Electrical heating type cigarette body

A technology of electric heating and cigarettes, which is applied in applications, tobacco, pipes, etc., can solve the problems of cigarettes losing their overall integrity, affecting the convenience and speed of the suction process, and insufficient uniformity of cigarette filling, so as to improve the uniformity of heat conduction Non-toxic and moisture-proof performance, solve the problem of frequent cleaning, and improve the sensory quality of flue gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

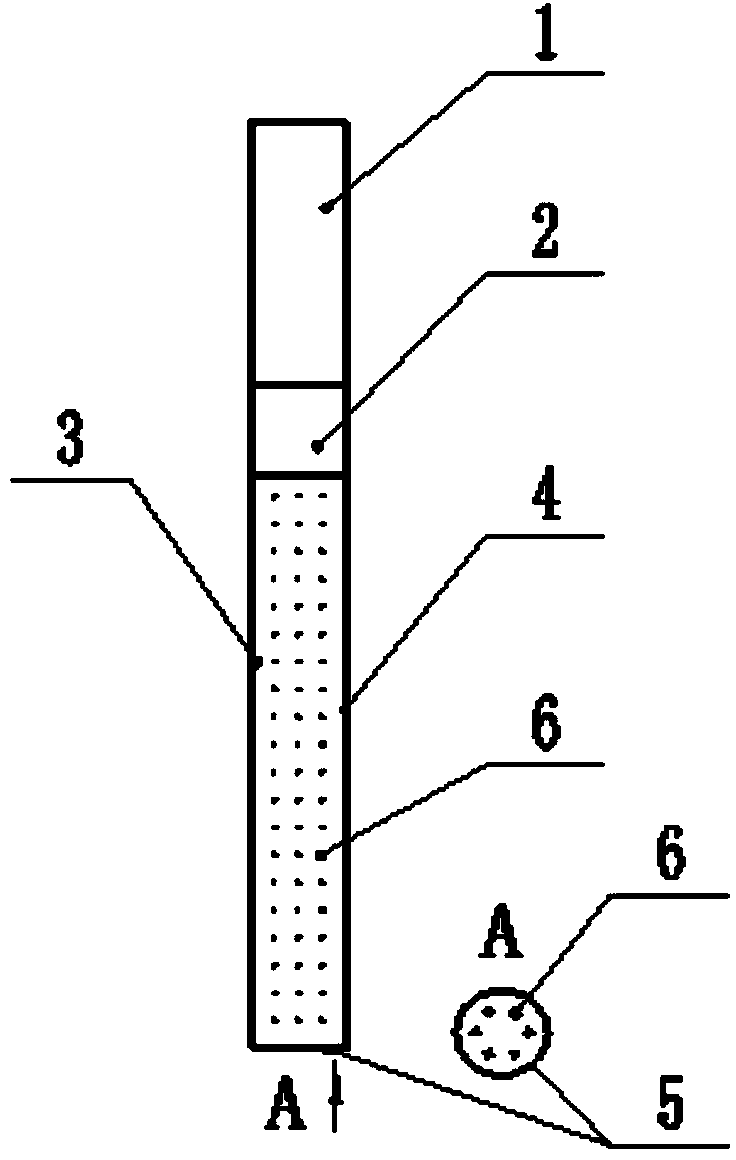

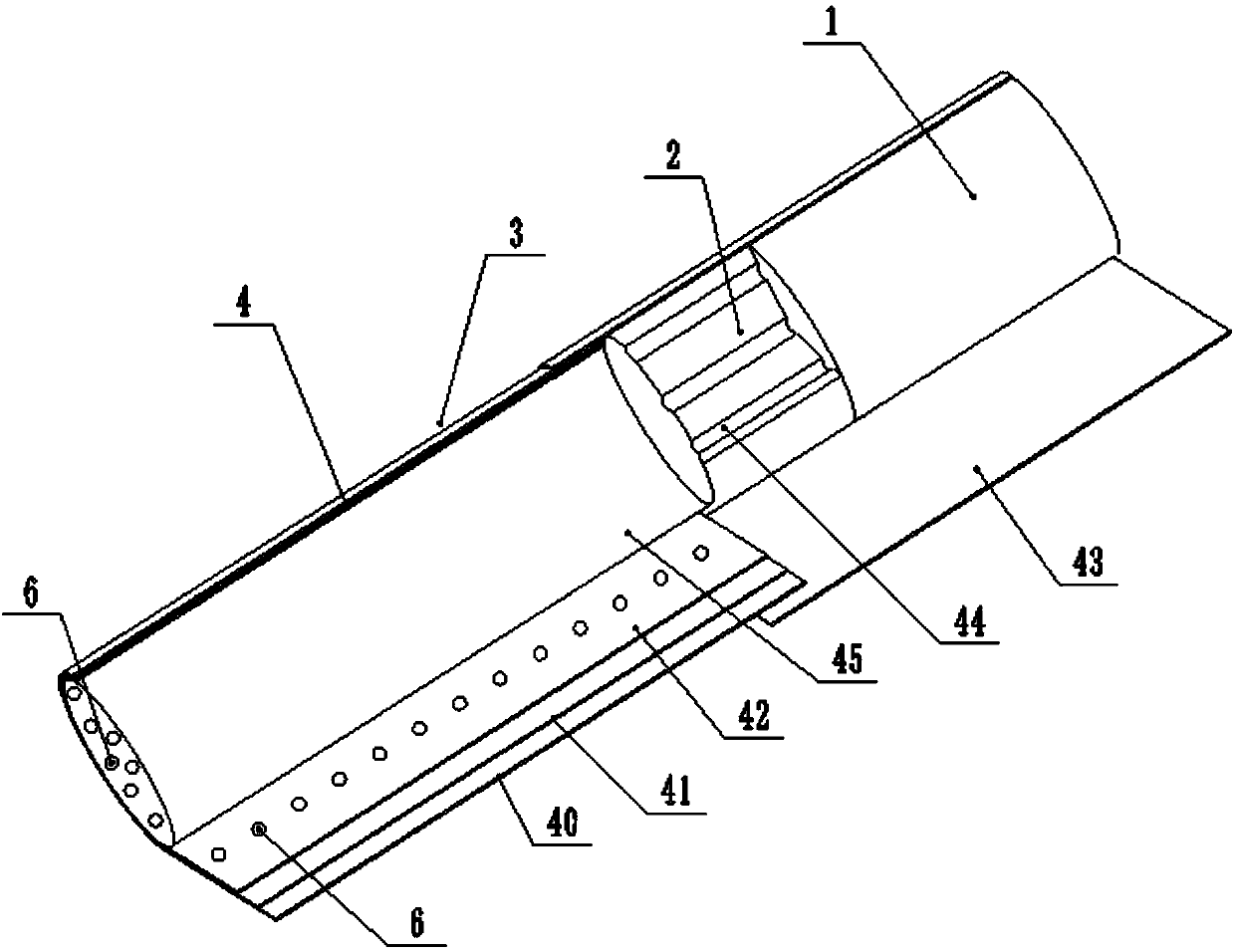

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: smoke release performance evaluation

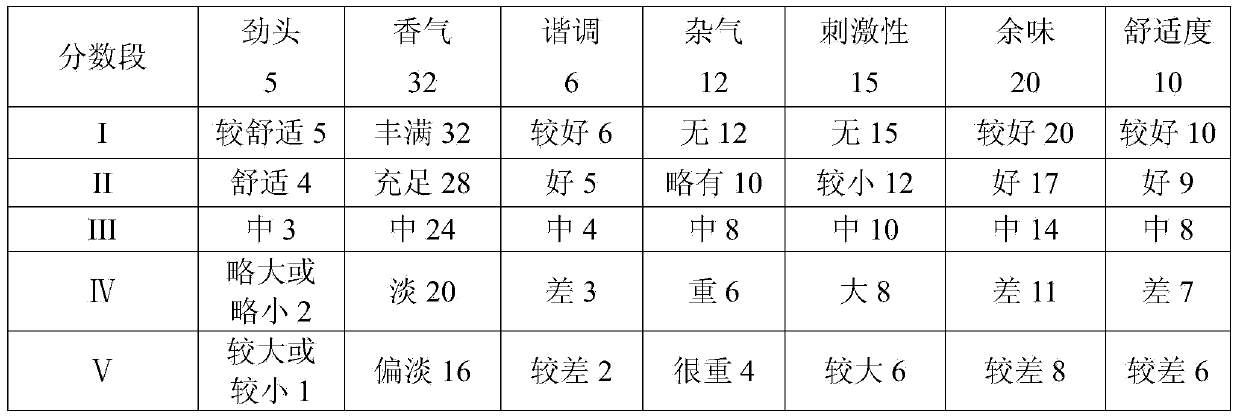

[0033] Utilize electric heating type cigarette stick of the present invention and traditional cigarette, existing special cigarette stick of electric heating type cigarette to carry out smoke release performance comparison test, smoke release performance evaluation score is set as shown in Table 1:

[0034] Table 1 Score setting of smoke release performance evaluation

[0035] Score segment

[0036] Inspection procedure: provide samples and inspection sheets to the evaluation experts, and require the evaluation staff to evaluate the indicators according to the requirements of the form.

[0037] Result statistics: The evaluation results of all appraisers are valid, and the arithmetic mean of the evaluation results of each appraiser is calculated, and the result is rounded to one decimal place. The evaluation results are shown in Table 2:

[0038] Table 2 Comparison table of smoke release performance evaluat...

Embodiment 2

