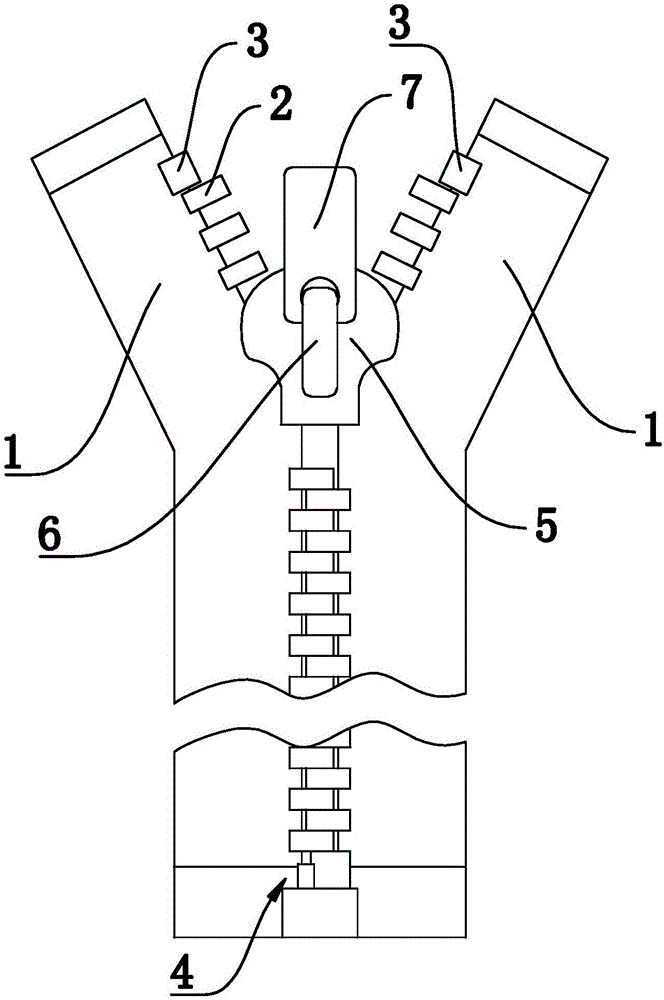

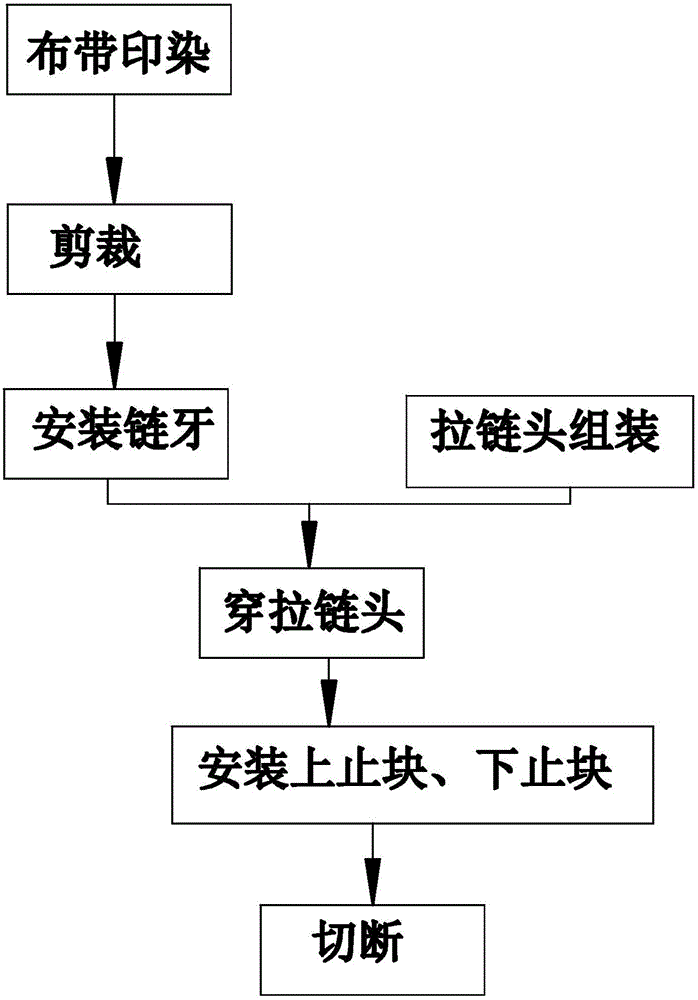

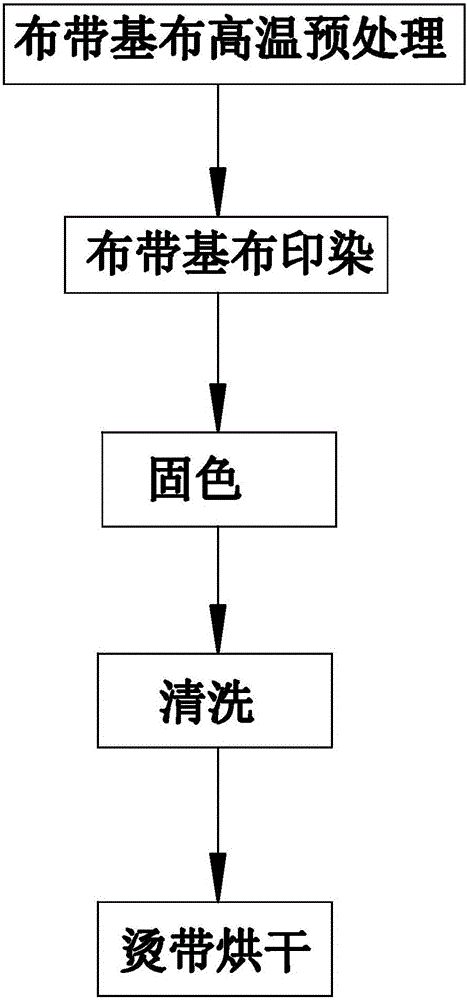

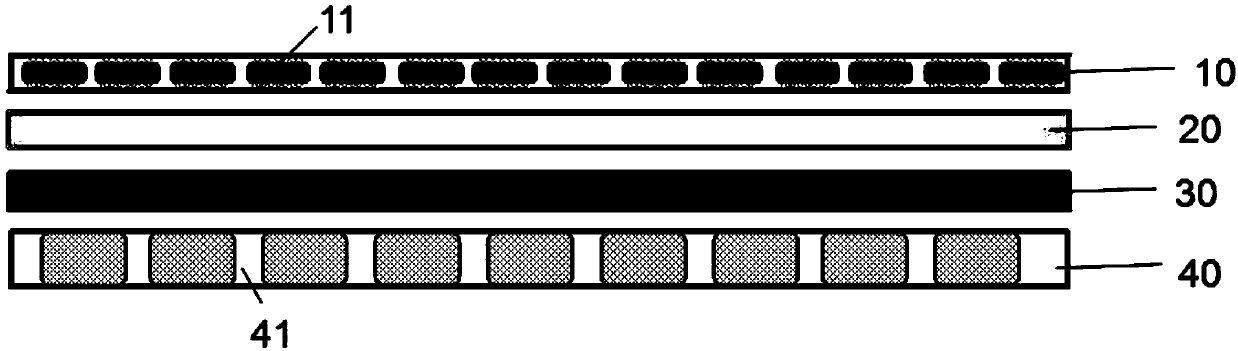

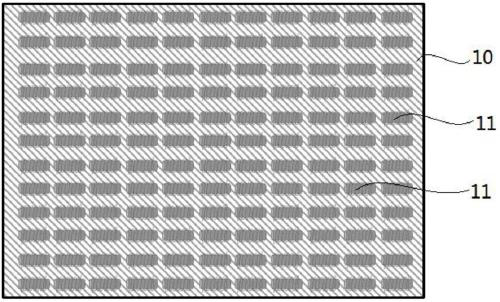

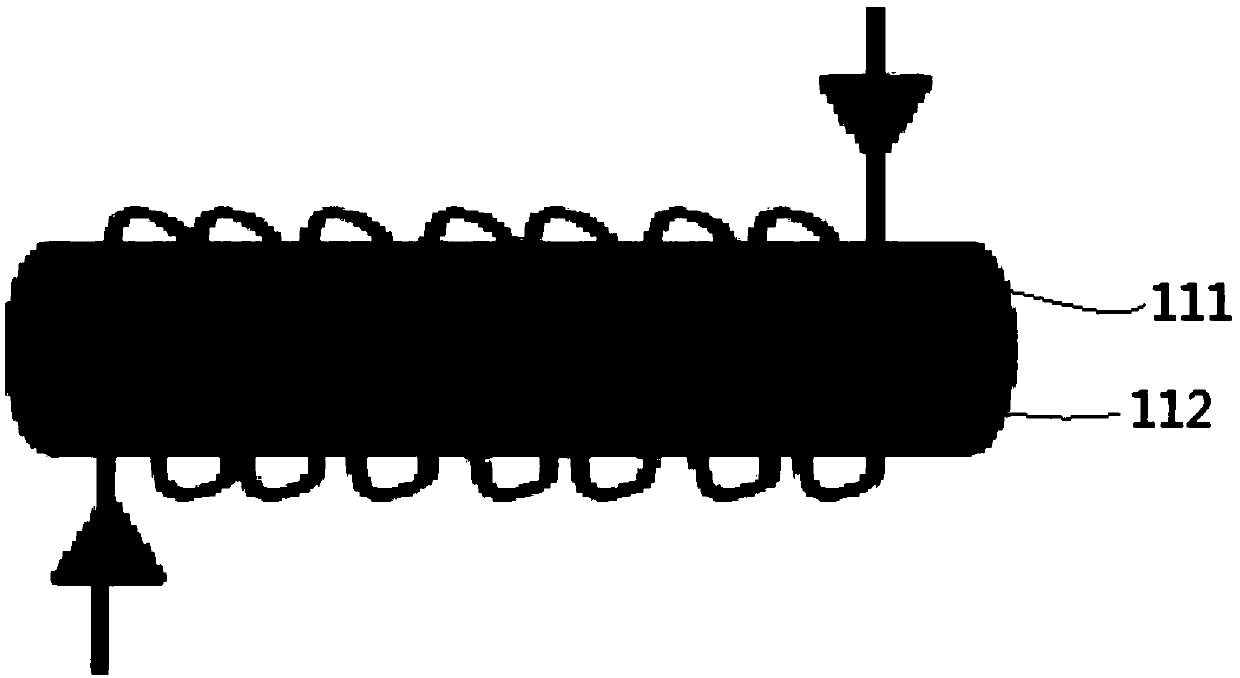

Manufacturing method of colorful zipper

The invention provides a manufacturing method of a colorful zipper. The manufacturing method of the colorful zipper comprises the following steps: A, carrying out printing and dyeing treatment on a cloth tape so that at least one tape surface of the cloth tape has various colors or has patterns with various colors; tailoring the cloth tape into two cloth strips which are matched with each other along the middle line of the cloth tape; B, mounting zipper teeth at edges of opposite sides of the two cloth strips to form zipper tapes; C, assembling a zipper slider by a zipper slider assembling machine, and threading the assembled zipper slider on the zipper tapes; D, mounting an upper stopping block and a lower stopping block on the zipper tapes; and E, cutting off the zipper tapes into a zipper with the preset length. The manufacturing method provided by the invention is high in production efficiency, and the colorful zipper produced by the manufacturing method meets requirements of fashion and trend.

Owner:JIAXING SHENGLONG ZIPPER MFG

Evaporating plating device and OLED panel evaporating plating method

PendingCN109536886AReduce slipMinimize Wrinkle of Metal MaskVacuum evaporation coatingSputtering coatingOrganic filmCrucible

The invention relates to the technical field of evaporating plating, and provides an evaporating plating device and an OLED panel evaporating plating method. The evaporating plating device comprises aheating crucible which is used for heating evaporating plating materials to enable the evaporating plating materials to be evaporated; and further comprises a magnetic plate which is positioned abovethe heating crucible, provided with magnetism and used for fixing a target substrate which is going to receive the evaporating plating. More than two magnetic objects are arranged in the magnetic plate, wherein the magnetism of the magnetic plate is gradually decreased from the middle to the edge. According to the technical scheme, the magnetism of the magnetic plate in the evaporating plating device is gradually decreased from the middle to the edge, so that the attraction force on the middle part of the target substrate is larger than the attraction force on the edge, the slippage of the target substrate and wrinkles on a metal mask are reduced, and the bonding degree of the metal mask and the substrate can be improved; and the phenomenon that an evaporating plating organic film patternis abnormal can be avoided, the debris risk of the target substrate can be reduced and the service life of the metal mask can be prolonged, so that the production efficiency is effectively improved,and the quality and the production progress of products are ensured.

Owner:FUJIAN HUAJIACAI CO LTD

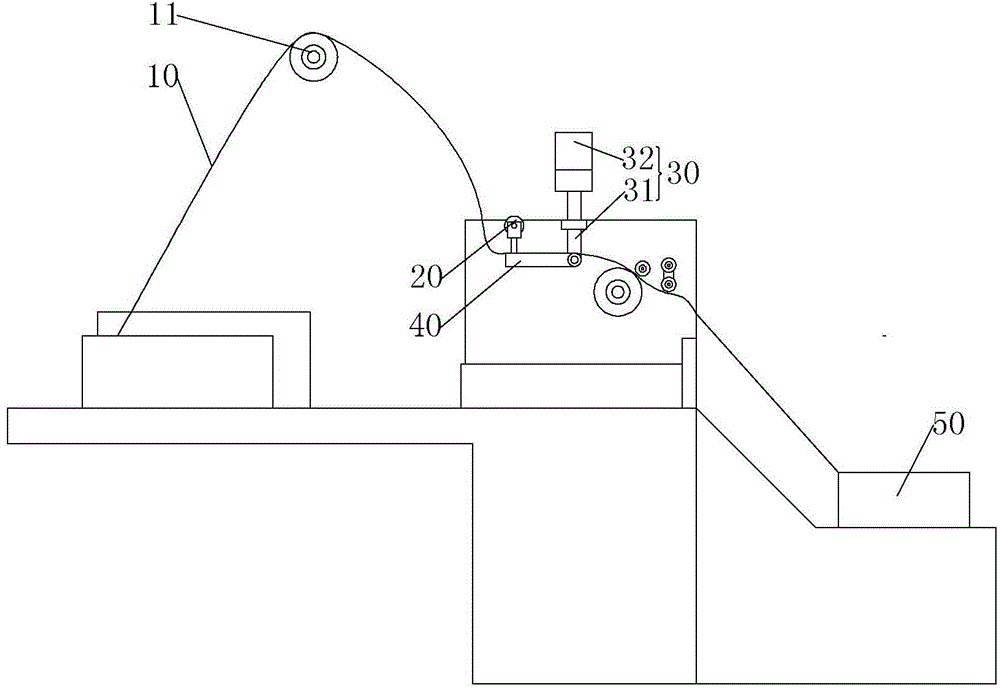

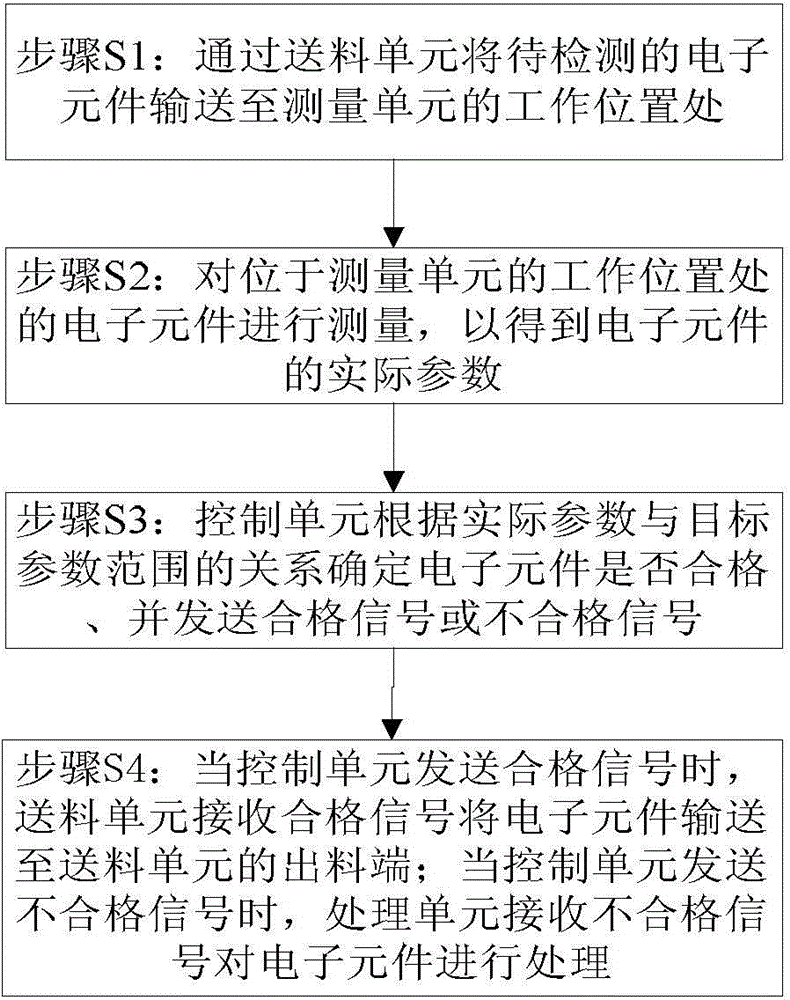

Electronic component detection device and electronic component automatic detection method

The invention provides an electronic component detection device and an electronic component automatic detection method. The electronic component detection device comprises a feeding unit; a measuring unit for measuring the actual parameters of an electronic component; a control unit, which is connected to the feeding unit and the measuring unit and is used to determine whether an electronic component is qualified or not according to the relationship between the actual parameters and a target parameter range and send the qualified signal or disqualified signal, wherein the feeding unit receives the qualified signal; and a processing unit, which is used to receive the disqualified signal from the control unit and process the disqualified electronic components. The electronic components are detected by the provided electronic component detection device, the detection efficiency is improved, the work labor for workers is reduced, the production supply is guaranteed, and the production efficiency is ensured. The provided electronic component automatic detection method can achieve automatic feeding, automatic detection, and automatic processing on qualified products and disqualified products, thus the work labor on workers is reduced, and the detection efficiency is improved.

Owner:GREE ELECTRIC APPLIANCES INC

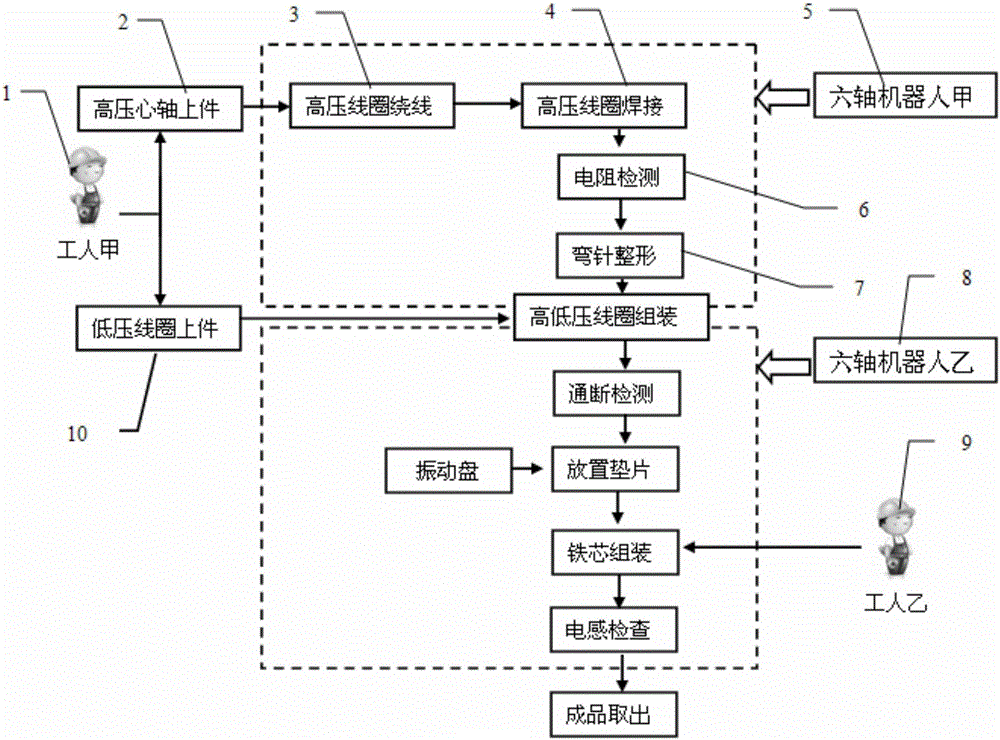

Automatic assembly system for automobile ignition coils

InactiveCN106710865AGuarantee the production progressQuick changeTransformersInductancesProduction scheduleLow voltage

The invention belongs to the technical field of industrial control, and particularly relates to an automatic assembly system for automobile ignition coils. The automatic assembly system comprises a worker A execution unit, a six-axis robot A execution unit, a six-axis robot B execution unit and a worker B execution unit. In order to guarantee the production schedule, fewer tool jigs are adopted in a production line, replacement and positioning can be quickly and conveniently conducted, robots are adopted in an assembly line, and flexible modification or function extension in future is convenient. In order to reduce the number of operation staff and the production cost as far as possible, two workers are employed to assemble parts and disassemble parts, wherein the worker A is responsible for assembling high-voltage coil spindles and low-voltage coils, the worker B is responsible for assembling iron cores, and the other assembly tasks are completed by two six-axis robots. Different from an automatic assembly line, the automatic assembly system is capable of achieving the overall process in full automation with fewer laborers, so that the labor cost is greatly reduced, the efficiency is improved, and the fault rate is reduced.

