Patents

Literature

66results about How to "Achieve infiltration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

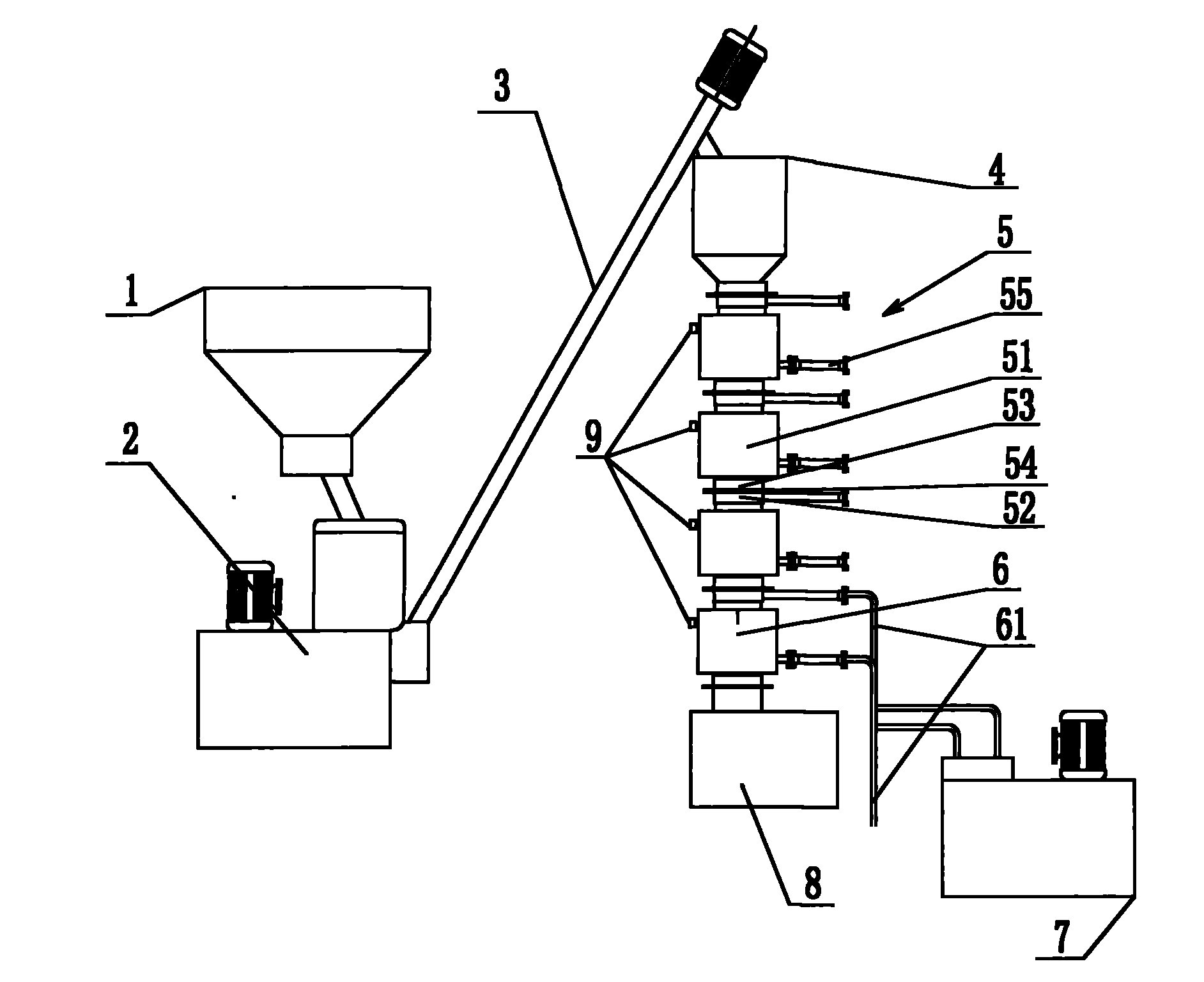

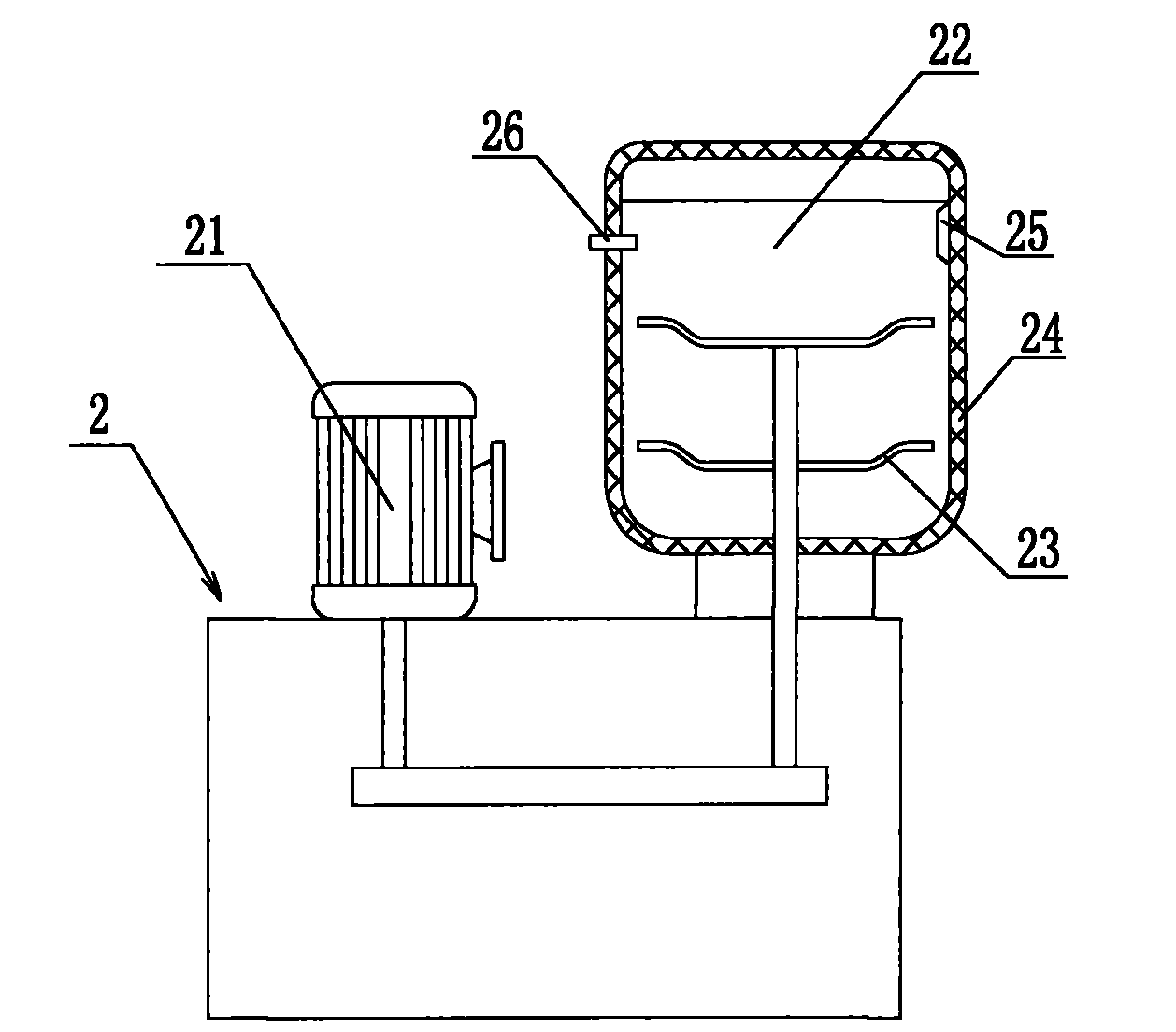

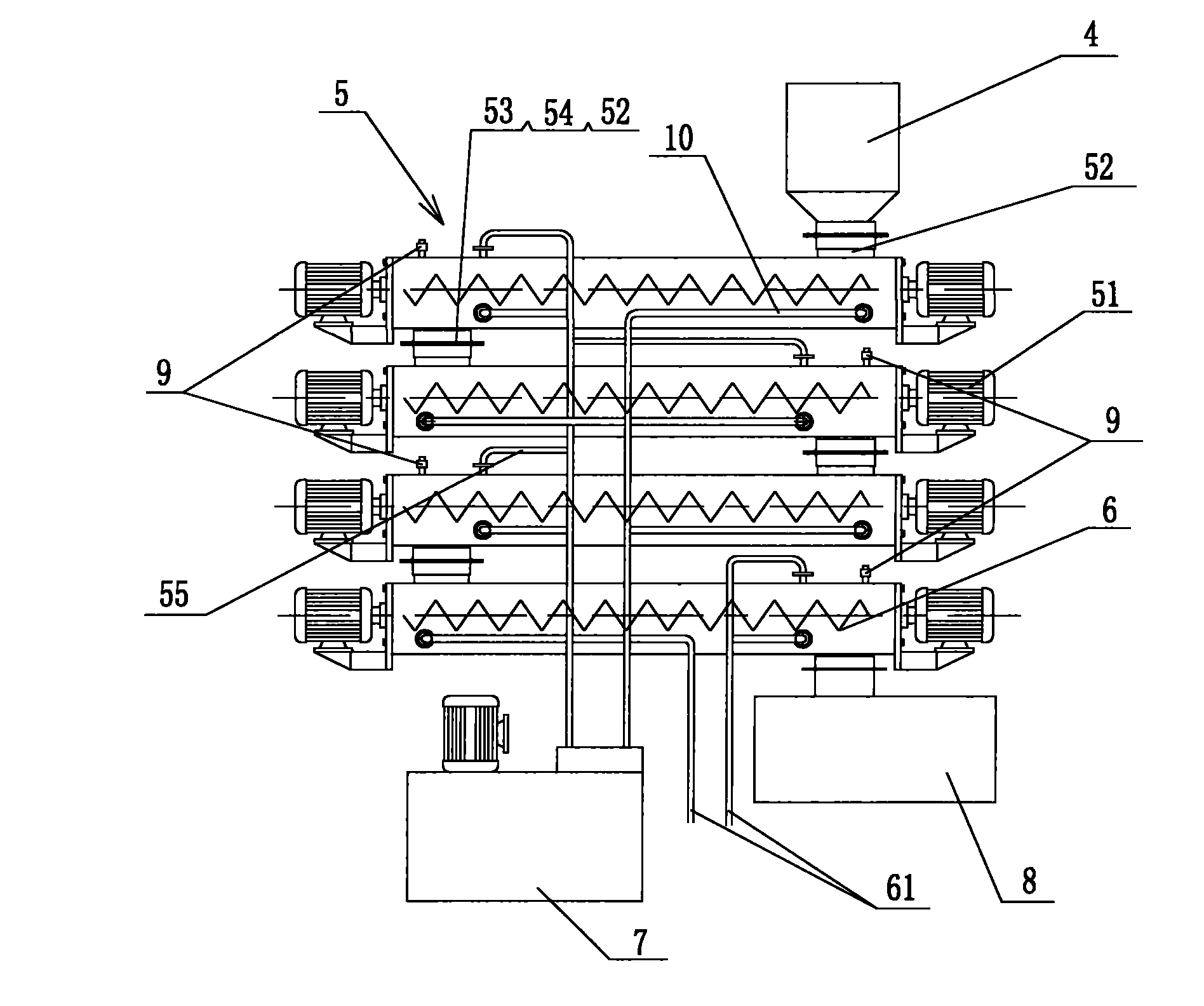

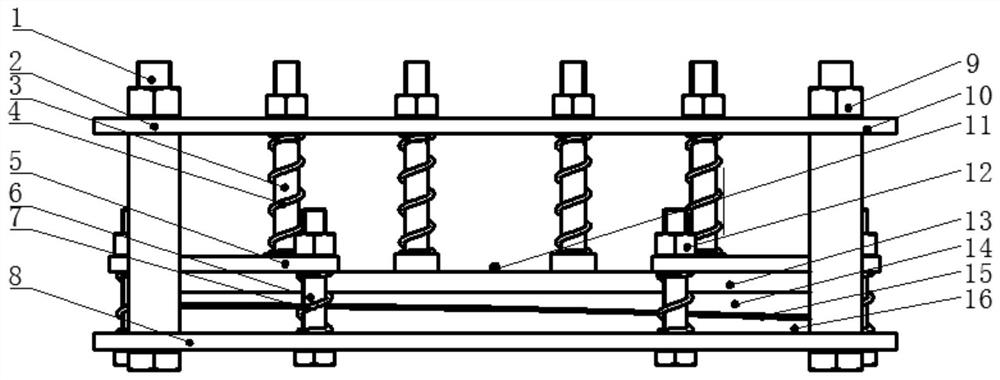

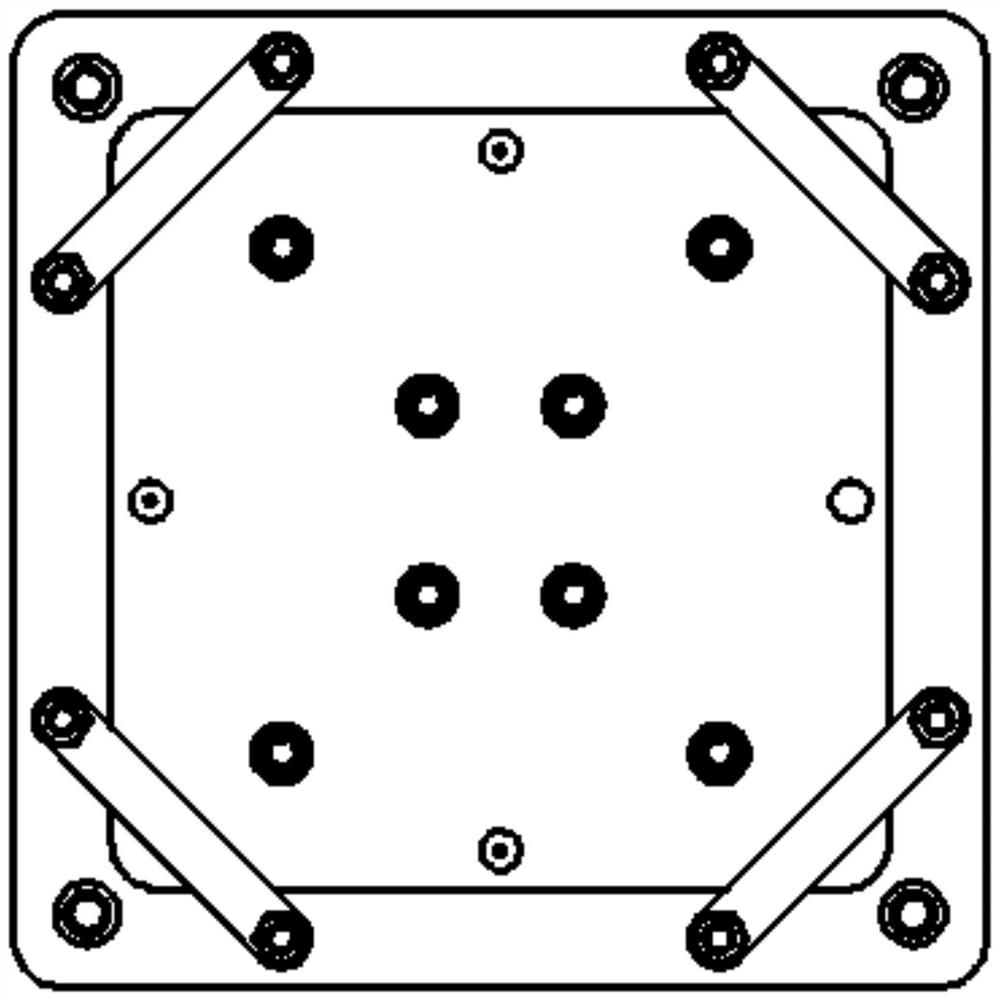

Automatic devulcanizing and plasticizing device and method for waste rubber powder

The invention provides automatic devulcanizing and plasticizing device and method for waste rubber powder. In the automatic devulcanizing and plasticizing device, a plastic highly stirring machine is applied to the automatic devulcanizing and plasticizing device for the waste rubber powder, which can realize high-speed stirring, enable ingredients to be mixed sufficiently and uniformly and realize the bulking, the immersing and the swelling of raw materials; a thermal reaction device comprises single or a plurality of plasticizing units; each screw material rod of a double-screw conveying device inside the thermal reaction device feeds by adopting differential motion; and if the thermal reaction device comprises a plurality of plasticizing units, the plasticizing units are arranged in a vertical spacing way, and each plasticizing unit is provided with an independent heating device which has short heating time and ensures the reaction to be sufficient. Because each screw material rod feeds by adopting the differential motion, the screw material rods are enabled to have self-cleaning function; meanwhile, the plasticizing units adopt a modular design, which enables the plasticizing units to be freely collated according to the different requirements of users on devulcanizing depth, thereby fully reducing equipment manufacturing cost and product production cost; and because of the adoption of a vertical spacing distribution structure, the equipment can be both expanded and conveniently maintained and overhauled.

Owner:袁红利

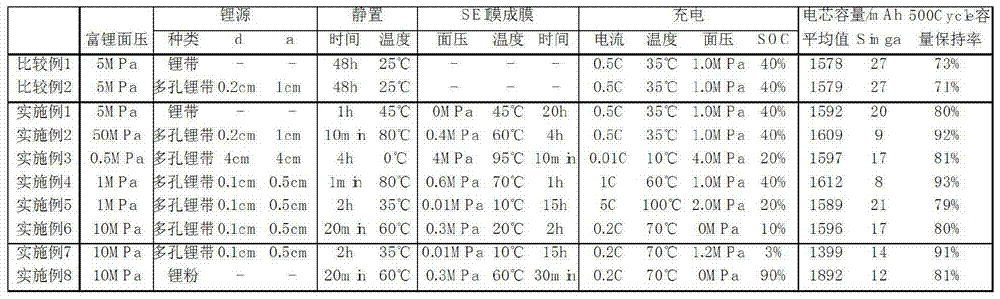

Preparation method of lithium ion battery

ActiveCN104752773AAchieve infiltrationImprove consistencyFinal product manufactureElectrolyte accumulators manufactureEntire cellLithium-ion battery

The invention belongs to the technical field of a lithium ion battery, and particularly relates to a preparation method of a lithium ion battery. The method mainly comprises the steps of preparing an electrode, preparing a naked cell which is convenient to be infiltrated by an electrolyte, injecting the electrolyte, infiltrating the naked cell, forming a solid electrolyte interface (SEI), and preparing a finished product cell. By utilizing the method to prepare the lithium ion battery, the rapid infiltration of the electrolyte can be realized, and the membrane reaction can be maximally limited by virtue of infiltration, so that after the entire cell is infiltrated, the composition consistency of the electrolyte on the electrode is relatively good, and thus the SEI formed in each area of the cell electrode is good in consistency.