[0040]As shown in Table 2, since the electric heating type cigarette provided by the present invention is provided with aluminum foil in the wrapping layer of the side wall of the cigarette and the wrapping layer of the bottom surface of the cigarette, the heating of the cigarette is more uniform and there are openings on the wrapping layer. With a certain number of ventilation holes, the airflow can flow in from multiple points in the axial and circumferential directions of the cigarette at the same time, increasing the contact between the airflow and the smoking material, so that the smoke release performance of the electric heating cigarette provided by the present invention far exceeds that of existing cigarettes. electric heating cigarettes, and is closer to the smoke release effect of traditional cigarettes. Embodiment 2: sensory quality evaluation

[0041] Utilize electric heating type cigarette stick of the present invention and traditional cigarette, existing special ...

Embodiment 3

[0049] Embodiment 3: evaluation of tobacco material shedding situation

[0050] Use the electric heating type cigarette stick of the present invention and the existing electric heating type cigarette special cigarette stick to carry out the evaluation of the tobacco material shedding situation in the process of use, and carry out by collecting and weighing the way of the tobacco material falling off during the smoking process Compare.

[0051] After using the electric heating type cigarette of the present invention and the existing electric heating type cigarette special cigarettes to smoke 100, the electric heating type cigarette of the present invention collected a total of 0.05g of shedding tobacco material, while the existing A total of 0.4 g of exfoliated tobacco material was collected from cigarettes dedicated to electric heating cigarettes.

[0052] It can be seen from the comparison that the shedding of the tobacco material of the electric heating cigarette stick of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com