Owner:TIANJIN TECH LEADER AUTOMATION EQUIP

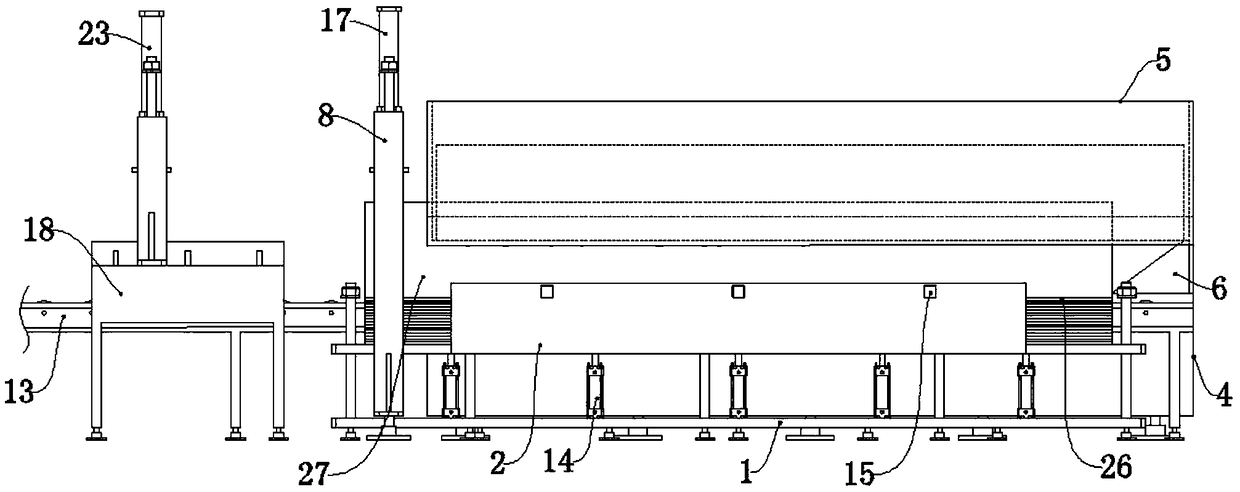

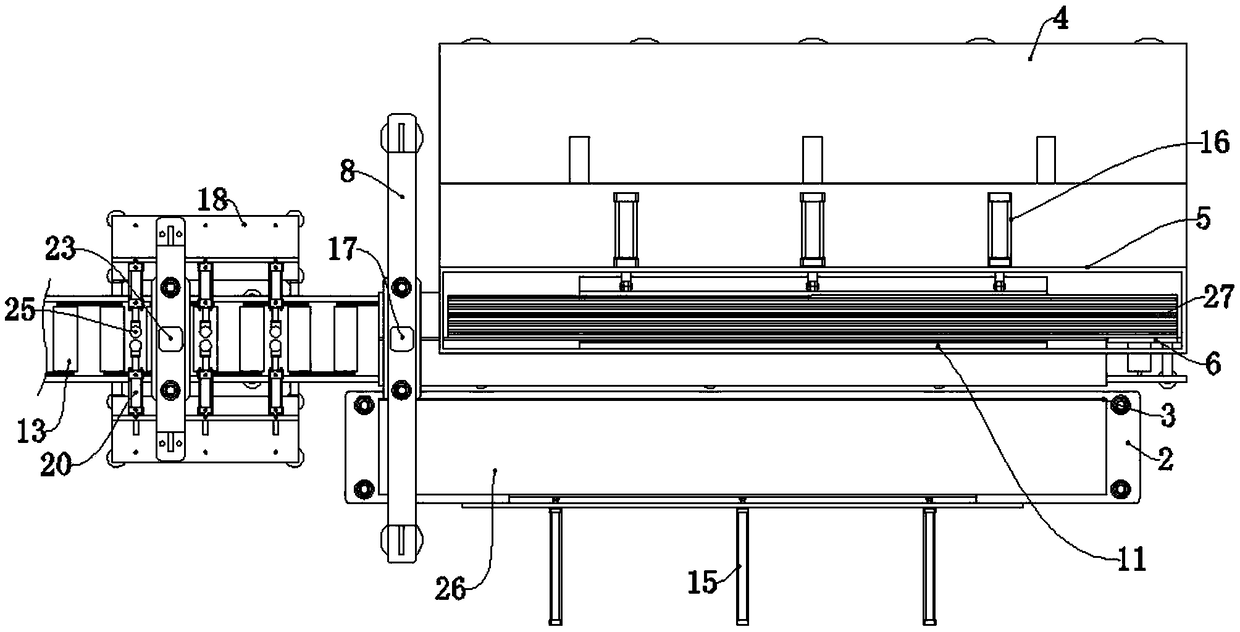

T-shaped steel assembly machine

PendingCN108655694AReduce labor intensityIncrease frictionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly machine

The invention relates to the technical field of steel structure processing equipment, and specifically relates to a T-shaped steel assembly machine. The T-shaped steel assembly machine comprises a conveyor, a wing plate feeding device, a web feeding device, a vertical prepressing device and a centering device, wherein the wing plate feeding device comprises a wing plate feeding device bracket, a wing plate support frame, a wing plate support frame lifting device and a wing plate horizontal pushing device; the web feeding device comprises a web feeding device bracket, a web box, a web horizontal pushing device and a guide inclined block; the vertical prepressing device is arranged downstream the wing plate feeding device and the web feeding device in the conveying direction of the conveyor,and the vertical prepressing device comprises a prepressing device bracket, a prepressing roller bracket, a prepressing roller and a prepressing roller bracket lifting device; and the centering device is arranged downstream the vertical prepressing device in the conveying direction of the conveyor. According to the T-shaped steel assembly machine, the production efficiency can be improved, the labor intensity of workers is reduced, and webs and wing plates are prevented from misplacing due to relative sliding during transportation.

Owner:SHAN DONG JUXIN GRP STEEL STRUCTURE CO LTD

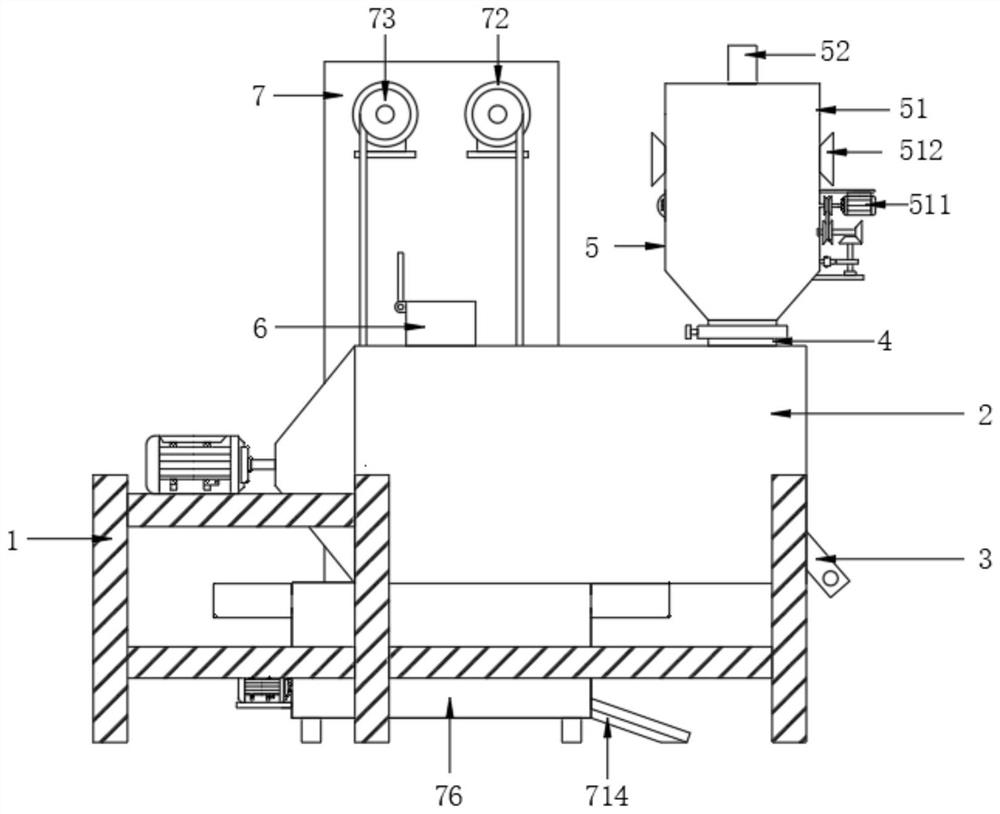

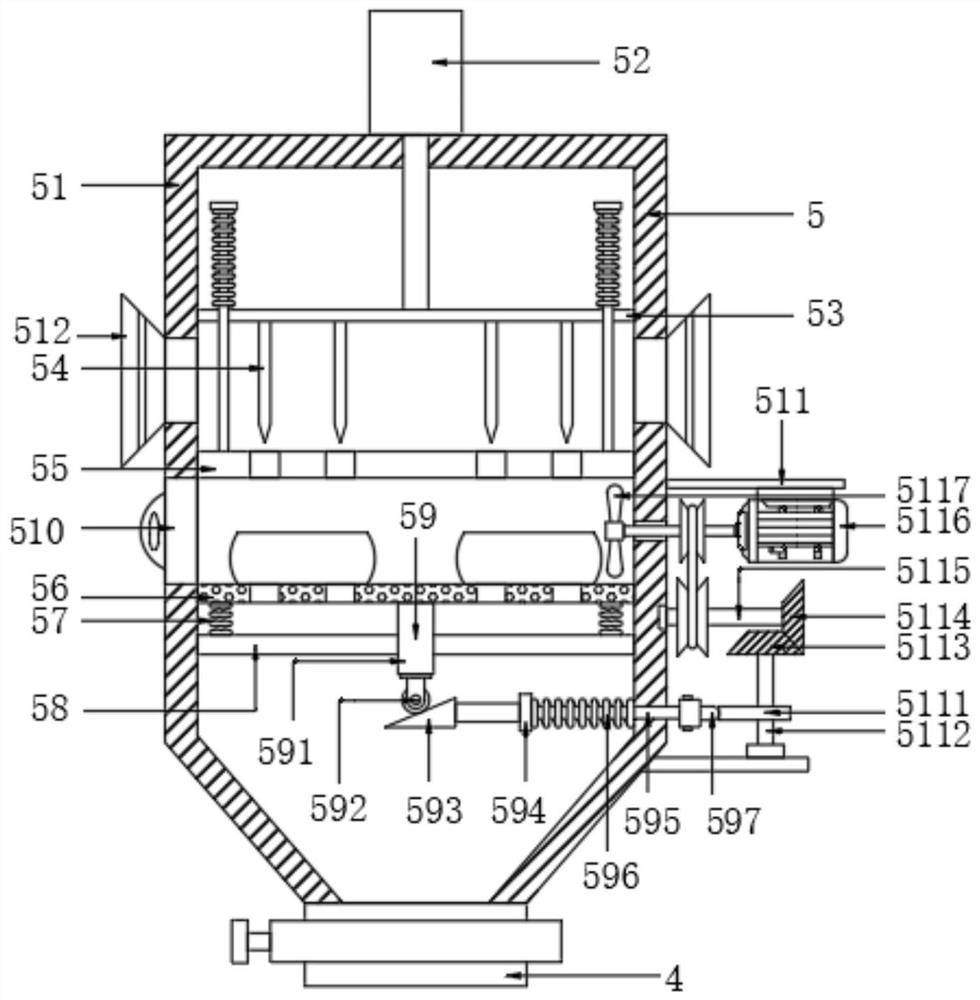

Mortar processing device with environment-friendly dust-proof collectable blanking feeding barrel

ActiveCN111745825AAvoid pollutionImprove processing efficiencyMixing operation control apparatusPretreatment controlStructural engineeringPolluted environment

The invention discloses the technical field of mortar production, and discloses a mortar processing device with environment-friendly dust-proof collectable blanking feeding barrel. The mortar processing device comprises a rack, the top of the rack is provided with a stirring barrel, the bottom of the stirring barrel is provided with a discharge port, the right side of the top of the stirring barrel is provided with a cement feeding port, the top of the cement feeding port communicates with a dustproof barrel, and a sand feeding port is formed in the left side of the top of the stirring barrel.Through the arrangement of the dustproof barrel, a cement bag does not need to be opened manually, dust generated when cement enters the cement feeding port cannot leak out, environment pollution isavoided, and meanwhile, through a vibration assembly in the dustproof barrel, cement can be accelerated to enter the cement feeding port, fan blades can be driven to rotate, the broken cement bag canbe blown into a door body, constructors can conveniently take out the broken cement bag, and the mortar processing and manufacturing efficiency is improved.