Owner:GUANGDONG ZHUGUANG NEW ENERGY TECH

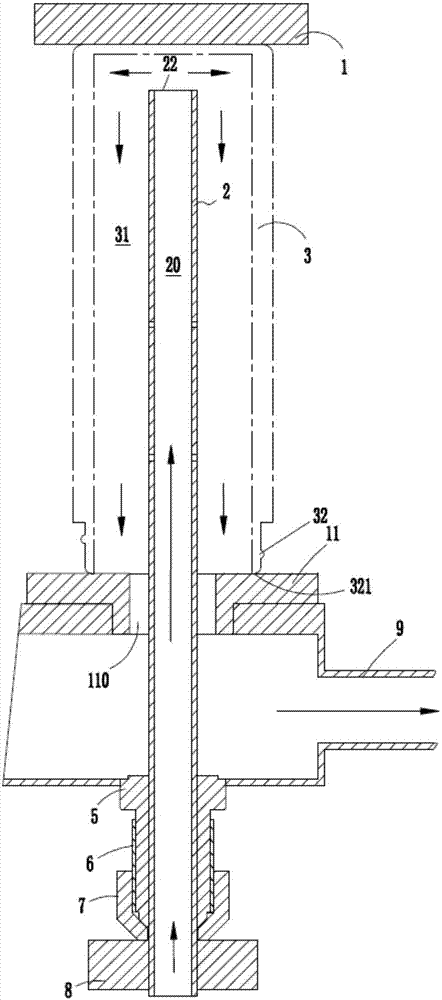

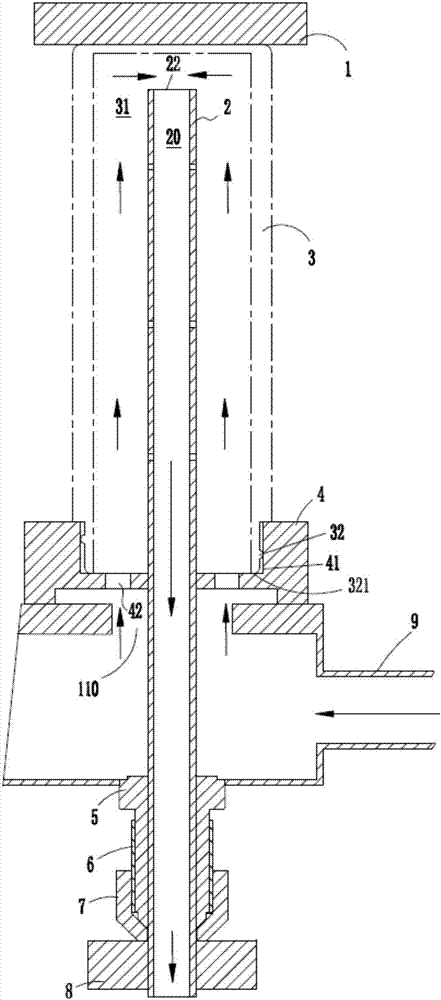

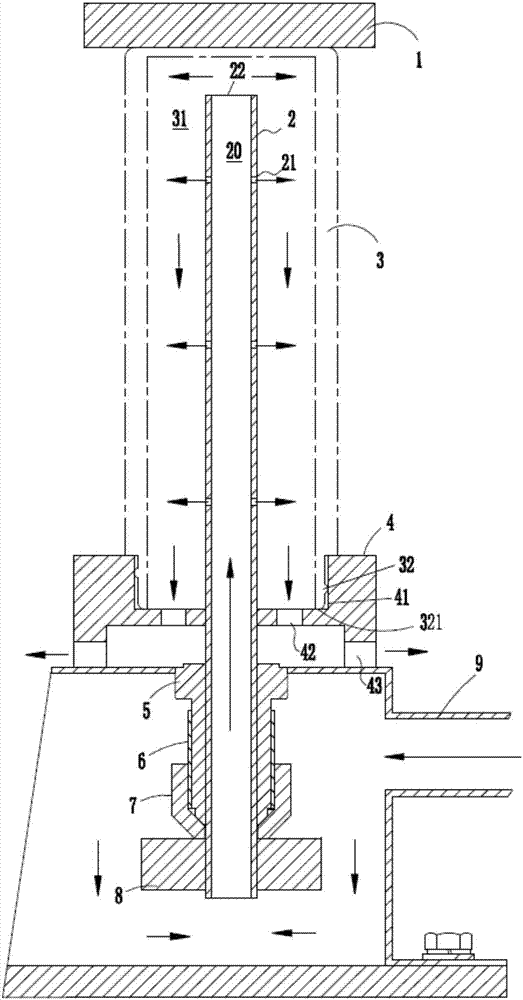

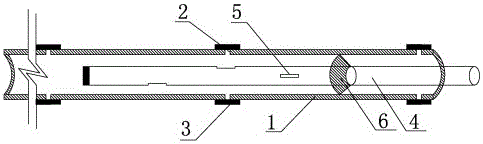

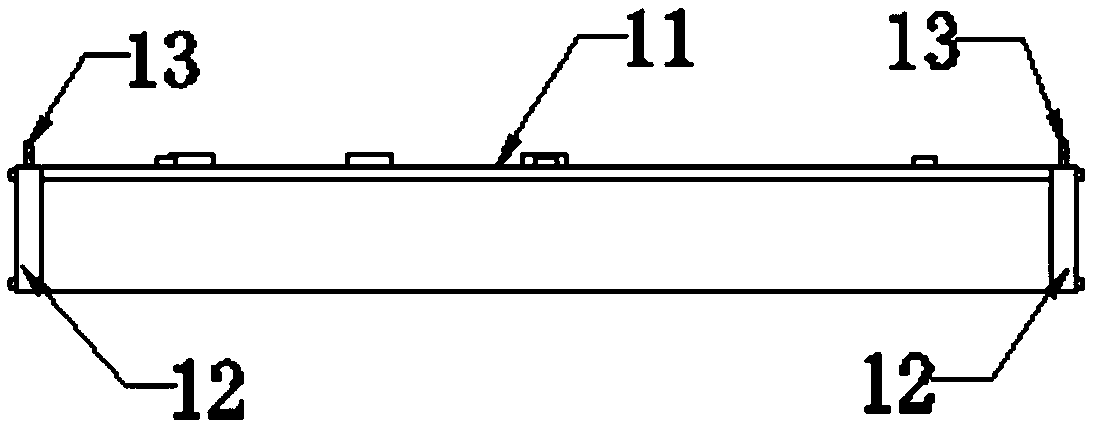

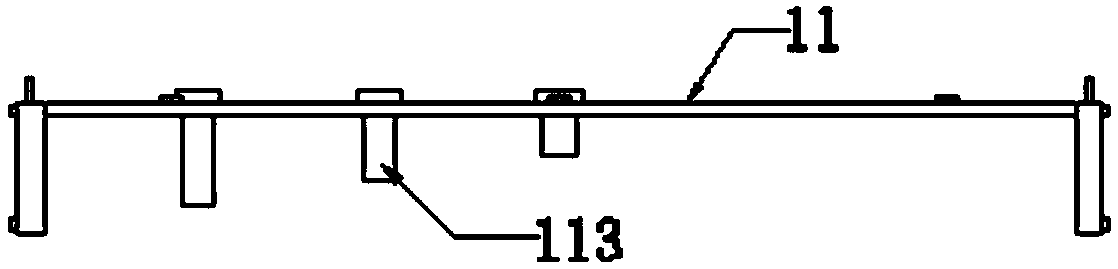

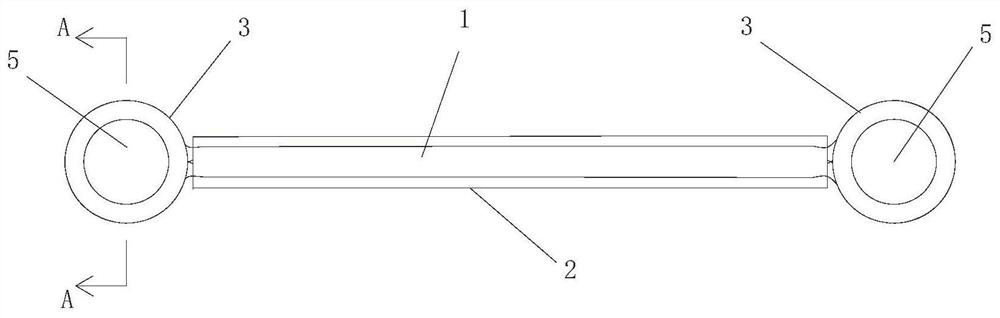

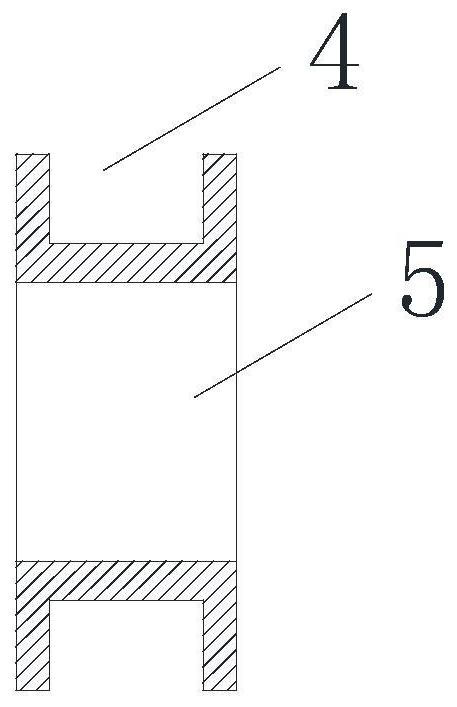

Inverted electrolytic polishing device and electrolytic polishing equipment thereof

ActiveCN106987894AAchieve infiltrationAvoid problemsElectrolysis componentsElectrolytic agentEngineering

The invention provides an inverted electrolytic polishing device and electrolytic polishing equipment thereof. The inverted electrolytic polishing device comprises an electrolytic bath, a plurality of electrolytic bars perpendicularly arranged in the electrolytic bath, an anode and / or a cathode infiltrated by electrolytic solutions circularly flowing in the electrolytic bath, and a backflow pipe. The electrolytic bars are hollow, two ends of each electrolytic bar extend into a workpiece and the backflow pipe respectively, the workpieces are located between the anode and the cathode and communicate with the backflow pipe through openings of the workpieces, and the openings of the workpieces are arranged downwards. The inverted electrolytic polishing device and the electrolytic polishing equipment have the advantages that the workpieces are placed upside down and the electrolytic solutions are injected upwards through the hollow electrolytic bars, so that the infiltration and contact degree of inner wall surfaces of the workpieces and the electrolytic solutions are achieved, the situation that bubbles occur when the inner wall surfaces are subjected to electrolytic polishing is effectively prevented, the electrolytic polishing effect is improved, and the automation degree and production efficiency of electrolytic polishing are improved.

Owner:无锡市鹏振智能科技有限公司

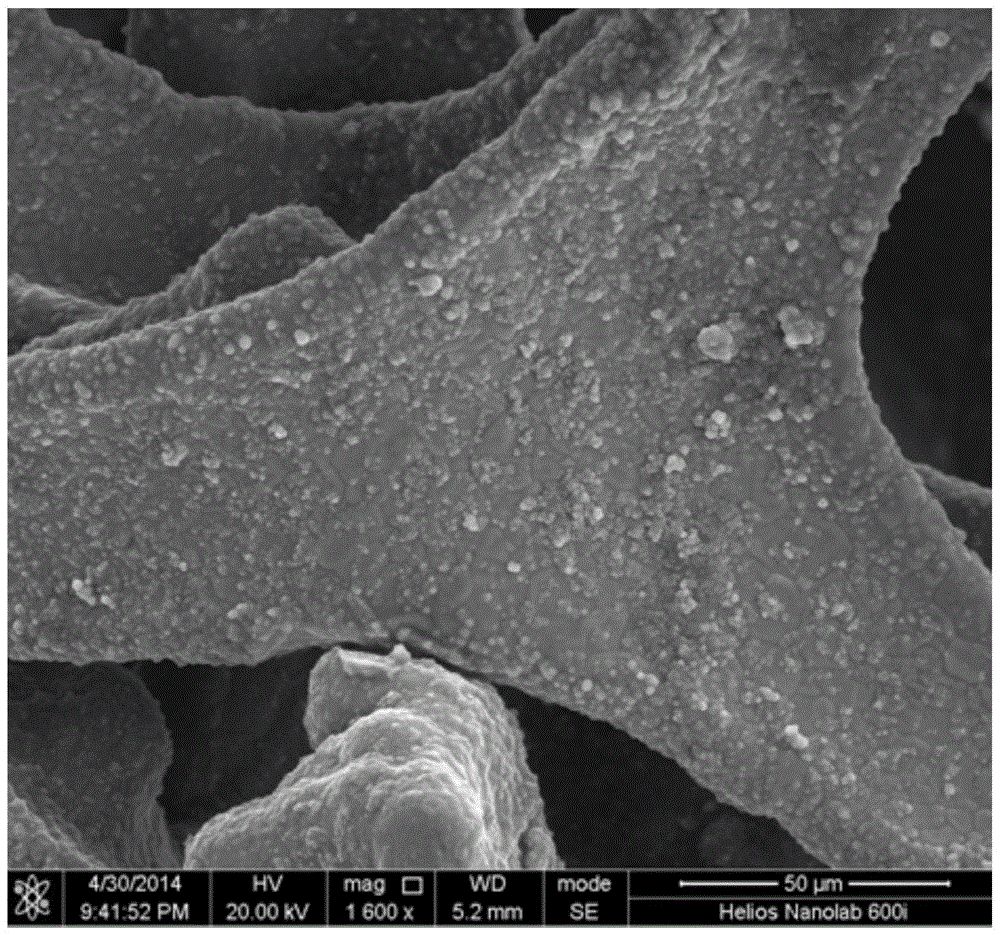

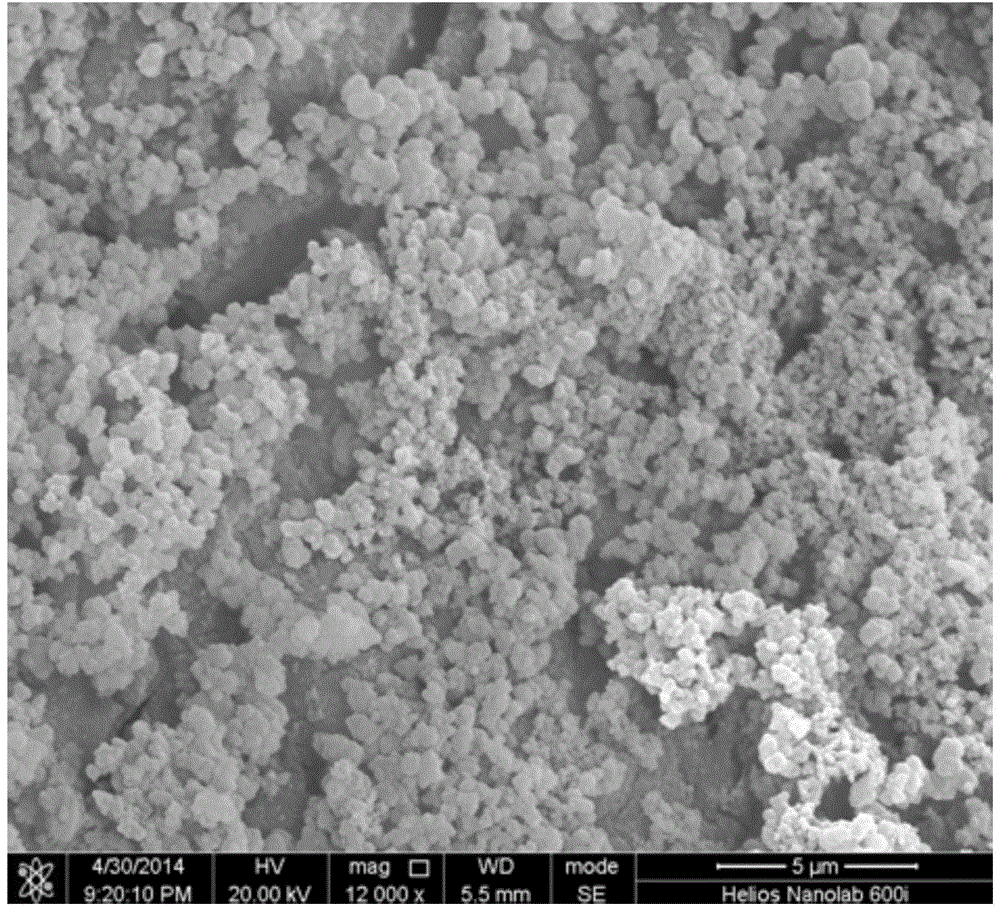

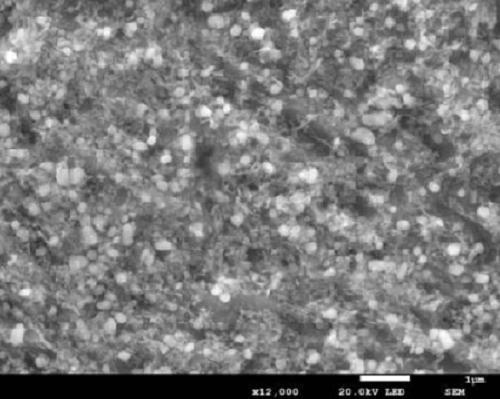

Method for preparing three-dimensional germanium/carbon nano composite film through ionic liquid electrodeposition

InactiveCN104894630AEasy deposition processReduce energy consumptionMaterial nanotechnologyCell electrodesComposite filmElectrical battery

The invention relates to a method for preparing a three-dimensional germanium / carbon nano composite film through ionic liquid electrodeposition, which relates to the method for preparing the germanium / carbon nano composite film. The method solve the technical problem that the circularity and multiplying power performance of a lithium ion battery are reduced during a charge and discharge process by a germanium cathode material of the current lithium ion battery. The method comprises the following steps: 1)electrophoretic deposition; 2)preparation of an ionic liquid electrodeposition liquid; 3)constant potential deposition; and 4)cleaning and drying. The prepared three-dimensional germanium / carbon nano composite film can effectively enhance the combination force between an active material and a current collector, volume expansion of the active material is reduced, transmission rate of the lithium ion and electron in the cathode material are increased, and the cycle performance, multiplying power performance and safety performance of the lithium ion battery are effectively increased.

Owner:HARBIN INST OF TECH

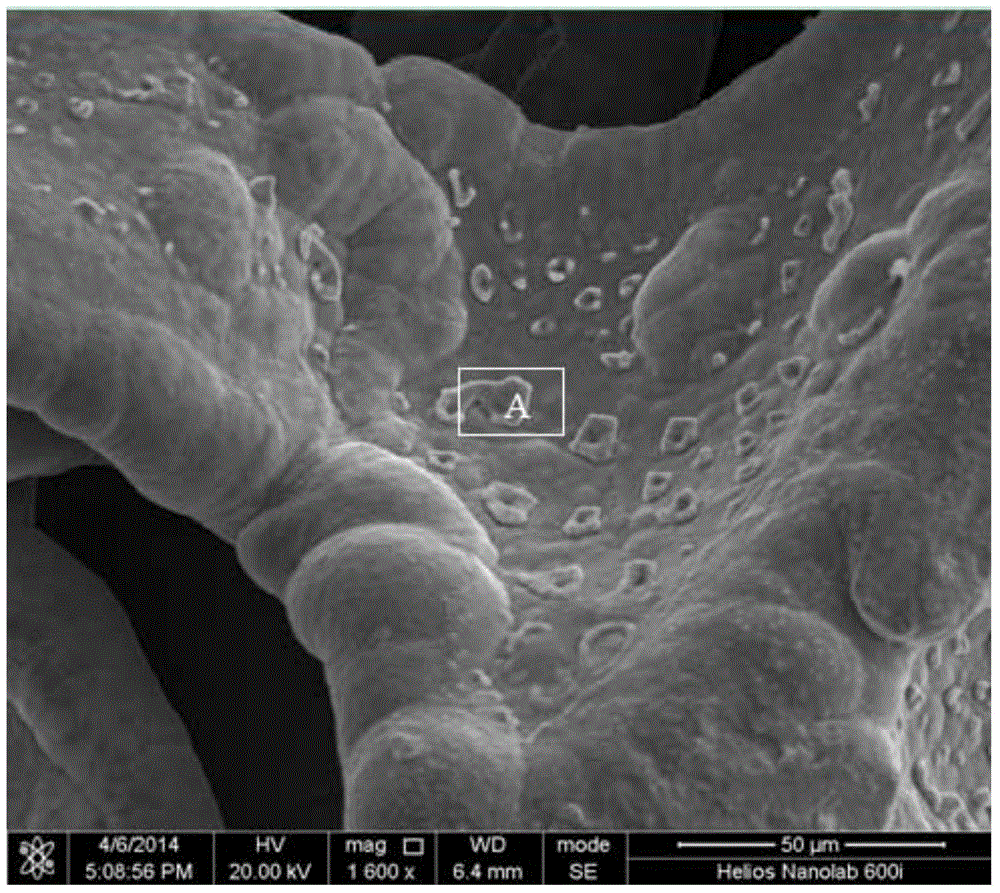

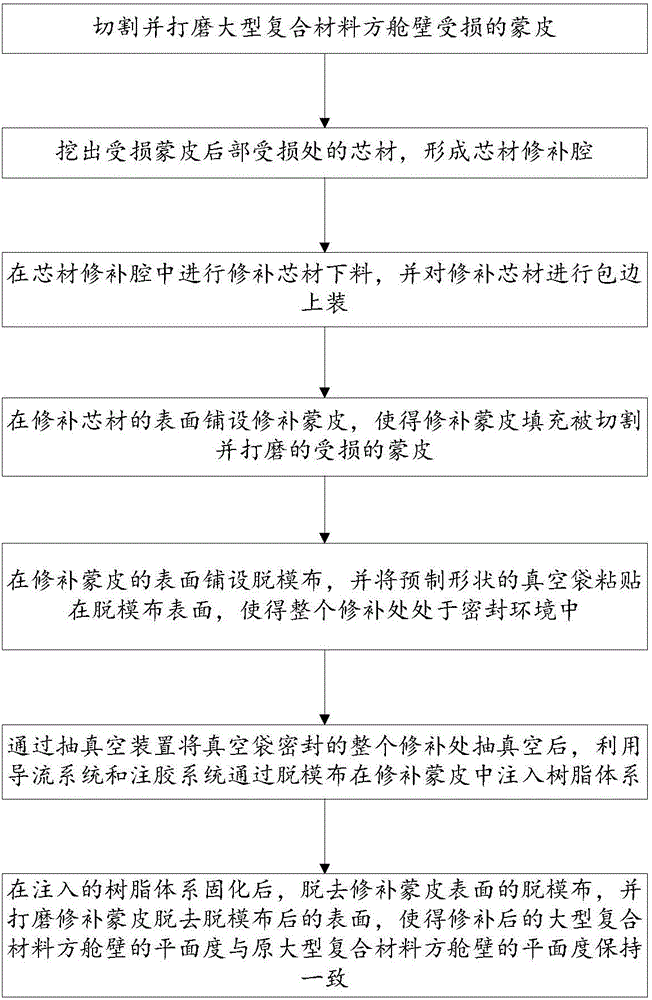

Repairing method of large composite material shelter

The invention relates to a repairing method of a large composite material shelter. The method comprises the following steps: cutting and polishing the damaged sheath of the wall of the large composite material shelter; digging out the damaged core material at the rear portion of the damaged sheath to form a core material repairing cavity; carrying out repairing core material discharging in the core material repairing cavity, and carrying out edge covering and loading of the repairing core material; laying a repairing sheath on the surface of the repairing core material; laying a demolding cloth on the surface of the repairing sheath, and allowing a whole repairing position to be in sealed environment; injecting a resin system to the repairing sheath through the demolding cloth by using a flow guiding system and a glue injecting system; and removing the demolding cloth on the surface of the repairing sheath, and polishing the demolding cloth removed surface of the repairing sheath. The shelter repairing method provided by the invention has the advantages of few consumables, low cost, good effect, elimination of the innate discontinuity characteristic of fibers in laminates, caused by traditional imbed parts, and solving of the repairing problem of large composite material shelters through well combining fault fibers.

