Automatic assembly system for automobile ignition coils

An ignition coil and automatic assembly technology, applied in coil manufacturing, induction energy storage devices, transformers, etc., can solve the problems of relying on labor, low efficiency and high failure rate, and achieve the effect of improving efficiency, reducing production costs and reducing operators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

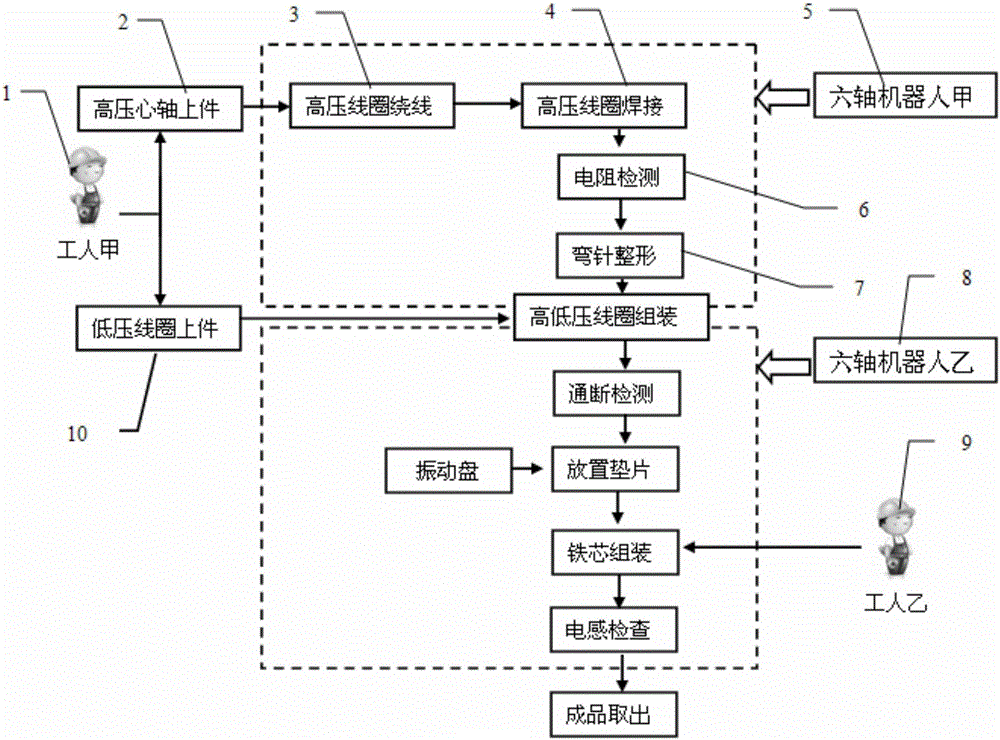

[0033] This embodiment: as figure 1 As shown, the automatic assembly system for ignition coils for automobiles is characterized in that it includes a worker A execution unit, a six-axis robot A execution unit, a six-axis robot B8 execution unit, and a worker B execution unit. The worker A execution unit includes a high-voltage coil core Shaft upper part 2 and low voltage coil upper part 10;

[0034] The execution unit of the six-axis robot A includes high-voltage coil winding 3, high-voltage coil welding 4, looper shaping 7, and coil resistance detection 6;

[0035] The execution unit of the six-axis robot B8 includes the handling of low-voltage coils, the assembly of high-voltage coils and low-voltage coils, and the assembly of high-voltage coils and iron cores;

[0036] Worker B Execution unit Execution unit includes iron core assembly.

[0037] The workflow is as follows:

[0038] 1. Worker A1 places the high-voltage mandrel on the high-voltage mandrel upper part A stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com