Owner:天门市天西天安干混砂浆有限公司

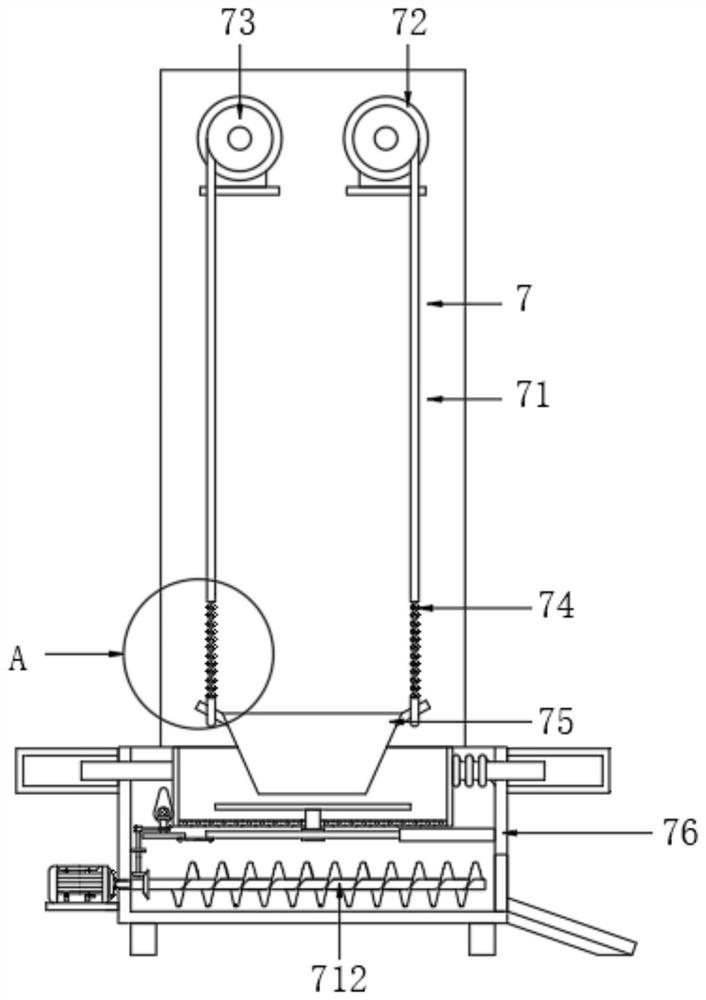

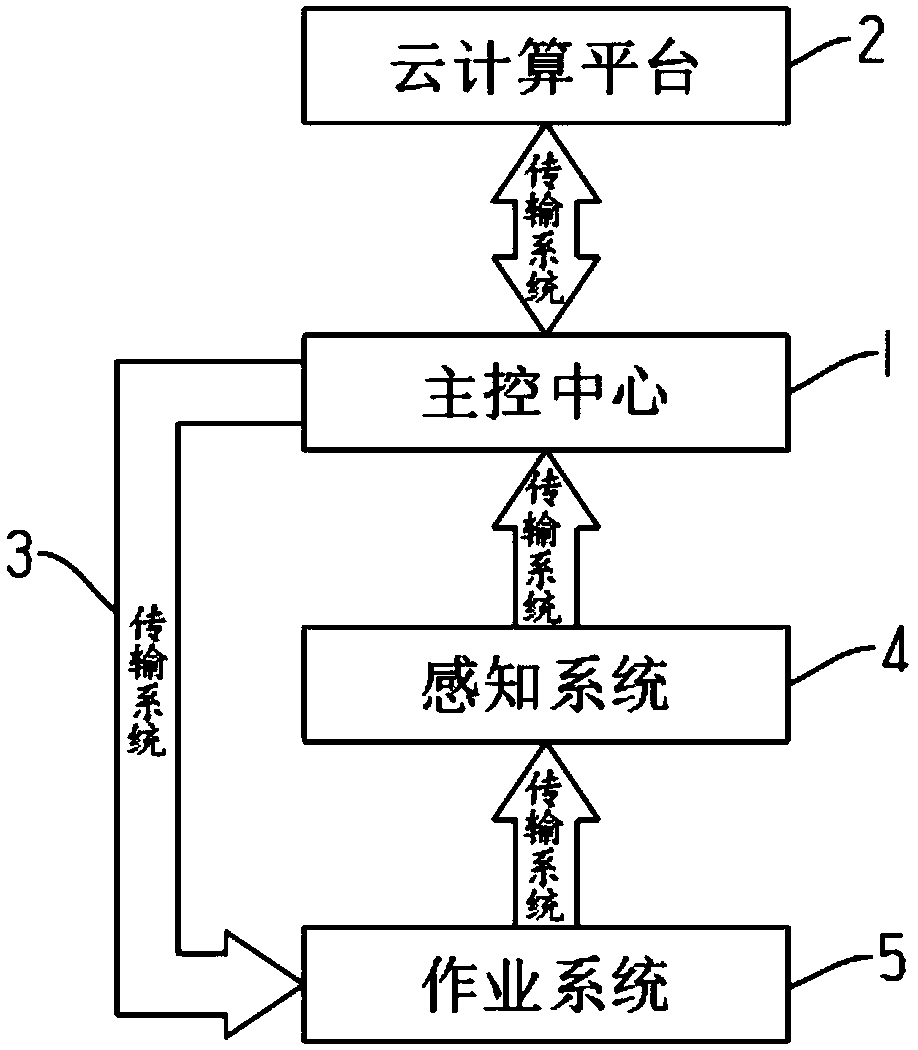

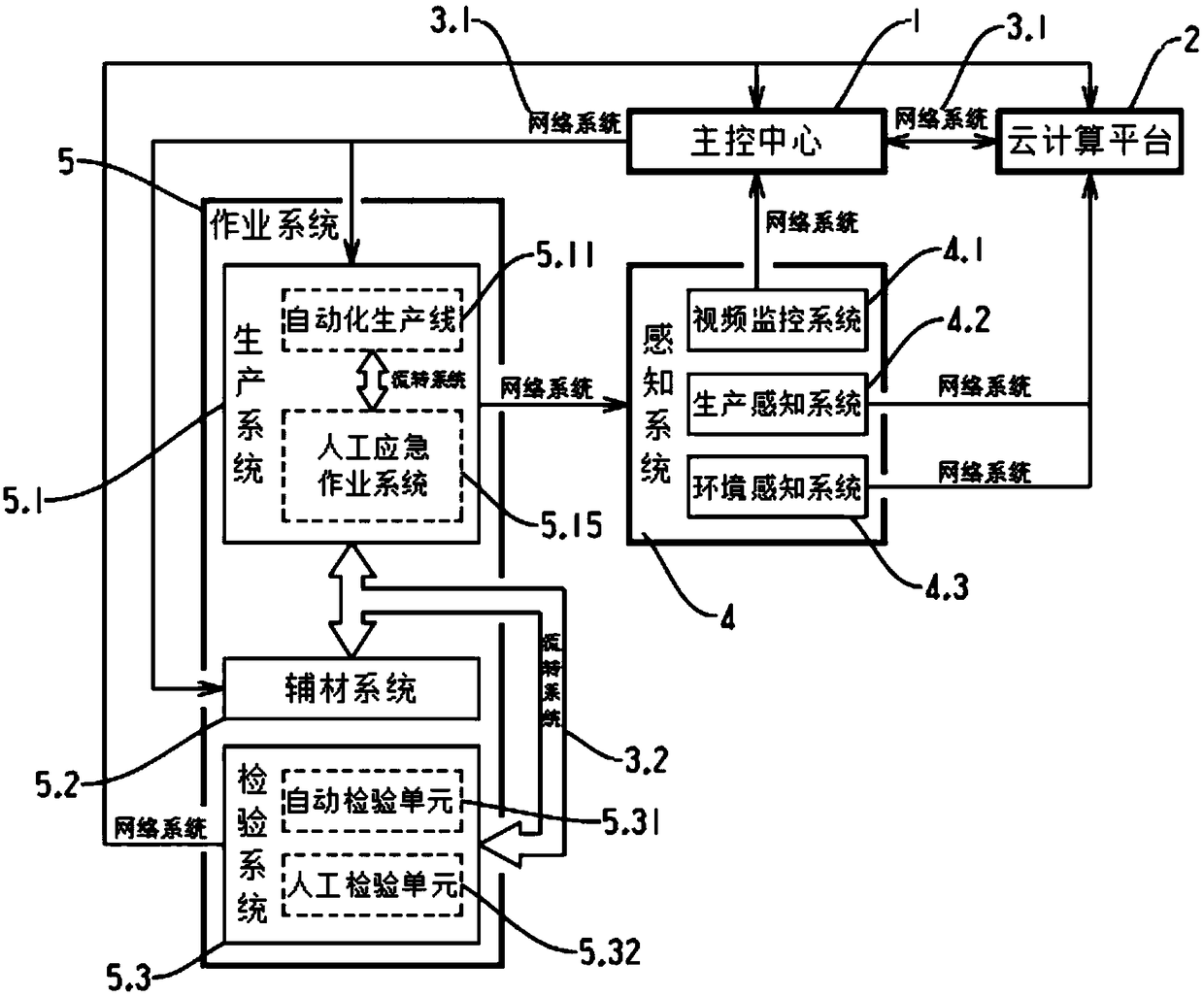

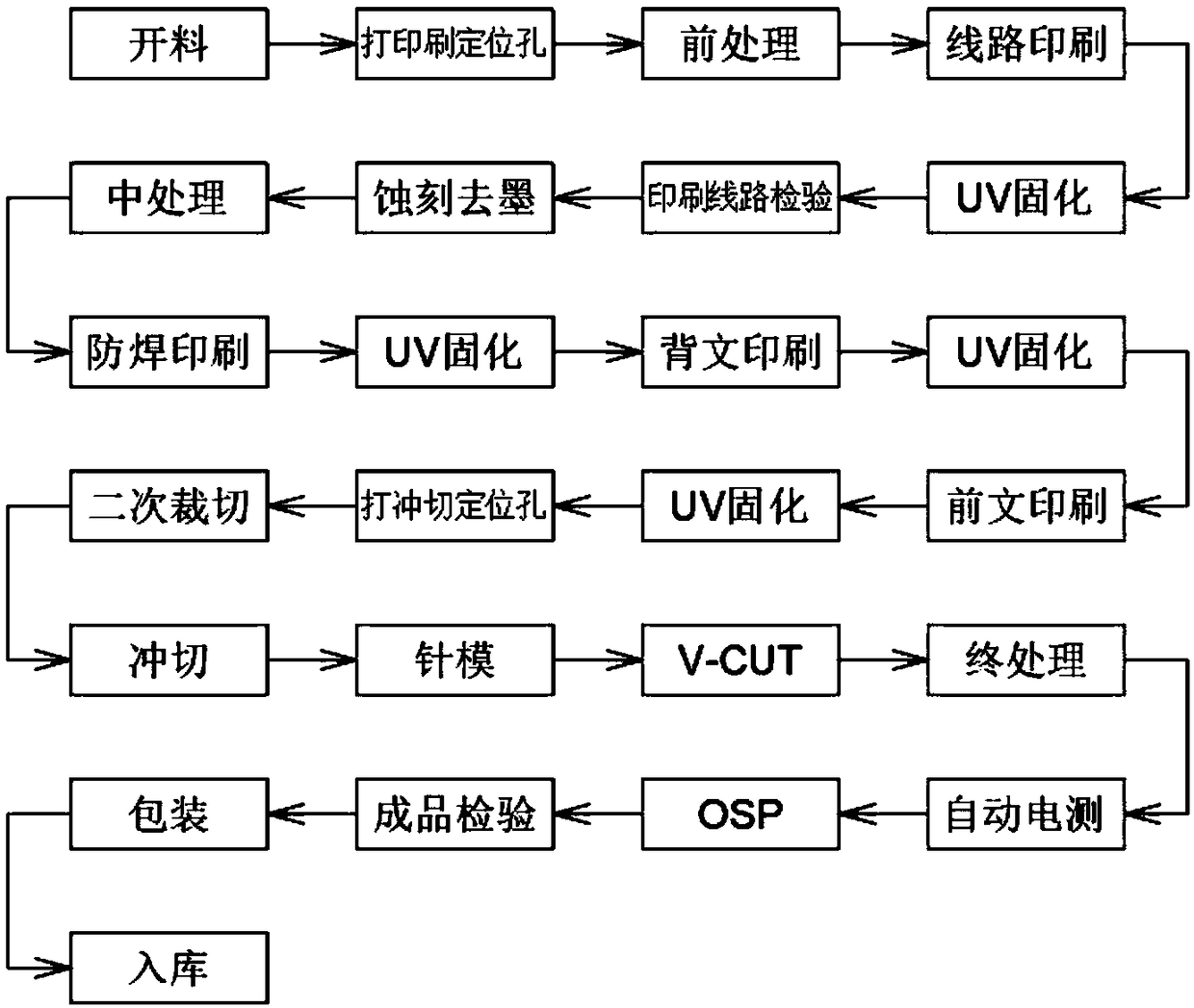

Circuit board production line Internet of Things system based on cloud computing platform

InactiveCN108919757AGuarantee the production progressGuarantee product qualityTransmissionTotal factory controlProduction lineProduction schedule

The invention discloses a circuit board production line Internet of Things system based on a cloud computing platform. The system comprises a main control center, the cloud computing platform, a transmission system, a sensing system and an operating system, the transmission system comprises a network system and a circulation system, the operating system comprises a production system, an auxiliarymaterial system and an inspection system, the sensing system comprises a video monitoring system, a production sensing system and an environment sensing system, the production system comprises an automatic production line and a manual emergency operating system, and the inspection system comprises an automatic inspection unit and a manual inspection unit. The Internet of Things system of the invention combines real-time production conditions, and then analyzes the production schedule and performs scientific arrangement through cloud computing, so that the manufacturing process can be effectively controlled, the yield is improved, the production efficiency is improved, resources are saved, and the cost is reduced.

Owner:KUNSHAN WANYUANTONG ELECTRONICS TECH

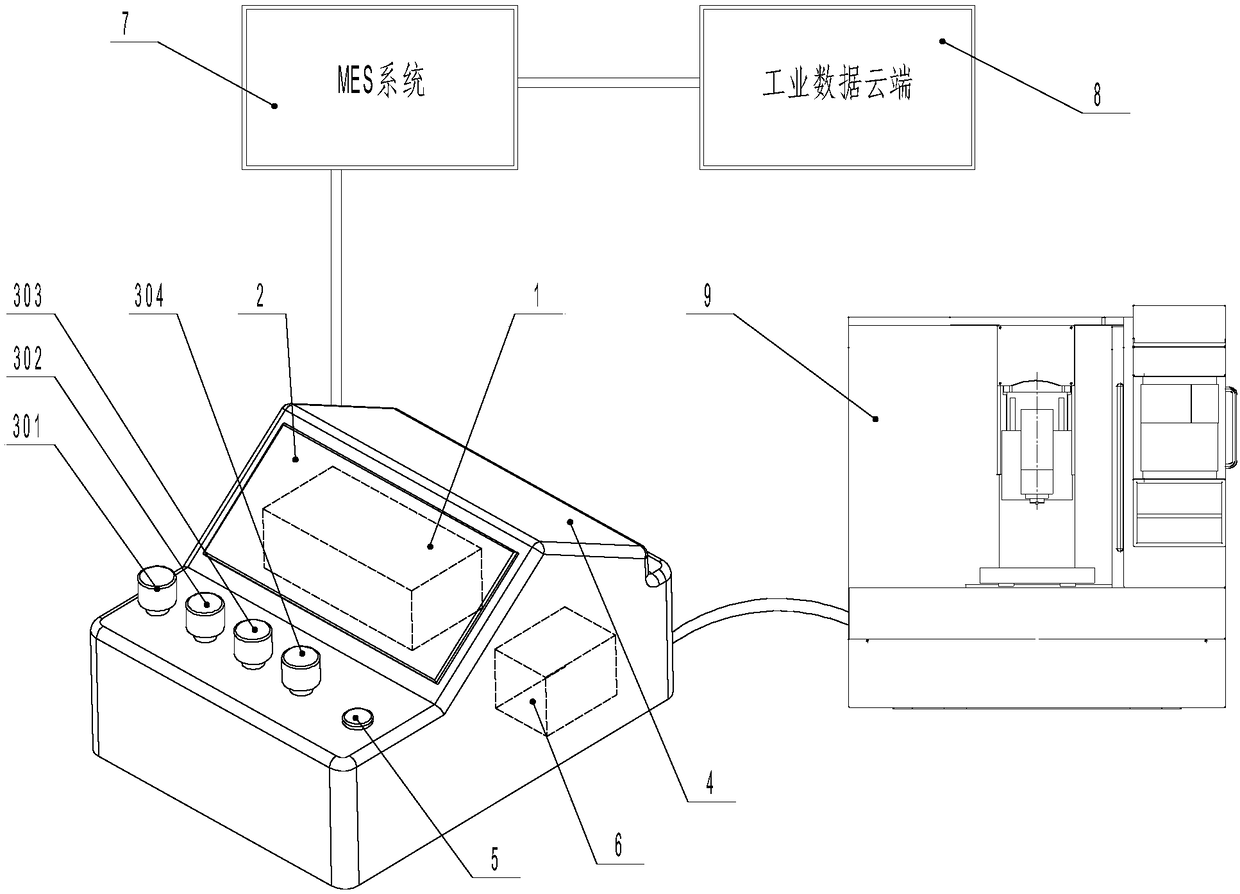

Automatic alarm device of load for CNC motion shaft and method thereof

InactiveCN109211545AIncrease valueGood effectMachine part testingForce sensorsData informationEngineering

The invention discloses an automatic alarm device of load for a CNC motion shaft and a method thereof, and relates to an alarm device and a method. The device comprises a collector, a computer, an alarm and the like; the input end of the collector is connected to each motion shaft of a CNC machining center, and the output end of the collector is connected to the computer through a PLC programmablecontroller; and the computer is connected to the alarm and the CNC machining center respectively. The method comprises the steps of: collecting the load data of each motion shaft of the CNC machiningcenter, and transmitting the data to the computer after calculated; the computer comparing the load data with a set load, if overloaded, stopping the machining equipment of the CNC machining center in time, meanwhile outputting an alarm signal to an alarm corresponding to the motion shaft, and performing storage and output on overloading data information; and the alarm giving out a sound-light alarm. According to the automatic alarm device of load for the CNC motion shaft and the method thereof, automatic alarm of the load of the CNC motion shaft can be realized, the damage probability of thedevice is reduced to the lowest, the good running is realized, and running life of the device is maximized.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

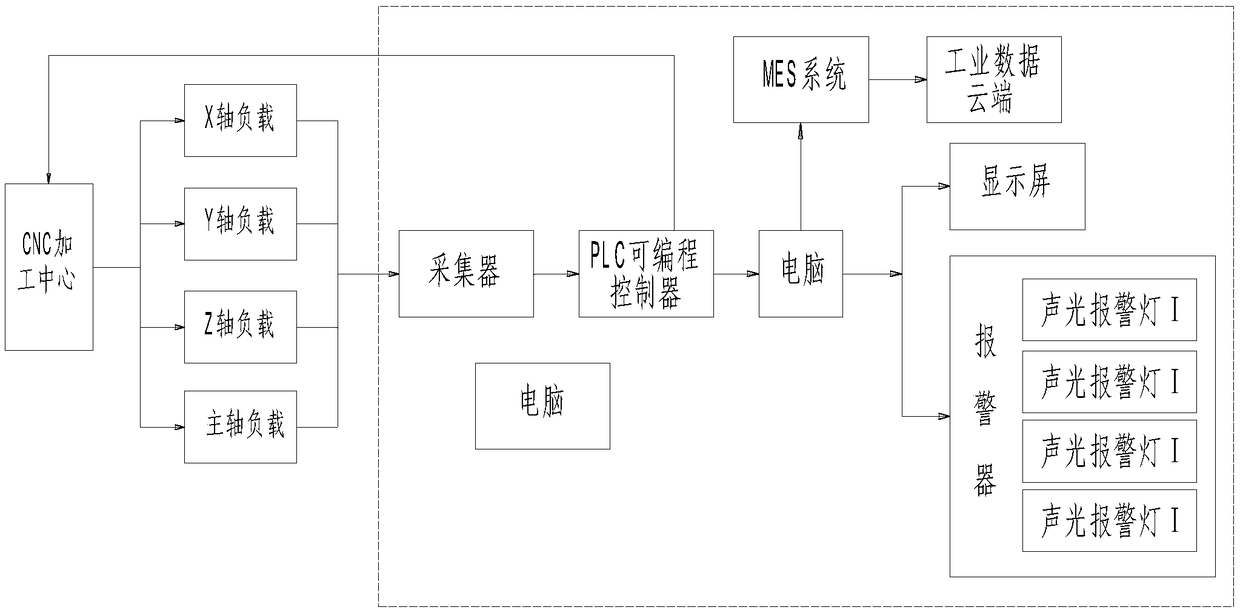

Online cleaning method for tubular reactors

The invention discloses an online cleaning method for tubular reactors. The method comprises the following operating steps of: releasing the interlocking between liquid ammonia and phosphoric acid of tubular reactors A and B; stopping feeding of the tubular reactors A and B, switching off phosphoric acid and liquid ammonia pipeline control valves, respectively switching on medium-pressure steam valves on acid pipes and ammonia pipes of the tubular reactors A and B so as to continuously purge the steam towards the interior of a rotor drum granulator, mixing phosphoric acid and steam together and carrying out acid pickling and purging on mixing heads A and B, and the tubular reactors A and B 5 for 8-15 minutes, observing the state of materials at an outlet of the granulator in real time through video monitoring, and keeping the tubular reactors A and B to run stably, wherein the purging frequency of the tubular reactors A and B is one time per three to five hours. The cleaning process is simple to operate, and the dirt on the tubular reactors can be effectively removed.

Owner:WENGFU (GRP) CO LTD

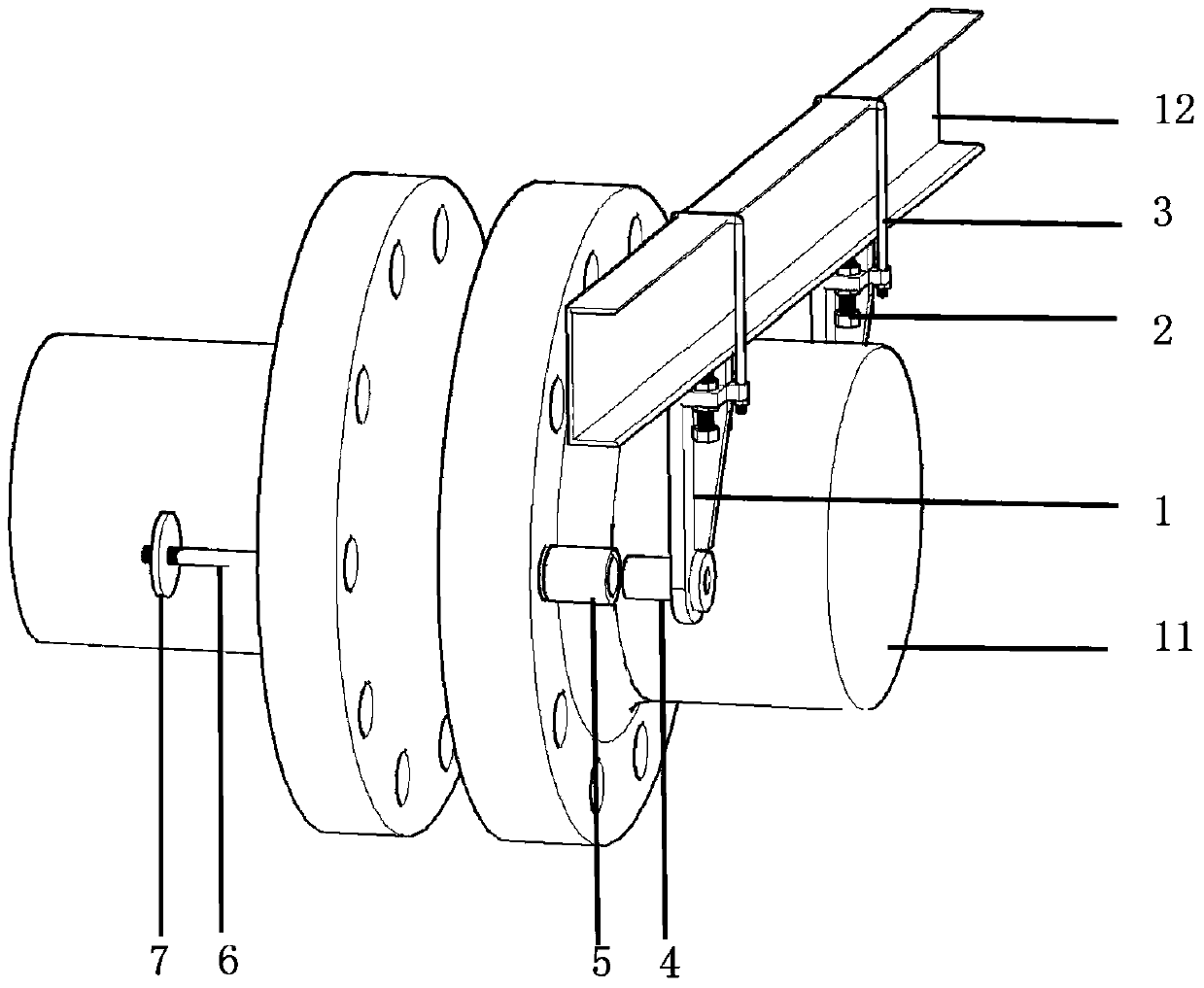

Device capable of preventing rotation in connection between ship shafting and front screw shaft and installing method thereof

A device capable of preventing rotation in connection between ship shafting and a front screw shaft comprises a limit plate, an adjusting bolt arranged at one end of the limit plate, a hook and a bolt arranged at the other end of the limit plate. A sleeve is sleeved on the outside of one end of the bolt, the inside of the bolt is connected with a screw, and a washer is arranged at the other end of the screw. An installing method of the device is further provided. The device can prevent damage to the screw shaft and relevant accessories, and the damage is caused by abnormal rotation caused under the condition that a propeller of the screw shaft is accidentally subjected to external force and has the advantages of being convenient to operate, capable of being used repeatedly and permanently, free of maintaining, low in manufacture cost and low in use cost.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Air vane torsion lever processing technology

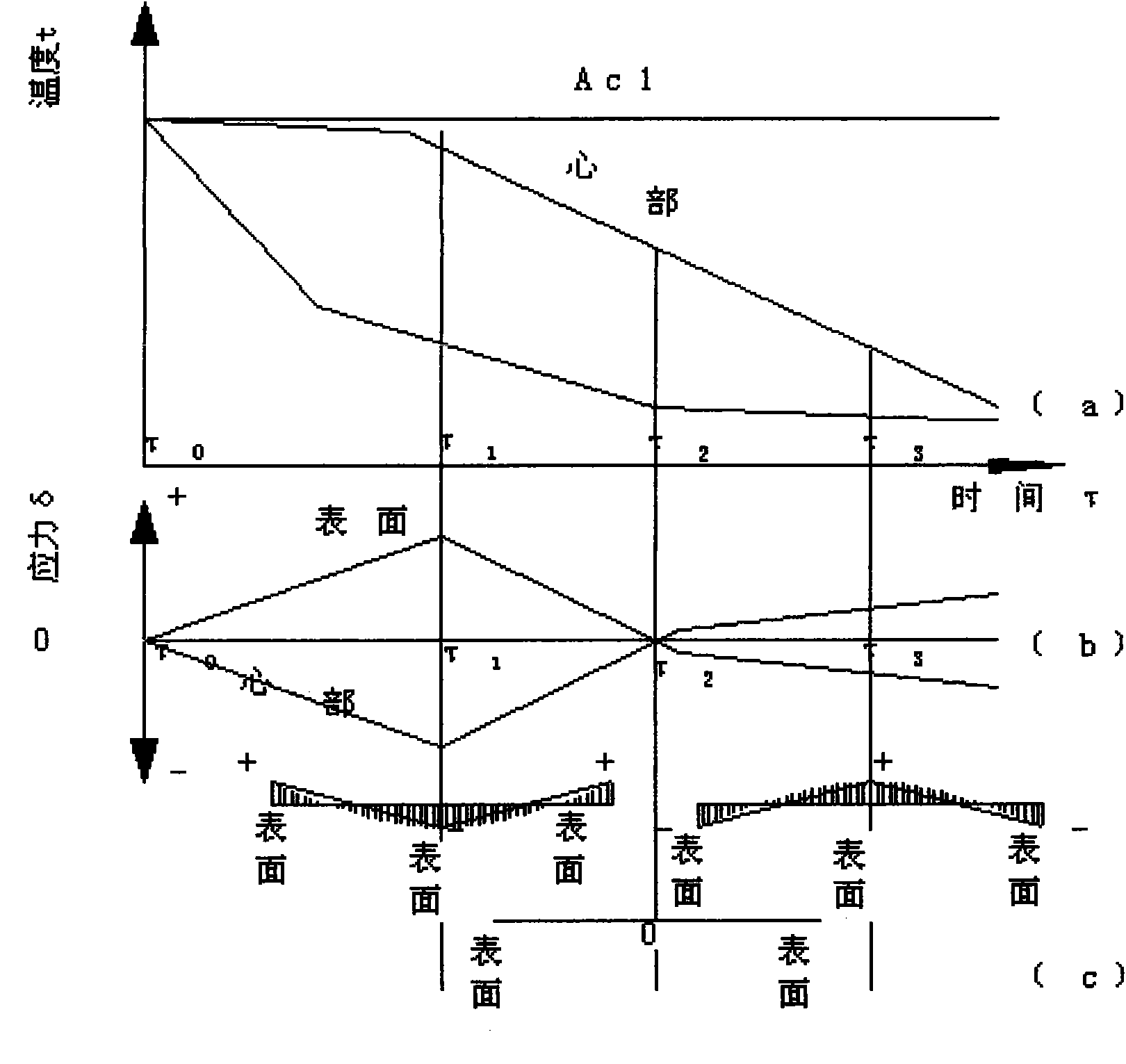

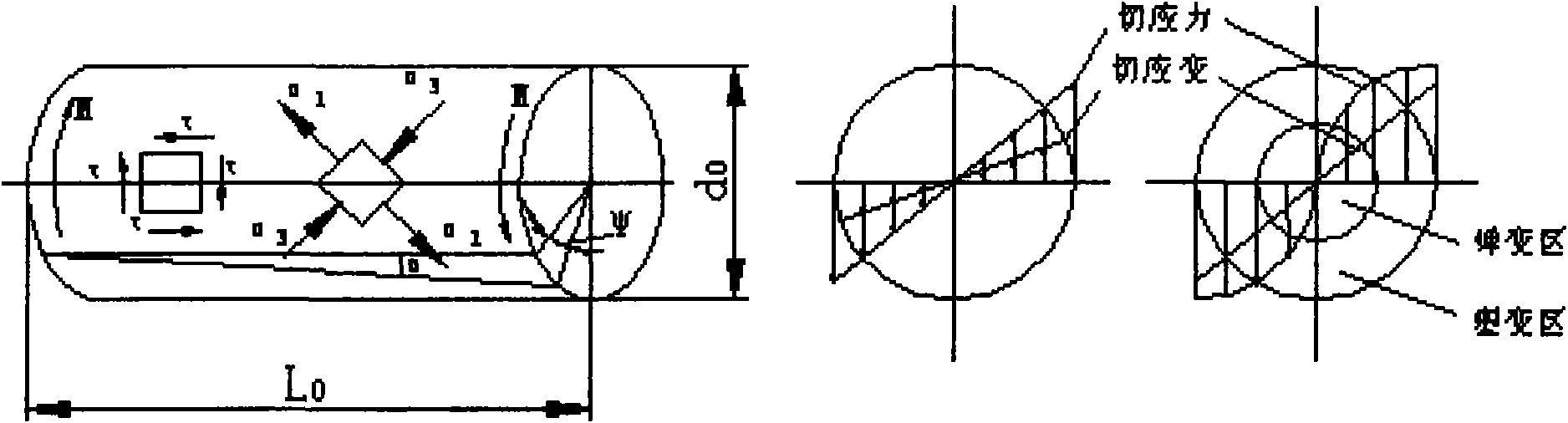

InactiveCN101856754AGuaranteed delivery progressReduce manufacturing costFurnace temperatureWorking environment

