Rotating-drum method based full flow processing system and rotating-drum method based full flow processing technique

A treatment system and full-process technology, which is applied in the full-process treatment system and process field of molten liquid steel slag treatment by the drum method, can solve the problems of occupying traffic resources, increasing operating costs, and environmental pollution, so as to reduce the traffic occupancy rate and avoid The effect of excessive investment and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

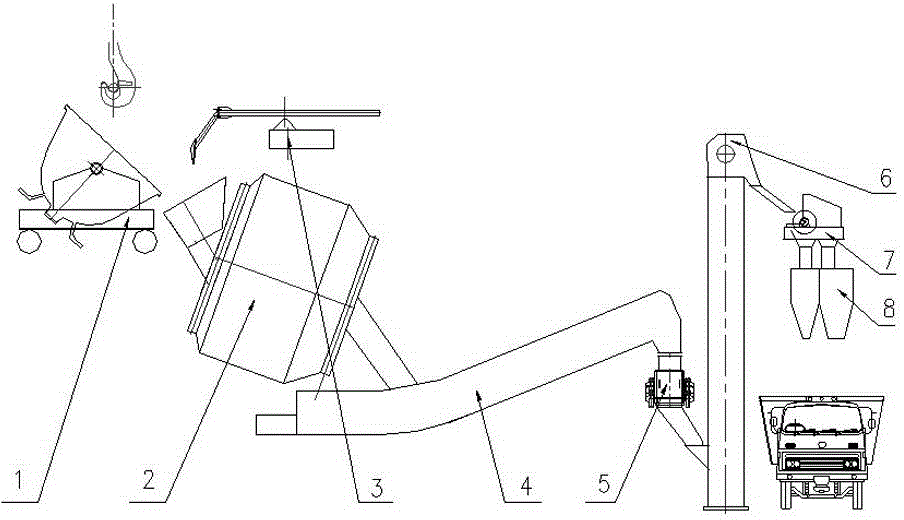

[0035] See figure 1 , a drum method steel slag whole process processing system provided in this embodiment is mainly composed of: a tipping device 1 for auxiliary feeding and a slag removal device 3, a drum device 2 for steel slag core processing, a finished product conveying device 4, a vibrating Sorting device 5, bucket elevator device 6, online magnetic separation device 7, material storage device 8, dust removal device, water system device, electrical control device, etc. Wherein, the bucket type lifting device 6 can be a chain bucket type. Wherein, the drum device 2 is connected to the finished product conveying device 4, the finished product conveying device 4 is connected to the vibration sorting device 5, and the vibrating sorting device 5 is connected to the bucket elevator device 6, and the bucket lift The lifting device 6 is connected to the online magnetic separation device 7, and the online magnetic separation device 7 is connected to the storage device 8; the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com