Patents

Literature

40 results about "Accumulative roll bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

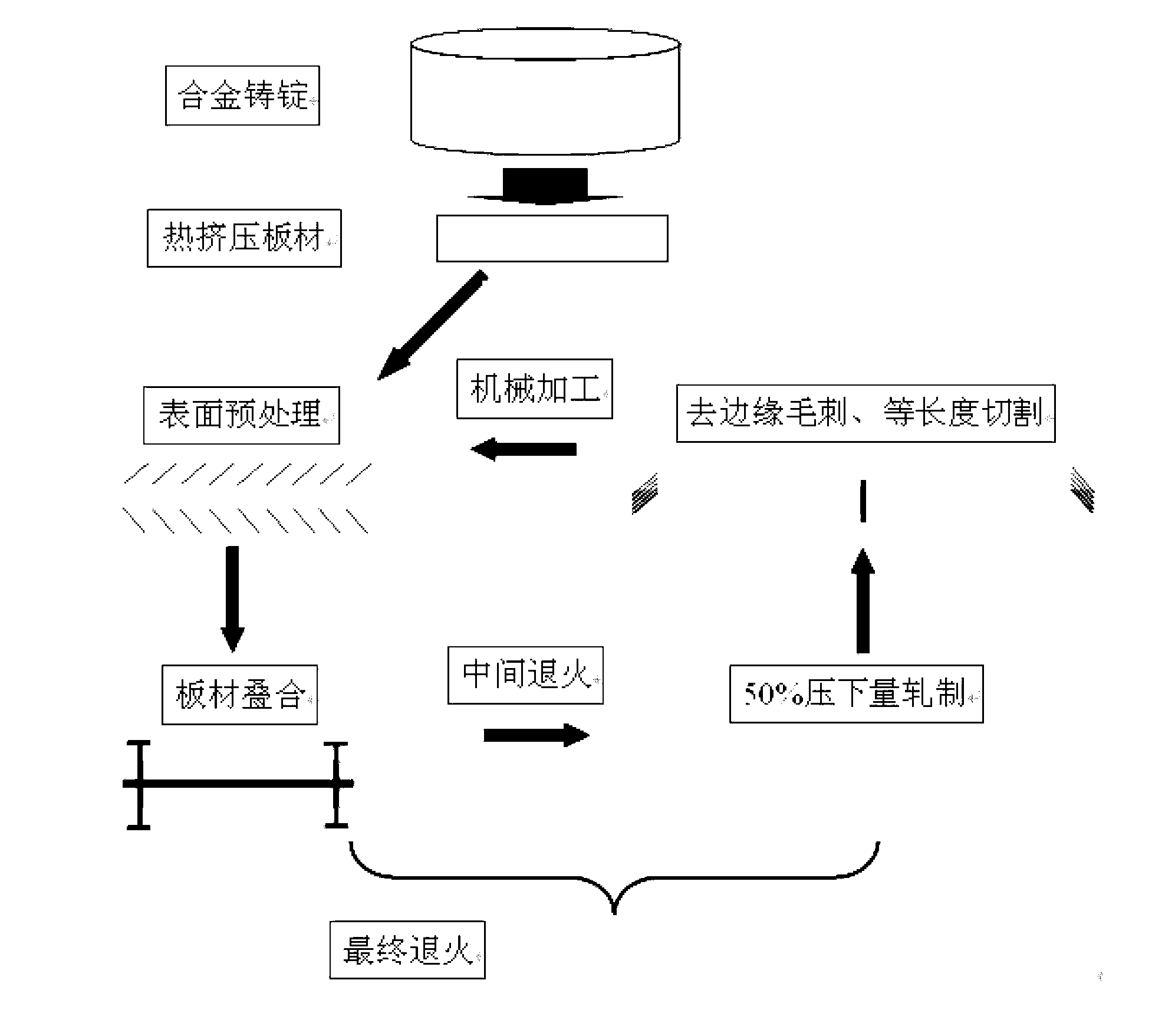

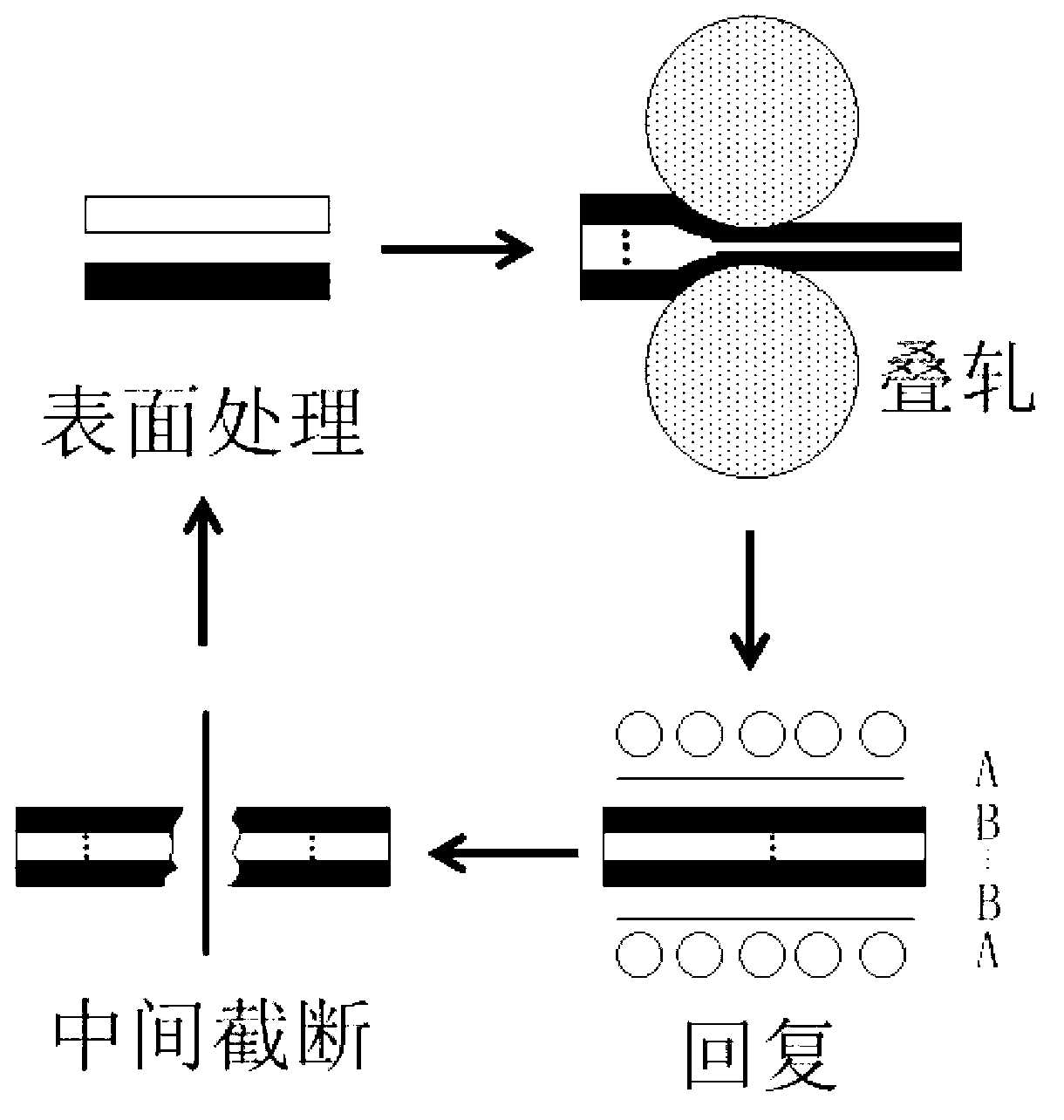

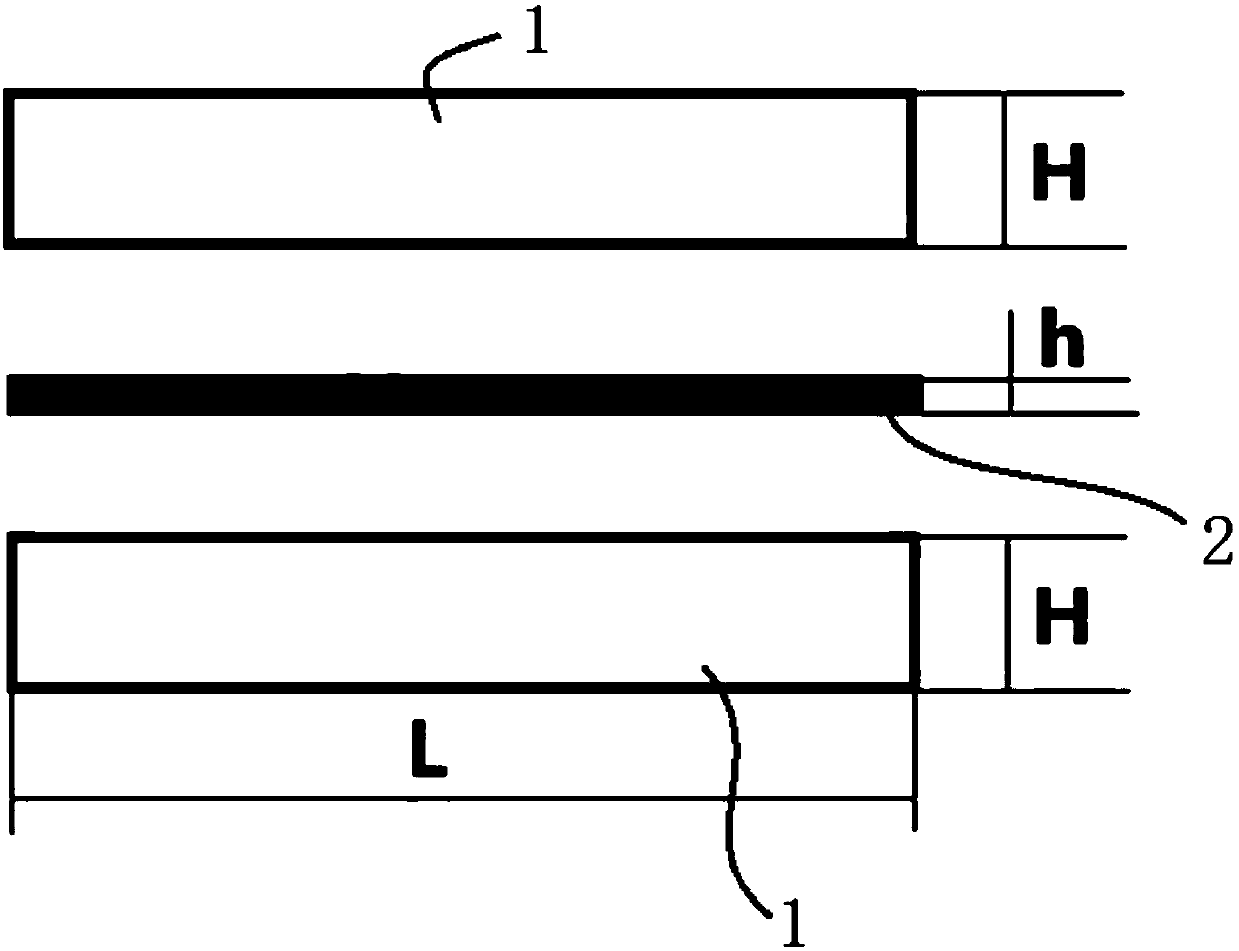

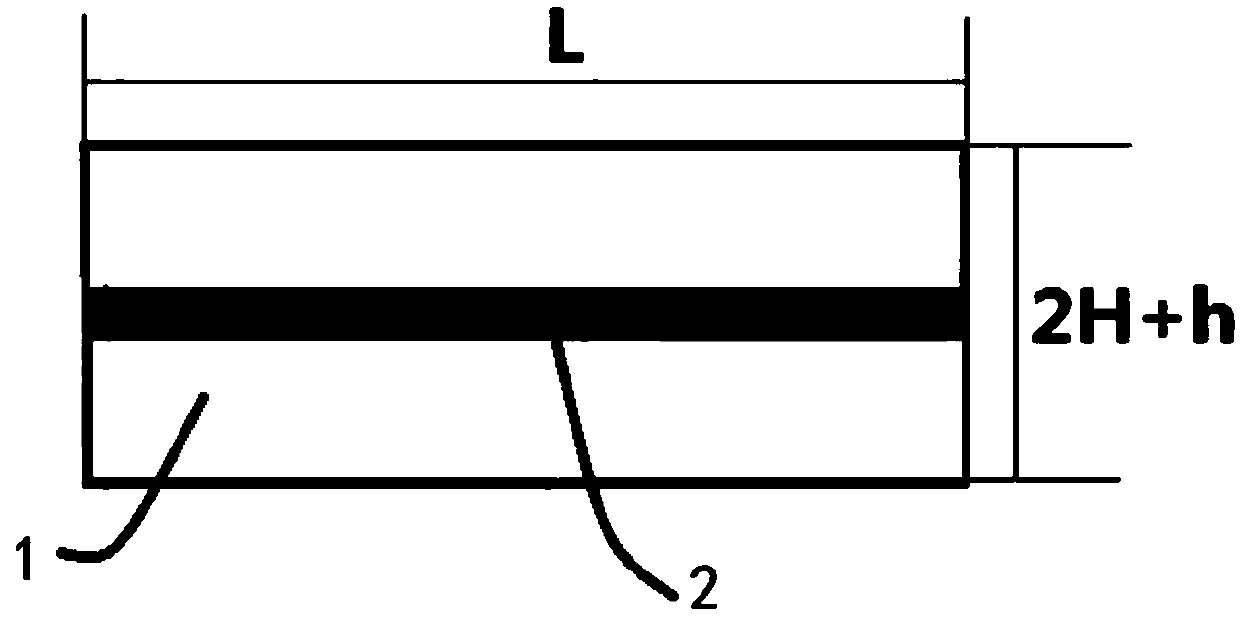

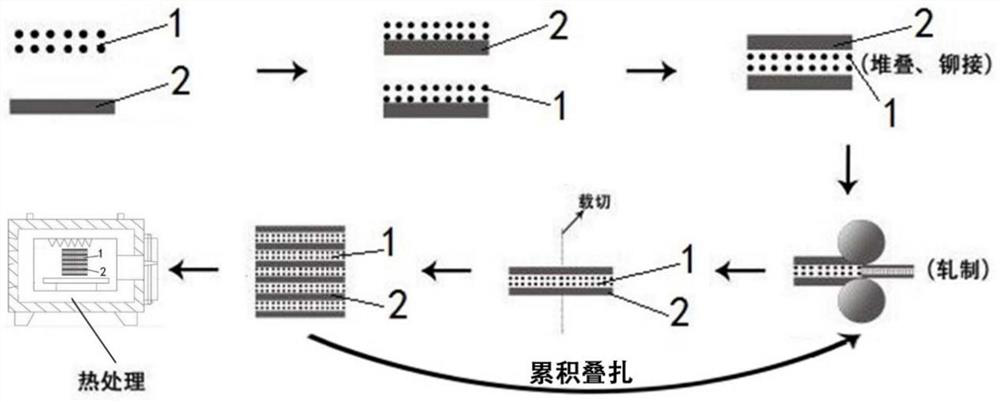