Owner:SHANDONG YINGTELI NEW MATERIAL

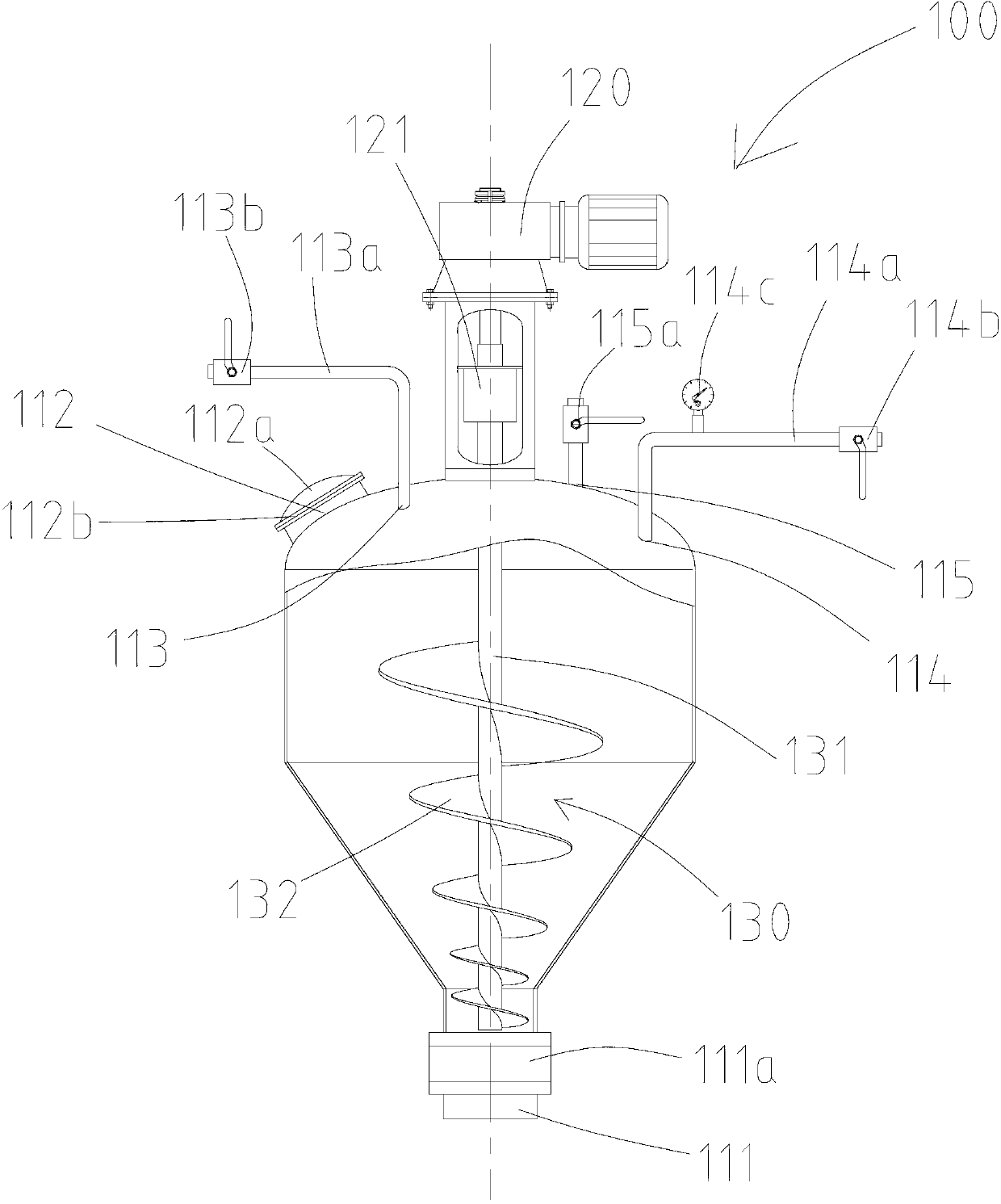

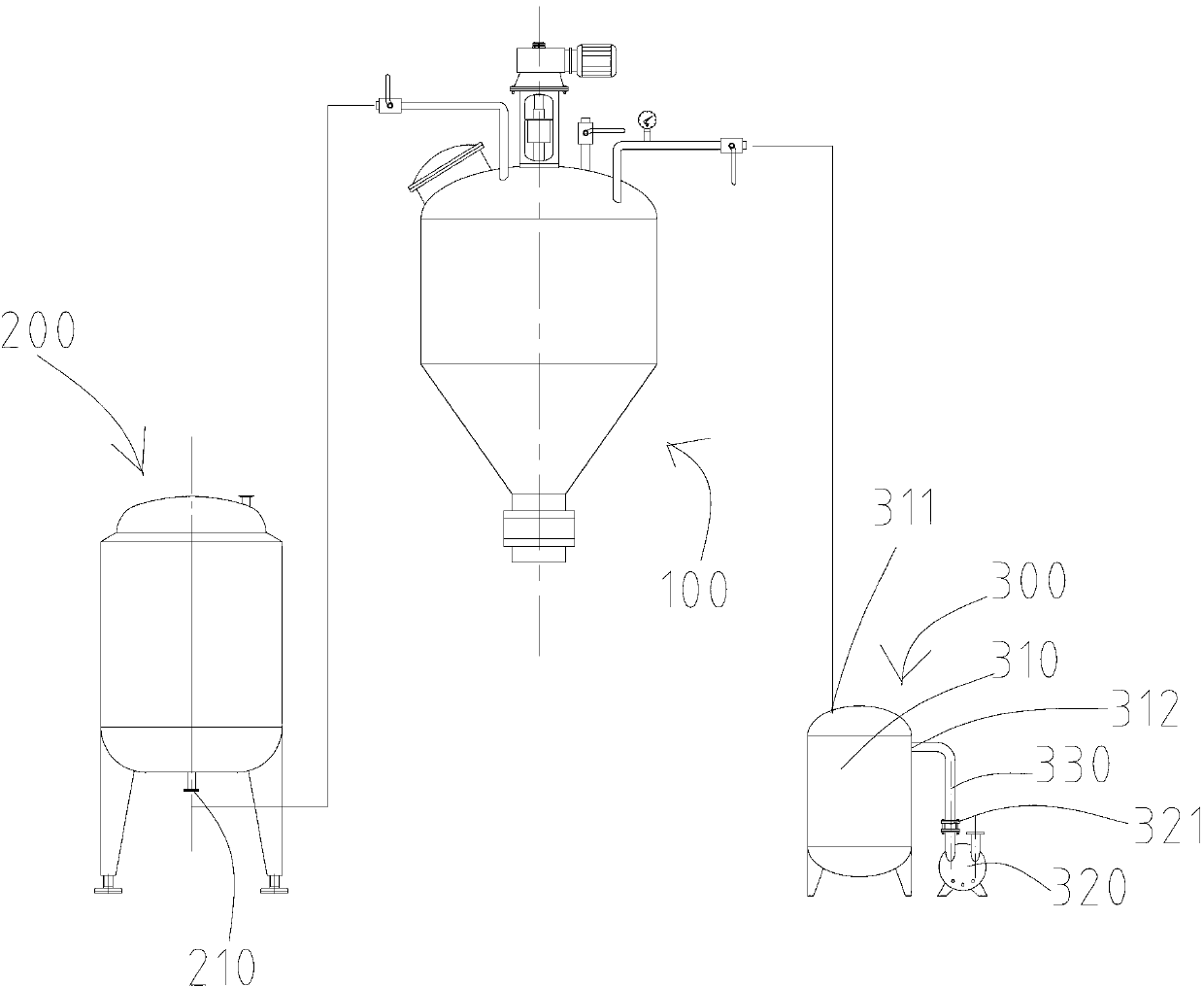

Vacuum infiltration device and method for pretreatment in animal and plant extraction processes

InactiveCN103272403AAchieve infiltrationShorten the timeRotary stirring mixersTransportation and packagingVacuum pumpingLiquid storage tank

The invention discloses a vacuum infiltration device for pretreatment in an animal and plant extraction processes. The device comprises an infiltrating tank, a liquid storage tank and a vacuum unit, wherein the infiltrating tank is provided with a discharge outlet, a vacuum release port, a feed inlet, a liquid feeding port and a vacuumizing port; the liquid storage tank is connected with the liquid feeding port of the infiltrating tank through a liquid feeding pipe; the vacuum unit is connected with the vacuumizing port of the infiltrating tank through a vacuum pumping pipe; the infiltrating tank is internally provided with a stirring device consisting of a stirring shaft and screw blades which are arranged on the outer wall of the stirring shaft, the diameter of the screw blade is gradually reduced from top to bottom, and the lower end of the screw blade extends to the discharge outlet; and the infiltrating tank is also provided with a slowdown motor which is controlled and connected through an electric appliance control device, an output shaft of the slowdown motor is connected with the stirring shaft in the stirring device through a coupling, and the rotating direction and rotating speed of the stirring device are controlled through the slowdown motor. According to the invention, an effect of infiltration can be achieved and the complete infiltration of an extracted object is realized in a short time, and the multiplication of microbes can be completely eradicated in an infiltration process in a vacuum environment.

Owner:SHANGHAI UNIWIN PHARMA MACHINERY

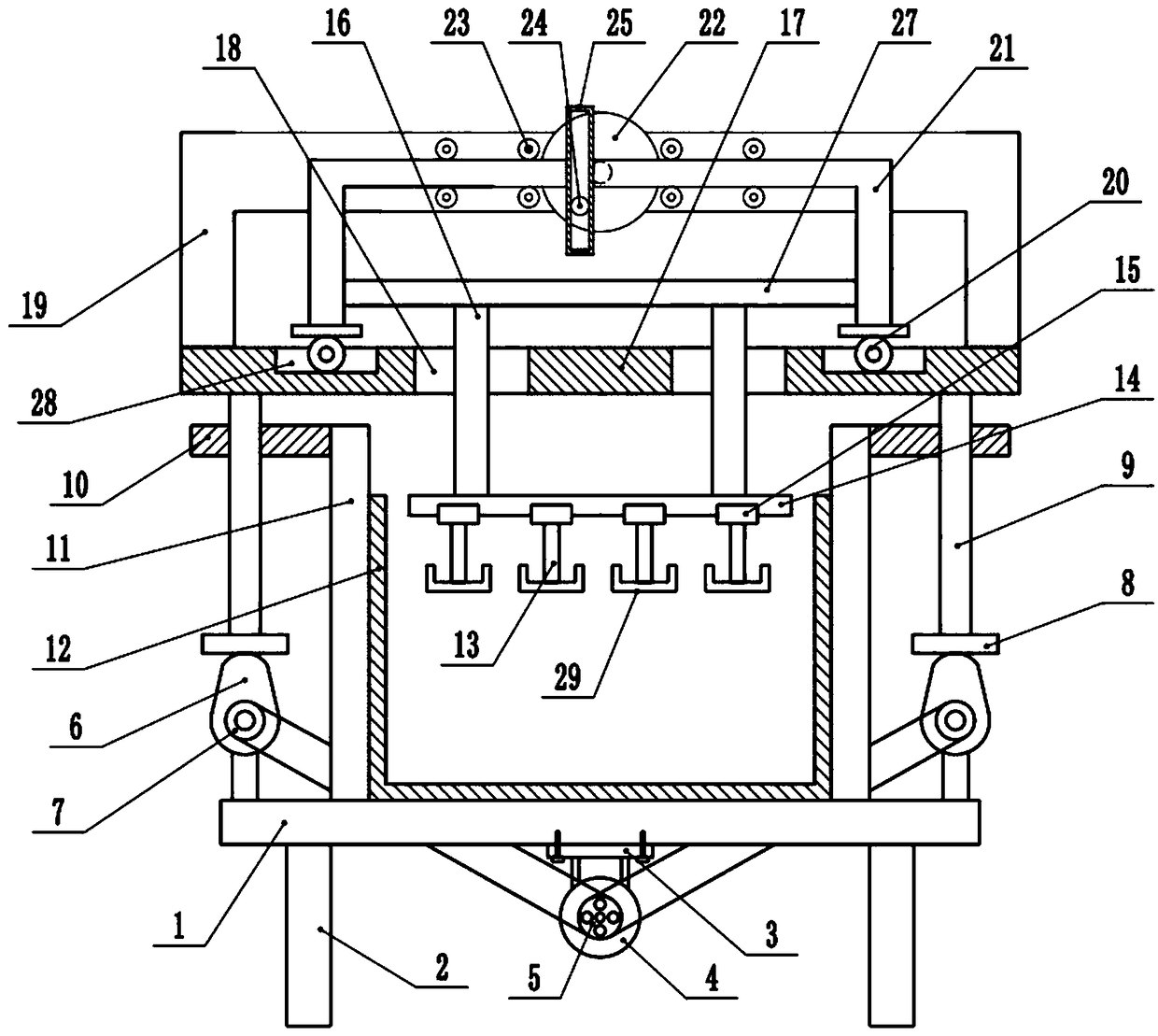

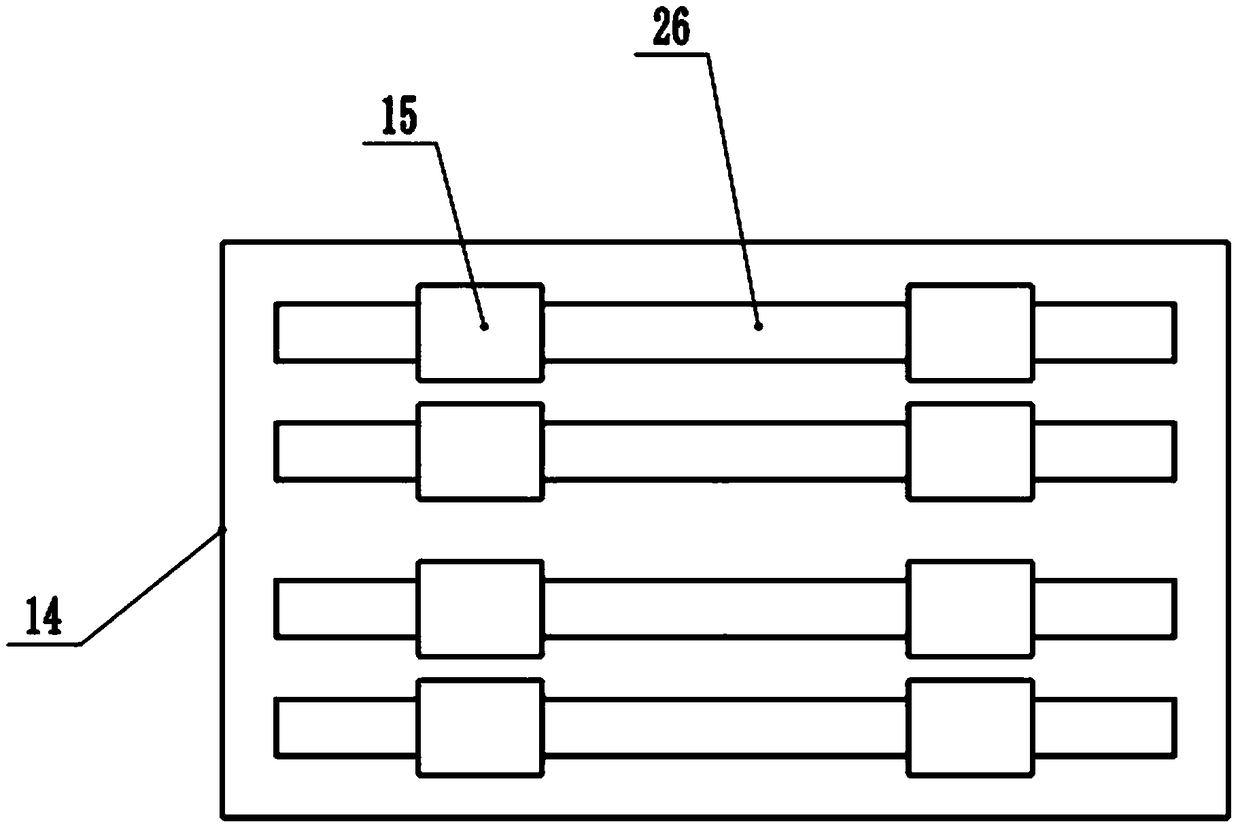

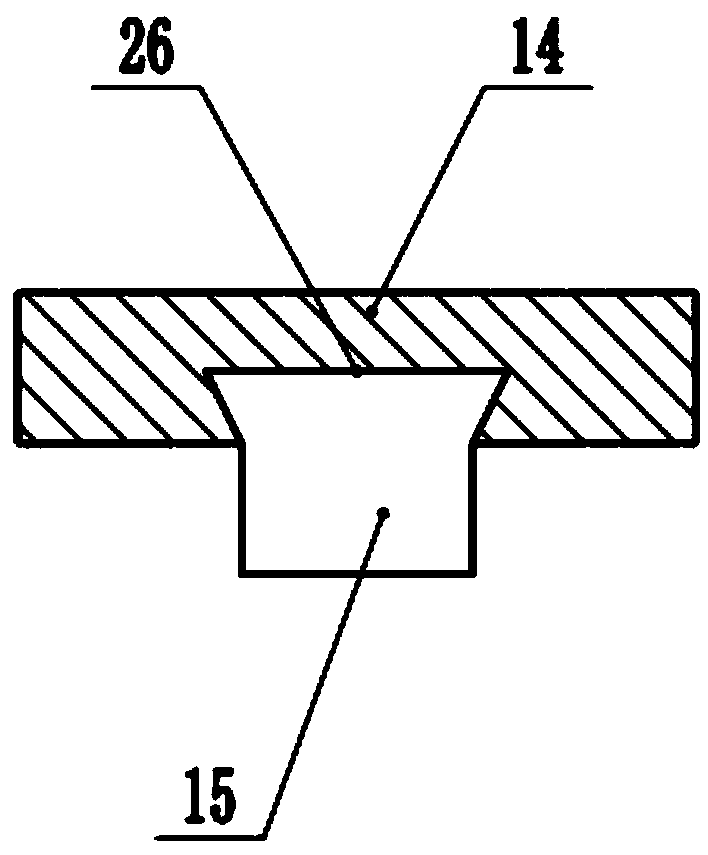

Automobile firmware infiltration processing treatment device

InactiveCN108993824AReasonable structureInnovative designLiquid surface applicatorsCoatingsReciprocating motionDrive motor

The invention discloses an automobile firmware infiltration processing treatment device which comprises a supporting seat, wherein a fixing seat is arranged at the middle part of the lower end of thesupporting seat; a drive motor is mounted at the lower end of the fixing seat; a driving belt pulley is mounted at the middle part of the front end of the drive motor; the driving belt pulley is connected with a driven belt pulley by virtue of a belt; a rotary cam is arranged at the middle part of the front end of the driven belt pulley; the upper end of the rotary cam is in contact with a liftingplate; a lifting column is mounted at the middle part of the upper end of the lifting plate; a lifting table is mounted at the upper end of the lifting column; support frames are mounted on two sidesof the upper end of the lifting table; rotating wheels are mounted at the middle parts of the front ends of the support frames; eccentric columns are mounted at the middle parts of of the front endsof the rotating wheels; moving frames are mounted on the outer sides of the eccentric columns in a sleeving manner; moving racks are arranged at two ends of the moving frames; moving plates are arranged between the bottoms of the moving racks. According to the automobile firmware infiltration processing treatment device disclosed by the invention, reciprocating motions in the upper, lower, left and right directions of the whole automobile firmware can be realized, so that the automobile firmware can be in full contact with a wetting fluid in an infiltration tank, and the condition that the automobile firmware is manually held to swing so as to be infiltrated is avoided.