The invention relates to an air vane torsion lever processing technology. The torsion lever manufacture flow comprises mechanical processing, thermal processing, heating and loading, magnetic powder inspection, wire-electrode cutting, mechanical processing, surface processing, angle test, duration running, angle test and delivery and warehousing. The invention is characterized in that the processing work environment temperature is not lower than 25 degrees centigrade, as for the heating and loading procedure, a torsion lever is twisted for 90 degrees on a frock and then is fixed, the entry temperature of a workpiece is not more than 30 degrees centigrade and is increased along with the temperature of a furnace, after being kept for 2 to 3 hours at 110 to 120 degrees centigrade, the temperature of the workpiece is reduced to 25 to 30 degrees centigrade along with the furnace temperature, the workpiece is discharged and is unloaded so that the torsion lever is restored, the torsion lever is twisted for 90 degrees again, installed and fixed, the temperature of the torsion lever rises to 110 to 120 degrees centigrade along with the furnace temperature, kept for 1.5 to 2 hours and is reduced to 25 to 30 degrees centigrade along with the furnace temperature before being discharged and unloaded to restore the torsion lever.

Owner:HONG KONG JIA REN IND DEV CO LTD

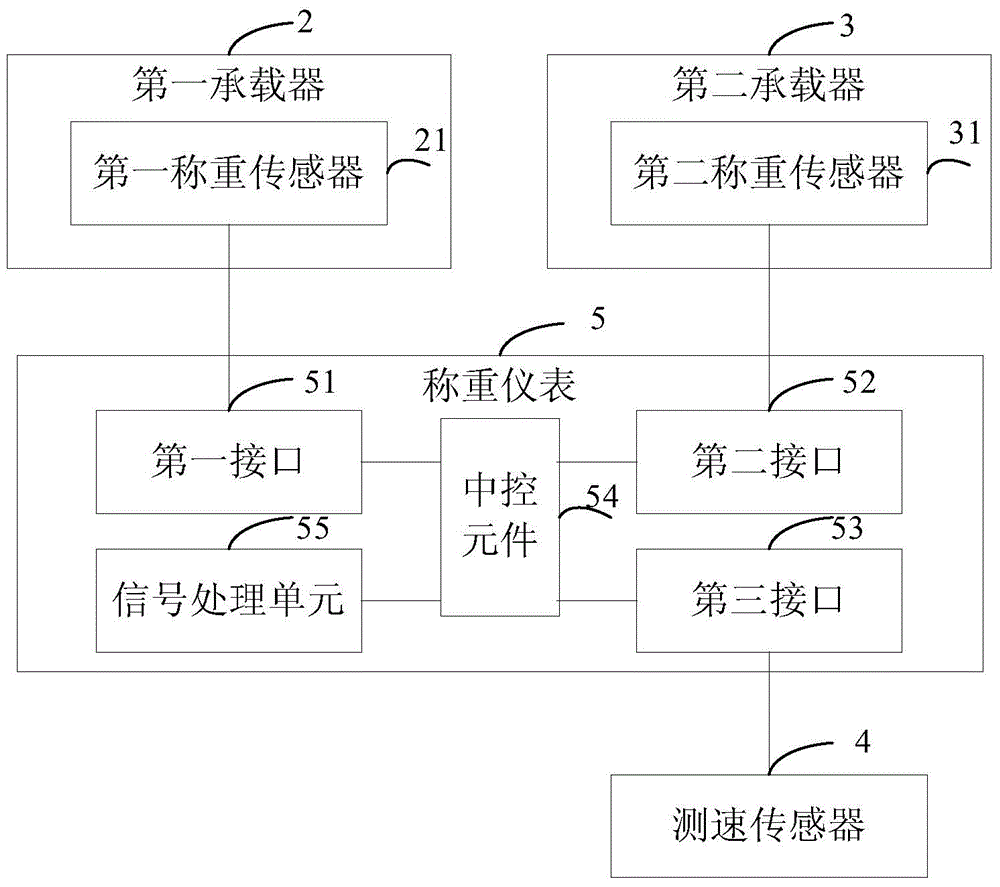

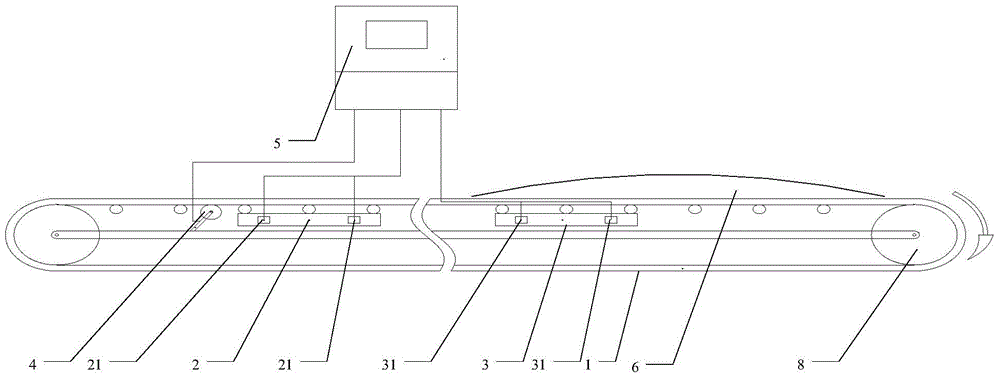

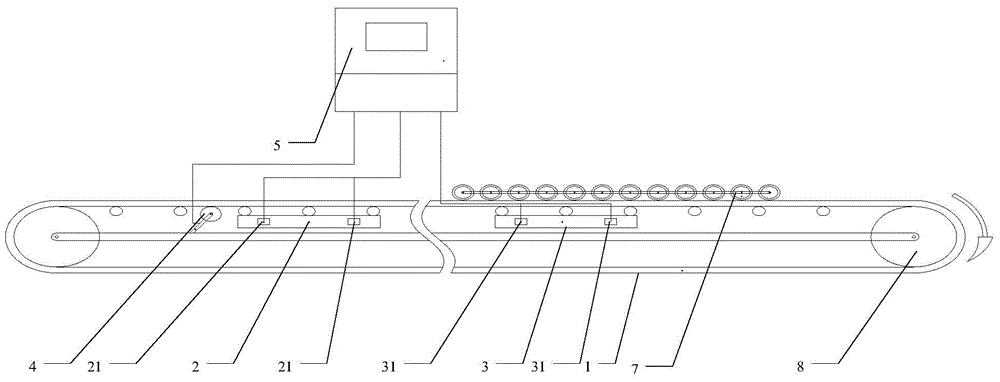

Calibration device and method of double-loader electronic belt scale

ActiveCN104880242AGuarantee the production progressSimple compositionWeighing apparatus testing/calibrationElectricityCalibration coefficient

The invention provides a calibration device and method of a double-loader electronic belt scale. The device comprises a belt, a first loader, a second loader, a speed measuring sensor and a weighing instrument. The first loader comprises a first weighing sensor. The second loader comprises a second weighing sensor. The weighing instrument is electrically connected with the first weighing sensor and the second weighing sensor respectively. A first interface and a second interface of the weighing instrument are respectively used for collecting gravity signals of transmitted materials measured by the first weighing sensor and the second weighing sensor in time intervals such as a preset first time interval, a calibration period and a preset second time interval; a third interface is used for receiving transmission speed signals sent by the speed measuring sensor; and a signal processing unit is used for calculating a second calibration coefficient of the first loader, for calculating a second calibration coefficient so as to finish calibrating the second loader, and for calculating a third calibration coefficient of the first loader so as to finish calibrating the first loader.