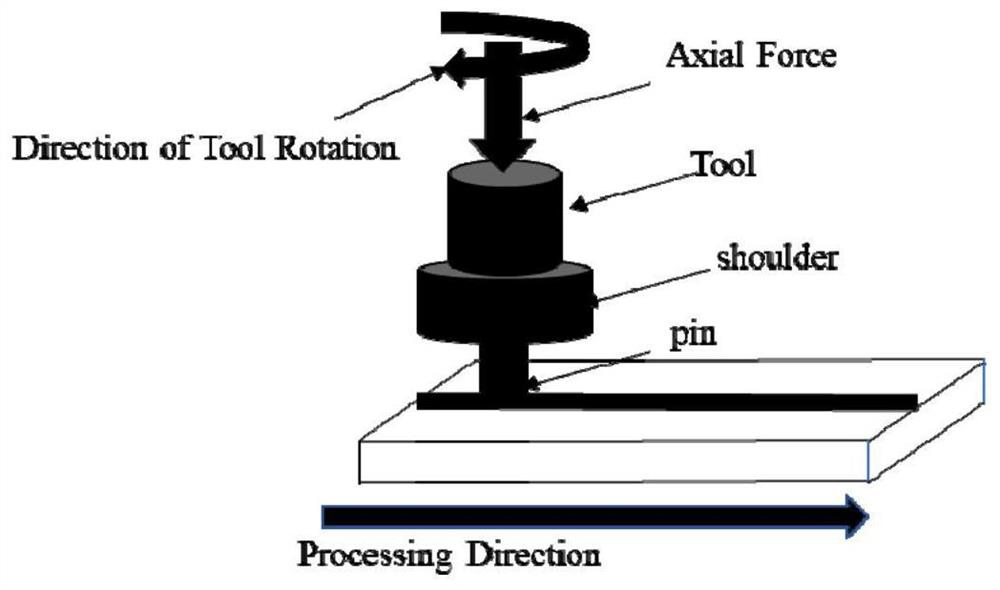

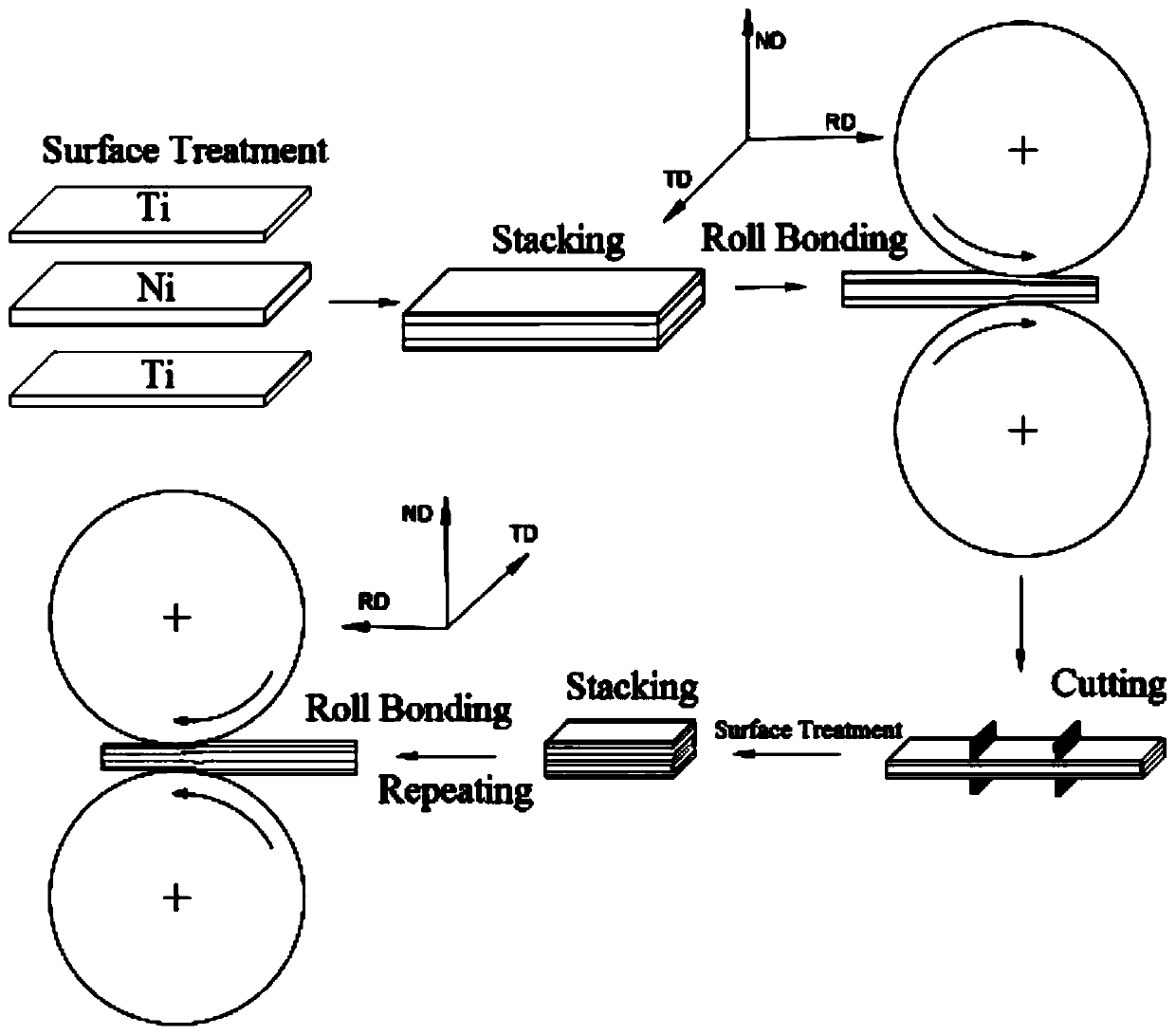

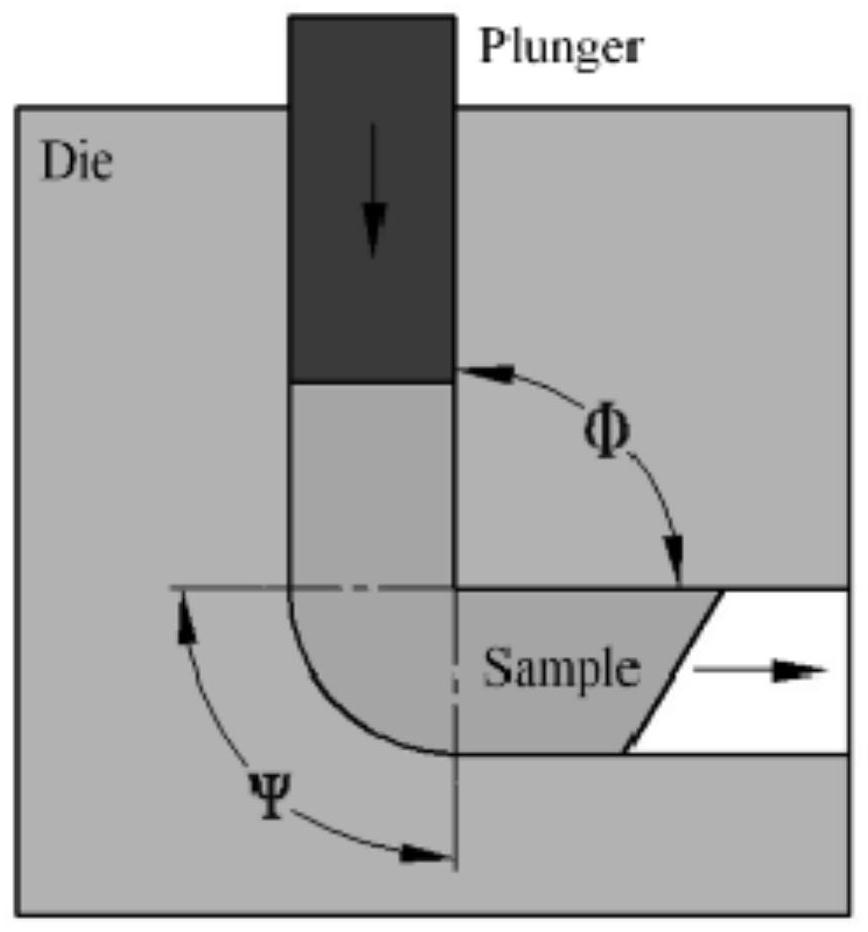

Accumulative roll bonding (ARB) is a severe plastic deformation (SPD) process. It is a method of rolling a stack of metal sheets, which are repeatedly rolled to a severe reduction ratio, sectioned into two halves, piled again and rolled. It has been often proposed as a method for the production of metal materials with ultrafine grain microstructure. The earliest works on ARB were by Nobuhiro Tsuji, Y. Saito and co-workers. To obtain a single slab of a solid material, the rolling involves not only deformation, but also roll bonding.