Owner:合肥岑遥新材料科技有限公司

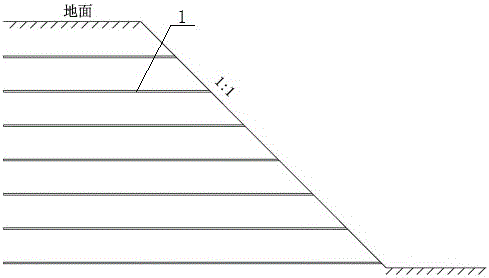

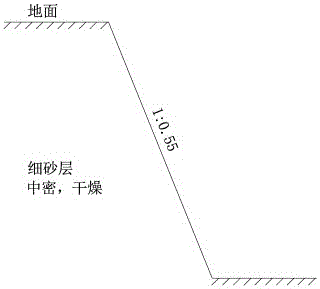

Grouting slurry for reinforcing tunnel face of jacking culvert of fine-sand layer and grouting method

ActiveCN105731978AImprove permeabilityNo pollution in the processUnderground chambersTunnel liningMicrofine cementSlurry

The invention provides grouting slurry for reinforcing the tunnel face of a jacking culvert of a fine-sand layer and a grouting method. When the jacking frame culvert is reinforced by a pipe curtain and the tunnel face needs to keep self-stabilization at certain slope ratio, the diluted water glass and prepared calcium chloride solution are sequentially adopted for horizontal grouting reinforcement by a modified perforated-pipe grouting technology; and the unconfined compressive strength of the reinforced soil body can reach 100-500kPa, and the slope ratio required by the blade feet of the jacking culvert can be realized. Compared with the reinforcement by chemical slurry and high-pressure jet grouting, the grouting method is safe and stable; compared with the reinforcement by superfine cement grouting, the spreading range is large, the strength after reinforcement can meet the requirement on slope ratio stability, the excavation is easy, the construction is convenient, and the construction cost is reduced by more than half; meanwhile, by adopting the grouting technology provided by the invention, sectional grouting can be realized, the pipeline is not blocked easily, and an aim of dominant permeation of slurry in the dense fine-sand layer is achieved; and a slurry plug is not arranged at the lower end but the upper part, the grouting range is expanded, and the grouting effect is relatively good.

Owner:中铁四院集团工程建设有限责任公司

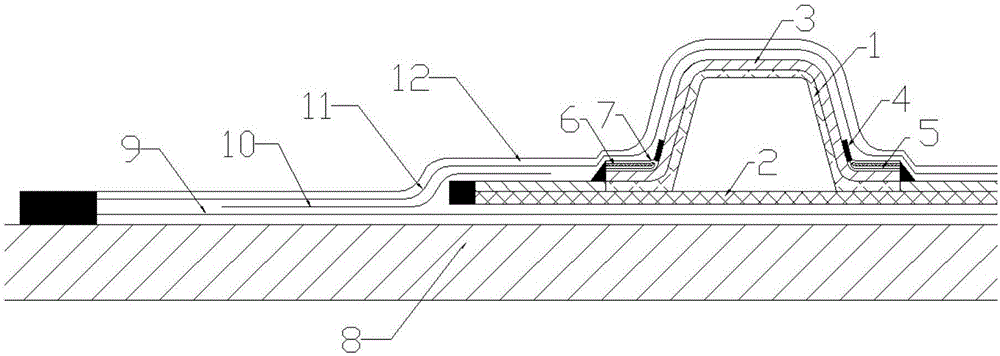

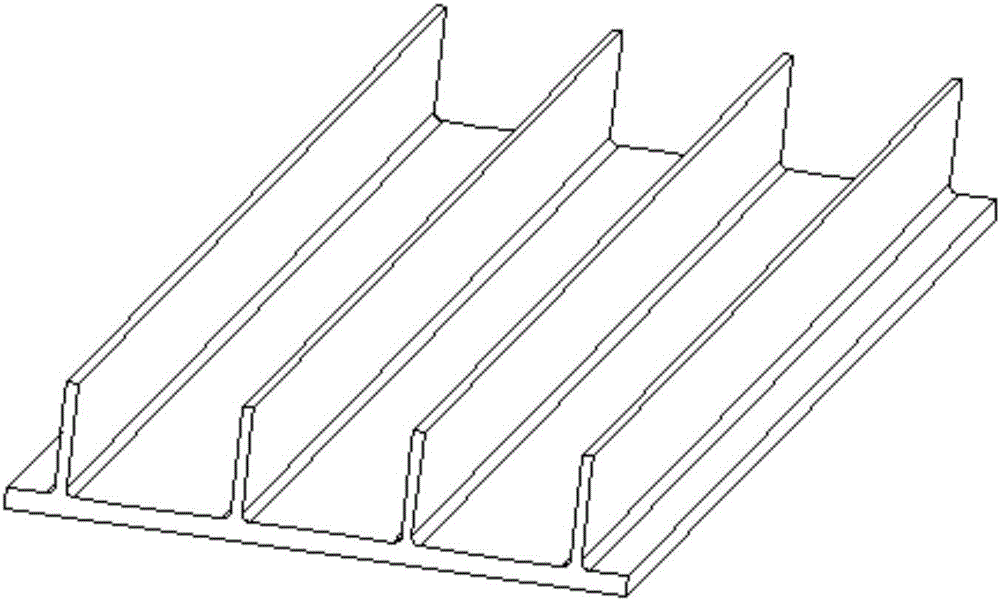

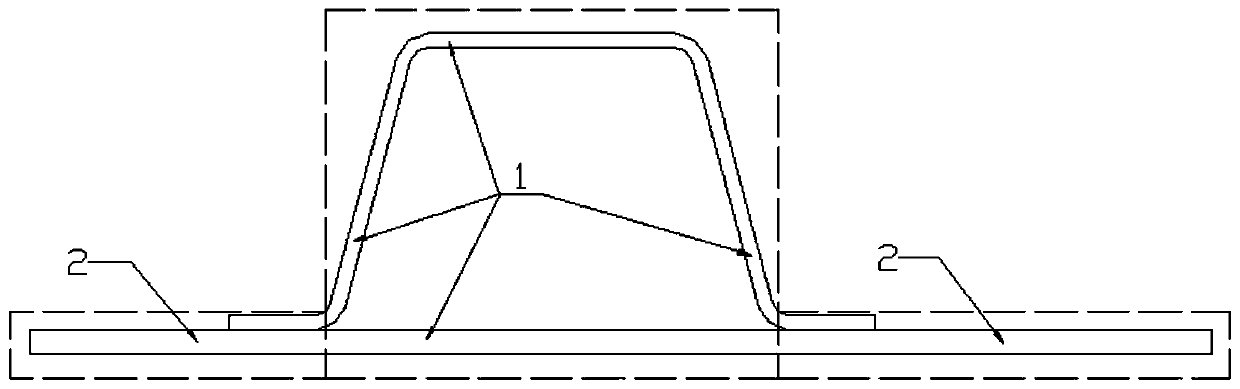

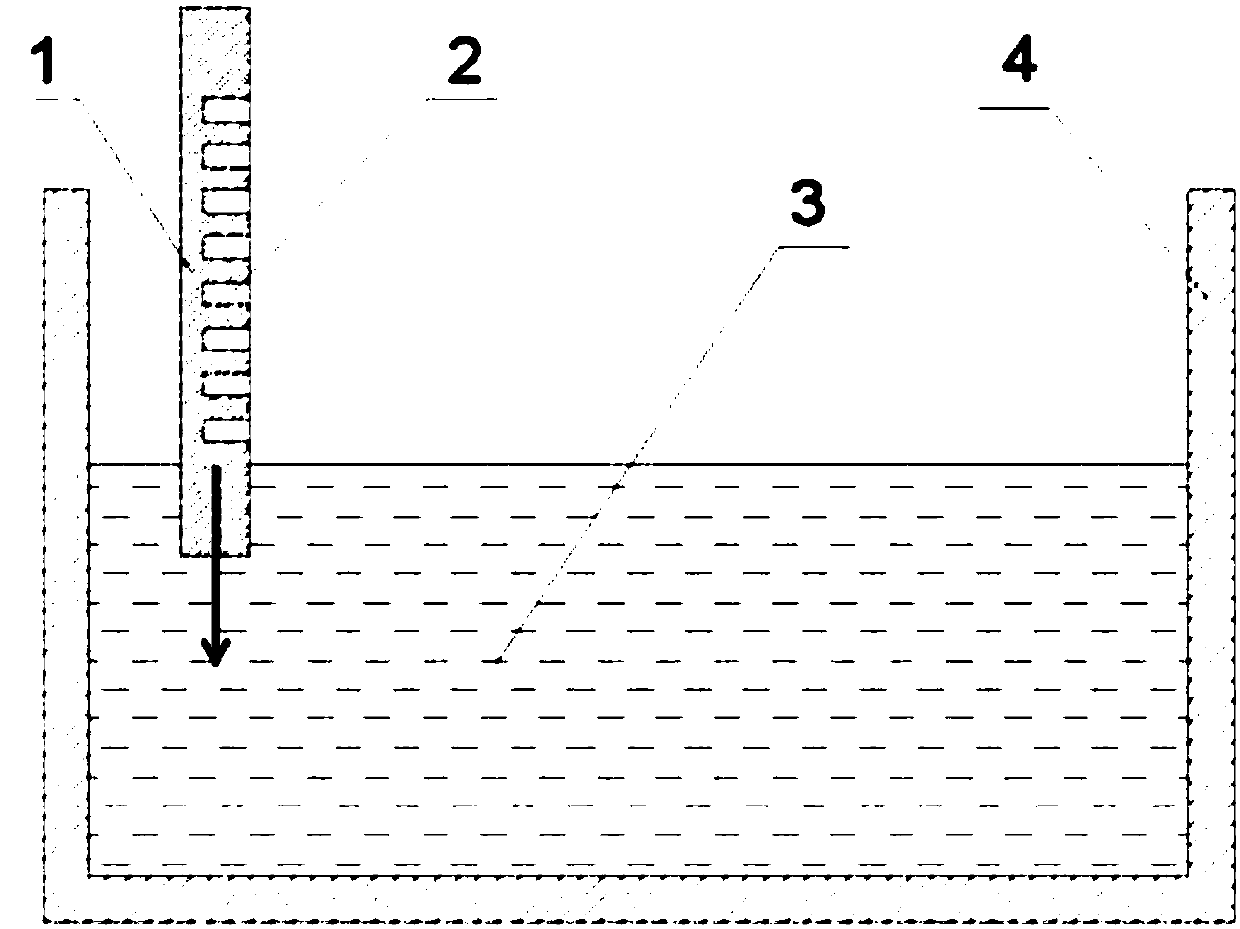

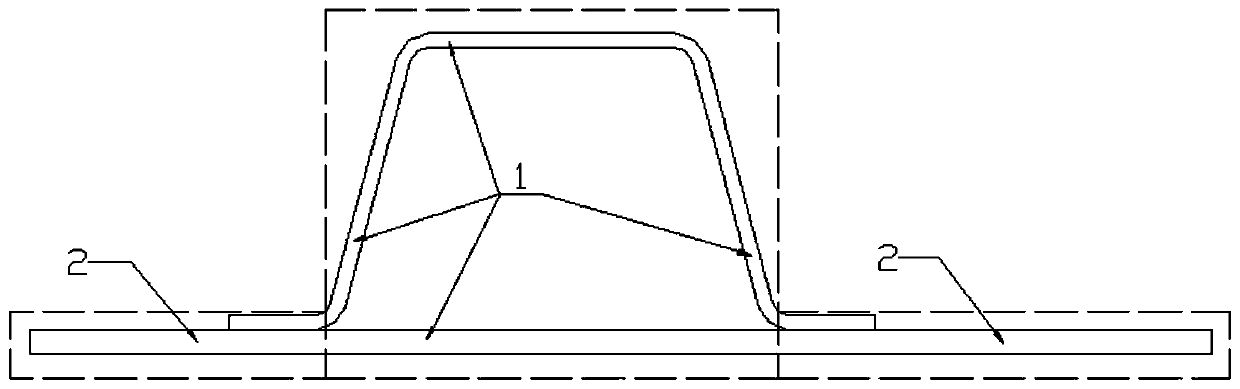

Resin film encapsulating and gas channel arranging method in RFI molding

The invention belongs to a resin-based composite liquid molding technique, relates to a resin film encapsulating and gas channel arranging method in RFI molding, and provides a gas channel arranging and resin film encapsulating method for an improved RFI technology. According to the method, in an area, needing resin infusion, of a wallboard, a resin film is encapsulated on the surface of a mold on the inner side of the wallboard by adopting an adhesive guide material, sealing strips and an isolating film; by arranging a gas channel between a wallboard preform and the mold to guide resin to permeate from top to bottom, complete wetting of the resin on the preform is achieved, and dry spots are avoided; good matching can be achieved when the wallboard preform and the mold are assembled, wallboard preform fiber deformation caused by resin flow in the resin laying and transferring process is avoided, and complete wetting of the resin on the preform is achieved on the premise of ensuring the quality of the inner surface and the outer surface of the wallboard.

