Commercial Waste Food Disposer

A technology of waste food and processor, applied in grain processing, solid waste removal, etc., can solve problems such as unfavorable environmental protection, waste of resources, etc., and achieve the effect of improving processing rate and processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

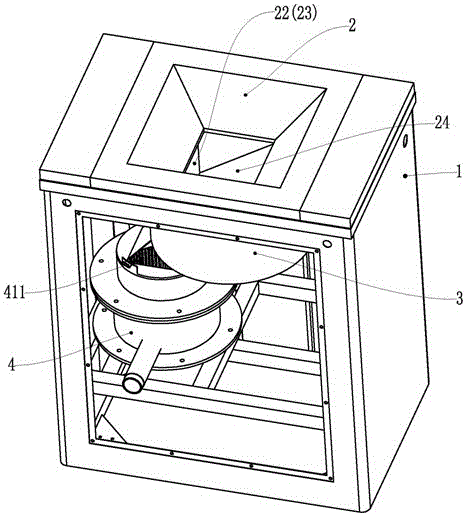

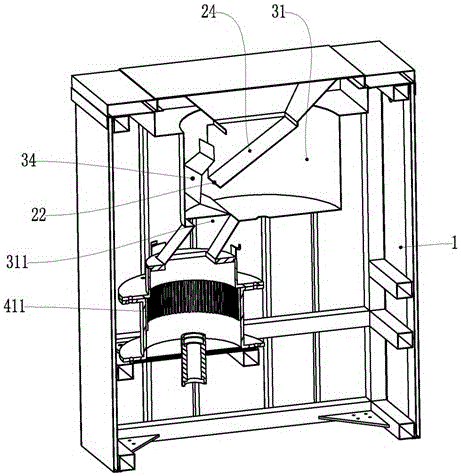

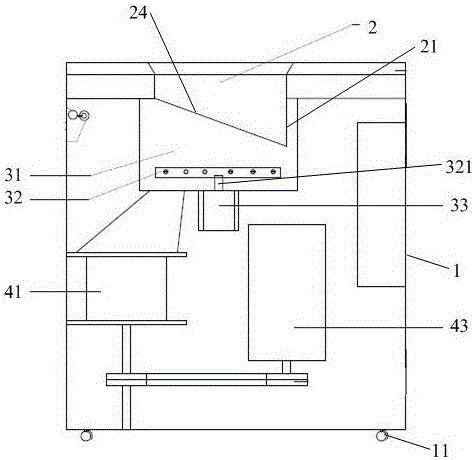

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0025] For the commercial waste food processor of this embodiment, refer to figure 1 , figure 2 and image 3 , comprising a casing 1, a shunt 3 and a shredder 4; the shunt 3 and the shredder 4 are arranged in the casing 1, the shunt 3 includes a shunt chamber 31, a shunt sweep 32 and a shunt motor 33, the The shunt motor 33 is arranged below the shunt bin 31, the shunt sweep 32 includes an axis 321 driven by the shunt motor 33 and a plurality of curved sweeping bars 322, one end of the sweeping bars 322 is fixed to the The axis 321, the other end extends radially, the bending direction of the sweeping strip 322 is opposite to the rotation direction of the sweeping strip 322; Below the distribution port 311 .

[0026] After the waste food left in the dining room or kitchen is poured into the div...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com