High-strength/toughness magnesium lithium alloy and preparation method thereof by accumulative roll bonding process

InactiveCN104498793AHigh fatigue limitImprove plasticityMetal rolling arrangementsLithiumThermal deformation

The invention provides a high-strength / toughness magnesium lithium alloy and a preparation method thereof by an accumulative roll bonding process. The method comprises the following steps: a) carrying out homogenizing treatment on a smelted magnesium lithium alloy cast ingot; b) carrying out thermal deformation processing to obtain a magnesium lithium alloy plate; c) carrying out stress-relief annealing; d) cutting the plate for accumulative roll bonding into two pieces with equal size, and carrying out surface treatment; e) fixing the two Mg-Li alloy plates; f) rolling; g) repeating the roll bonding according to the steps d)-f) 4-6 times; and h) carrying out annealing treatment. The obtained alloy comprises the following components in percentage by mass: 7.5-9.5% of Li, 2.5-3.5% of Al, 0.5-1.5% of Zn, less than 0.03% of inevitable impurities (Fe, Cu, Ni, Mn and Si), and the balance of Mg. The magnesium lithium alloy is reinforced according to the specific alloying elements and proportioning thereof, and subjected to multipass accumulative roll bonding at proper temperature to refine the magnesium lithium alloy crystal grains, so that the alloy has higher strength on the premise of keeping favorable plasticity.

Owner:HARBIN ENG UNIV

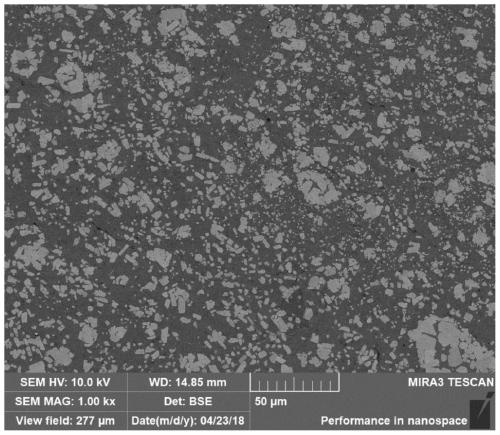

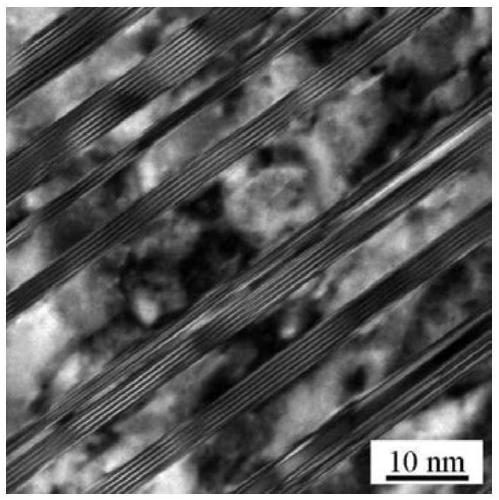

Preparation method of ultrafine grain rare earth magnesium alloy

The invention provides a preparation method of an ultrafine grain rare earth magnesium alloy. The method comprises the following steps of: firstly performing solution treatment on a rare earth magnesium alloy cast ingot to obtain the rare earth magnesium alloy after the solution treatment; then performing heat deformation processing on the obtained rare earth magnesium alloy after the solution treatment to obtain a heat-deformed rare earth magnesium alloy plate, wherein the heat deformation processing temperature is 350 DEG C-450 DEG C; and finally performing accumulative roll bonding with the single-pass rolling reduction of 50% on the obtained heat-deformed rare earth magnesium alloy plate, and annealing to obtain the ultrafine grain rare earth magnesium alloy. According to the preparation method provided by the invention, a heat deformation processing-accumulative roll bonding compound process is firstly adopted to successfully prepare the ultrafine grain rare earth magnesium alloy, and the problem of deterioration of mechanical properties, which is caused by non-uniform distribution of thick and big LPSO (long period stacking ordered) phases in the alloy is effectively solved; and furthermore, the preparation method provided by the invention has the advantages of simple process flow and low equipment cost, and is favorable for further large-scale industrial production.