Owner:AVIC COMPOSITES

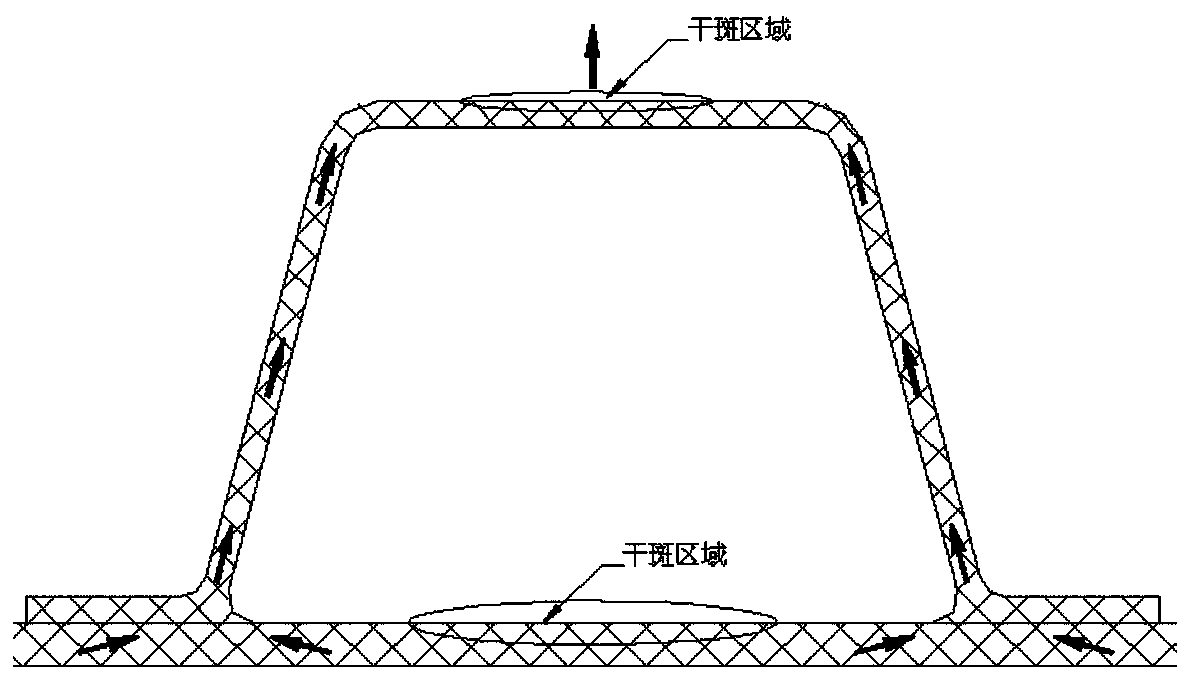

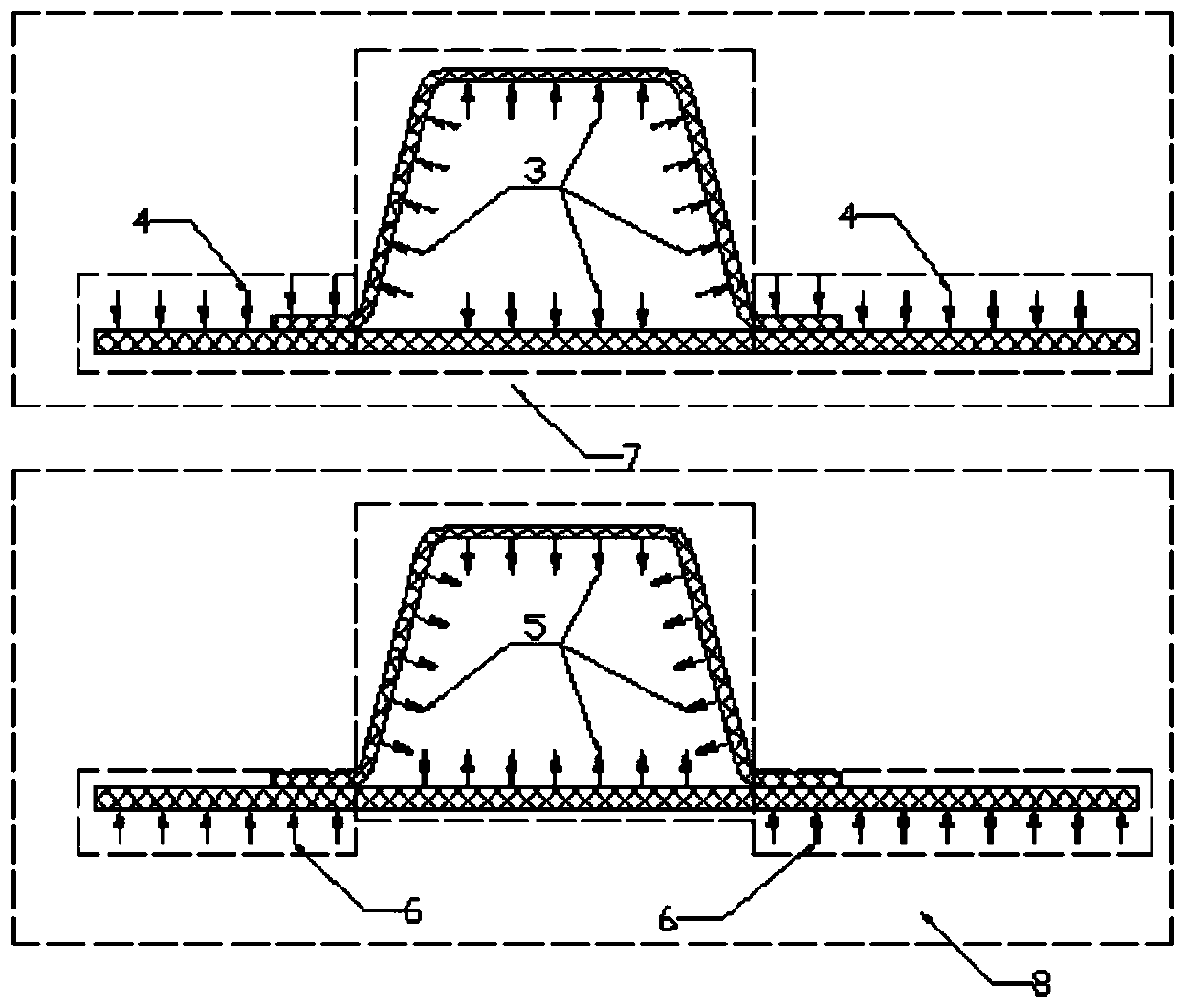

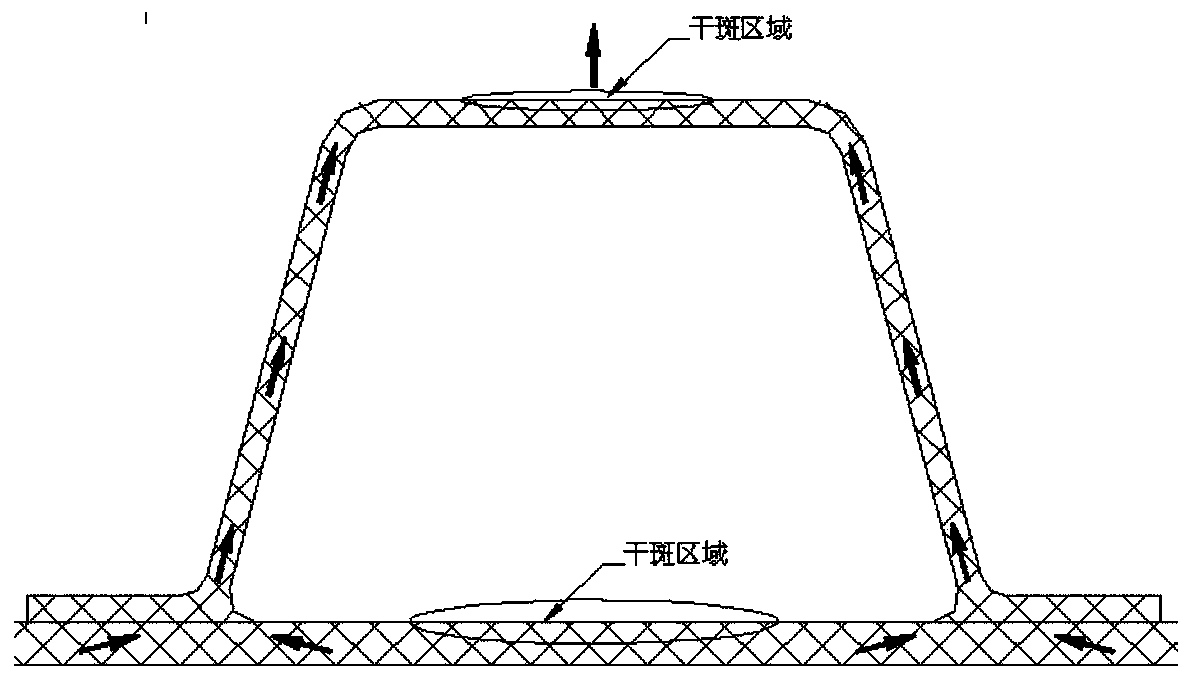

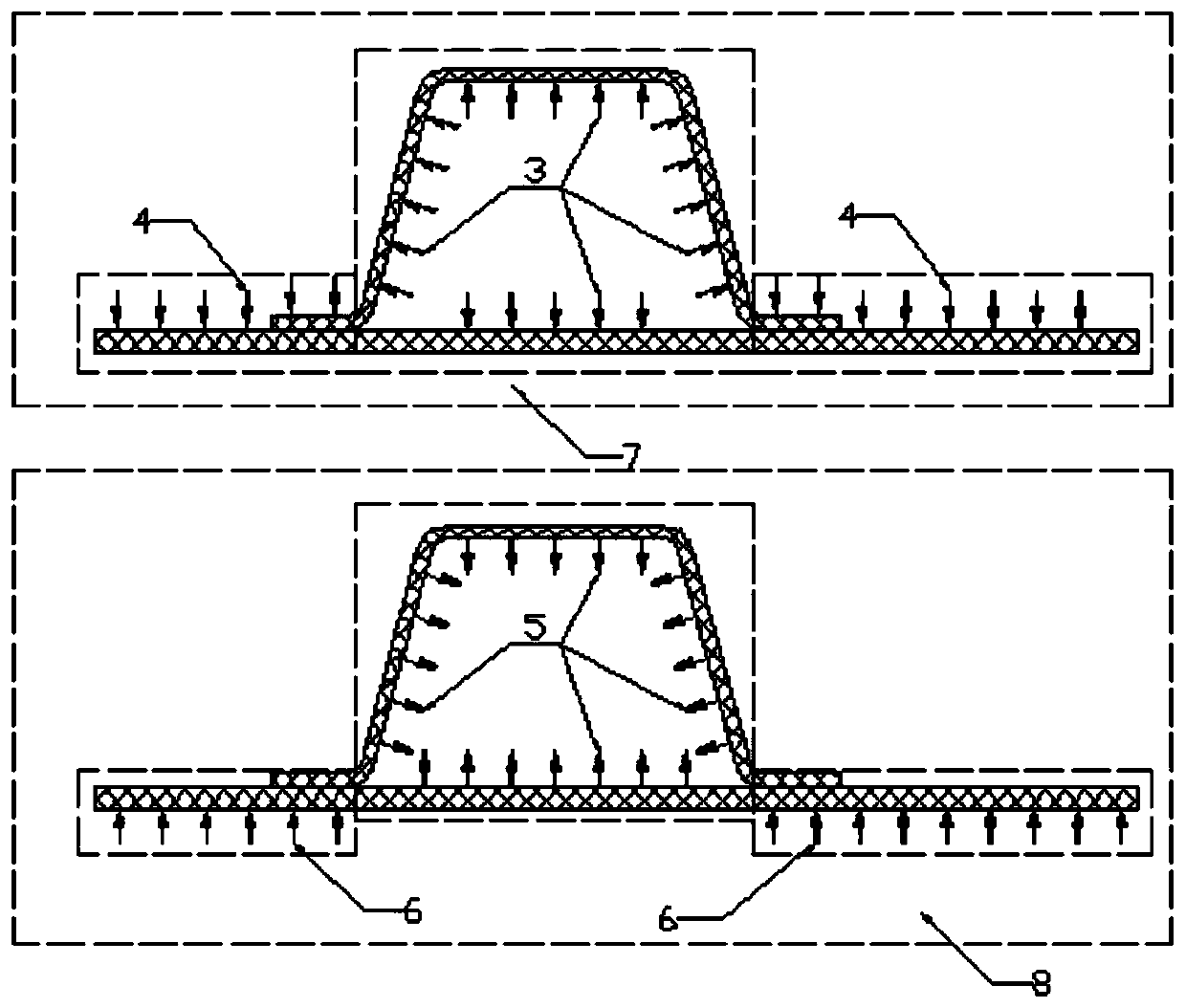

Resin flowing control method for cap-shaped additional rib wall plate RFI overall forming

The invention belongs to the technical field of low-cost manufacturing of high-performance resin matrix composite materials and relates to a resin flowing control method for cap-shaped additional ribwall plate RFI overall forming. In a traditional RFI technology, resin is diverted at the root parts of cap-shaped additional ribs, the resin flows towards cap tops along the interlayer of the two sides of each cap-shaped additional rib, dry spots are likely to be generated at the cap tops and cap bottoms, and part scrapping is caused. By means of the resin flowing control method for cap-shaped additional rib wall plate RFI overall forming, structure characteristics of a cap-shaped additional rib wall plate and RFI technology resin flowing characteristics are taken into consideration, the cap-shaped additional rib wall plate is decomposed into two kinds of structure units including a ring-shaped structure and a plate-shaped structure, a resin flowing module suitable for resin flowing control of the ring-shaped structure and the plate-shaped structure at the same time is established, a cap-shaped additional rib wall plate RFI overall forming resin flowing model is formed, resin laying is conducted according to the established resin flowing model, a gas way is arranged in the RFI technology process for guiding the resin to flow, and complete soaking of a cap-shaped additional rib wall plate pre-formed body in the resin is achieved.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Water-based metal cleaning agent

The invention provides a water-based metal cleaning agent. The water-based metal cleaning agent comprises 70 g / L-100 g / L of glycollic acid, 10 g / L-18 g / L of malic acid, 5 g / L-10 g / L of sodium dodecyl benzene sulfonate, 5 g / L-8 g / L of sodium citrate, 6 g / L-10 g / L of sodium metasilicate pentahydrate, 0.8 g / L-1.6 g / L of peregal O-15 and 2.2 g / L-2.4 g / L of fatty alcohol-polyoxyethylene ether AEO-9. The water-based metal cleaning agent can achieve synchronous performing of oil removing and rust removing of the metal surface in the same acid solution under the heating-free normal-temperature state, raw materials are saved, the processing speed is high, and the cleaning effect is good.

Owner:LUOYANG LVREN ENVIRONMENTAL EQUIP

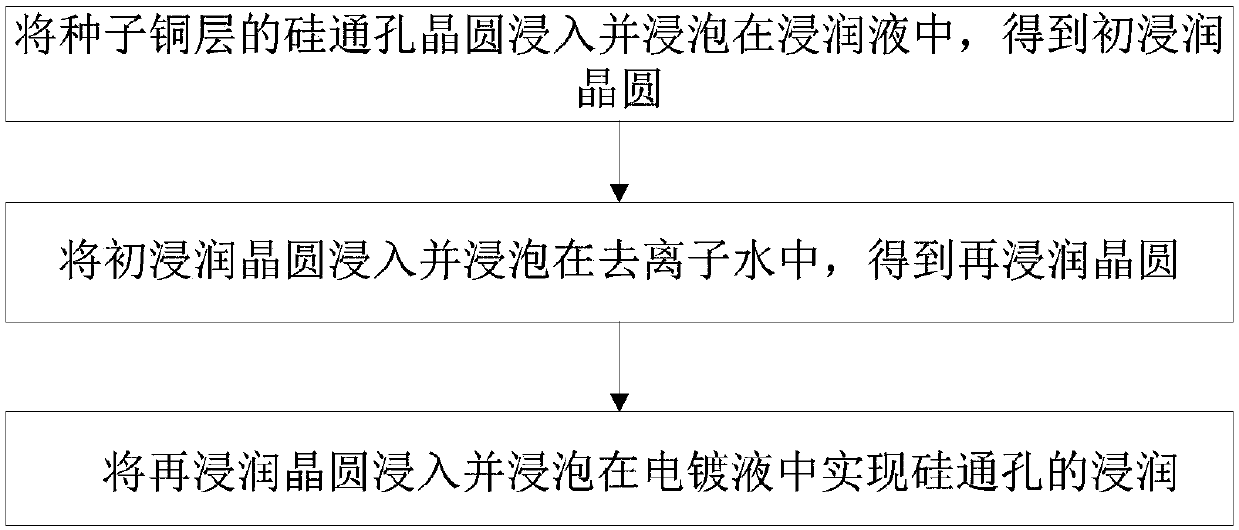

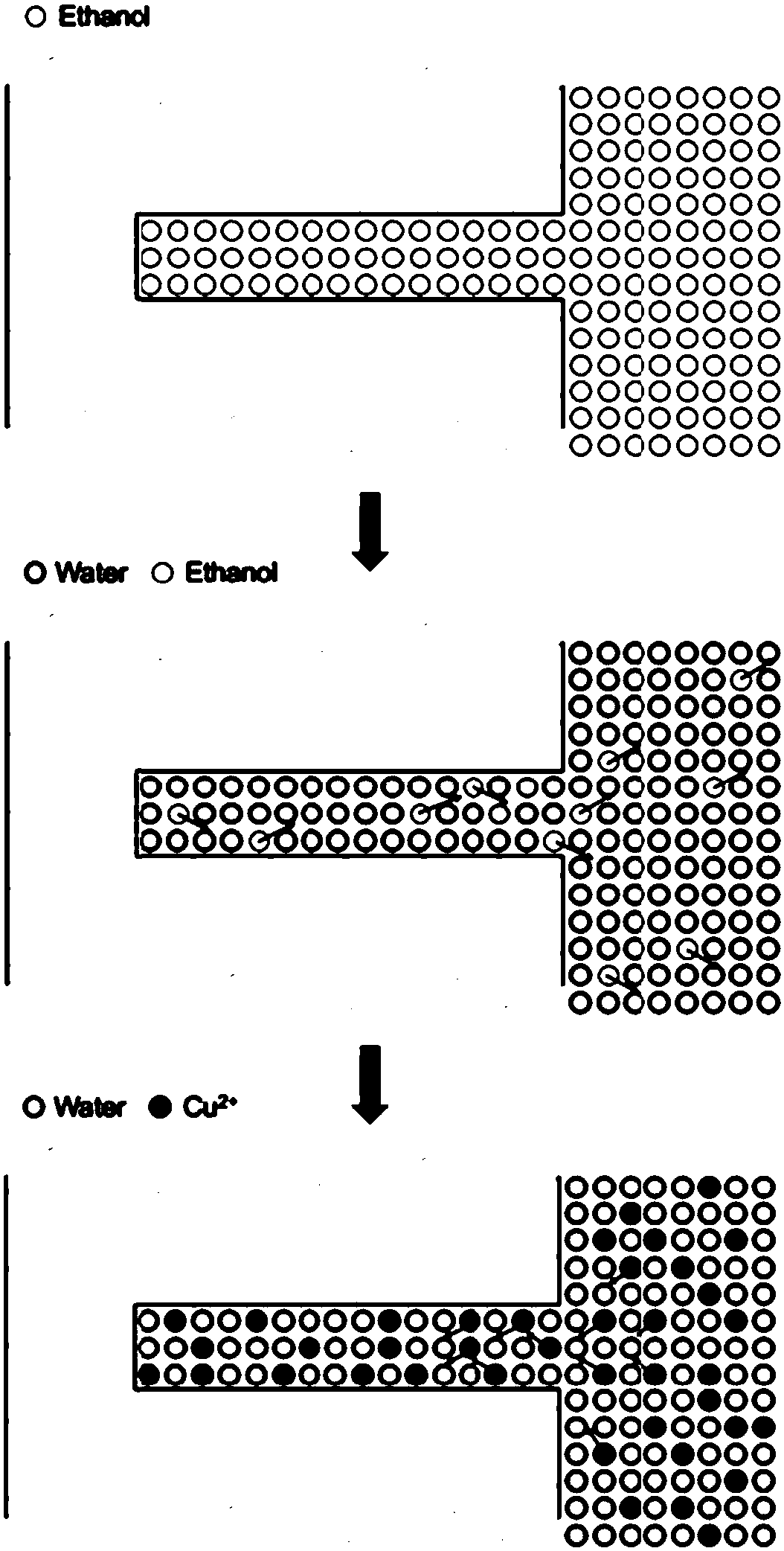

Three-step pre-wetting method of through-silicon-via plating

ActiveCN107833858ALow costReduce processing timeSemiconductor/solid-state device manufacturingSemiconductor devicesDiameter ratioCopper

The invention discloses a three-step pre-wetting method of through-silicon-via plating. The method comprises a step of immersing a through-silicon-via wafer of a seed copper layer in an infiltration liquid and obtaining an initial wetted wafer when the through-silicon-via wafer of the seed copper layer is completely wetted, a step of immersing the initial wetted wafer into deionized water to obtain a re-wet wafer, and a step of immersing the re-wet wafer into an plating solution such that solute in the plating solution is diffused into a through silicon via to realize the internal infiltrationof the through silicon via. According to the method, the infiltration of the through silicon via with a higher depth-diameter ratio can be achieved, a problem of seed layer falling is not caused, thecost is reduced, the process time is greatly shortened, and the efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

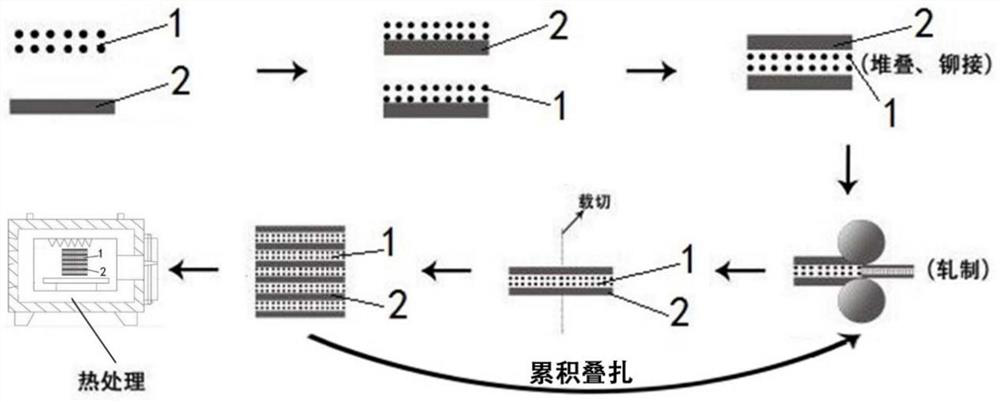

High-entropy alloy particle reinforced metal matrix composite material and preparation method thereof

ActiveCN111672906AHigh densityGood phase diffusionFurnace typesAuxillary arrangementsHigh entropy alloysComposite plate

The invention discloses a high-entropy alloy particle reinforced metal matrix composite material and a preparation method thereof. The method comprises the following steps of 1, taking two metal plates with the same size, uniformly coating high-entropy alloy particles on the surface of the metal plates, and then sequentially stacking, riveting and rolling the two metal plates to form a composite plate; 2, carrying out accumulative stitch welding on the composite plate, and cutting, stacking and riveting each time of the accumulative roll bonding until the thickness of a lamination reaches therequired thickness to form a composite material; and 3, carrying out heat treatment on the composite material after accumulative roll bonding, so that a diffusion layer is formed between the high-entropy alloy particles and the metal plates, and the high-entropy alloy particle reinforced metal matrix composite material is obtained. The high-entropy alloy particle reinforced metal matrix compositematerial with improved strength and good plastic toughness is obtained.

Owner:CHANGAN UNIV

Formula and preparation method of nano and nano-micron carbon material-reinforced ultrafine grain surface layer tissue and steel material with surface layer structure

ActiveCN109852924AAchieve infiltrationImprove wear resistanceSolid state diffusion coatingMicron scaleCarbon nanotube

The invention provides a formula of the nano-and nano-micron carbon material-reinforced ultrafine grain surface tissue. The formula comprises a component A, the component A is composed of at least onecomponent of nano-or nano-micron-scale diamond, a carbon nano tube, graphene and fullerene, multi-element thermal diffusion and heat treatment are carried out on the surface layer of the steel or steel product through the nano and nano-micron carbon material, so that the infiltration of the material and the reconstruction of the surface particle reinforced continuous gradient ultra-fine grain structure are realized, and the surface layer and the deep surface layer of the steel or steel product are nano-carbon material reinforced continuous gradient ultrafine grain structures with ultrahigh mechanical physical properties. The nano-micron carbon material and the nano-micron carbon material are mutually used as a main dispersing agent and an infiltration promoting agent, the modified nano-nano-micron carbon material and other dispersing agents are combined through mechanical and chemical methods, a mixture of the penetration enhancer is applied to the surface of steel or steel products and is diffused for several hours under vacuum or anaerobic conditions to achieve high-strength multi-element thermal diffusion of the components into the steel matrix.

Owner:贾春德

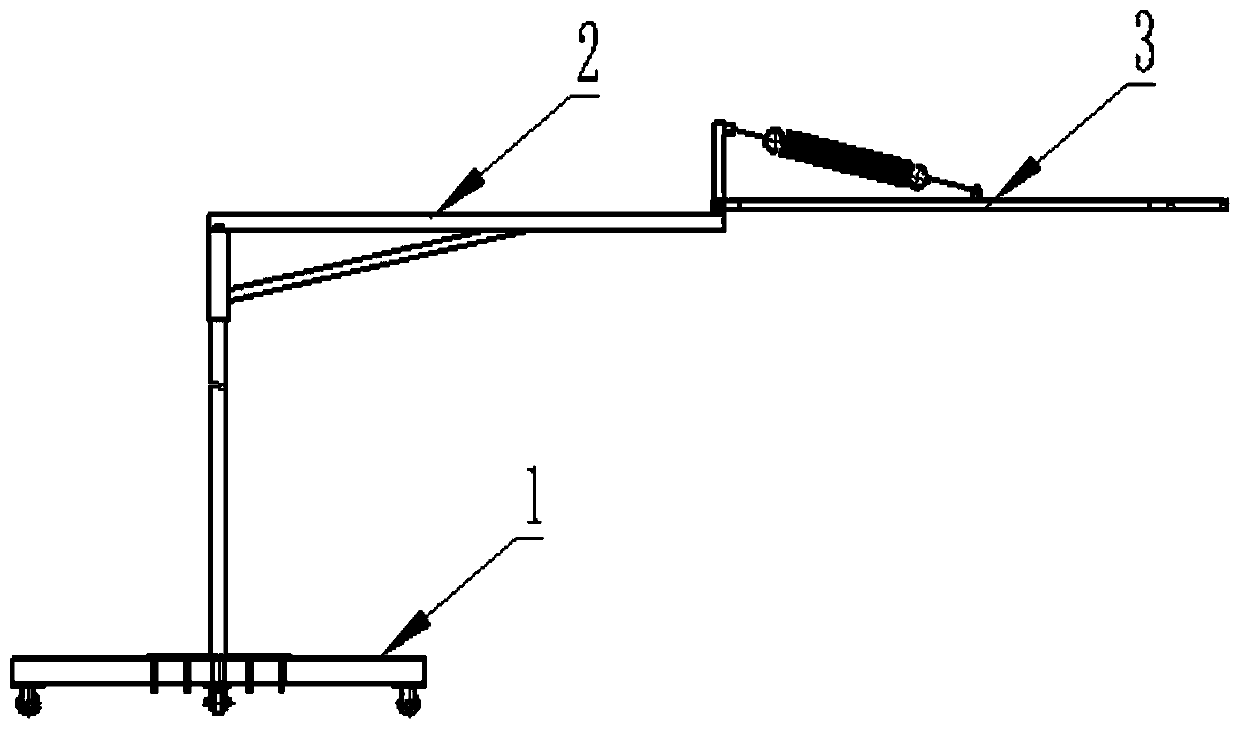

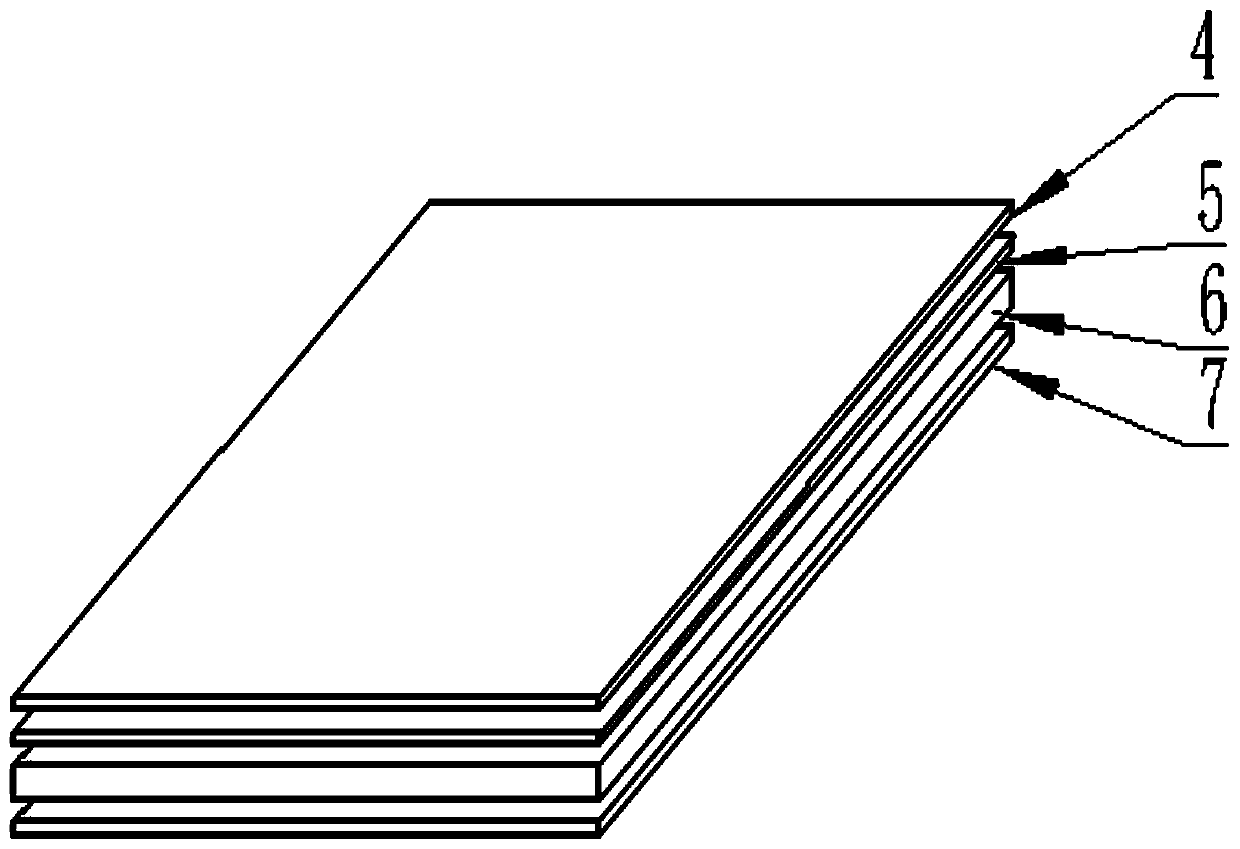

Spraying method glass steel floating disc and construction method

ActiveCN110077731AImprove product qualityAchieve infiltrationEngine sealsLiquid surface applicatorsFiberLow speed

The invention discloses a spraying method glass steel floating disc and a construction method. A floating disc plate of the floating disc comprises a lower conducting layer, a lower glass steel layer,a polypropylene honeycomb layer, an upper glass steel layer and an upper flame retardant conducting layer. A main tool is a glass steel spraying gun; the glass steel spraying gun pulls out continuousglass fibers through a quick motor; scissors are used for quickly cutting the fibers; a high-pressure pump sends out resins; and the resins, the fibers and a proper amount of curing liquid are mixedfor high-speed spraying to achieve the purpose of quick construction. The continuous glass fibers are used for replacing hand pasting method short-cut felts and glass fiber cloth. The continuous glassfibers are manufactured by such processes as high-temperature melting, wire drawing, winding and weaving with glass as raw materials; and main components are silicon dioxide, aluminum oxide, calciumoxide, boron oxide, magnesium oxide and sodium oxide. The constraints of low efficiency and low speed of a hand pasting glass steel floating disc can be solved; the purposes of shorting the construction period, simplifying the process and improving the product quality in the glass steel floating disc construction process are achieved; and the labor cost can be effectively saved.