Owner:BEIJING COAL MINING ELECTRIC EQUIP TECHN DEV +1

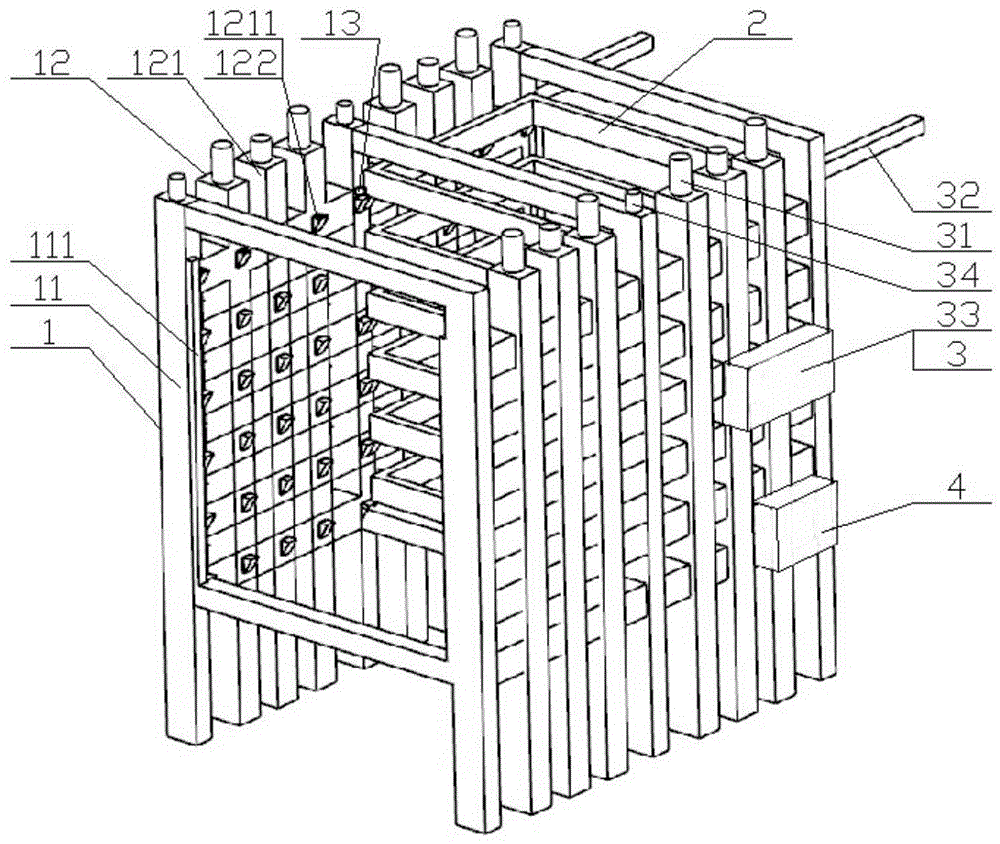

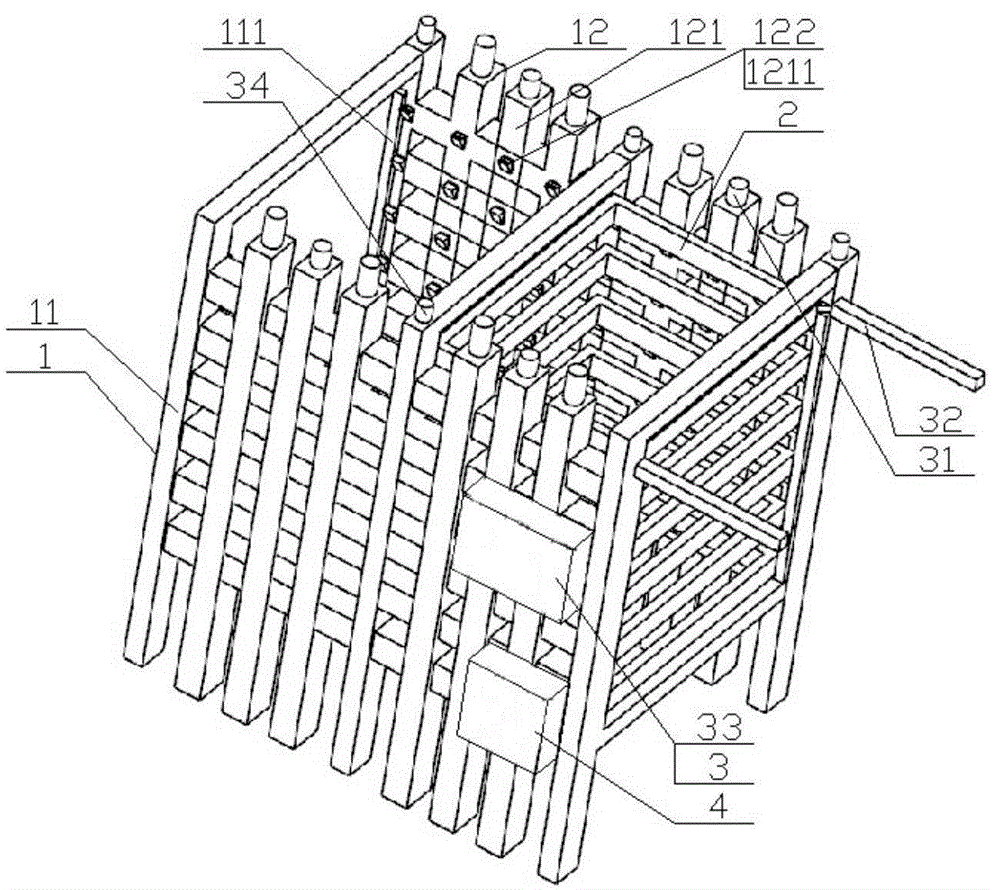

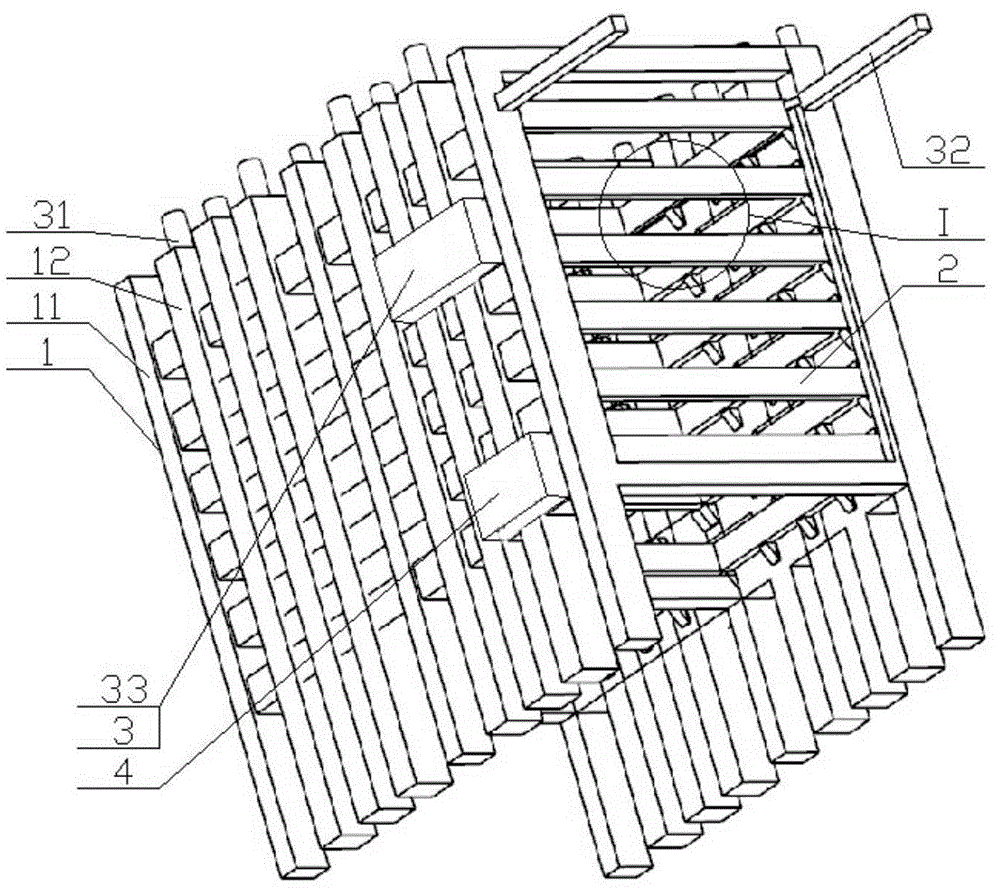

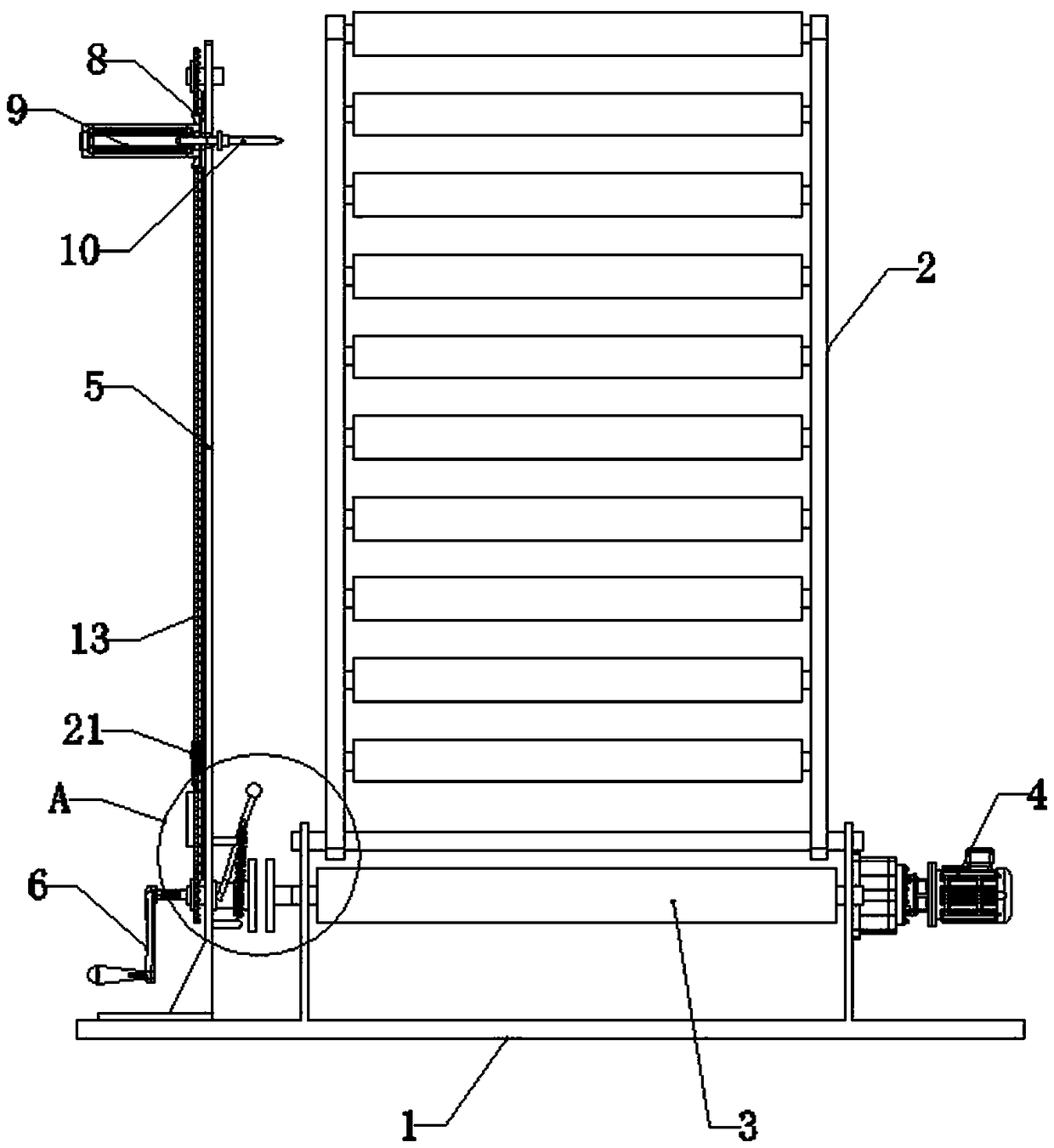

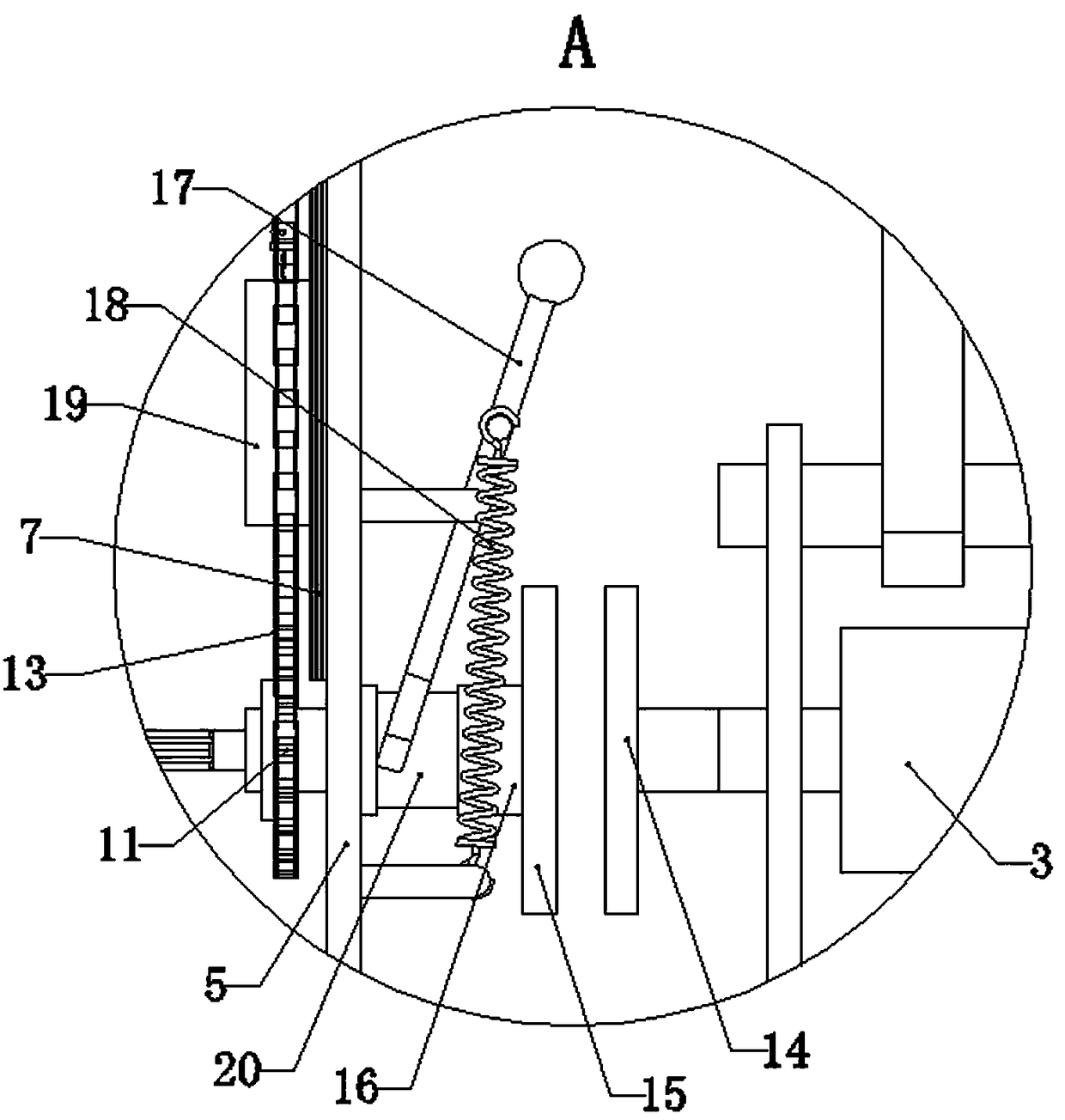

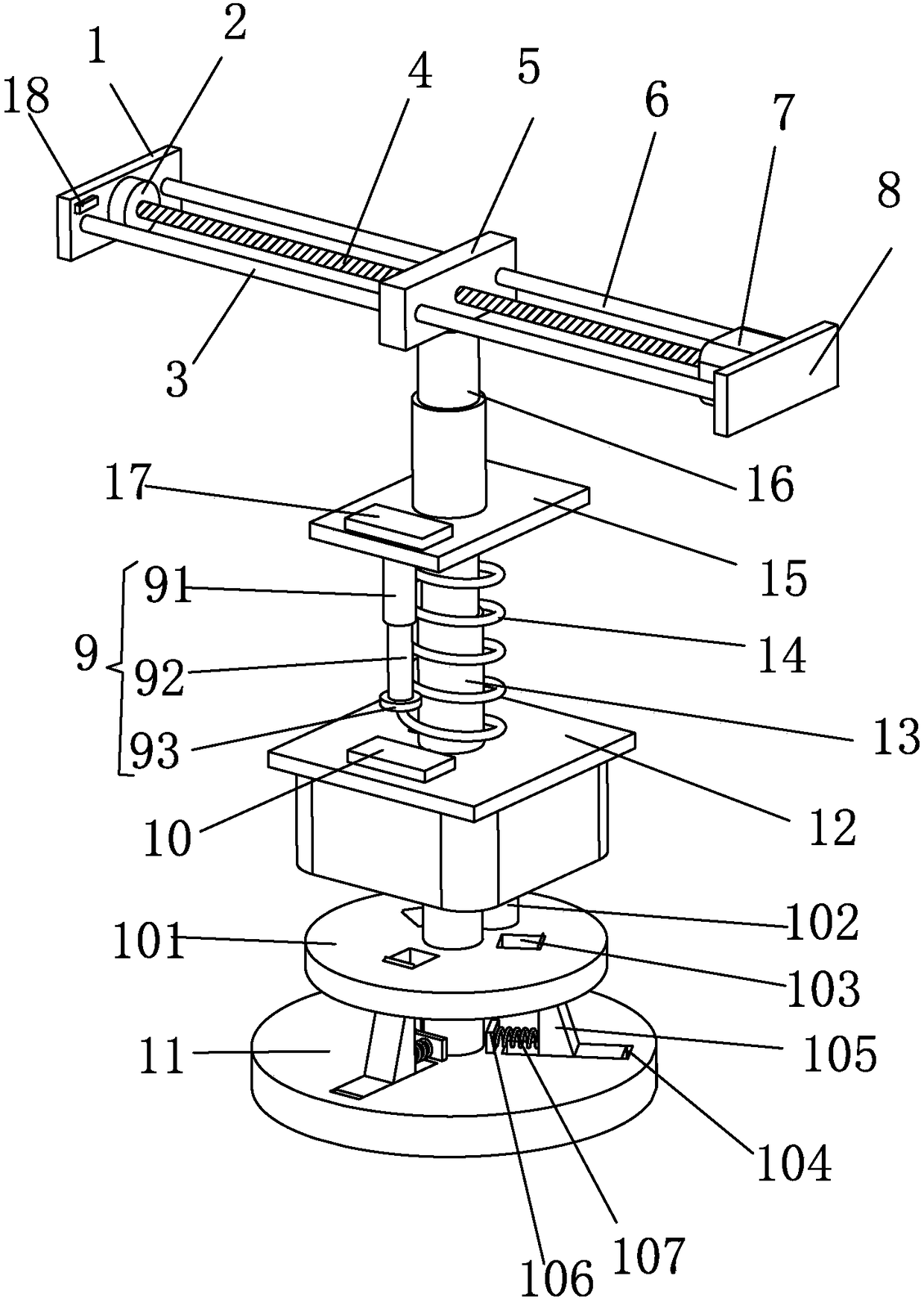

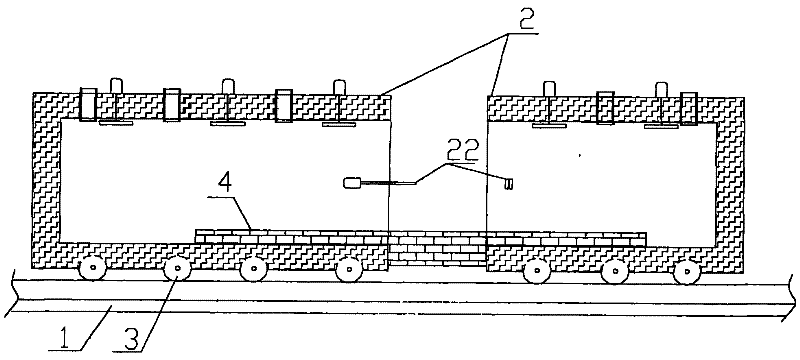

Digital-bus-based bracket and tray assembly capable of supplying materials circularly

ActiveCN104670775AReduce labor intensityImprove supply efficiencyStorage devicesElectric controlPower control

The invention discloses a digital-bus-based bracket and tray assembly capable of supplying materials circularly. The digital-bus-based bracket and tray assembly capable of supplying the materials circularly comprises a multilayer bracket (1), a plurality of trays (2), a power device (3) and an electric control device (4). The multilayer bracket comprises a bracket body (11) and tray supporting mechanisms (12), the bracket body is of a square frame structure and is provided with two accommodating cavities, the tray supporting mechanisms are arranged on the inner side faces of the accommodating cavities and comprise vertical support beams (121), support claws (122), vertical connection rods I (123) and vertical connection rods II (124). The trays are erected on the support claws on the inner walls of the accommodating cavities of the bracket in layers. The power device comprises support claw extension controlling mechanisms (31), tray thrusting and extension mechanisms (32) and a power control mechanism (33). The digital-bus-based bracket and tray assembly capable of supplying the materials circularly has the advantages that multiple trays can be supplied continuously at one time and can be set out automatically, influence of human factors on production progress is reduced, and high production efficiency is achieved.