Owner:XINJIANG TENGXIANG MAGNESIUM PROD CO LTD

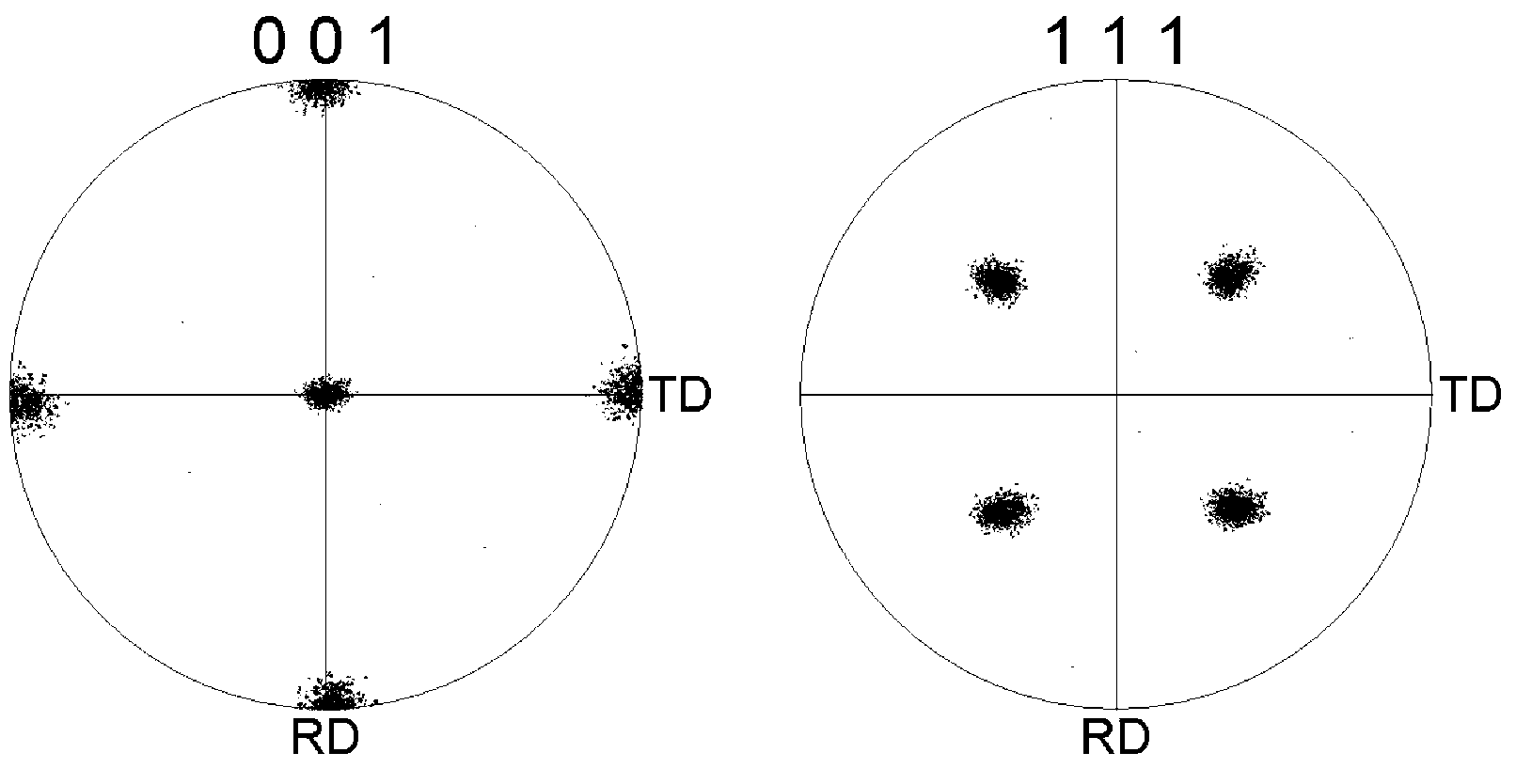

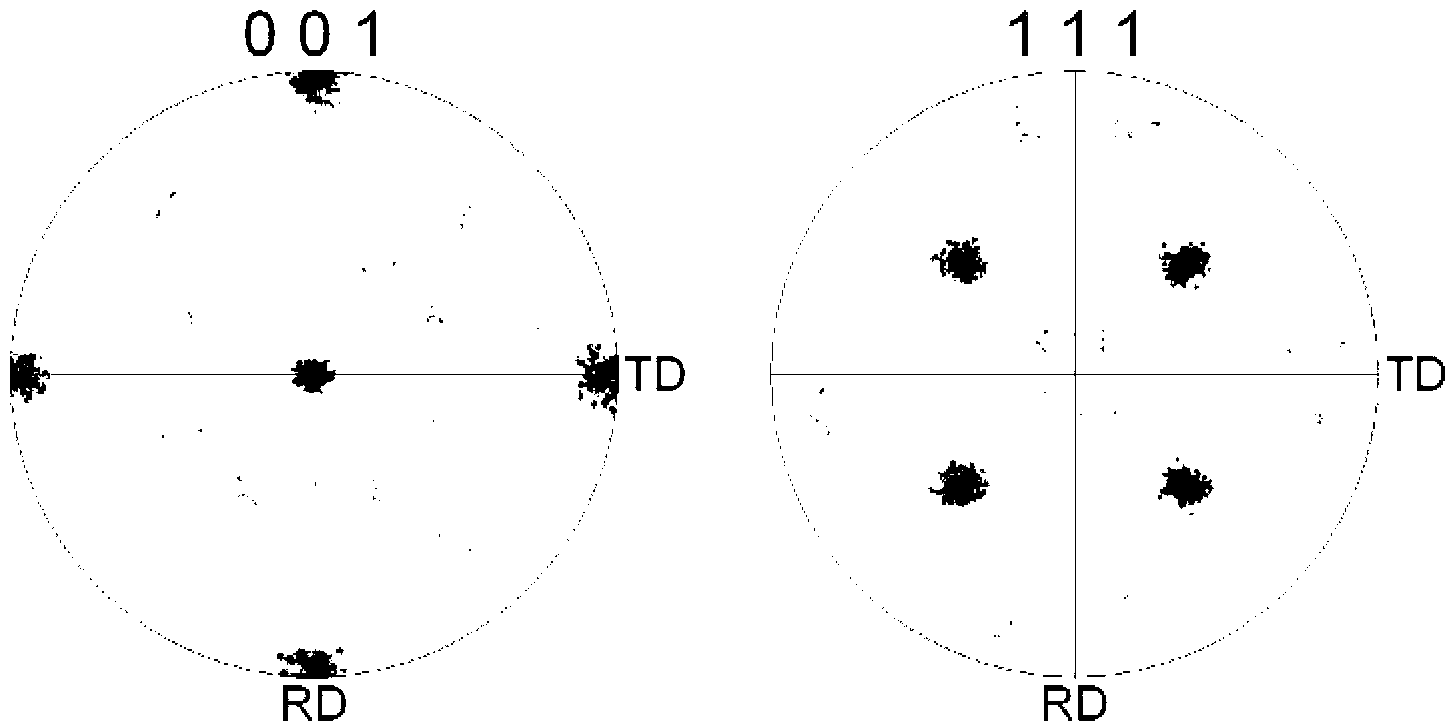

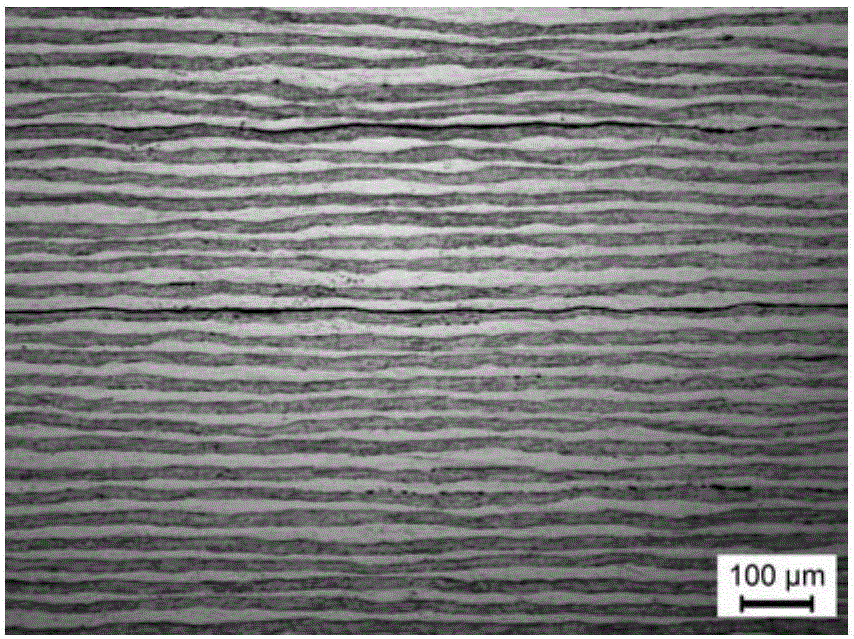

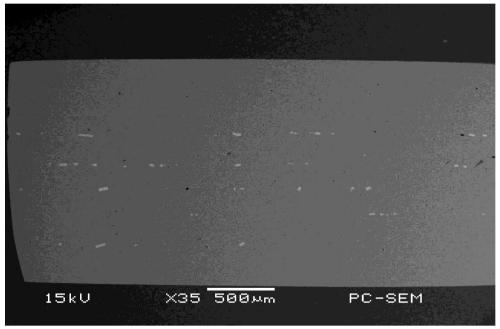

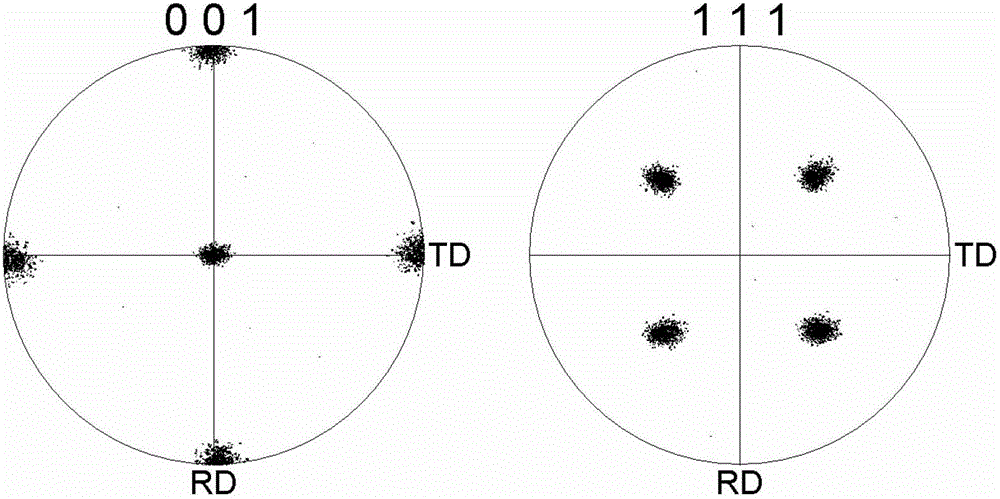

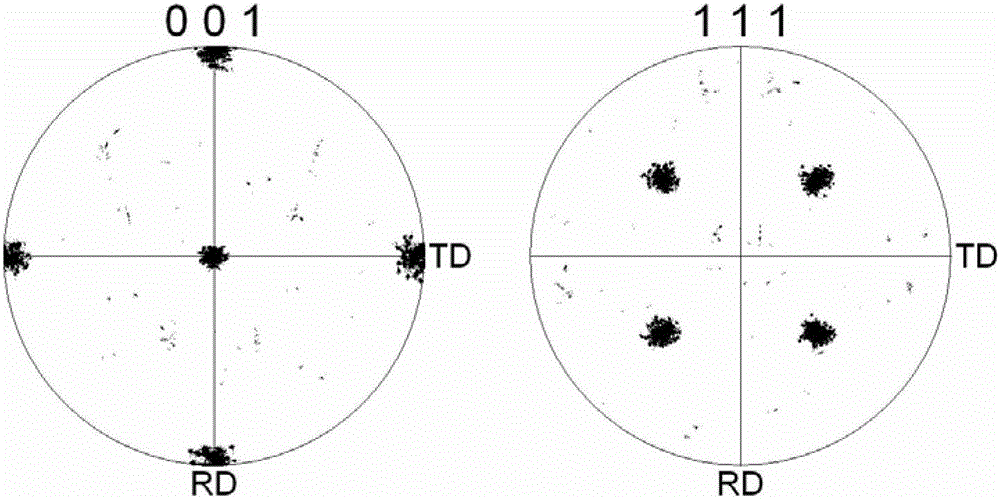

Preparation method of Ni-W alloy composite baseband with no or low magnetism and cubic texture