Owner:沃德林科环保设备(北京)有限公司

Anti-washout anti-erosion ecological vegetation net mat

The invention belongs to the technical field of flexible slope protection and particularly relates to an anti-washout anti-erosion ecological vegetation net mat. According to the main technical scheme, the net mat comprises a folding net, grass seed adhering paper and a top net layer are laid on the upper portion of the folding net, and a geotextile layer and a ground net layer are fixedly connected with the bottom of the folding net in sequence. According to the ecological vegetation net mat of the structure, soil fixation, vegetation and side slope protection can be achieved, and the situations are effectively avoided that the thickness of a multi-layer composite ecological protection mat is limited, the rainwater flow enters the bottom of the protection mat, water and soil loss of the bottom is caused, the side slope is collapsed, and the ecological environment of side slope vegetation is damaged. The mat has the advantages of simple structure and convenient construction.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

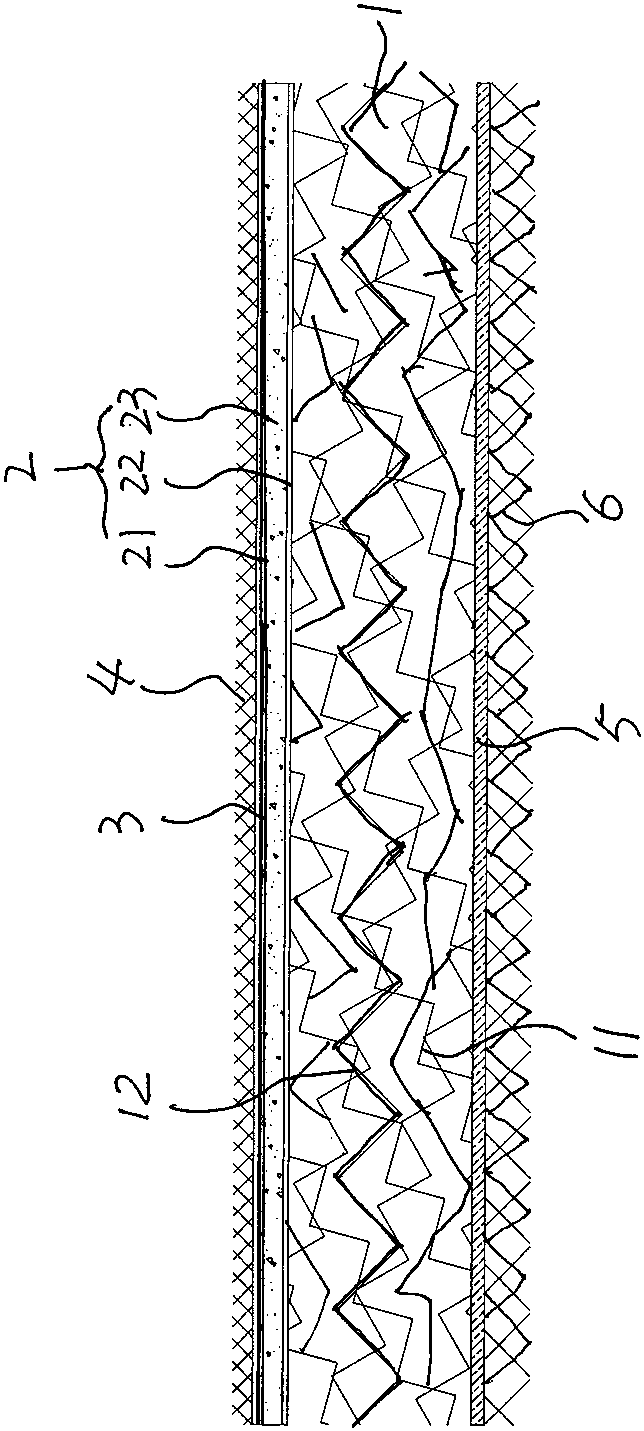

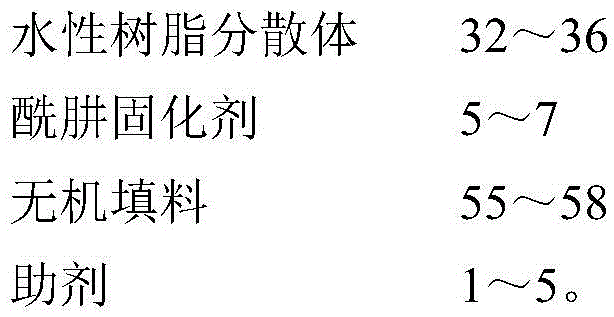

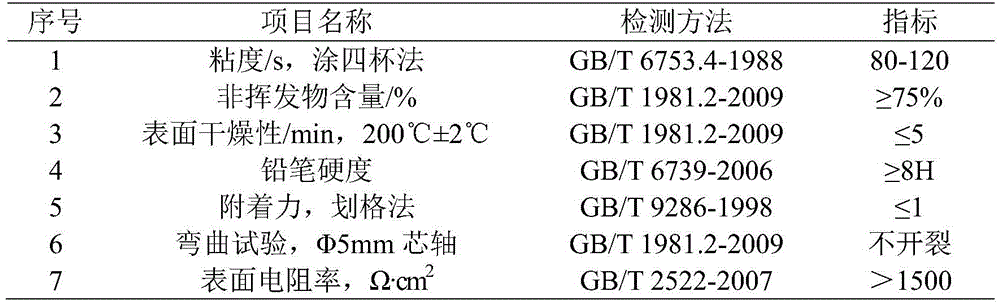

Water-soluble silicon steel sheet insulating paint and preparation method thereof

The invention relates to a water-soluble silicon steel sheet insulating paint which comprises the following components in parts by weight: 32-36 parts of water-based resin dispersion, 5-7 parts of hydrazide curing agent, 55-58 parts of inorganic filler and 1-5 parts of assistant. By using the polyurethane modified epoxy resin as the dispersion base, since the polyurethane has the characteristics of excellent adhesiveness and excellent flexibility, the modified water-soluble silicon sheet paint film has high adhesiveness, can not easily peel under the action of punching vibrations or external force, and implements favorable insulation effect. The motor has the advantages of longer service life and high reliability.

Owner:ZHEJIANG RONGTAI TECH ENTERPRISE

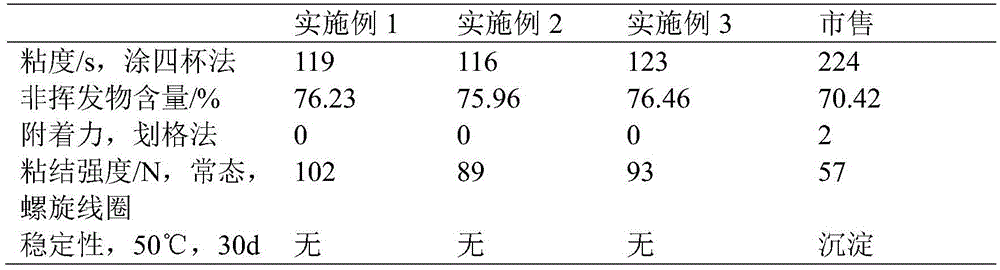

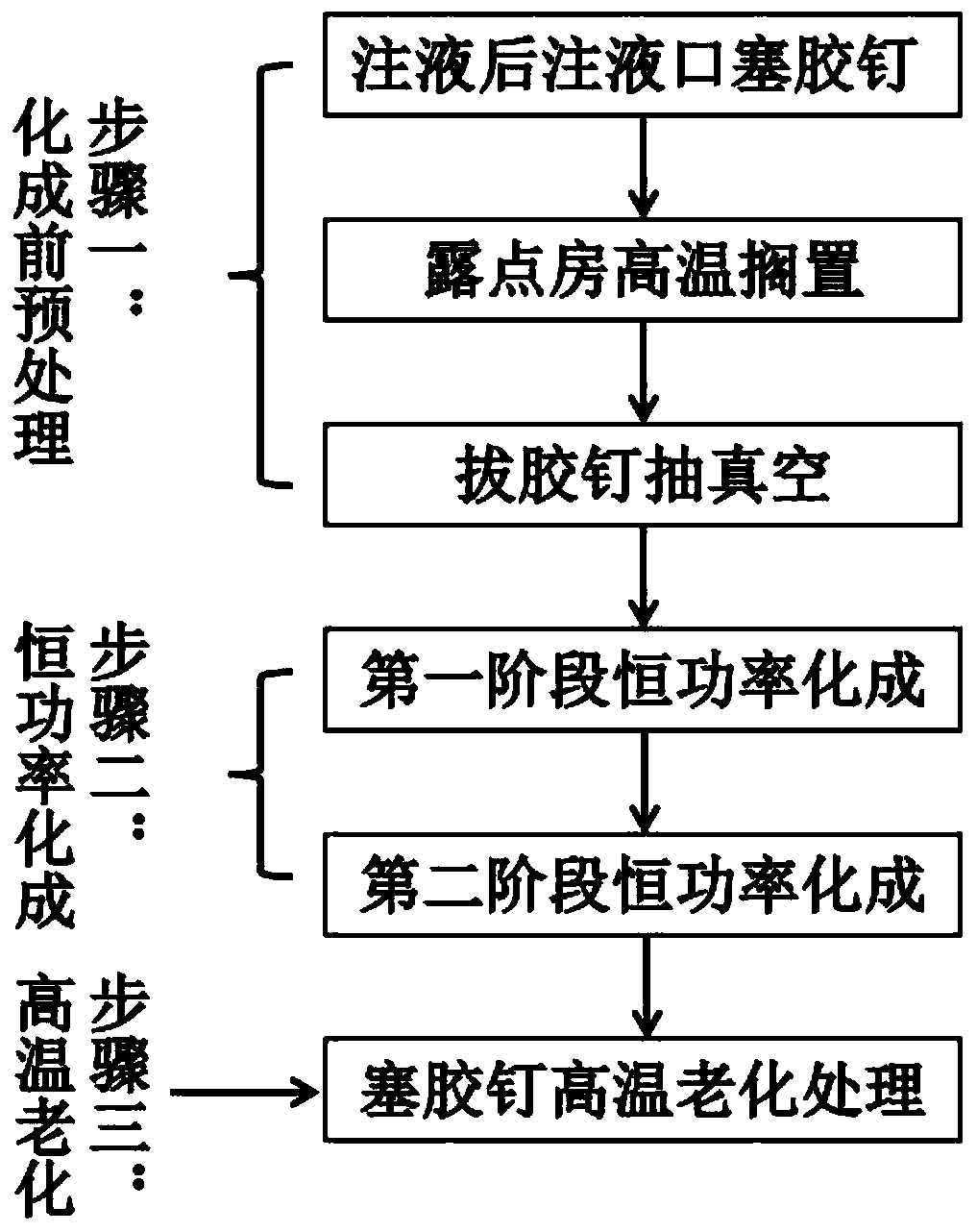

Formation method of lithium iron phosphate battery with square aluminum shell for energy storage

ActiveCN111106405AAchieve infiltrationAchieve stabilityFinal product manufactureSecondary cells charging/dischargingComposite materialElectrical battery

The invention discloses a formation method of a lithium iron phosphate battery with a square aluminum shell for energy storage. The formation method mainly comprises three steps of high-temperature shelving before formation, two-stage constant-power high-temperature formation and high-temperature aging after formation. The method comprises the steps of 1 high-temperature shelving before formation:firstly, plugging a glue nail into a battery liquid injection port after liquid injection, putting the battery liquid injection port in a high-temperature room for shelving, fully infiltrating a polepiece, stabilizing, pulling out the glue nail, putting on a high-temperature formation cabinet, and vacuumizing; 2 high-temperature constant-power formation: performing two-stage constant-power formation treatment on the pretreated battery in a high-temperature state and a vacuum state; and 3 high-temperature aging: plugging the glue nail into the battery subjected to high-temperature constant-power formation, and carrying out aging treatment under a high-temperature environment condition, so that the film formation on the surface of the negative electrode material is more stable. According to the method, aiming at the use mode and characteristics of the energy storage battery, a high-temperature negative-pressure constant-power formation mode is adopted, so that the SEI film formation stability of the energy storage lithium iron phosphate battery is improved, and large-scale industrial production is easy to realize.

Owner:SHANGHAI ELECTRICAL GUOXUAN NEW ENERGY TECH CO LTD

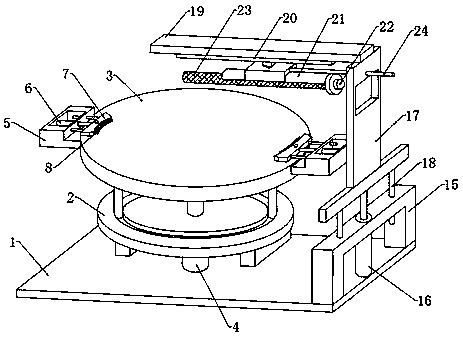

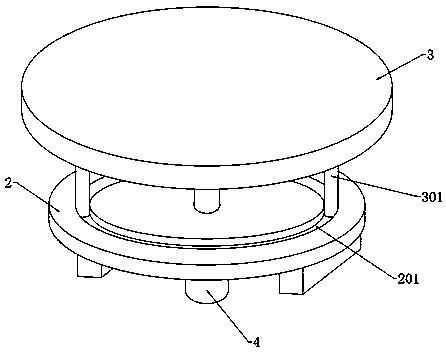

Rust removal treatment device for surface of disc-type metal casting

ActiveCN111266935AImprove processing qualityImprove stabilityGrinding carriagesGrinding drivesCircular discOil and grease

The invention discloses a rust removal treatment device for the surface of a disc-type metal casting and belongs to the technical field of rust removal for castings. According to the rust removal treatment device for the surface of the disc-type metal casting, through cooperation of a pair of casting positioning mechanisms and a polishing roller capable of moving in the up-down and left-right directions, after the disc-type metal casting is positioned, based on different to-be-treated surfaces of the casting, the horizontal position and vertical position of the polishing roller are adjusted toperform targeted treatment on the plane and convex surface of the casting, and the treatment flexibility of the device is effectively improved. An oil seal mechanism capable of being pushed is additionally arranged in the casting positioning mechanism, under pushing of an oil injection piston, the oil seal mechanism makes liquid fat permeate into an oil seal sponge, the oil seal sponge and the outer end wall of the casting form a layer of oil film, and meanwhile the oil seal sponge with some oil not only effectively improves the tightness of adhering to the outer side of the casting, but alsoeffectively achieves a protection function on the casting when clamped.

