High-entropy alloy particle reinforced metal matrix composite material and preparation method thereof

A technology of high-entropy alloys and composite materials, applied in the field of high-entropy alloy particle-reinforced metal-matrix composite materials and its preparation, can solve problems such as the formation of stable and effective metallurgical interfaces by difficult metal particles, and achieve excellent interface bonding strength, high-entropy alloy particles Uniform reinforcement distribution and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

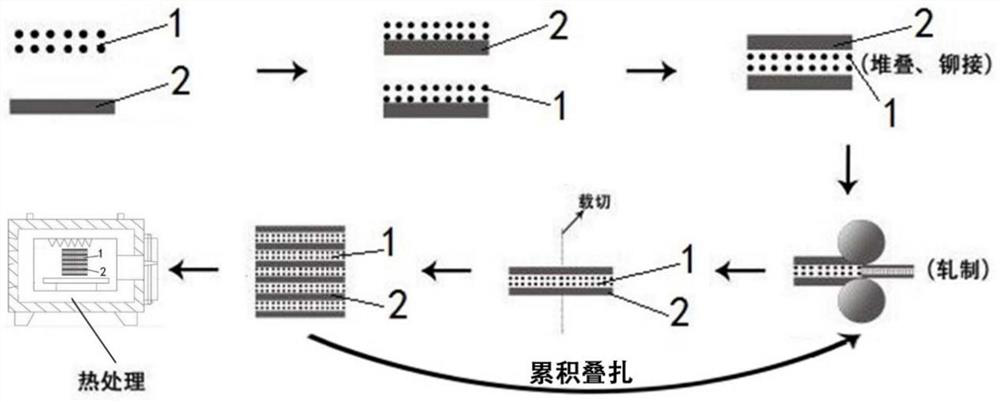

[0044] The high-entropy alloy particle 1 is made of AlCoNiCrFe, and the metal plate 2 is made of 5052Al to prepare a sandwich-structured high-entropy alloy particle-reinforced metal matrix composite. figure 1 It is the evolution diagram and process flow diagram of the preparation of the imitation sandwich structure high-entropy alloy particle reinforced aluminum matrix composite material of the present invention.

[0045] First, cut the aluminum plate with a length, width, and thickness of 400×100×1.5mm into two pieces with an equal size of 200×100×1.5mm, and treat the surface. Use acetone to clean the oil on the surface of the aluminum plate, and clean the surface of the material after cleaning with acetone. Soak in lye for 30 minutes, choose 2% NaOH solution for lye, rinse with deionized water and dry, and finally clean the surface with a wire brush to expose fresh metal on the surface. Then, the AlCoNiCrFe high-entropy alloy particle powder with a particle size of 38-75 μm ...

Embodiment 2

[0048] The high-entropy alloy particle 1 is made of AlCoNiCrFe, and the metal plate 2 is made of 5052Al to prepare a sandwich-structured high-entropy alloy particle-reinforced metal matrix composite.

[0049] This embodiment is similar to Embodiment 1, except that during surface treatment, the metal plate 2 is soaked in a NaOH solution with a concentration of 2% for 20 minutes, the number of rolling passes is 10, and the rolling temperature is 320°C. , the heat treatment temperature is 530 ℃, the holding time is 6h, and the imitation sandwich structure high-entropy alloy particle reinforced aluminum matrix composite is prepared.

Embodiment 3

[0051] The high-entropy alloy particle 1 is made of AlCoNiCrFe, and the metal plate 2 is made of 5052Al to prepare a sandwich-structured high-entropy alloy particle-reinforced metal matrix composite.

[0052] This embodiment is similar to Embodiment 1, except that during surface treatment, the metal plate 2 is soaked in a NaOH solution with a concentration of 2% for 20 minutes, the number of rolling passes is 10, and the rolling temperature is 20°C. , the heat treatment temperature is 530 ℃, the holding time is 6h, and the imitation sandwich structure high-entropy alloy particle reinforced aluminum matrix composite is prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com