The invention provides a preparation method of a Ni-W alloy composite baseband with no or low magnetism and a cubic texture and belongs to the technical field of preparation of high-temperature coating superconducting basebands. The method comprises the following steps: respectively preparing two Ni-W alloy billets with different W contents and the same size; overlaying, welding and fixing the two Ni-W alloy billets together; coldly rolling the two Ni-W alloy billets, wherein the total deformation is 50%; carrying out restorative heat treatment on the two Ni-W alloy billets during rolling; cutting off edge cracks and burrs of the Ni-W alloy billets; dividing the Ni-W alloy billets into twos from the middle parts; carrying out accumulative roll bonding on the Ni-W alloy billets, so that outermost layers of the multi-layer overlaid and rolled billets are all Ni-W alloys with low W contents, wherein the accumulative roll bonding repeats overlaying, welding, rolling and restorative heat treatment for 1-4 times; carrying out restorative annealing on the Ni-W alloy billets between cold rolling and rolling; and recrystallizing and annealing the Ni-W alloy billets in two steps. The preparation method of the Ni-W alloy composite baseband with no or low magnetism and the cubic texture, provided by the invention, can obtain the composite baseband with excellent performance.

Owner:深创超导(深圳)科技有限公司

High-strength and toughness magnesium-lithium alloy layered composite material and preparation method thereof

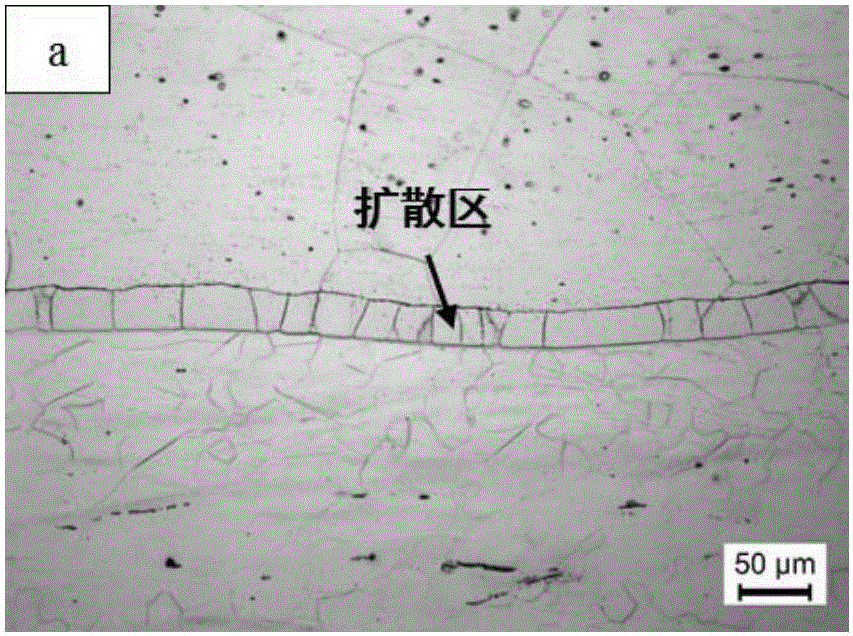

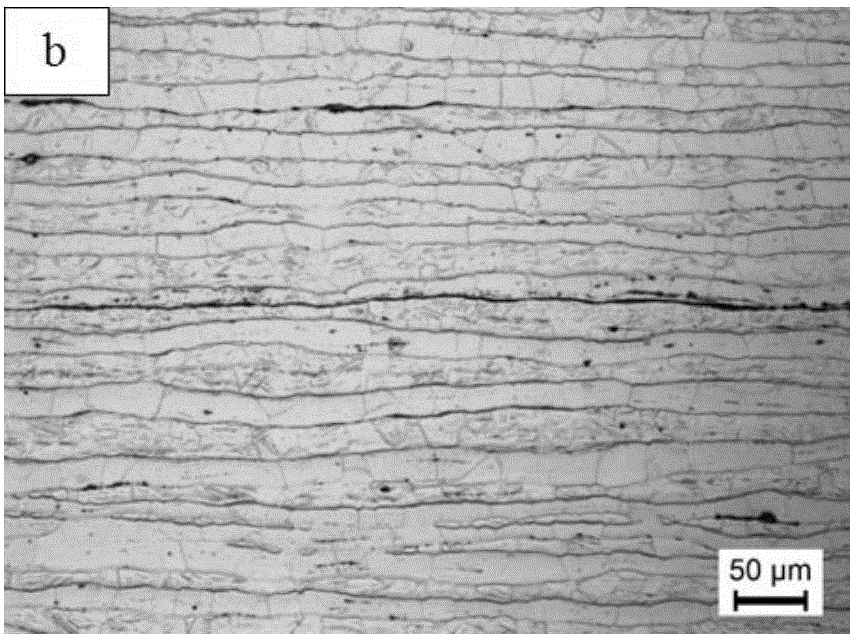

The invention provides a high-strength and toughness magnesium-lithium alloy layered composite material and a preparation method thereof. The preparation method comprises the following steps: 1, cutting an alpha-Mg single phase Mg-Li alloy plate and a beta-Li single phase Mg-Li alloy plate to from two places with same dimensions; 2, fixing the Mg-Li alloy plates obtained in step 1; 3, carrying out composite rolling on the well fixed Mg-Li alloy plates; 5, cutting an Mg-Li alloy plate obtained in step 3 to form two pieces with same dimensions, superposing and fixing the two pieces, and carrying out composite rolling; 5, repeating step 4 5-8 passes to obtain an accumulative roll-bonded composite plate; and 6, annealing the accumulative roll-bonded composite plate obtained in step 5 in a heat treatment furnace. Accumulative roll-bonding is carried out to realize formation of a rub rolling area in order to realize the good interface combination effect of the composite plate. The annealing treatment further improves the interface combination strength, the elongation percentage and other mechanical performances of the composite plate.