Owner:XUZHOU DKEC ELECTRICAL TECH

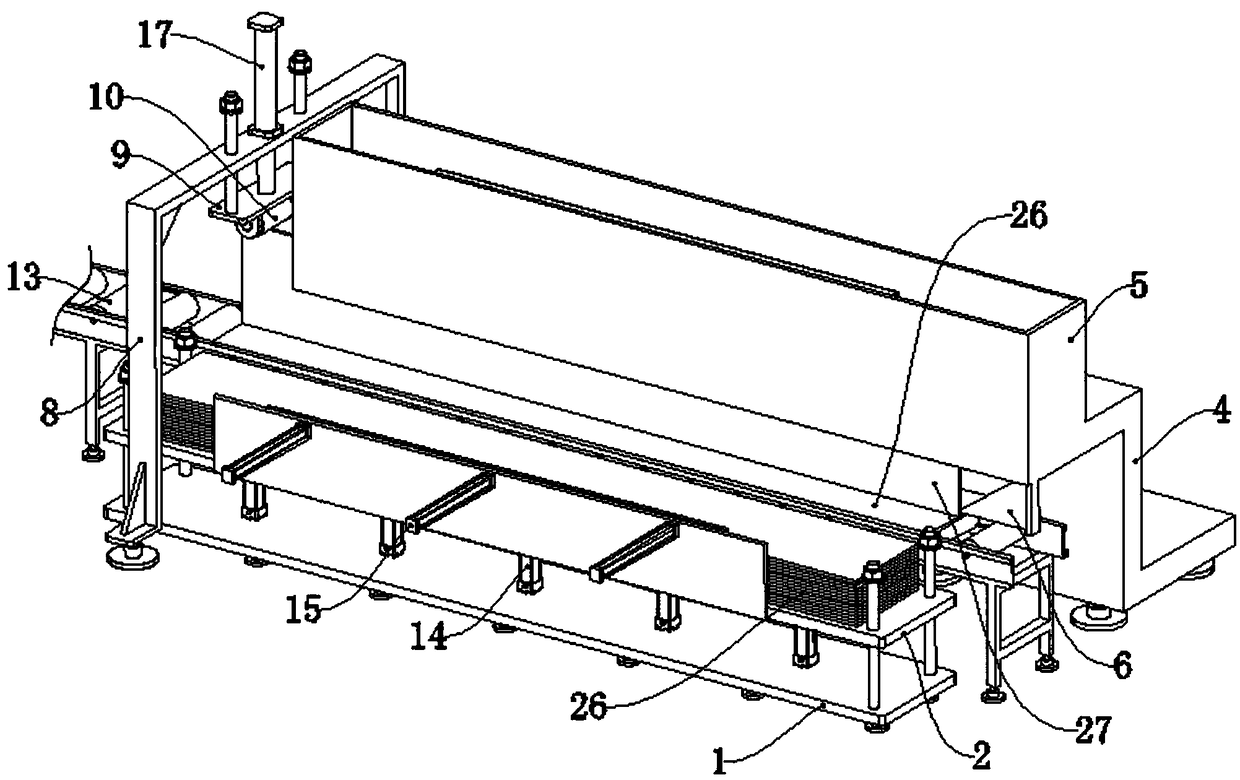

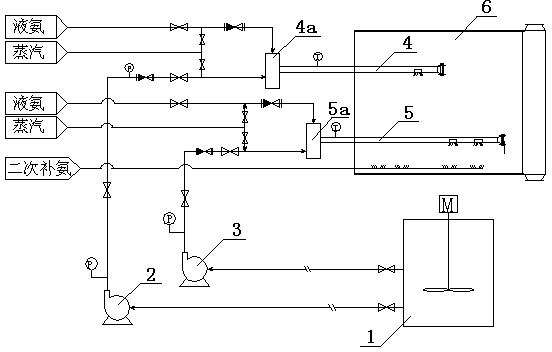

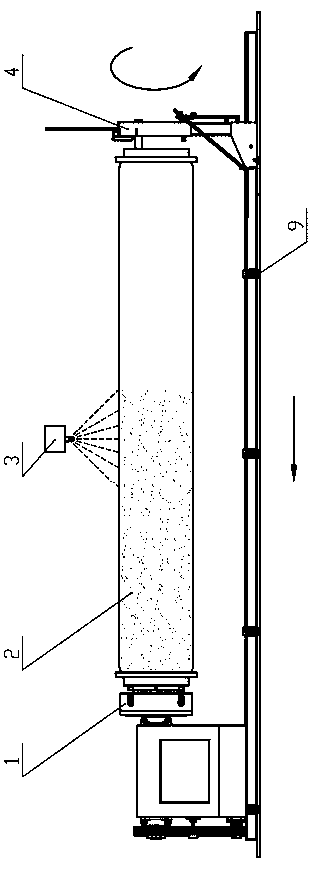

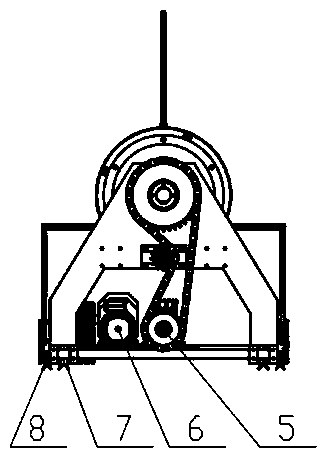

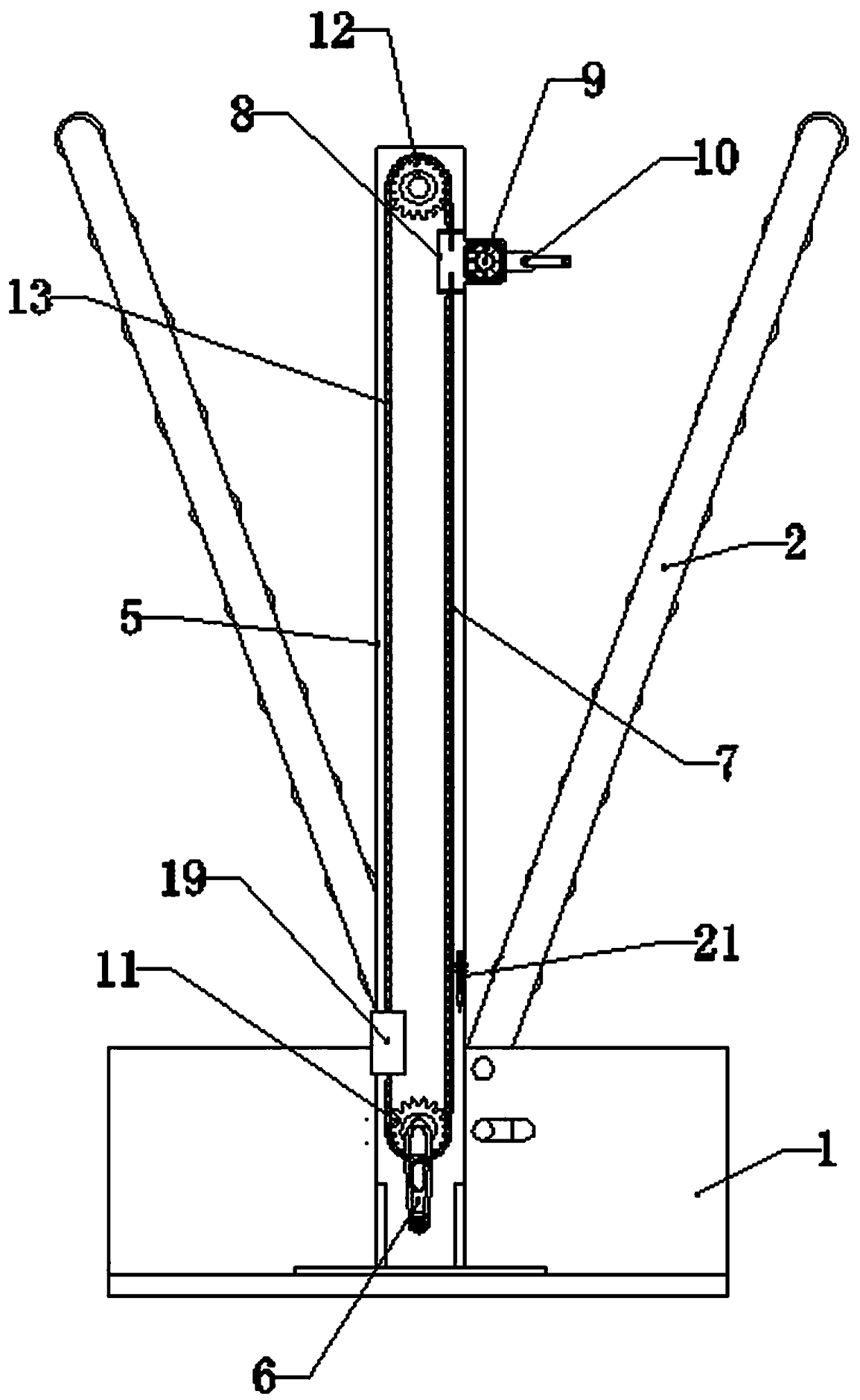

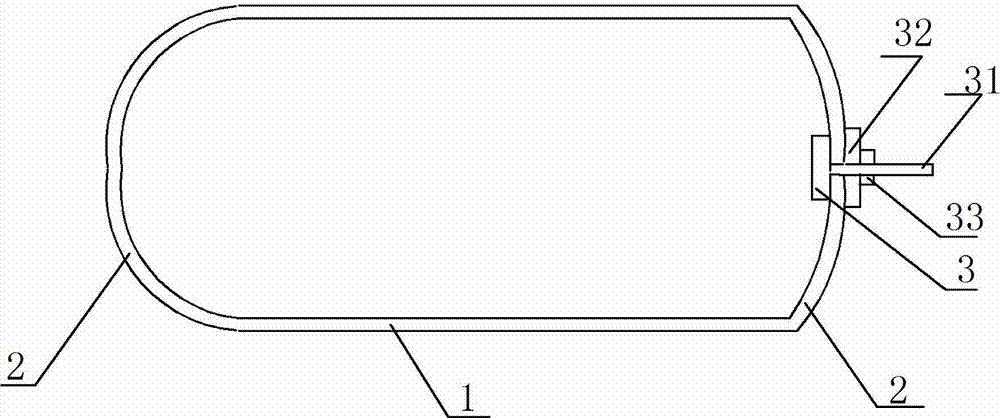

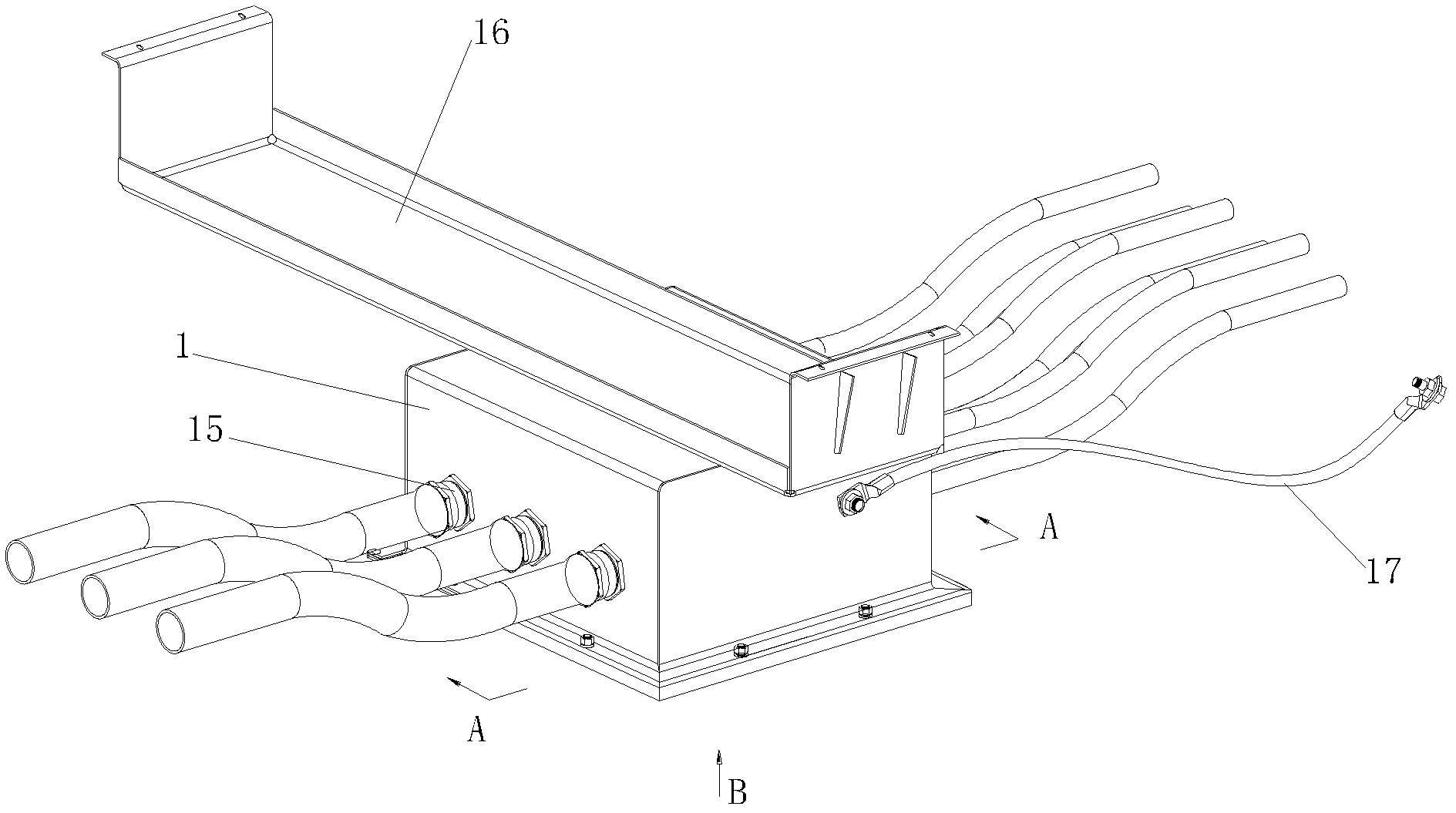

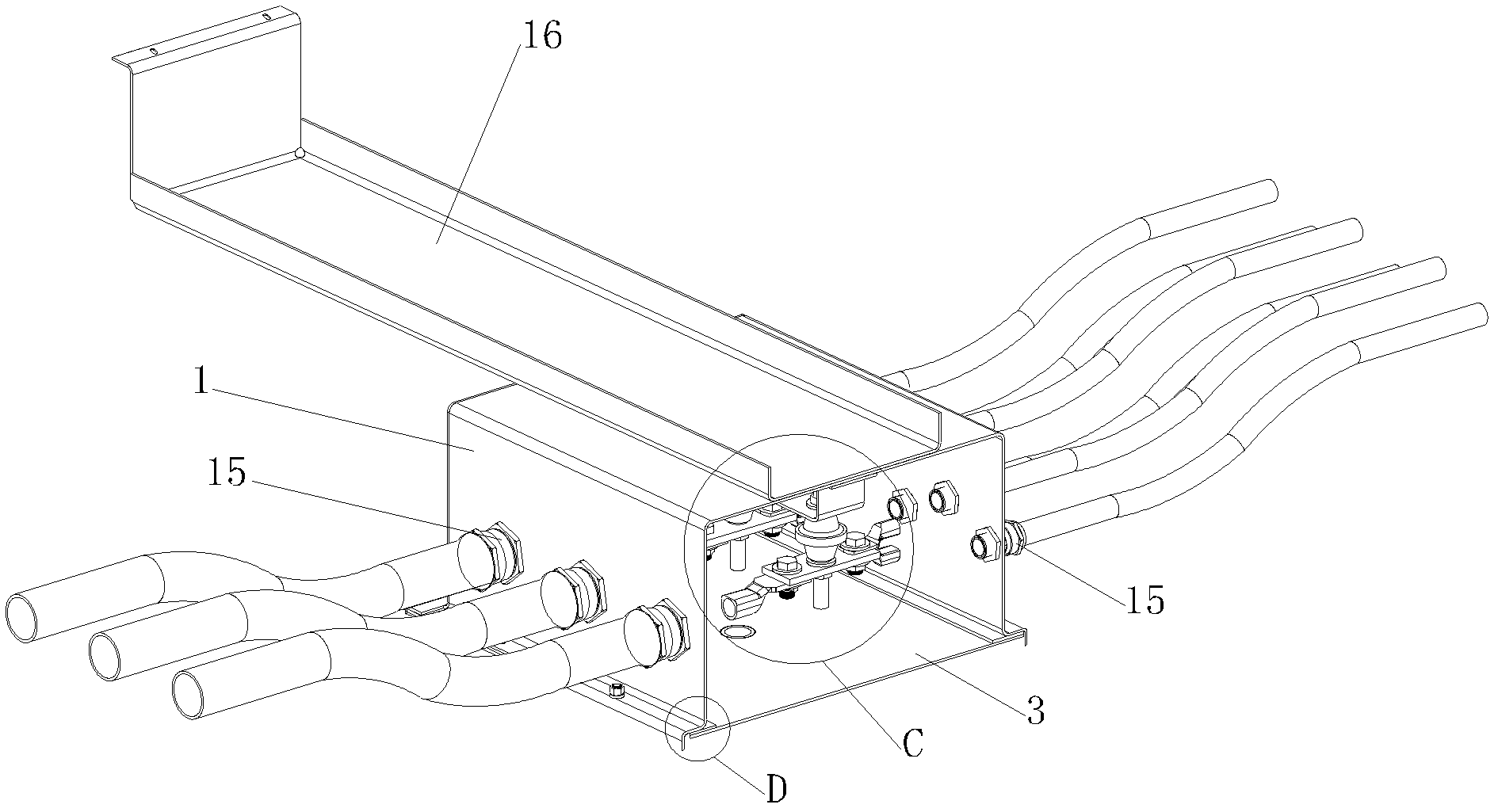

Advancing device and advancing method for polyurethane spraying foaming of prefabricated directly-buried thermal insulation tube

PendingCN109453922AImprove uniformityGuaranteed DensitySpraying apparatusThermal insulationSpray foams

The invention provides an advancing device and an advancing method for polyurethane spraying foaming of a prefabricated directly-buried thermal insulation tube. In the polyurethane spraying foaming process of an existing prefabricated directly-buried thermal insulation tube, the steel tube is installed on a hand-cranking frame, and the advancing and rotating motions are adjusted by manpower, so that the advancing speed and the rotating speed are not uniform, the polyurethane spraying thickness is not uniform, and the polyurethane spraying density and quality are influenced. The advancing device comprises an inner chuck (1) and a polyurethane spray gun (3); the inner chuck (1) is a four-jaw linkage inner chuck; one end of the steel tube (2) is arranged on the inner chuck (2), the other endof the steel tube is connected with a driven end (4), the two ends of the steel tube sleeve with protection plates, a driven end guide rail (8) is arranged at the bottom of the driven end, the inner chuck is connected with a steel pipe autorotation power end (5) through a connecting shaft, the bottom of the polyurethane spray gun is connected with a spraying advancing power end (6), the spraying advancing power end comprises a transmission mechanism, and the transmission mechanism enables an advancing mechanism to horizontally move through chain transmission. The device is used for carrying out spraying foaming on the polyurethane of the prefabricated directly-buried thermal insulation tube.

Owner:HARBIN LOGSTOR ENERGY SAVING TECH

Film blowing machine with air supplementing device as well as method for supplementing air for film bubbles

PendingCN108248003AGuarantee the production progressGuarantee product qualityDrive motorPlastic film

The invention relates to the technical field of manufacturing equipment of a plastic film, in particular to a film blowing machine with an air supplementing device. The film blowing machine with the air supplementing device comprises a machine frame, a reverse Y-shaped frame, a traction roller, a traction roller driving motor and the air supplementing device; the air supplementing device comprisesa bracket, a chain transmission mechanism, a hand crank, a guide rail, a sliding block, an air cylinder, an air supplementing needle and a clutch; the air cylinder is arranged on the sliding block; the air supplementing needle is connected with a piston rod of the air cylinder; and the traction roller can drive the sliding block through the clutch and the chain transmission mechanism to perform transmission at the speed as same as the traction speed. The invention also provides a method for supplementing air for the film bubble by using the device. Compared with prior art, the film blowing machine with the air supplementing device has the following beneficial effects: the air supplementing needle and the film bubble can move at the same time through the air supplementing device, so shut-down is not needed, the production progress and the product quality are guaranteed, the energy consumption cost is reduced and the film blowing machine with the air supplementing device is simple and labor-saving in operation.

Owner:山东富力包装材料股份有限公司

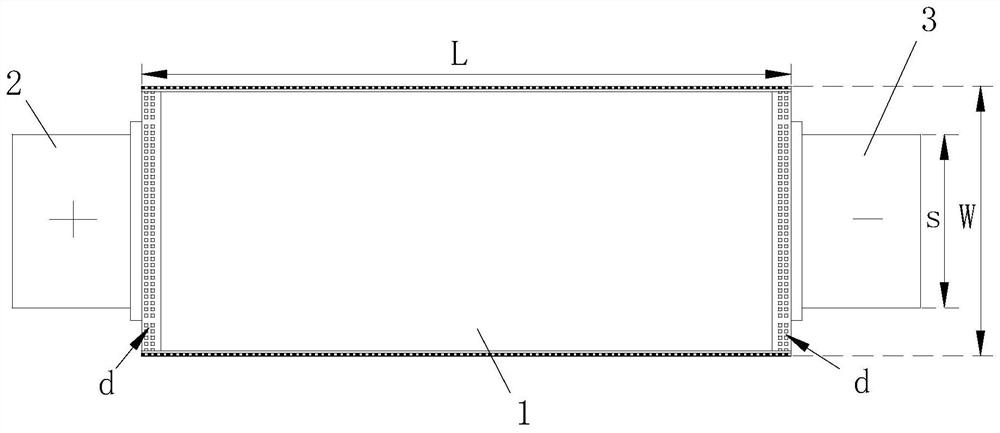

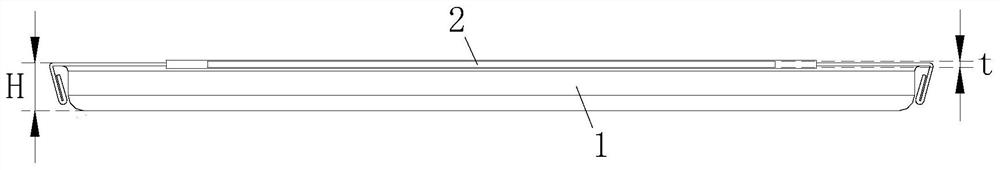

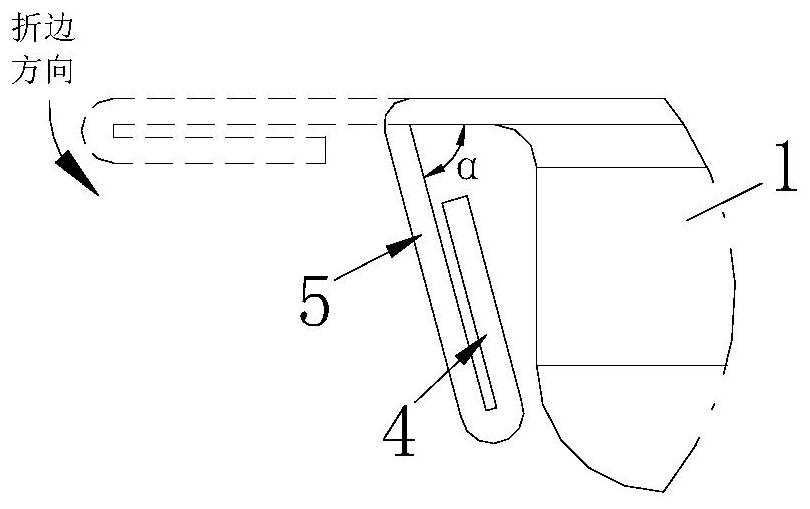

HEV soft package battery cell and battery pack

InactiveCN112349950AGuaranteed high rate charge and discharge capabilityGuaranteed powerFinal product manufactureLi-accumulatorsPlastic filmBattery cell

The invention provides an HEV soft package battery cell and a battery pack, the HEV soft package battery cell comprises a battery cell main body and a battery cell tab, the battery cell main body is provided with an aluminum-plastic film shell, and a pole group and an electrolyte which are sealed in the aluminum-plastic film shell, the battery cell tab is provided with a positive pole tab and a negative pole tab, one ends of the positive pole tab and the negative pole tab are positioned in the aluminum-plastic film shell and are connected with pole group, and other ends of the positive pole tab and the negative pole tab extend out of the aluminum-plastic film shell. The battery cell is characterized in that the battery cell main body is of a cuboid structure, the length L of the battery cell main body is smaller than or equal to 250 mm, the width W and the thickness H of the battery cell main body meet the conditions that 20%L <= W <= 60%, and 1%L <= H <= 5%L. According to the HEV softpackage battery cell, the high-rate charging and discharging capacity of the battery cell can be guaranteed, the power performance of the battery cell is guaranteed, the safety performance of the battery cell can also be improved, and the HEV soft package battery cell has good practicability.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Method for determining machining positioning datum of metal honeycomb plate

InactiveCN105964828AQuality improvementAccuracy improvement problem improvementMetal working apparatusProduction scheduleHoneycomb

The invention belongs to the composite material manufacturing technology, and in particular relates to a method for determining the positioning reference of a metal honeycomb panel in the process of honeycomb processing. Both the front and back sides of the honeycomb core need to be processed to have sags, and the alignment accuracy of the back side is not accurate, which seriously affects the product quality. In the present invention, any position on the processing platform is set as the coordinate origin in the controller; at two predetermined positions of the metal honeycomb panel, a sharp knife is controlled to cut a cross coordinate hole; the metal honeycomb panel is turned over, along the Bond the opaque adhesive tape to the line connecting the centers of the two cross coordinate holes; start the sharp knife from the center of one of the cross coordinate holes, move close to the surface of the metal honeycomb panel along the X direction of the machine tool, so that the sharp knife track coincides with the edge of the tape for processing. The method of the invention improves the problem of improving the precision of metal honeycomb reverse alignment, improves the quality of metal honeycomb double-sided processing, and ensures production progress.

Owner:HARBIN

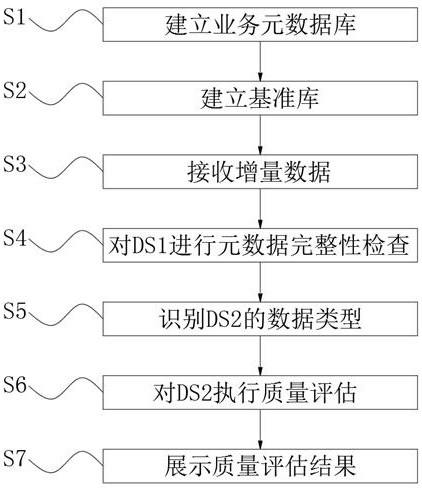

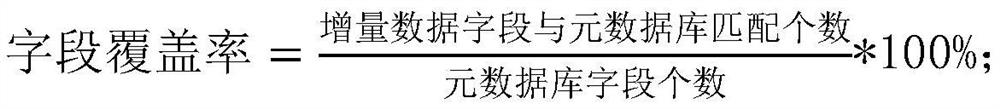

Method and device for evaluating spatio-temporal data quality

PendingCN113282588AEfficient quality assessmentReduce manufacturing costSoftware testing/debuggingResourcesData integrityEvent trigger

The invention discloses a method and a device for evaluating spatio-temporal data quality. The method comprises the following steps: establishing a service metadatabase; establishing a reference library; receiving incremental data; performing metadata integrity check on the DS1; recognizing the data type of the DS2; performing quality evaluation on the DS2; according to the method, the production efficiency and the data quality can be improved, the time-space data quality evaluation standard, rule and method which are ready to use after box opening are adopted, forward monitoring is conducted on the data source and the production process through an event triggering mechanism, quality evaluation is integrated into all links of production through an automatic technical means, and the production efficiency is improved. Hidden data problems are found and solved in time, data quality is improved, discovery cost, positioning cost and repair cost are reduced, pollution of unqualified incremental data to reference data is eradicated, data credibility is improved. Meanwhile, production progress is guaranteed, data production and quality management are supported in an agile research and development mode, flexible and changeable data requirements are met in time, and data quality is improved. The production progress is guaranteed.

Owner:亿景智联(苏州)科技有限公司

Cover pressing device

The invention discloses a cover pressing device which comprises a second supporting plate. The middle portion of the lower surface of the second supporting plate is fixedly connected to the upper endof a telescopic rod. The lower end of the telescopic rod is fixedly connected to the middle portion of the upper surface of a first supporting plate. The telescopic rod is connected to a spring in a sleeved mode. A limiting device is fixedly arranged on the front side of the lower surface of the second supporting plate. An electric suction cup is fixedly arranged on the middle portion of the lowersurface of the first supporting plate. The middle portion of the upper surface of the second supporting plate is fixedly connected to the lower end of the electric telescopic rod. The upper end of the electric telescopic rod is fixedly connected to the lower surface of a moving block. A bottle cover flexibly contacts the upper end of a bottle by the telescopic rod and the spring, and therefore the bottle cover is not liable to be damaged by pressing and the manufacturing schedule is guaranteed. A plurality of grippers are contracted so that the bottle cover is gradually positioned to a central position. A PLC detects the rubber pad moving by a set distance by a micro switch. The PLC controls the electric suction cup to stop working. Cover pressing of the bottle cover is convenient to detect and the structure is simple.

