All-fiber mantle-mobile hot air circulation annealing furnace

A hot air circulation and annealing furnace technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as cost increase, inability to process in the same furnace, and investment increase, so as to reduce energy and cost, improve heat treatment efficiency, and ensure production progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

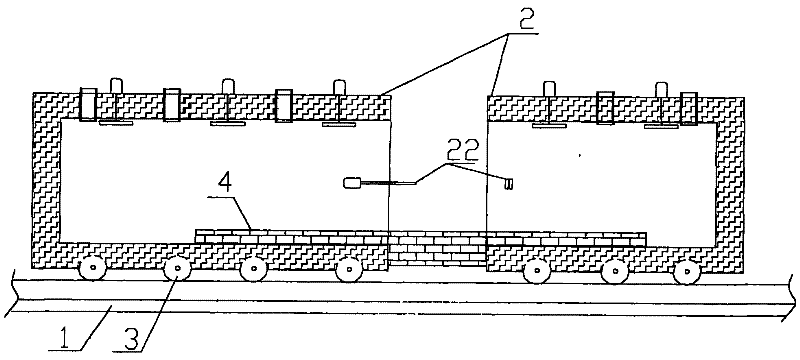

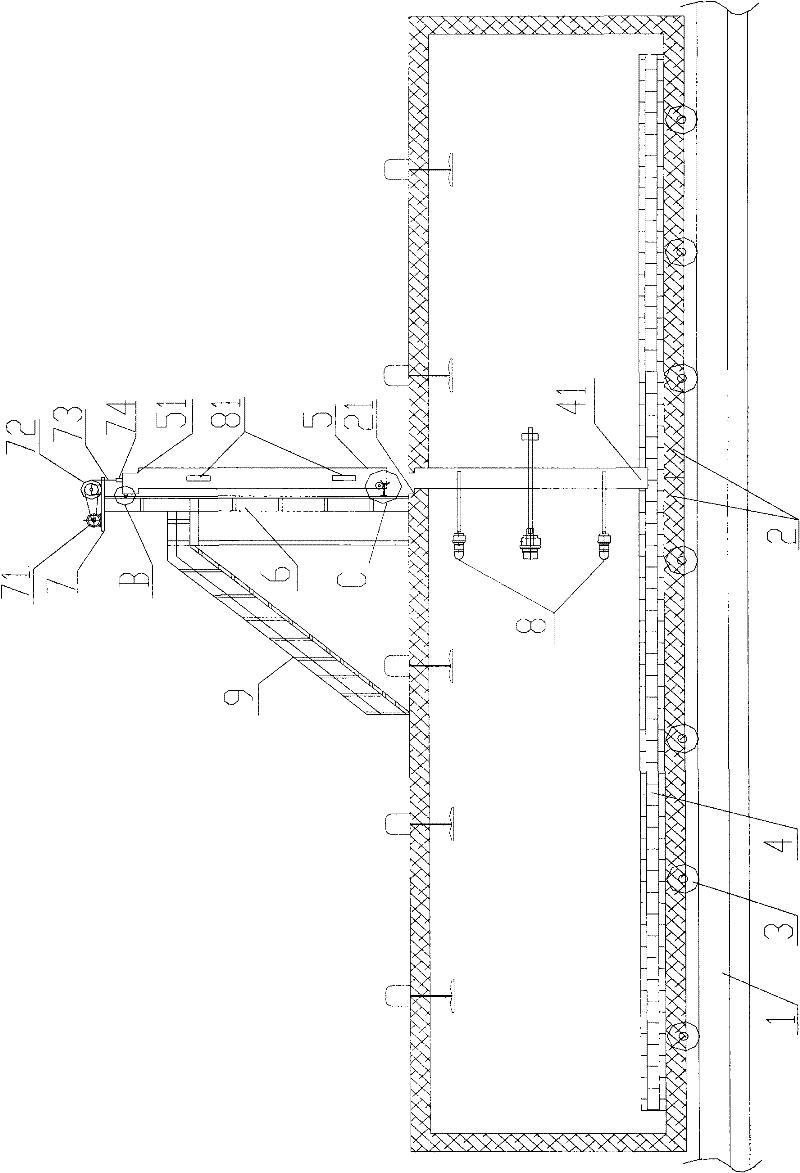

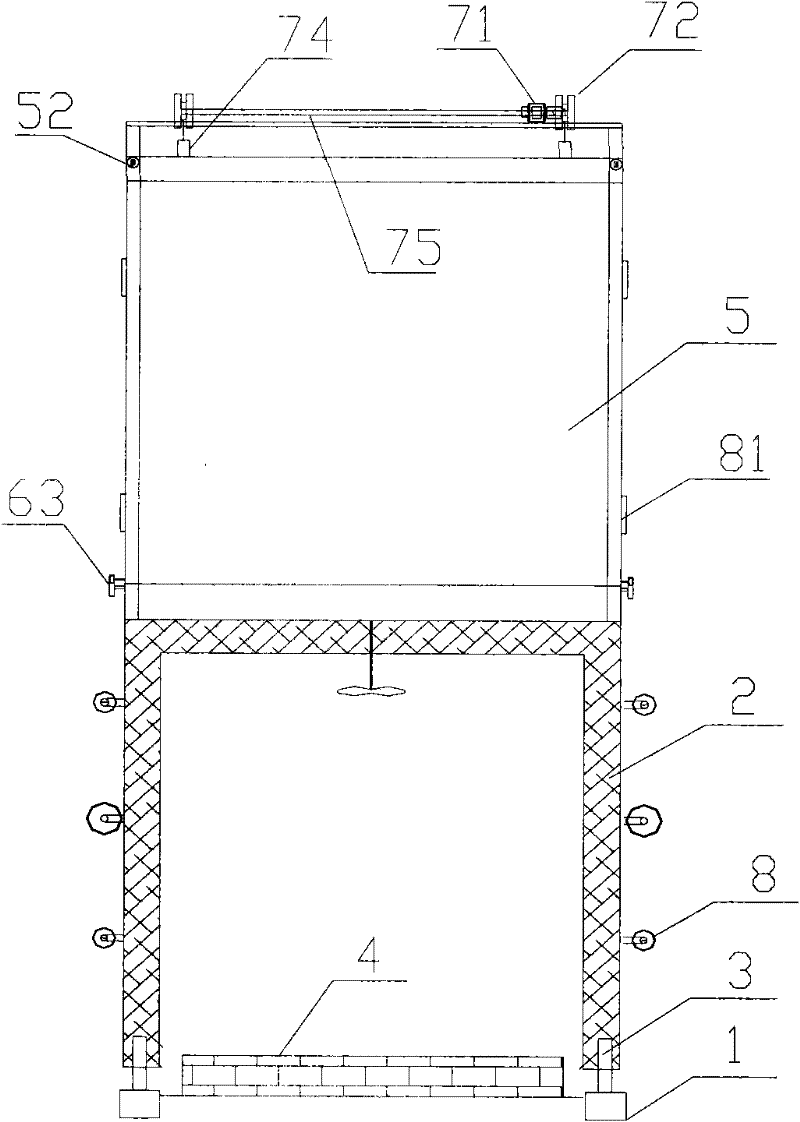

[0017] Such as figure 2 and image 3 As shown, the all-fiber hood mobile hot air circulation annealing furnace of the present invention includes two furnace hoods 2 arranged on guide rails 4 through rollers 3 and a furnace platform 4 located in the furnace hood 2, and also includes a furnace gate 5, two Lifting lug 74, two vertical rods 6, platform 7, four pull rods 8, four handles 81, two transmission wheels 72 and motor 71, the two vertical rods 6 are vertically arranged on the top surface of any one of the furnace cover 2 On both sides of the furnace mouth, the platform 7 is horizontally arranged on the tops of the two vertical rods 6, the motor 71 and the two transmission wheels 72 are respectively arranged on both sides of the platform 7, and the two transmission wheels 72 pass through the rotating shaft 75 connection, the two lifting lugs 74 are arranged on the top surface of the furnace gate 5 at intervals, the two lifting lugs 74 are connected to the two transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com