Owner:HARBIN ENG UNIV

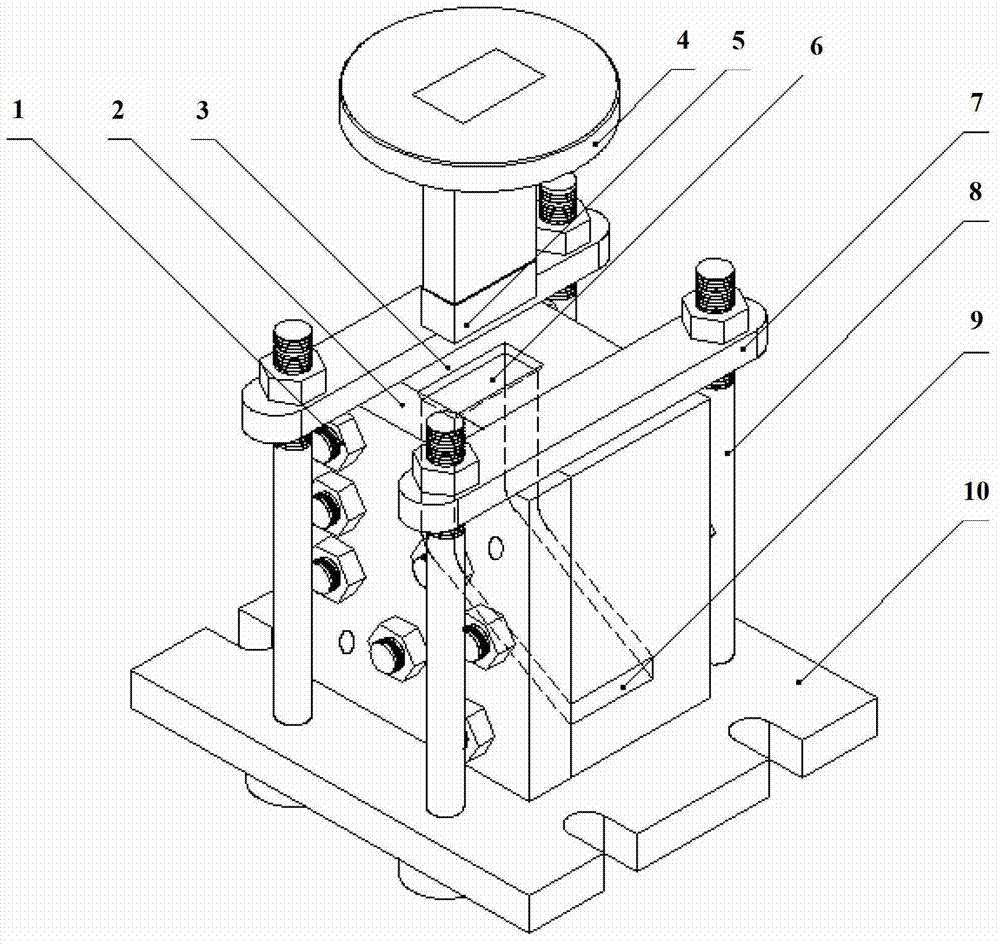

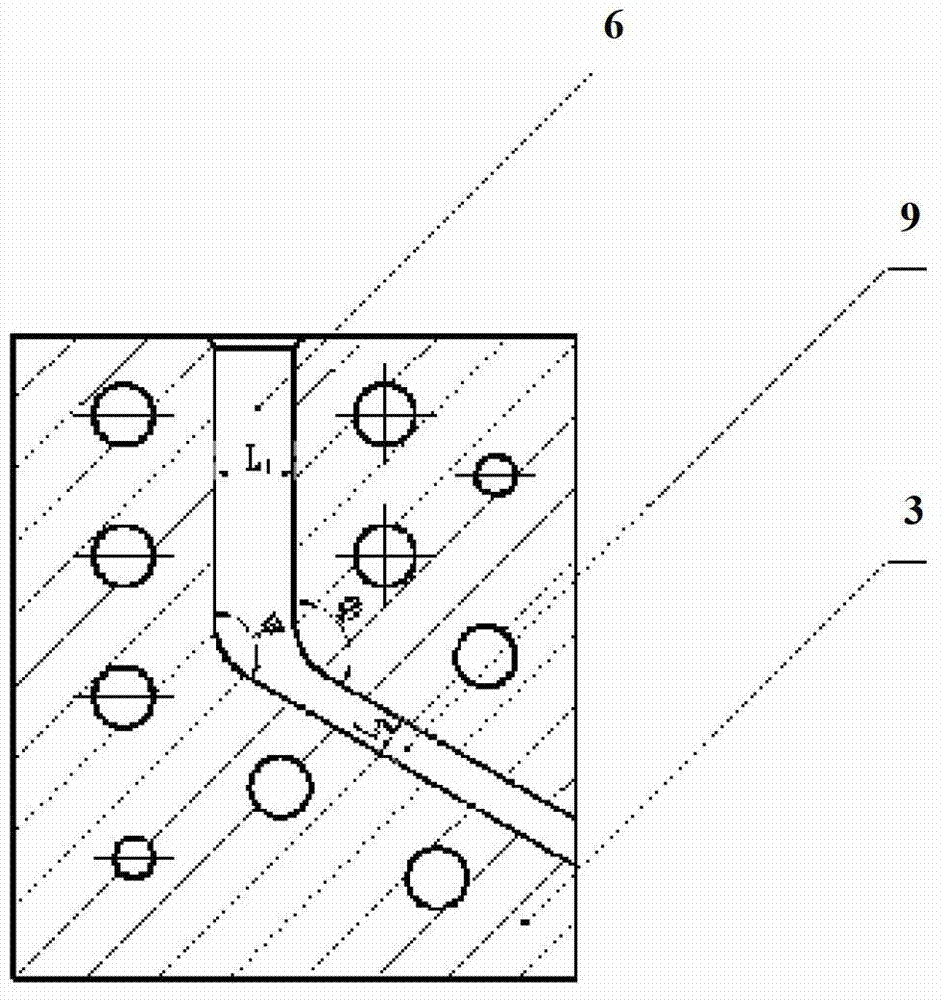

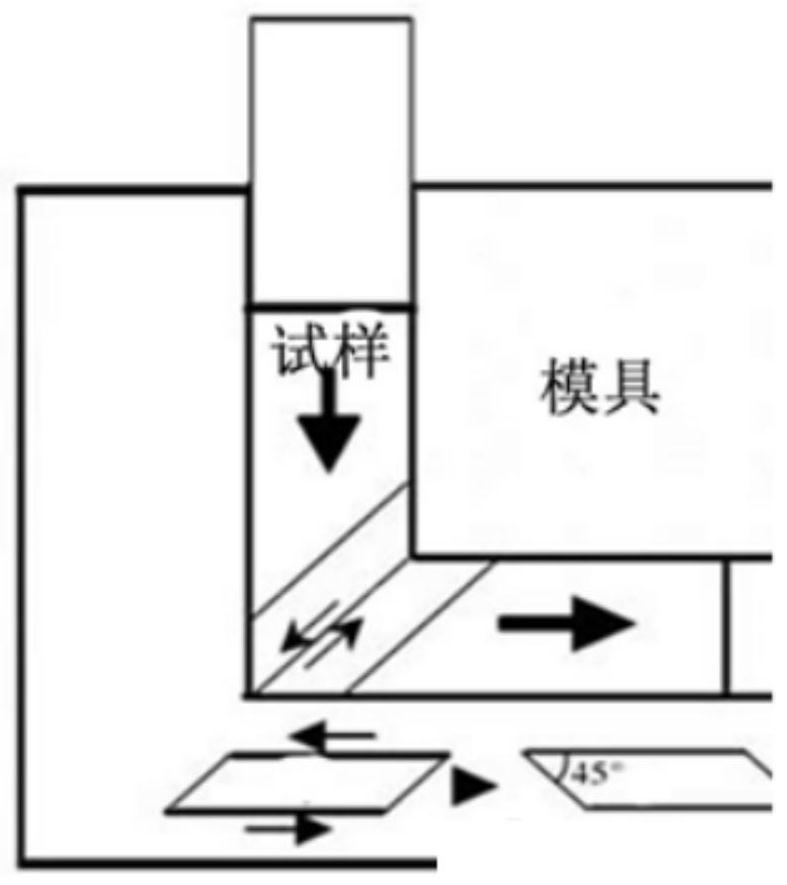

Severe plastic deformation method and severe plastic deformation device for pressing and rolling corner of non-equivalent passage

The invention discloses a severe plastic deformation method and a severe plastic deformation device for pressing and rolling the corner of a non-equal channel. According to the severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel, an equal-channel angular pressing (ECAP) technology and an ARB (Accumulative Roll Bonding) technology are integrated. The concrete process comprises the following steps that pressing force is applied after a test sample, a punching head and a mould are simultaneously preheated to pressing and rolling temperature, so that the test sample passes through the position of the channel corner of the device for pressing and rolling the corner of the non-equal channel completely; compressive deformation is generated when shear deformation is generated by the test sample so as to finish a first pass pressing and rolling process; the test sample is cut into L1 / L2 parts along a length direction, and the L1 / L2 parts are placed in an I channel; and the steps are repeated so as to finish multi-pass pressing and rolling deformation. The mould of the device is provided with the I channel and an II channel which are intersected and also have non-equal sections. The design is reasonable, the structure is simple, and the manufacturing cost is low. According to the method disclosed by the invention, the advantages of the ECAP technology and the ARB technology are integrated, and the mechanical property of a material is effectively enhanced. The process is short in procedure, high in efficiency and low in cost and is simple to operate. The severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel can be widely used for the field of processing metal materials, such as pure metal and alloy.