Owner:济南市平阴鑫森有限责任公司

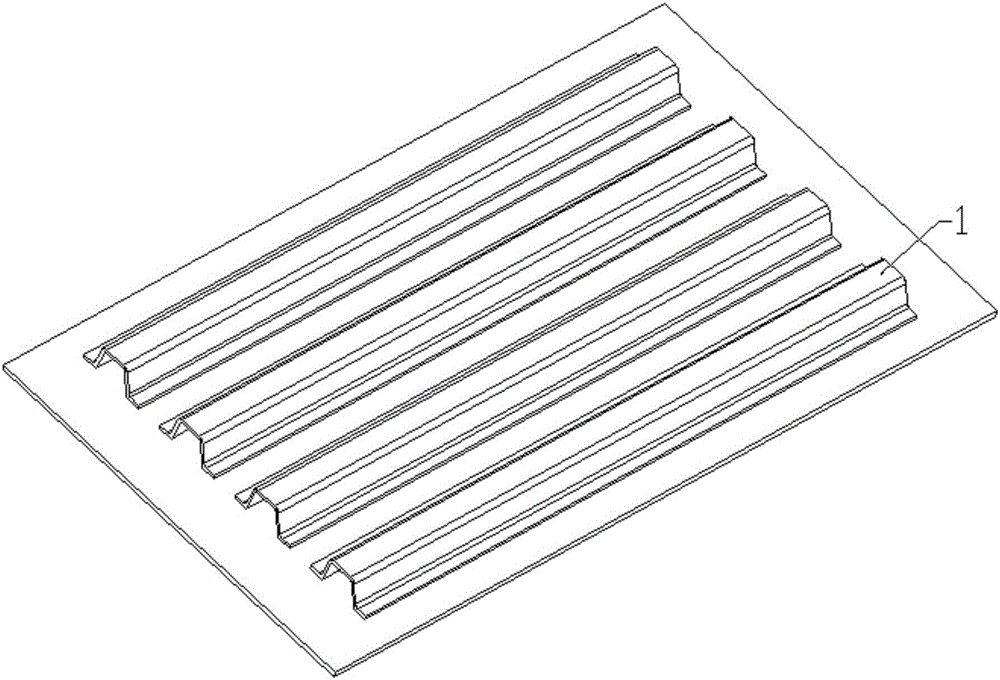

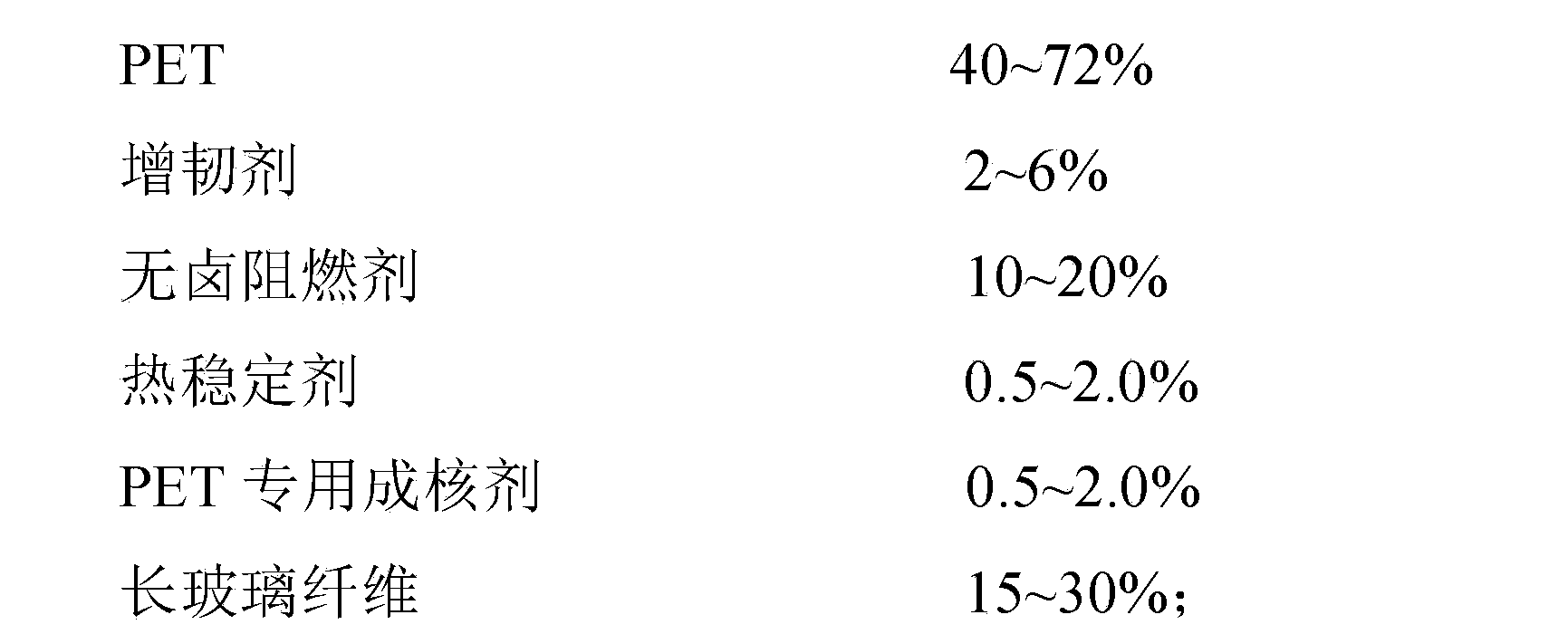

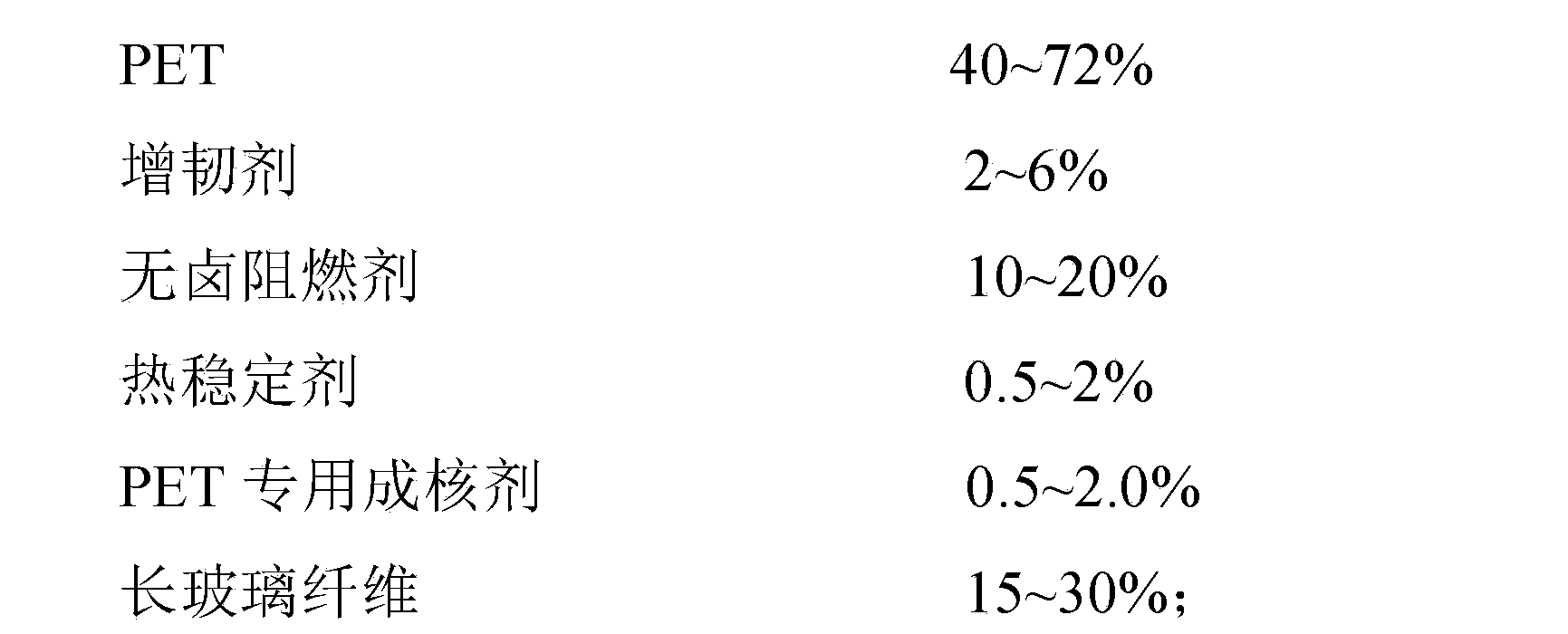

Halogen-free fire retardation long glass fiber reinforced PET composite material and preparation method thereof

ActiveCN103834142AAchieve infiltrationSolve serious defects of decompositionAlkali freeFlexural modulus

The present invention discloses a halogen-free fire retardation long glass fiber reinforced PET composite material, which comprises, by weight, 40-72% of PET, 2-6% of a toughening agent, 10-20% of a halogen-free fire retardation agent, 0.5-2.0% of a thermal stabilizer, 0.5-2.0% of a special PET nucleating agent and 15-30% of long glass fibers, wherein the long glass fibers are special LFT alkali-free continuous long glass fibers for PET. The prepared material has characteristics of high fluidity, excellent heat resistance, high rigidity, high impact, high dimensional stability, excellent fire retardation and high CTI value, wherein the test results show that the tensile strength is more than or equal to 100 MPa, the flexural modulus is more than or equal to 6500 MPa, the notched impact strength is more than or equal to 15 kJ / m<2>, the heat distortion temperature (1.80 MPa) is more than or equal to 245 DEG C, the fire retardation grade achieves UL94 1.6mmV-0, and the CTI value is more than or equal to 500 V. In addition, the high temperature and low temperature double melt infiltration tank series connection technology is adopted to solve the high temperature decomposition disadvantage of the halogen-free fire retardation agent.

Owner:JIANGSU KINGFA SCI & TECH ADVANCED MATERIALS CO LTD

Production method of duck seasoned with soy sauce

InactiveCN106261874AKeep the original flavorPreserve the original structureClimate change adaptationFood ingredient as taste affecting agentFlavorCooking process

The invention provides a production method of a duck seasoned with soy sauce. According to the technical scheme, aiming at relieving nutrition loss caused in the production process, a conventional production technology is improved from two aspects, wherein on one hand, the dosage of salt is reduced, a white bar duck is salted in a pickling process by using miso soup with low salt content, diluent soup is adopted in the follow-up sauce cooking process, and direct contact between duck meat and the salt is reduced as much as possible, so that an original structure of protein is retained, and the flavor is not changed. Besides, boiling is performed in a mode of low temperature of 70 to 75DEG C, and uniform heating of the inside and the outside of a duck body is guaranteed by a mode of filling an inner cavity of the duck body with glass beads; meanwhile, the boiling time is prolonged, and the meat of the duck body is still enabled to be thoroughly cooked and become soft and pappy under the condition of relatively low temperature. By means of a low-temperature heating mode, nutrients can be retained as much as possible; meanwhile, original flavor of duck meat is favorably guaranteed, and a mouth feel level is improved.

Owner:天津滨海新区鸿博鸿食品有限公司

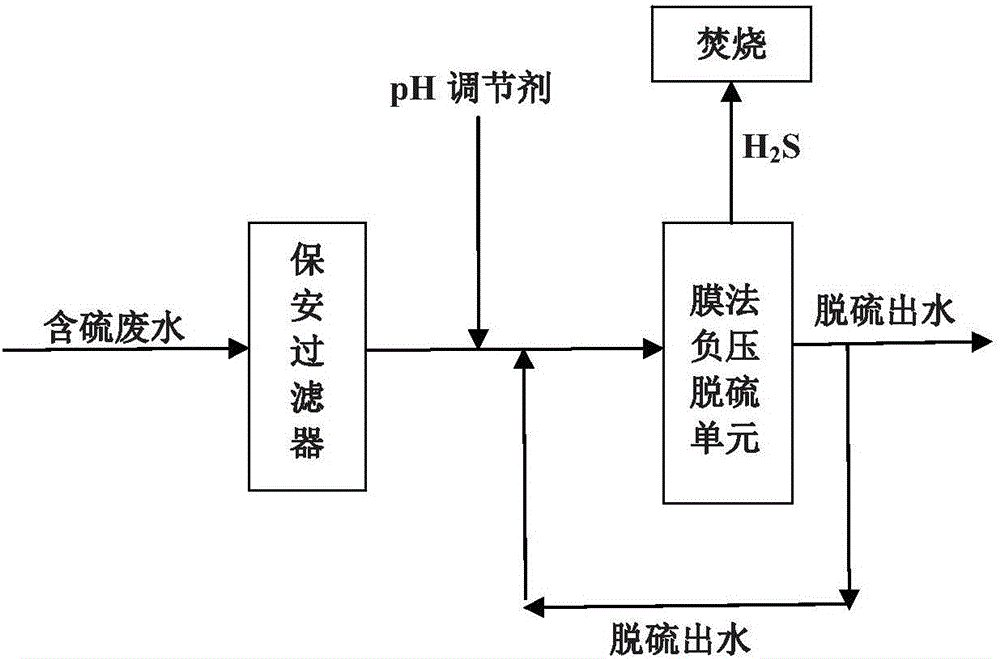

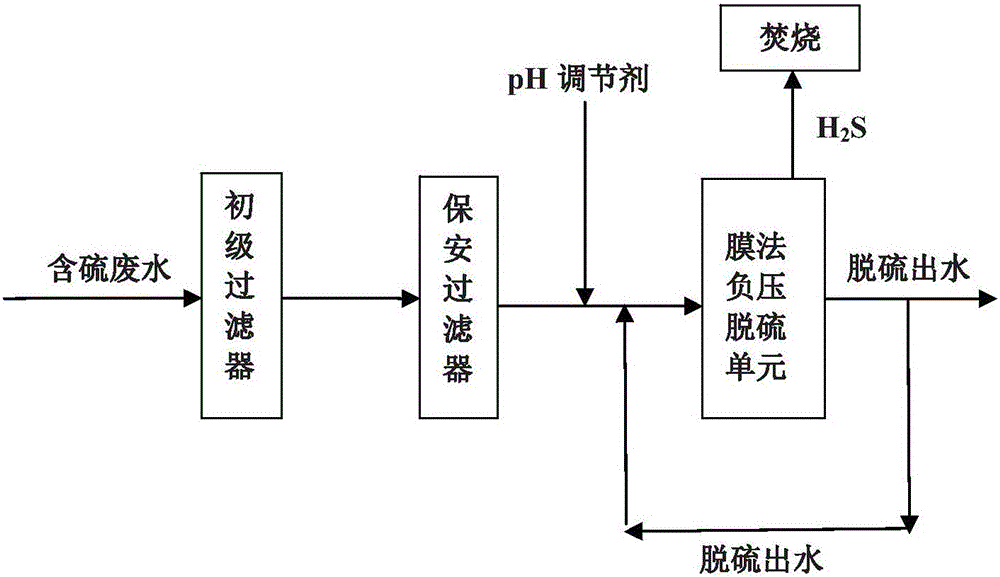

Method for processing sulfur-containing waste water

InactiveCN106256783AAchieve absorptionAchieving Wetting of the Hydrophobic MembraneMultistage water/sewage treatmentMembrane methodIndustrial waste water

The invention relates to the field of industrial waste water processing, and especially relates to a method for processing sulfur-containing waste water. The method comprises the following steps: 1) adjusting the pH value of the sulfur-containing waste water to 4-6 by employing a pH conditioning agent; and 2) inputting the sulfur-containing waste water after pH regulation into a membrane method negative pressure desulfurization unit for desulphurization processing. The method by employing the membrane method negative pressure desulfurization technology for processing sulfur-containing waste water has the advantages of simple equipment, high automation degree, easy operation maintenance, strong environmental adaptability, less land occupation, and high desulphurization efficiency, can realize the skid-mounted processing, and greatly reduces the operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

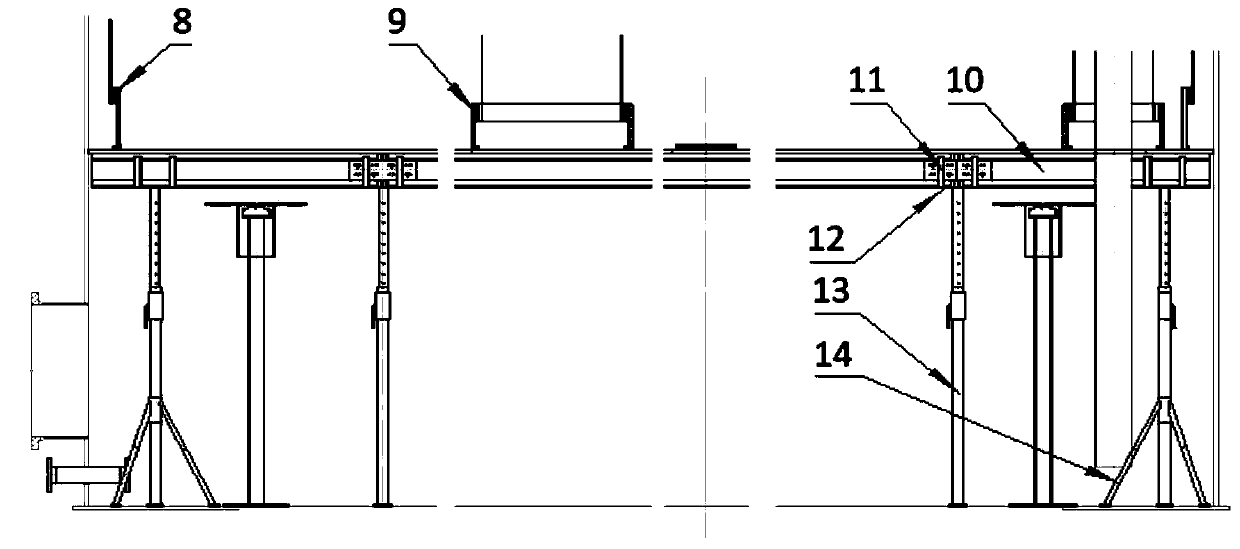

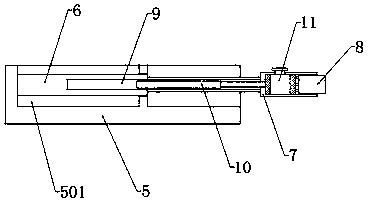

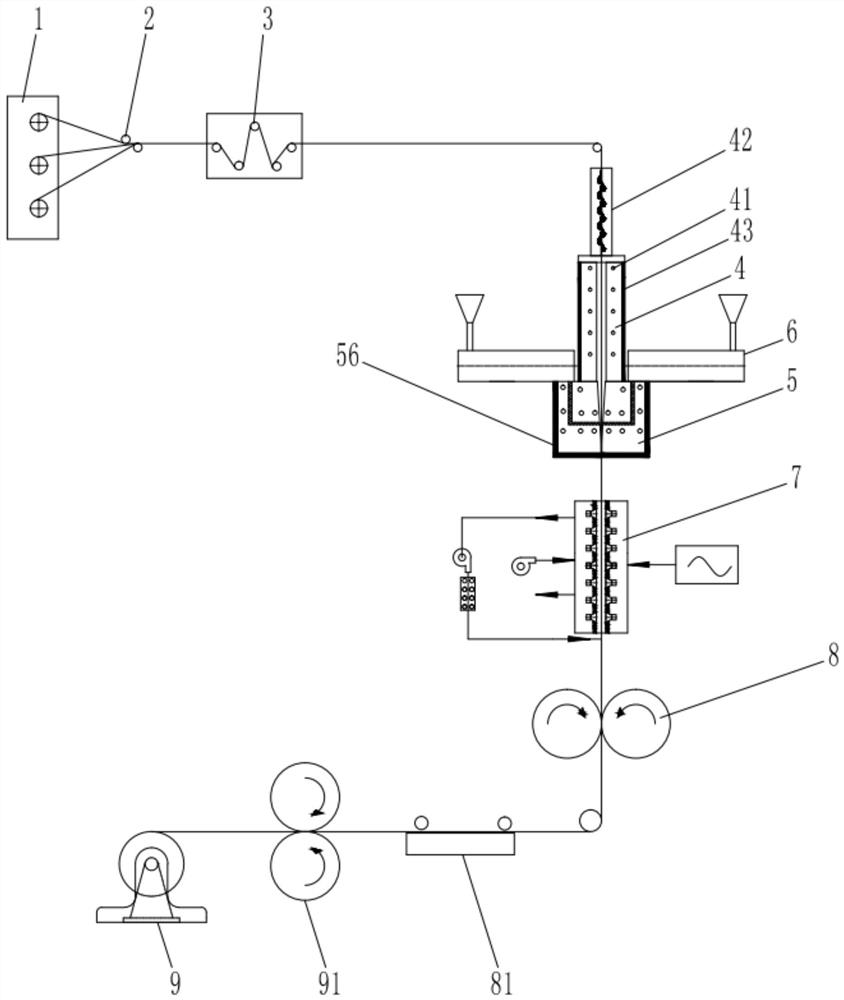

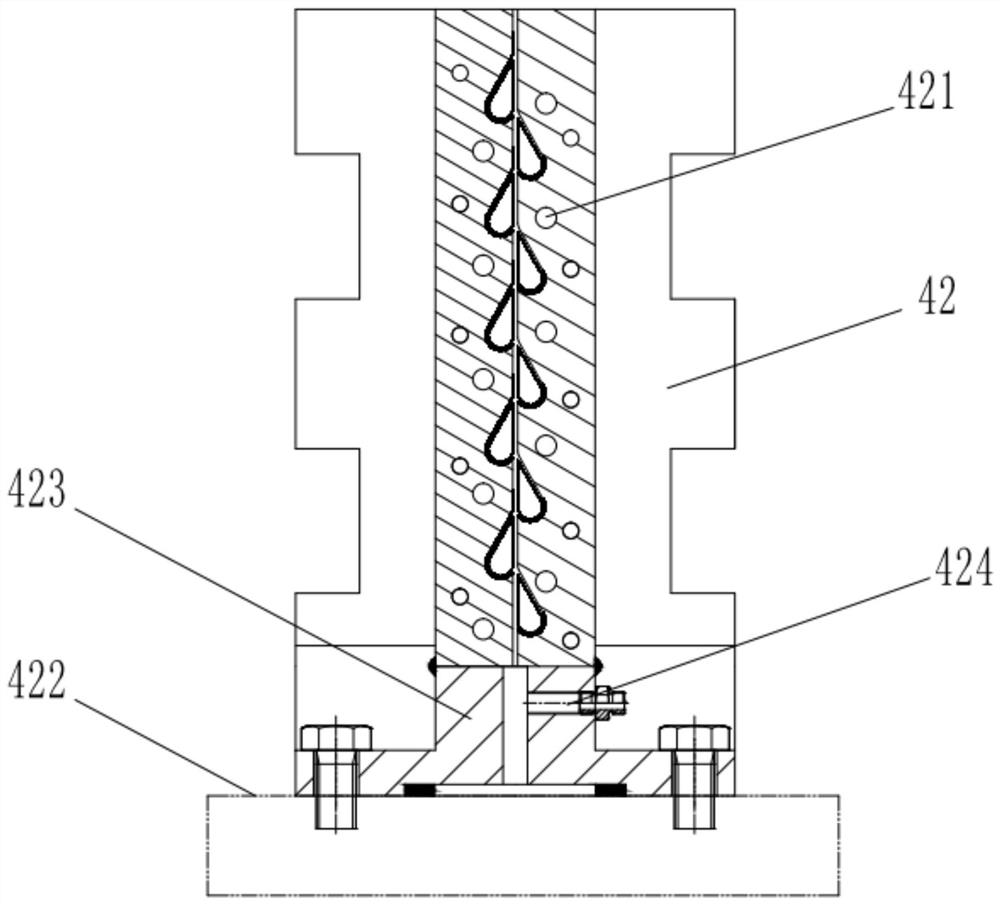

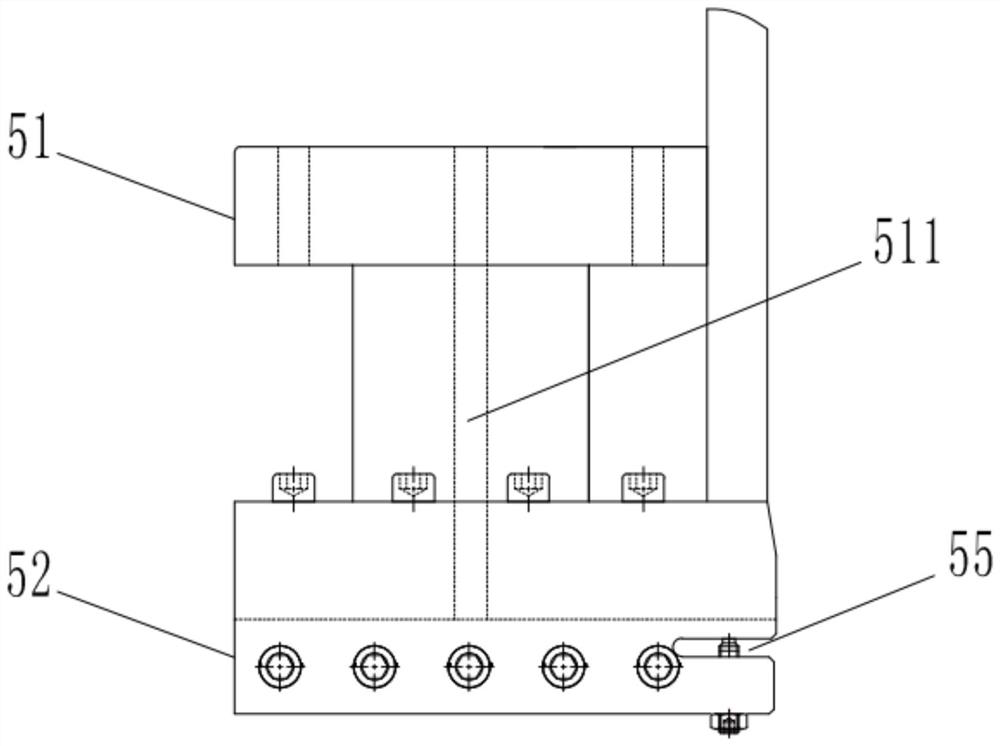

High-frequency vibration continuous fiber prepreg production device

The invention discloses a high-frequency vibration continuous fiber prepreg production device, relates to the technical field of continuous fiber prepreg production, and is mainly used for solving the problem that prepregs are difficult to soak in methods or equipment adopted for continuous fiber prepreg production at present. The primary structure of the device is that the device comprises a creel, a guide roller group, a yarn spreading roller group, a drying oven, an extrusion forming mold group, an ultrasonic impregnation module group, an extrusion roller group, a cooling platform, a pull roll group and a winding mechanism which are arranged in sequence. According to the high-frequency vibration continuous fiber prepreg production device provided by the invention, continuous fibers before being coated with resin are vacuumed through a negative pressure vacuum channel, and ultrasonic vibration is applied to the continuous fibers coated with the resin through ultrasonic impregnation modules, so that the fibers can be fully infiltrated by the resin.