Owner:张福谦

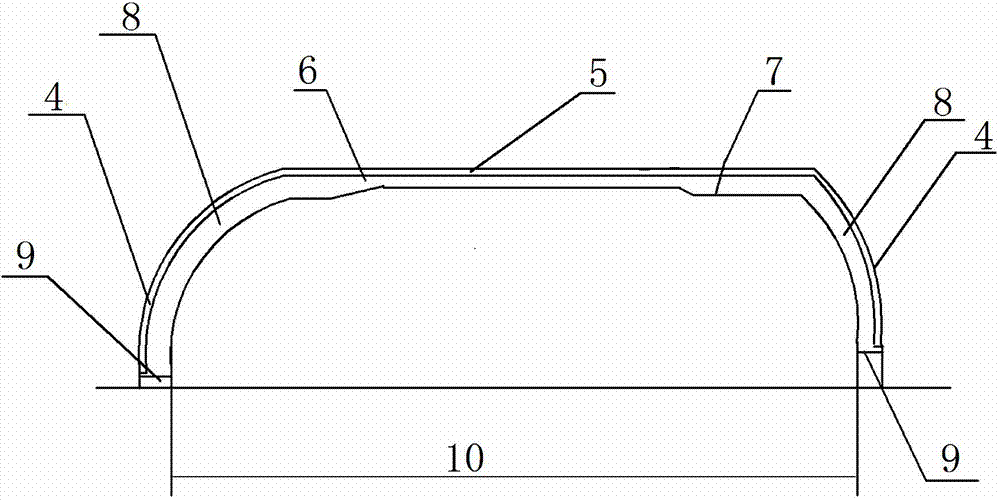

Rubber airbag for manufacturing heat insulating layer of engine

InactiveCN104842479AComplete vulcanizationReduce manufacturing costCoatingsAirbagUltimate tensile strength

The invention relates to a rubber airbag for manufacturing a heat insulating layer of an engine and belongs to the technical field of airbag manufacturing. The rubber airbag for manufacturing the heat insulating layer of the engine comprises a bag body and seal heads at the two ends thereof, wherein the thickness of the bag body is 2 to 4mm; the bag body and the seal heads are integrally formed; one seal head is provided with an inflating device; the inflating device comprises a T-shaped air nozzle, and the T-shaped air nozzle is fixed on the seal head through a pressing plate and a nut; threads are processed on the T-shaped air nozzle, and the threads are matched with the nut. During use, the pressure loss of the rubber airbag is smaller than 0.1MPa and the profile quality and surface smoothness of the heat insulating layer are remarkably improved; since no separating agent is used, interface defects caused by interface pollution are fundamentally eliminated and the product quality is obviously improved; since the difference between material systems of the airbag and the heat insulating layer is greater and the airbag is naturally separated from the heat insulating layer in the air extraction process during demolding, the labor intensity of an operator is reduced and the rubber airbag can be used at 150 DEG C for a long time; the goal of guaranteeing the profile of the heat insulating layer and the product quality of the engine can be achieved.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

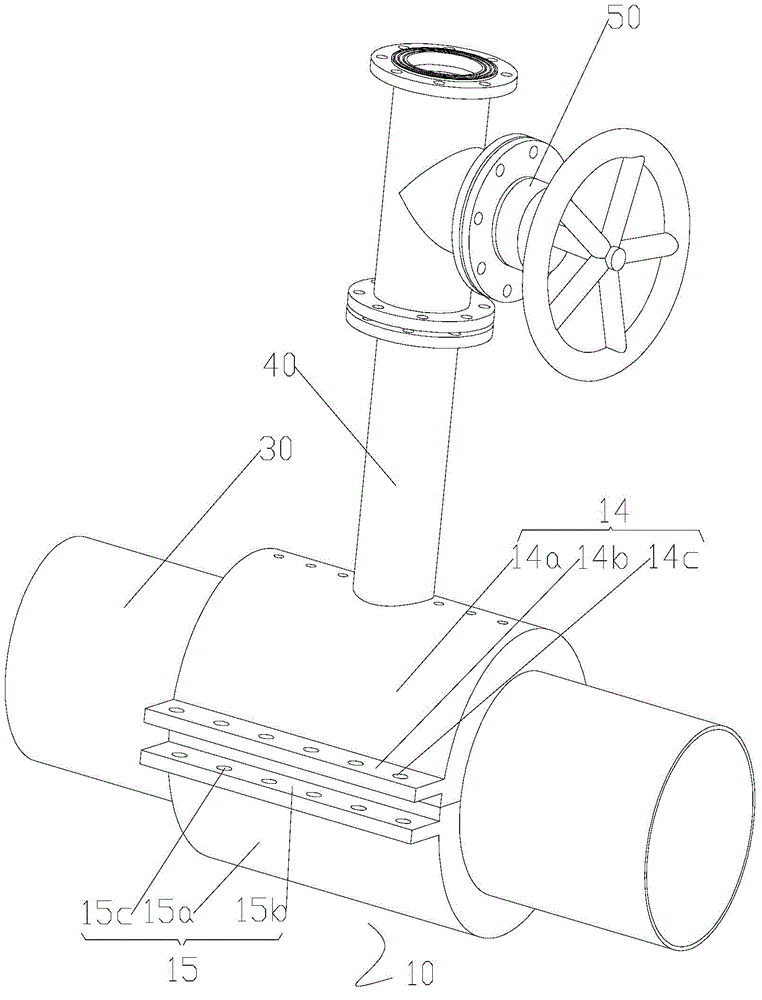

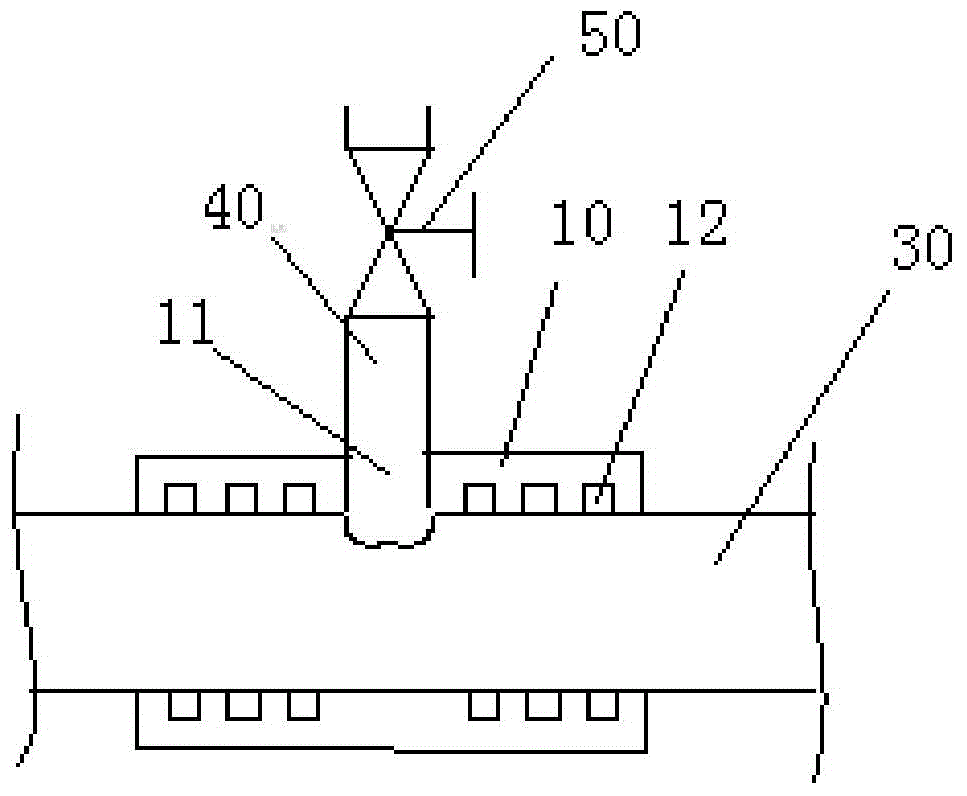

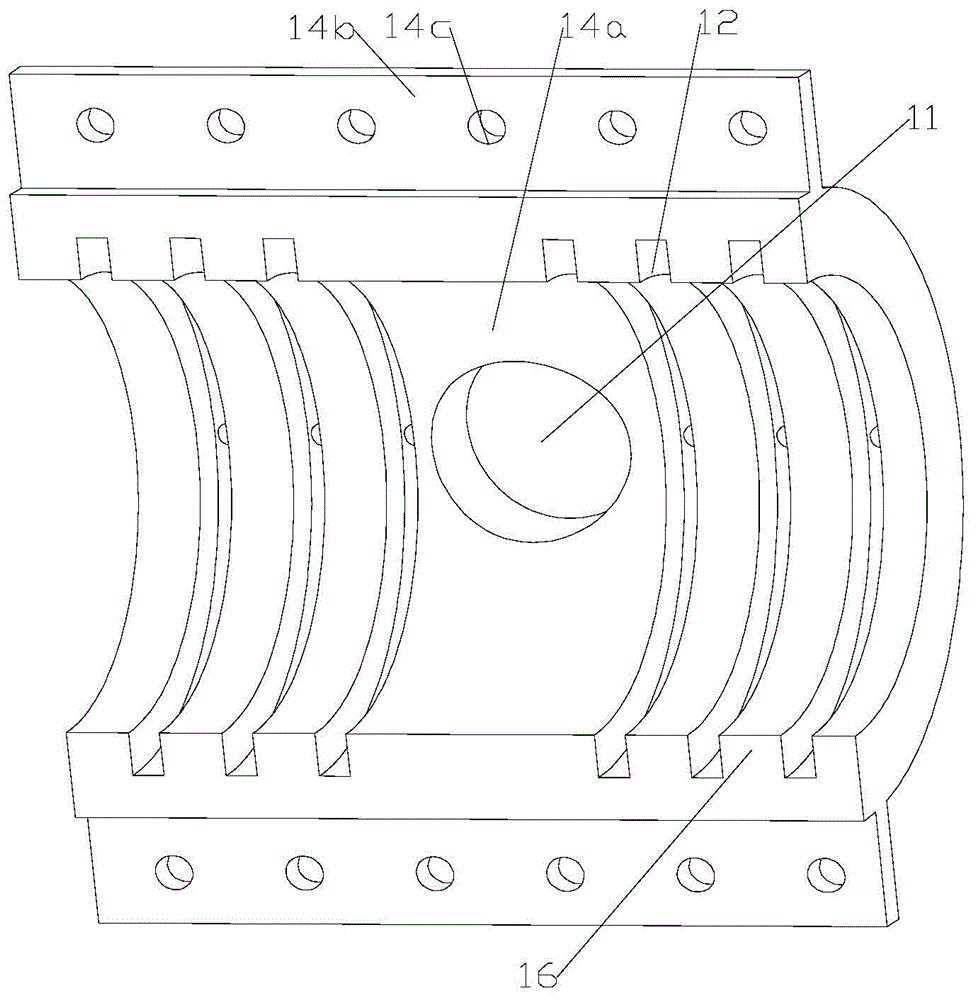

Punching auxiliary device for steel skeleton polyethylene plastic composite pipe

InactiveCN105818201AGuaranteed tightnessImprove controllabilityMetal working apparatusProduction schedulePunching

The invention provides a punching auxiliary device for a steel skeleton polyethylene plastic composite pipe. The punching auxiliary device comprises a sealed sleeve, sealing parts, a connection pipe section and a switching valve, wherein the sealed sleeve and the steel skeleton polyethylene plastic composite pipe are coaxially arranged, the sealed sleeve is detachably and tightly held on the outer side of the steel skeleton polyethylene plastic composite pipe, and the pipe wall of the sealed sleeve is provided with an open-hole which is formed in a penetrating mode and used for avoiding a punching tool; the sealing parts are arranged on the sealed sleeve and located at the two ends of the sealed sleeve; the first end of the connection pipe section communicates with the open-hole of the sealed sleeve and is in butt joint with the open-hole; and the switching valve is used for controlling opening or closing of the connection pipe section and arranged on the connection pipe section. The punching auxiliary device for the steel skeleton polyethylene plastic composite pipe is capable of conducting punching operation on the steel skeleton polyethylene plastic composite pipe which works normally without production stopping or waiting, not only is the construction efficiency improved, but also the production schedule is ensured, and the losses caused by production stopping is avoided.

Owner:PETROCHINA CO LTD +1

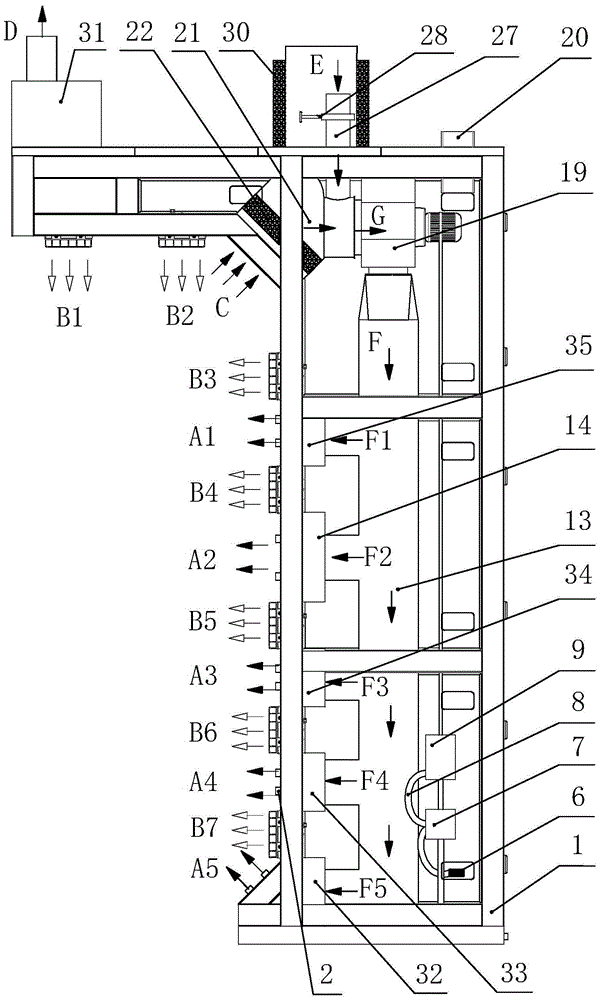

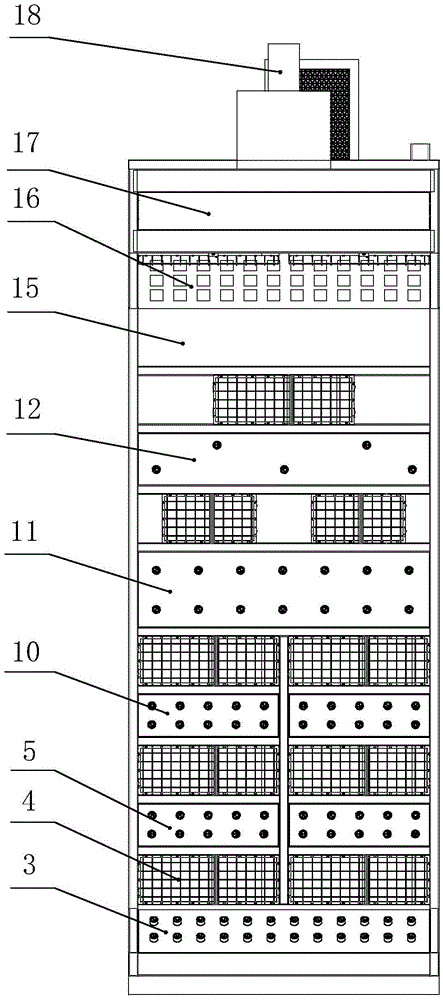

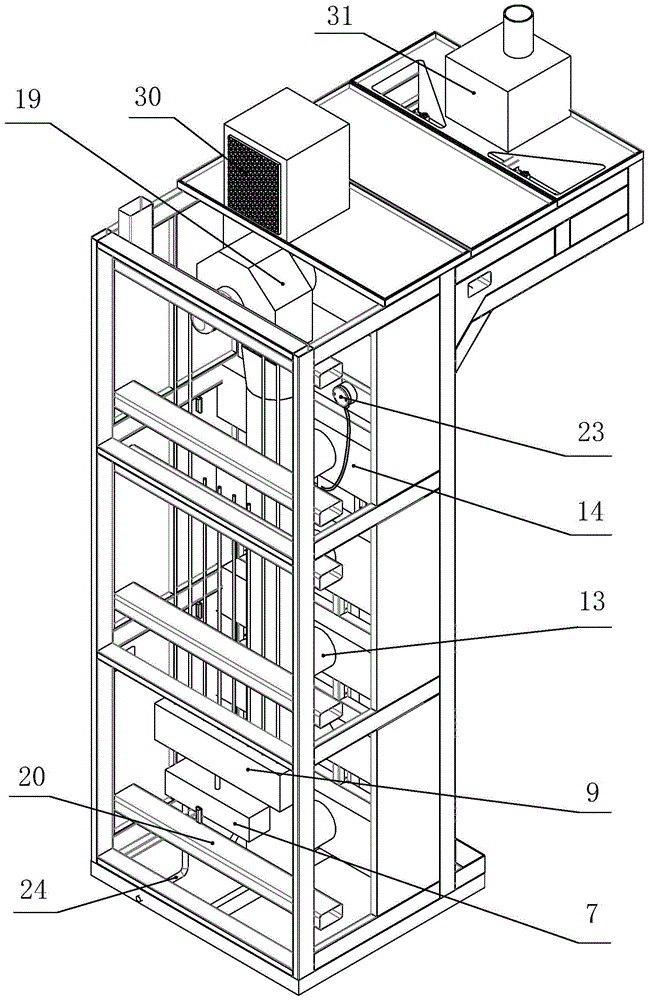

Gas-catalytic, flameless and infrared-radiation hot air internal recycle drying unit module of passenger car

ActiveCN105457865AGuarantee the production progressDoes not affect drying progressPretreated surfacesCoatingsEnvironmentally friendlyHeating efficiency

The invention discloses a gas-catalytic, flameless and infrared-radiation hot air internal recycle drying unit module of a passenger car, and relates to a drying device for quickly drying putty and a film on the surface of the passenger car. The gas-catalytic, flameless and infrared-radiation hot air internal recycle drying unit module comprises a fixed bracket, wherein a hot air internal recycle system and at least one gas-catalytic, flameless and infrared-radiation heater are arranged in the fixed bracket; the hot air internal recycle system comprises an air feeding system and an air return system which are communicated with each other; the air feeding system is provided with a flow-equalizing air feeding plate below each gas-catalytic, flameless and infrared-radiation heater; and the gas-catalytic, flameless and infrared-radiation heater is connected to a gas source through a gas inlet tube. In use, even a circulating fan of the hot air internal recycle system on one drying unit module has faults, the circulating fans of the rest of drying unit modules still can operate without affecting drying progress of a product. The gas-catalytic, flameless and infrared-radiation hot air internal recycle drying unit module is uniform in heating, capable of avoiding generating chromatic aberration during product drying, has characteristics of being high in heating efficiency, low in cost, environmentally-friendly, safe and reliable, and the like, and is easy to popularize and use.

Owner:唐山宏正机械设备有限公司

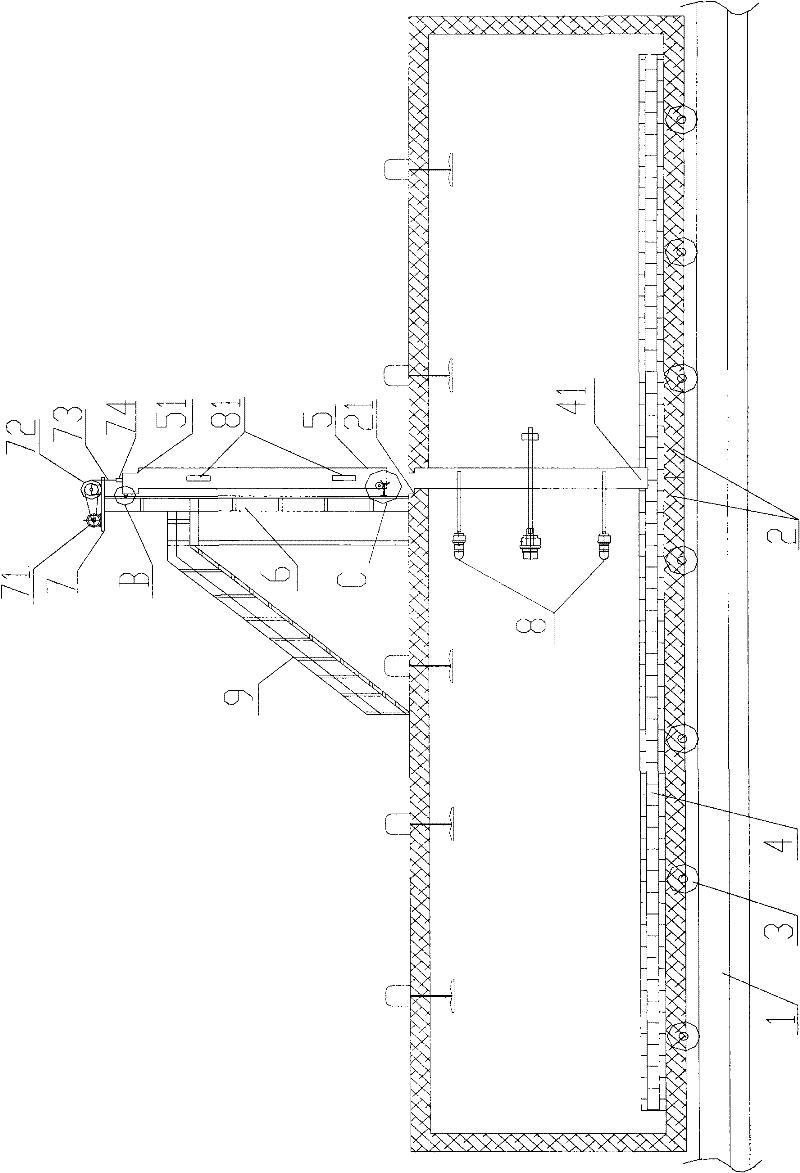

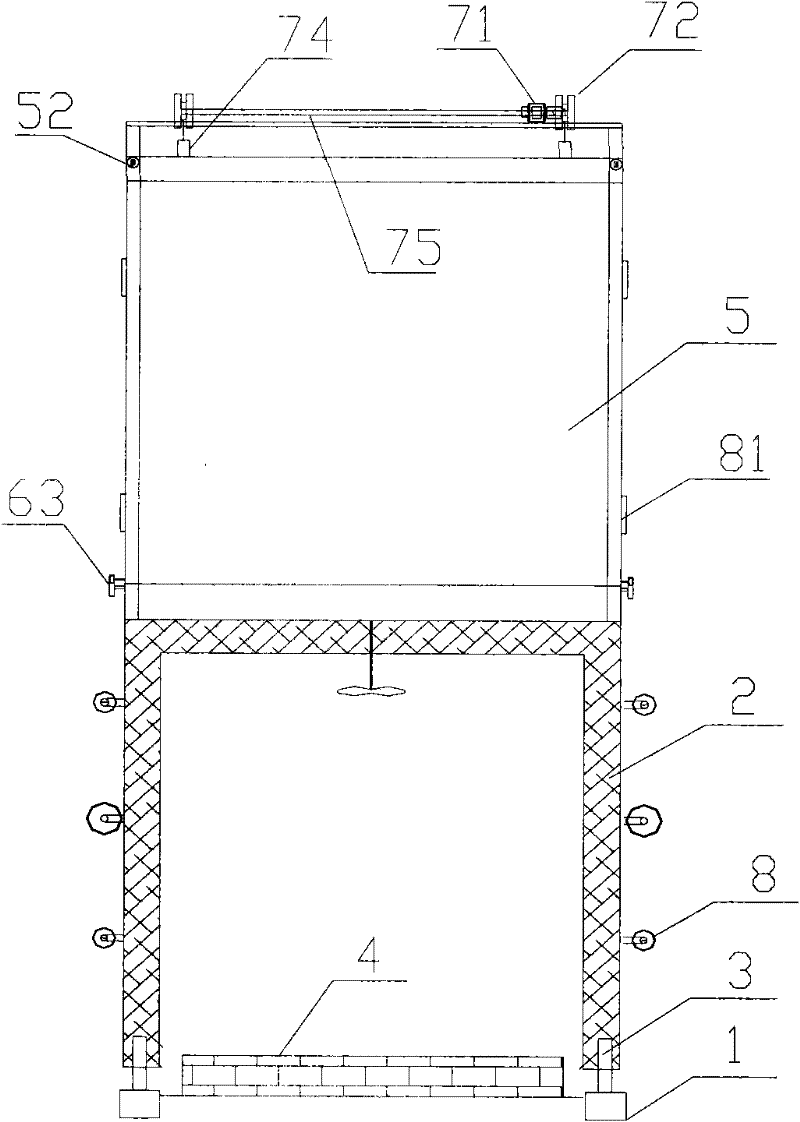

All-fiber mantle-mobile hot air circulation annealing furnace

InactiveCN102220467AAvoid investmentReduce energyFurnace typesHeat treatment furnacesProduction scheduleMotor drive