Owner:四川兴宇航科技有限公司

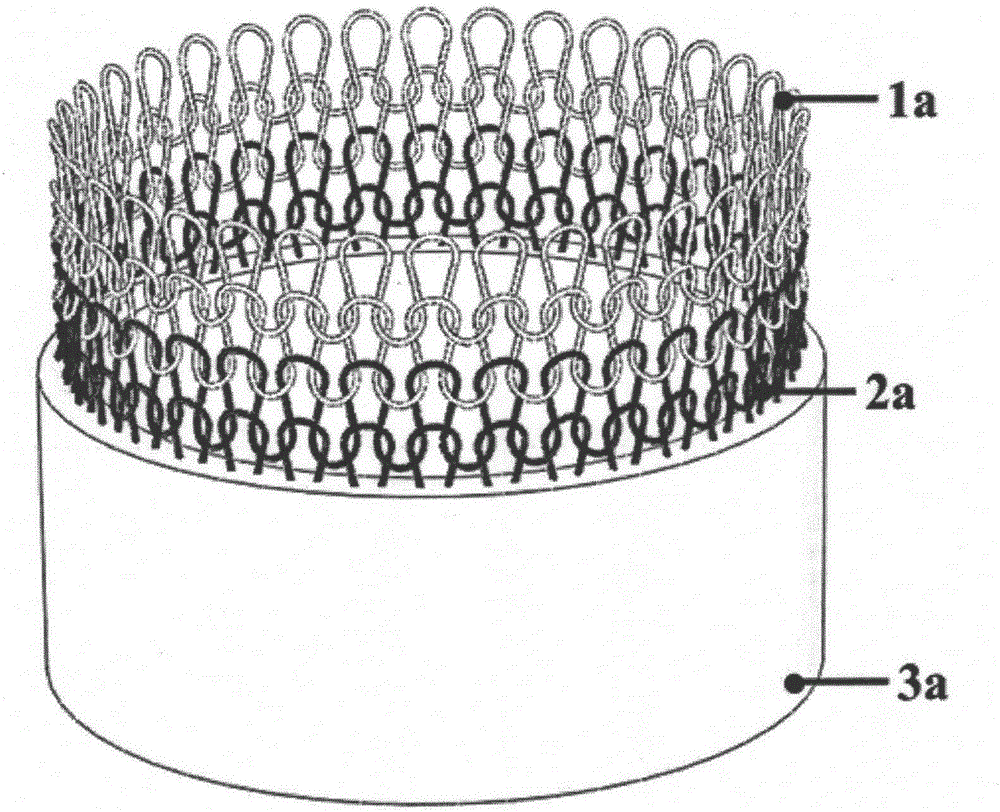

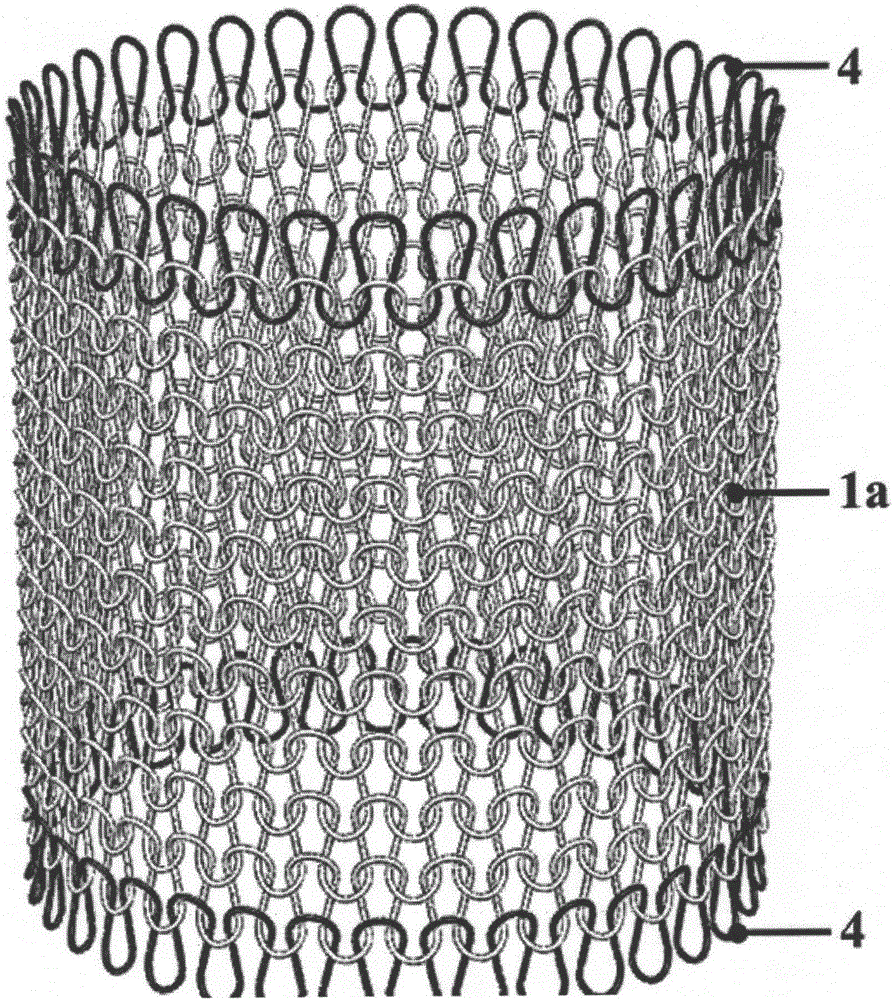

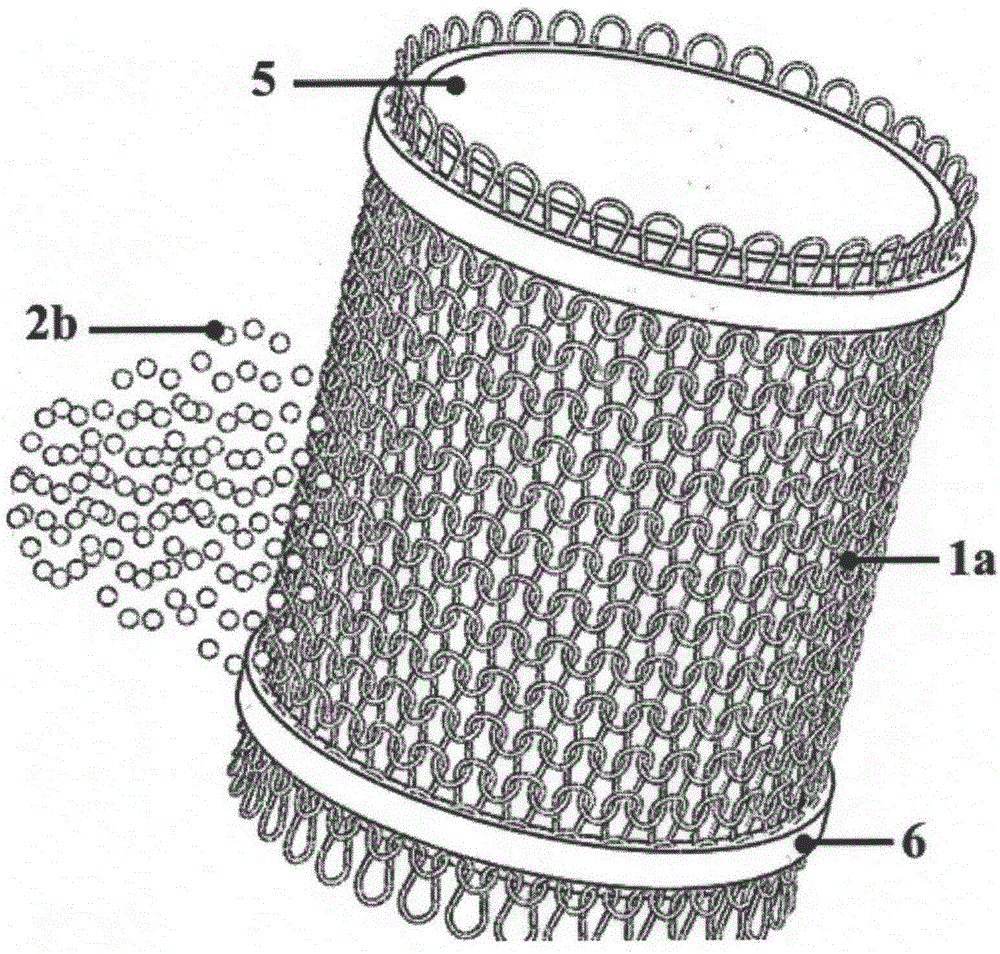

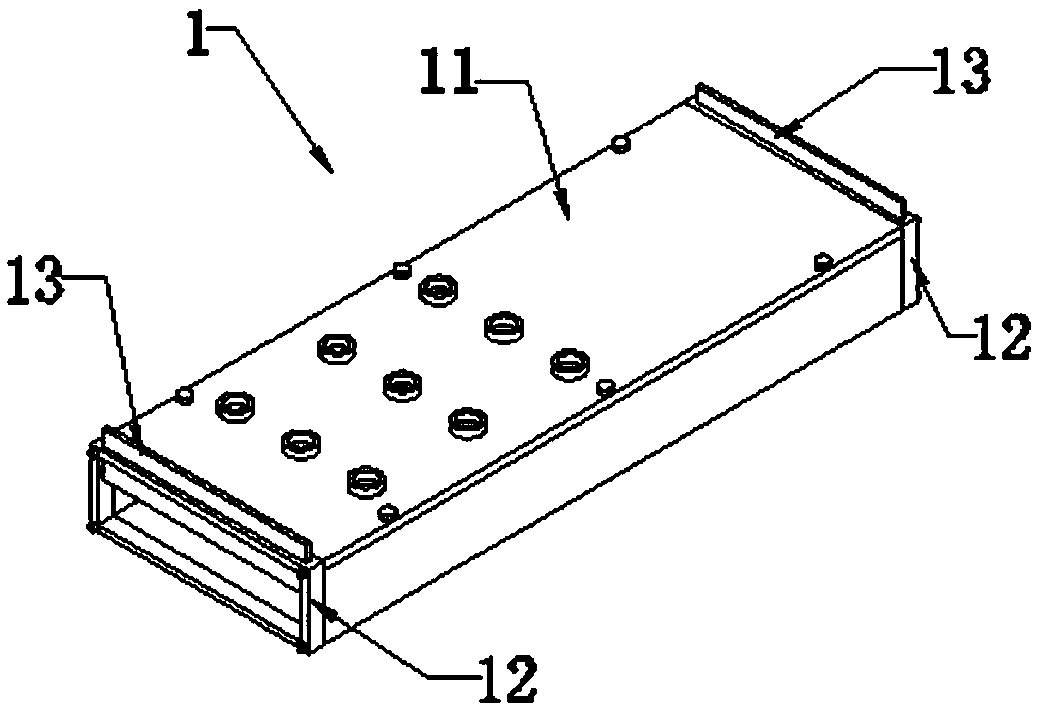

Precision seamless spinning base flat belt and preparation method thereof

ActiveCN106217705AIntegrity guaranteedAvoid subsequent jointsWeft knittingLinear densityRubber solvent

The invention discloses a precision seamless spinning base flat belt and a preparation method thereof. The precision seamless spinning base flat belt is formed by compounding integrally formed fabric reinforcement, a polyurethane rubber friction layer and an adhesion layer. The preparation method comprises the following steps: integrally preparing a seamless flat knitted fabric through common multifilaments by using a customized circular knitting machine, and leading high-linear-density and high-elasticity multifilaments into two ends of the fabric; cleaning and drying the fabric reinforcement, and successively attaching an adhesive and rubber cement to the surface of the fabric in a superfine liquid drop mode by a spraying method; and carrying out processes such as rubber plate adhesion, vulcanization and cutting on an obtained spinning base to obtain the precision seamless spinning base flat belt. The adhesive is uniformly attached to the surface of the precision seamless spinning base flat belt prepared by the invention, and while adhesion fastness of the fabric and a rubber layer is improved, the use amount of the adhesive is greatly reduced. The precision seamless spinning base flat belt has the advantages of high efficiency and environmentally friendliness.

Owner:DONGHUA UNIV +1

Fibre-reinforced composite material impregnation system as well as resin fibre mixing mould thereof and application thereof

The invention discloses a fibre-reinforced composite material impregnation system. The fibre-reinforced composite material soaking system comprises dosing equipment, mixing equipment, a storage tank and a resin fibre mixing mould, wherein the dosing equipment supplies a resin matrix material; the mixing equipment is connected with the dosing equipment, and is configured to uniformly mix the resinmatrix material from the dosing equipment; the storage tank is connected with the mixing equipment; a supercharge hole is formed in the storage tank; a plurality of supply holes are formed below the storage tank; a plurality of glue injecting holes of the resin fibre mixing mould are arranged below the material supply holes in a one-to-one correspondence mode. According to the soaking system, themechanization degree is high, efficient and stable production efficiency is achieved, and the problems that fibre and resin matrix are impregnated unevenly as multiple persons alternately rub in turn,the cost is high, the dimension of a formed product is limited and the like are solved.

Owner:洛阳科博思新材料科技有限公司

Multipurpose high-strength integrated solid carbon fiber inhaul cable and preparation method thereof

PendingCN112761070AThe production process is simpleAchieve controllabilityBridge structural detailsFiberTitanium alloy

The invention discloses a multipurpose high-strength integrated solid carbon fiber inhaul cable which comprises an inhaul cable body which is formed by twisting, compacting and curing a pre-impregnated carbon fiber winding formed by winding pre-impregnated carbon fibers for multiple times; the cable comprises an inhaul cable main body and closed rings formed at the two ends of the inhaul cable main body, the inhaul cable main body is of a solid structure. The fiber length direction of the pre-impregnated carbon fiber is the same as the length direction of the inhaul cable main body; The cable also includes a wire winding formed by winding and tightening a wire on the inhaul cable main body and two alloy joints respectively fastened in the closed rings, the alloy joints are made of non-cast stainless steel or titanium alloy, the alloy joints are provided with connecting holes, and the axis direction of the connecting holes is perpendicular to the length direction of the inhaul cable main body. Complete infiltration and combination of dense carbon fibers and preimpregnated resin glue liquid are truly achieved through twisting and fastening of the preimpregnated carbon fibers, the requirements for high strength and light weight are met by matching with use of an alloy connector, installation is easy, and the use length is not limited.

Owner:江苏集萃碳纤维及复合材料应用技术研究院有限公司

Lithium iron phosphate battery cell, high-energy-density lithium iron phosphate battery and preparation method of battery

InactiveCN111244371AEnsure safetyIncrease energy densityPhosphatesFinal product manufactureLithium iron phosphateHigh energy

The invention discloses a lithium iron phosphate battery cell, a high-energy-density lithium iron phosphate battery and a preparation method of the battery, wherein the lithium iron phosphate batterycell is prepared by sequentially overlapping and winding a positive pole piece, a first diaphragm, a negative pole piece and a second diaphragm, the positive pole piece comprises a positive current collector and a positive coating coated on the surface of the positive current collector, and the negative pole piece comprises a negative current collector and a negative coating coated on the surfaceof the negative current collector. According to the invention, the monomer energy density of the lithium iron phosphate battery is improved to 190-195 Wh / kg, and the energy density of the system aftergrouping exceeds 140 Wh / kg, so that the endurance requirement of a passenger vehicle of more than 400 km is met, and a solution is provided for the wide application of the lithium iron phosphate battery in the field of passenger vehicles.

Owner:QINGDAO GUOXUAN BATTERY CO LTD

Resin flow control method for RFI integral forming of cap type reinforced rib wallboard

InactiveCN111152479AShorten the timeImprove molding efficiencyResin-Based CompositeMechanical engineering

The invention belongs to the technical field of low cost manufacturing of high performance resin-based composite materials, and relates to a resin flow control method for RFI integral forming of a captype reinforced rib wallboard. In a conventional RFI process, a resin is divided at the root part of a cap type reinforced rib and flows to the cap top along layers between two sides of the cap typereinforced rib to generate dry spots at the cap top and the cap bottom, so that a part is scraped. By considering the structural characteristic of the cap type reinforced rib wallboard and the flowingcharacteristic of the resin in the RFI process, the cap type reinforced rib wallboard is decomposed into two structural units: an annular structure and a plate shaped structure, and a resin flow model suitable for resin flow control of the annular structure and the plate shaped structure simultaneously is established to form a resin flow model for RFI integral forming of the cap type reinforced rib wallboard. The resin is guided to flow in the RFI process course by paving the resin and arranging a gas circuit according to the established resin flow model, so that a preformed body of the cap type reinforced rib wallboard is infiltrated fully.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Welding method of curved-surface microstrip antenna

InactiveCN111958079AMeet welding requirementsStrong welding adaptabilityAntenna adaptation in movable bodiesWelding apparatusStructural engineeringClose contact

The invention provides a welding method of a curved-surface microstrip antenna, and aims to provide the welding method of the curved-surface microstrip antenna, which is high in welding success rate and high in welding quality so as to meet the reliability requirement of the curved-surface microstrip antenna in long-term use. The method comprises the following steps that a clamping tool for supporting an upper pressing plate and a lower pressing plate through a fixed stand column is prepared, a pressure stand column is sleeved with a main pressure spring, and penetrates through the upper pressing plate to be connected with a main pressure nut; a layer of welding flux is printed at the bottom of the micro-strip in a steel mesh printing mode, and the micro-strip is fixed to a base, a flexible voltage-sharing plate and a rigid voltage-sharing plate through pins; auxiliary pressing plates are arranged at the four corners of the rigid voltage-sharing plate, and the auxiliary pressing plates, auxiliary stand columns and auxiliary pressure springs are fixed to the lower pressing plate through auxiliary pressure nuts to compress main pressure springs and the auxiliary pressure springs, sothat the micro-strip makes close contact with the base; and after assembly is completed, the whole clamping tool is put into a vacuum gas phase furnace to be heated, and after cooling, the tool is disassembled to complete welding of the micro-strip and the base.

Owner:10TH RES INST OF CETC

Preparation method of dye leveling agent

PendingCN110396836AAchieve infiltrationIncrease enzyme activityDyeing processOn/in organic carrierCross-linkFatty alcohol

The invention relates to a preparation method of a dye leveling agent, and belongs to the technical field of dye additives. Mixed enzymes and acrylamide are mixed for polymerization under the action of an initiator to form polyacrylamide, the enzymes are encapsulated, metal elements in mixed liquid are adsorbed, the enzyme activity is increased by using the metal elements, cross-linking with chitosan and mixed sugar is achieved under the action of an assistant, incomplete cross-linking is achieved under the action of N-methylenebisacrylamide and glutaraldehyde, and an acylating agent is used for acylation to increase active groups. When the dye leveling agent is in use, firstly the mixed enzymes increase surface active groups by partially destroying the surface of a fabric; then the dyeingagent is bonded with the surface of the fabric under the action of glutathione synthetase through an incompletely cross-linked material, and the adoption of fatty alcohol is more conductive to infiltration of raw materials; finally the dyeing agent is adsorbed on the surface of the fabric under the action of the formed polyacrylamide and loaded chitosan and is separated from the surface of the fabric with the increase of the temperature, and thus coloring can be better achieved.

Owner:李辉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com