The invention discloses an all-fiber mantle-mobile hot air circulation annealing furnace, and is characterized in that: two mantles are located on a guide rail by two rollers, a furnace platform is positioned in the two mantles, two poles are located at two sides of the top mouth of any mantle, a platform is horizontally arranged at the tops of the two poles, a motor and a transmission wheel are separately located at both sides of the platform, two lifting lugs are located at the furnace gate top at a certain interval and are connected with the transmission wheel through a steel wire, the rotation shaft of the motor drives the transmission wheel through a belt, the furnace gate rises or descends along the mantle mouth through the motor and transmission wheel, a groove is opened on the furnace platform surface, the furnace gate is located in the groove when the furnace gate descends to the furnace platform, two pull rods are located at the sides of the mantle with the two poles at a certain interval, and two pull pieces are located at a side of the furnace gate at a certain interval, matching with the two pull rods. The annealing furnace can economically implement the heat treatment of the parts with different sizes at different temperature, avoid the investment in arranging multiple annealing furnaces, reduce energy consumption and cost for heat treatment, guarantee the production schedule and improve the heat treatment efficiency.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

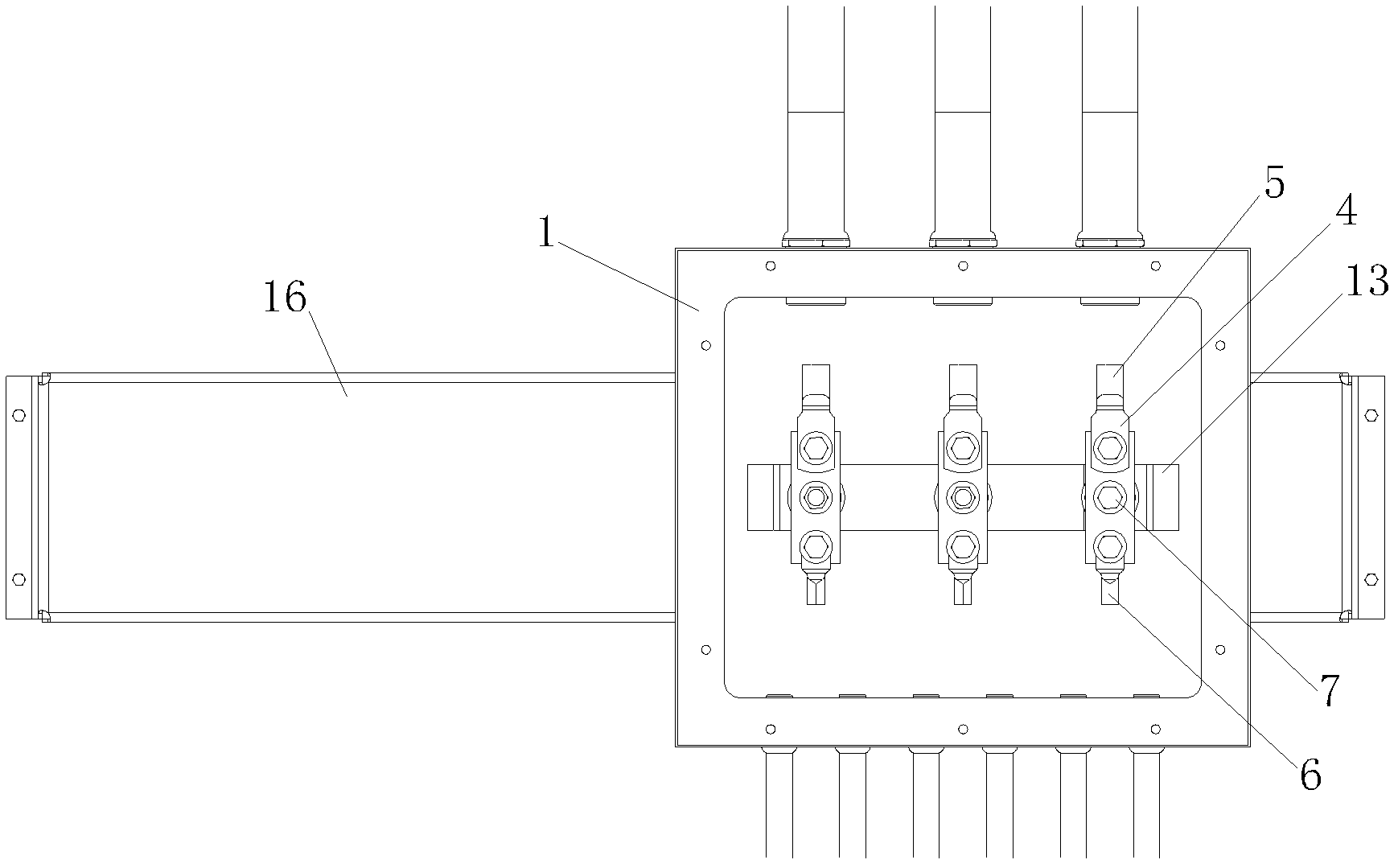

Special 3-to-6 electrical cabinet for metro vehicle

The invention discloses a special 3-to-6 electric cabinet for a metro vehicle, which comprises a cabinet body, wherein the lower part of the cabinet body is provided with an opening, and the opening is provided with a detachable cover plate which is matched with the opening; three conducting copper bars are arranged inside the cabinet body in parallel, a first binding terminal is respectively arranged at the same ends of the three conducting copper bars, two second binding terminals are respectively arranged at the other end of each conducting copper bar, and an insulator is respectively arranged in the middle part of each conducting copper bar; and the lateral wall of the cabinet body at each first terminal binding terminal is provided with three first threading holes, and the lateral wall of the cabinet body at each second binding terminal is provided with 6 second threading holes. The special 3-to-6 electrical cabinet for the metro vehicle is low in cost and easy to maintain, ensures the production progress of the metro vehicle and greatly reduces the maintenance cost of the metro vehicle in the future.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

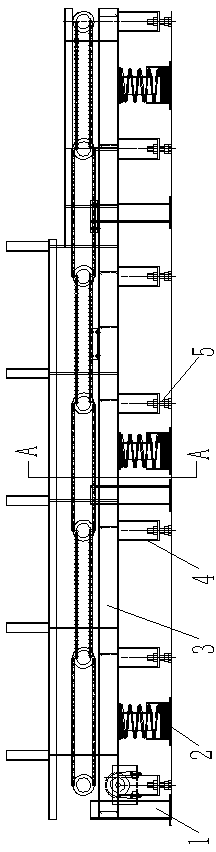

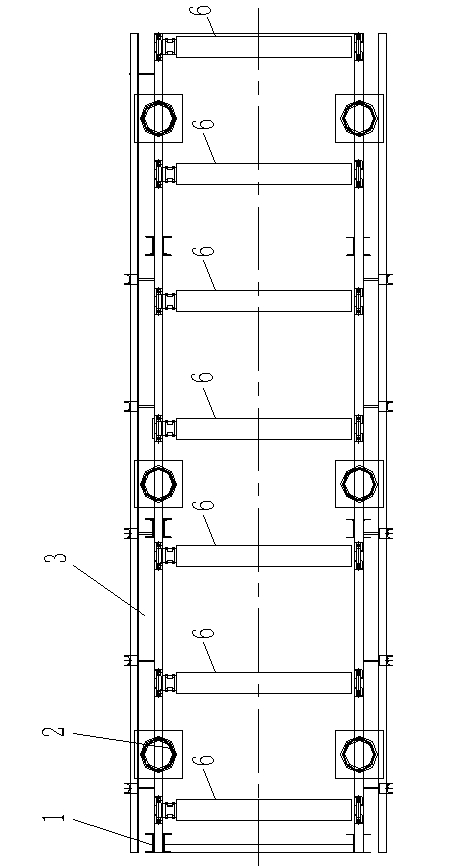

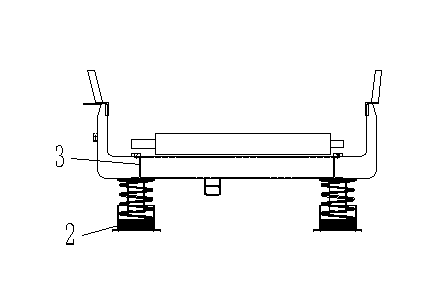

Roll shaft channel device of double-block type sleeper production line

InactiveCN102699995AImprove stabilityReduce impactNon-rotating vibration suppressionAuxillary shaping apparatusProduction lineAnchor bolt

The invention discloses a roll shaft channel device of a double-block type sleeper production line, and belongs to the technical field of sleeper production equipment. The roll shaft channel device comprises a roll shaft channel framework (3), wherein a plurality of brackets (4) connected with the ground are arranged on the lower part of the roll shaft channel framework (3). The roll shaft channel device is characterized in that at least two elastic buffering devices (2) are arranged on the lower part of the roll shaft channel framework (3); at least two transverse limiting devices (1) are arranged on two sides of the roll shaft channel framework (3); and the brackets (4) are connected with the ground through foundation bolts in a vertically movable manner. The roll shaft channel device is supported by the elastic buffering devices, and the transverse displacement of the roll shaft channel device is limited by the transverse limiting devices; when a die is hoisted, the elastic buffering devices convert part of impact of the die on a roll shaft channel into elastic potential energy during falling of the die, so that the direct impact of the die on a roll shaft is reduced, and frequency damage to the roll shaft channel is avoided; and furthermore, the production continuity and the quality of a product are guaranteed, and the construction safety is improved.

Owner:中铁十局集团第四工程有限公司

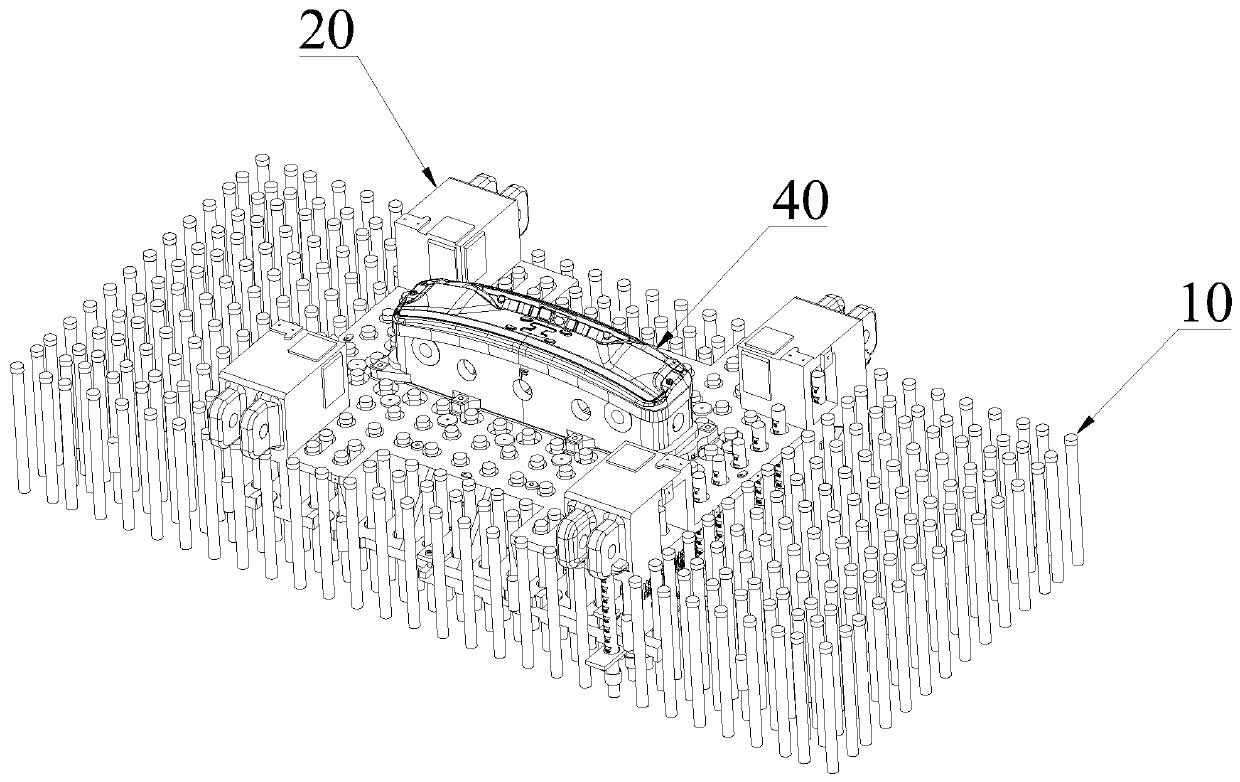

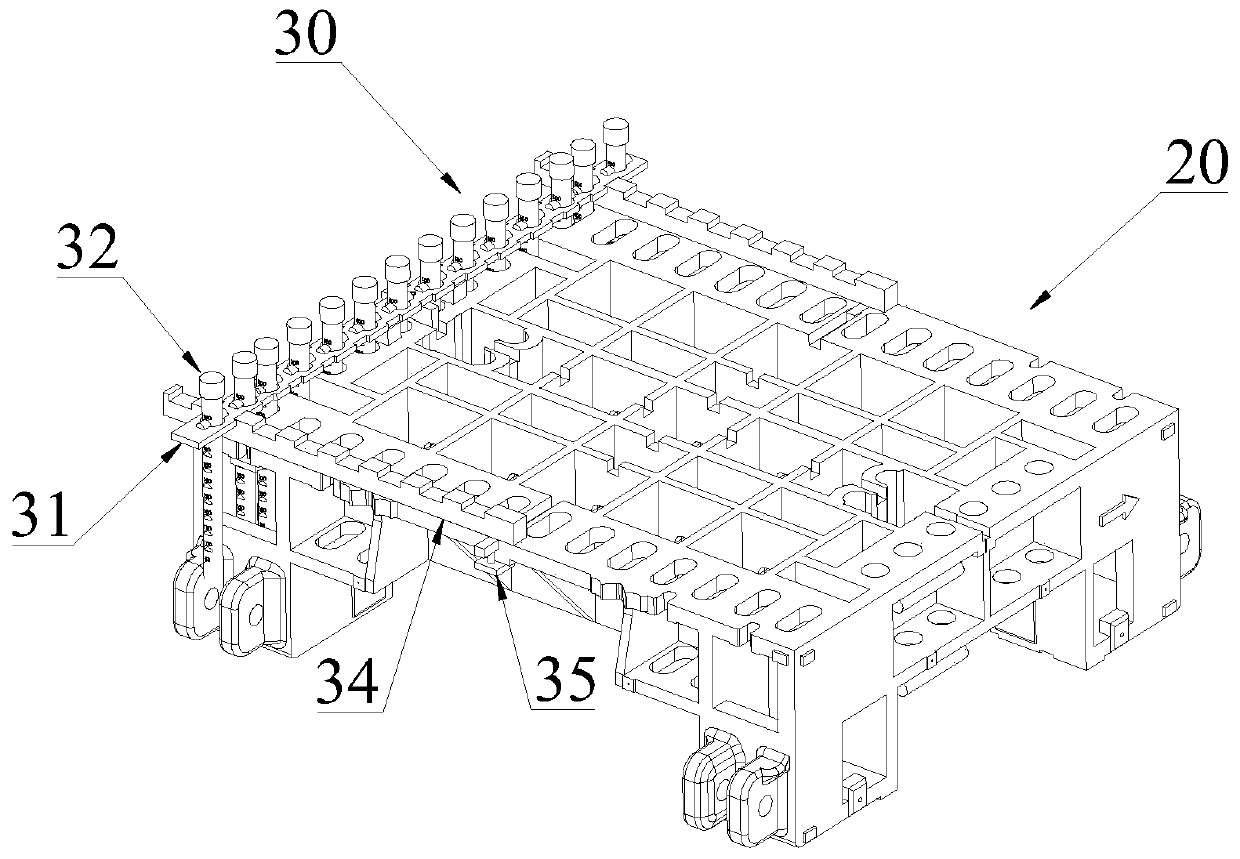

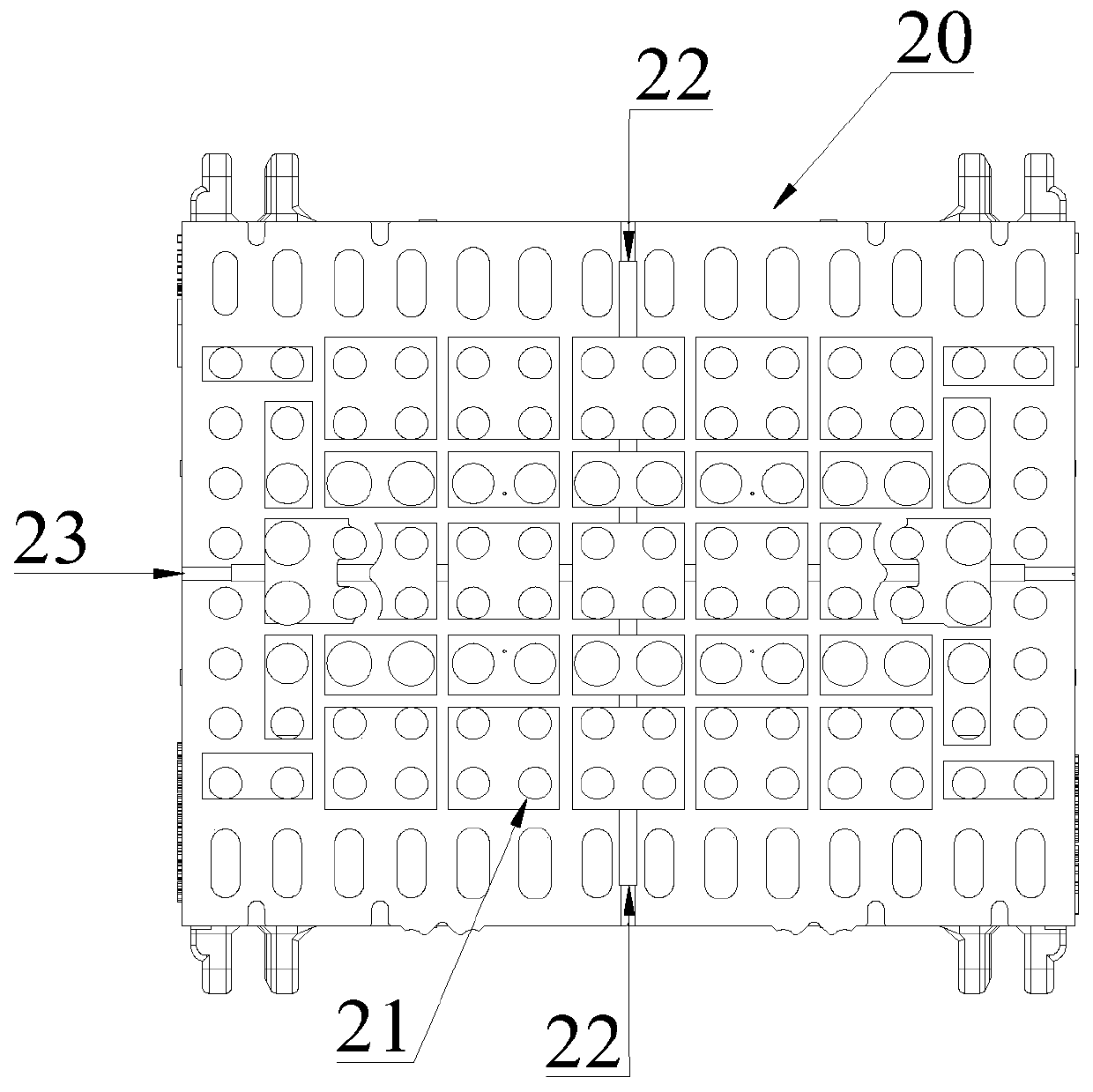

Ejector rod interference checking device

PendingCN110132558AFree from frequent maintenanceFree from frequent replacementMachine part testingVisual testingCost (economic)

The invention discloses an ejector rod interference checking device. The device comprises a test plate and test bars, wherein the test plate is provided with a plurality of ejector rod holes, and theejector rod holes are in fit with die holder through holes of a lower die holder; each test bar is of a cylindrical structure and is movably arranged in one ejector rod hole, and the length of each test bar is greater than the depth of each die holder through hole; and the test plate is attached to the lower surface of the lower die holder, and the test bars are inserted into the die holder through holes. Through the device, a simulation function on an air cushion ejector rod is achieved; before a stamping procedure, the air cushion ejector rod is in inserted fit with the lower die holder first, visual testing and checking on interference are realized in advance, an unqualified lower die holder can be machined and corrected again in time, the air cushion ejector rod on a machine table is protected, frequent maintenance and replacement are avoided, economic cost and manpower cost are saved, and meanwhile production progress is guaranteed.

Owner:广州广汽荻原模具冲压有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com