Owner:SOUTH CHINA UNIV OF TECH

Method for manufacturing Mg-Li/Al material by means of accumulative roll-bonding

InactiveCN106493170AHigh strengthImprove corrosion resistanceTemperature control deviceMetal rolling arrangementsLithiumReduction rate

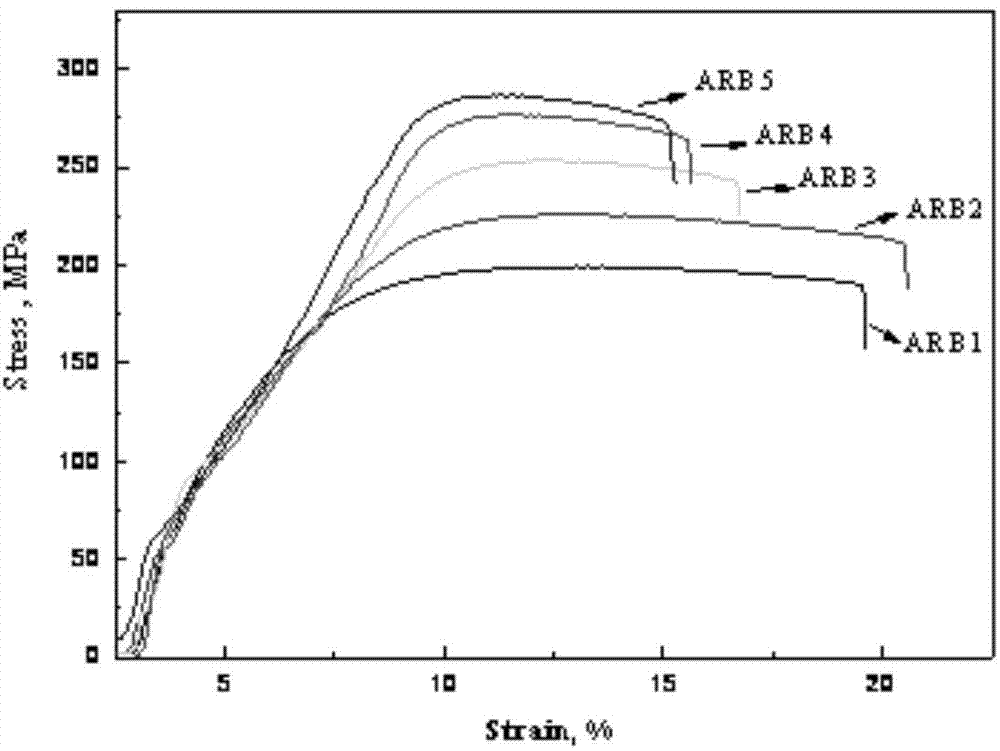

The invention provides a method for manufacturing an Mg-Li / Al material by means of accumulative roll-bonding. The method comprises the steps of: a) cutting to-be-accumulatively roll-bonded magnesium lithium alloy panel and aluminum alloy panel into pieces which are equal in dimension; b) cleaning the surfaces and then polishing the pieces; c) perforating the obtained magnesium lithium alloy panel and the aluminum alloy panel in the step b) at four corners and fixing the same with rivets; d) rolling the Mg-Li / Al alloy panel obtained in the step b), wherein the rolling temperature is 400 DEG C, the reduction rate is 50%, and the temperature before rolling is maintained for 10-15min; and e) performing ply rolling 4-6 times according to the steps a)-d). The Mg-Li / Al laminar composite board is prepared by virtue of an accumulative roll-bonding process, so that the corrosion resistance of the magnesium lithium alloy is improved while the strength of the magnesium lithium alloy is improved. The Mg-Li / Al laminar composite board which is high in strength and corrosion resistance is finally obtained. The tensile strength of the board at the room temperature reaches 270-290MPa, and the ductility of the board reaches 7.1-9.7%.

Owner:HARBIN ENG UNIV

Method for preparing alkene alloy by accumulative roll bonding technology and alkene alloy

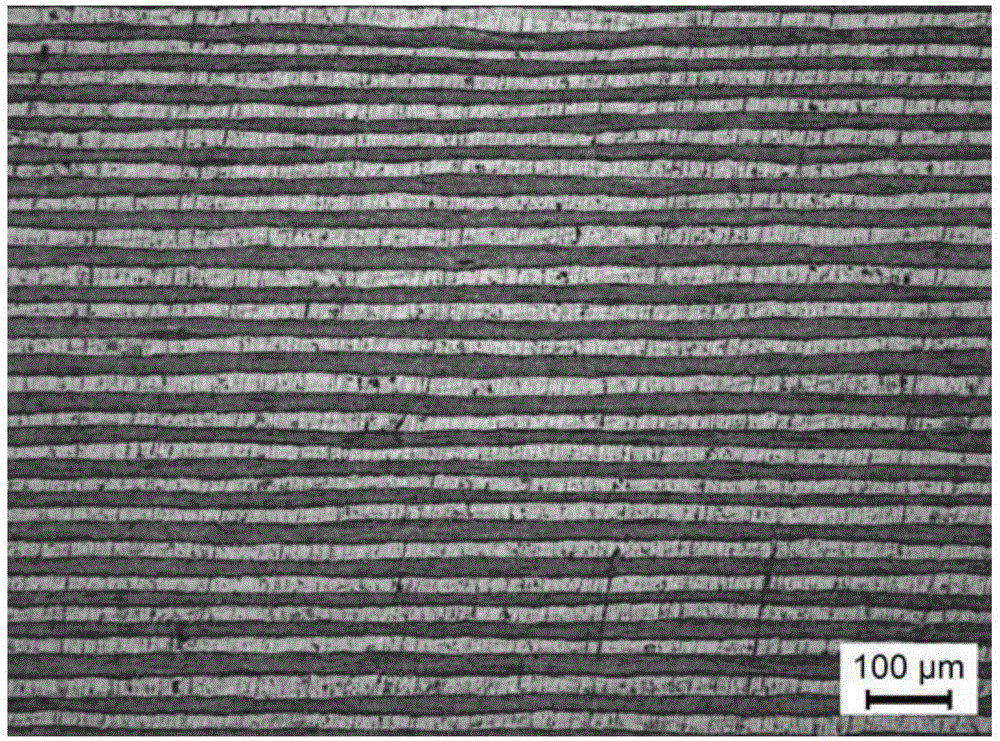

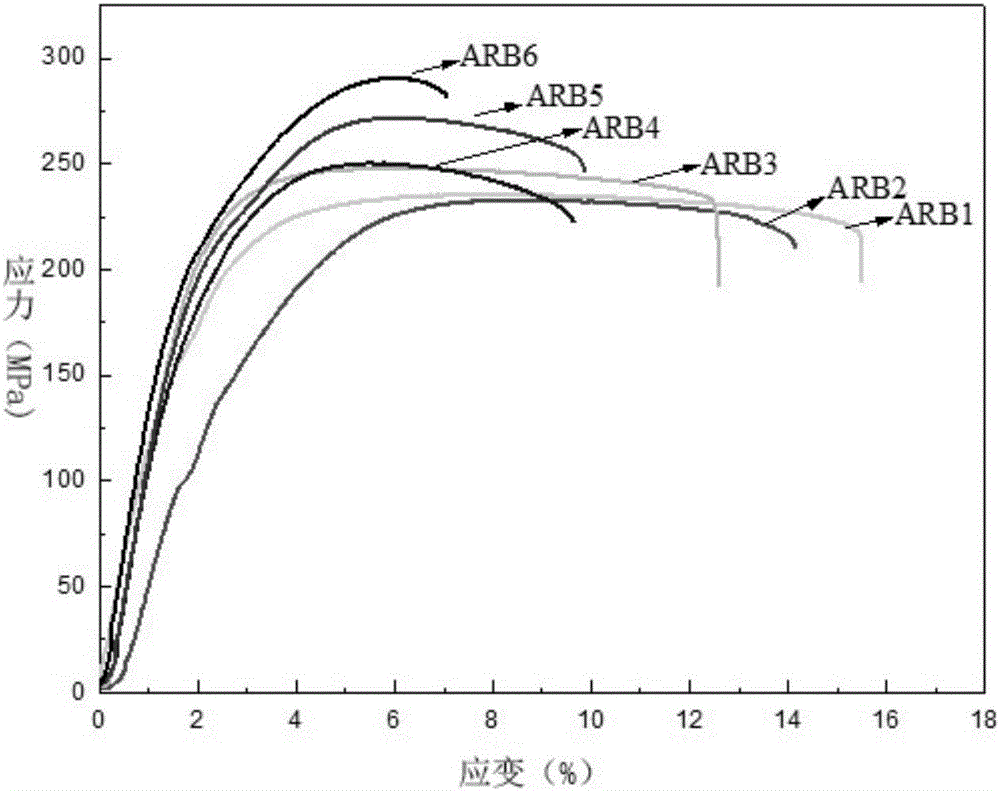

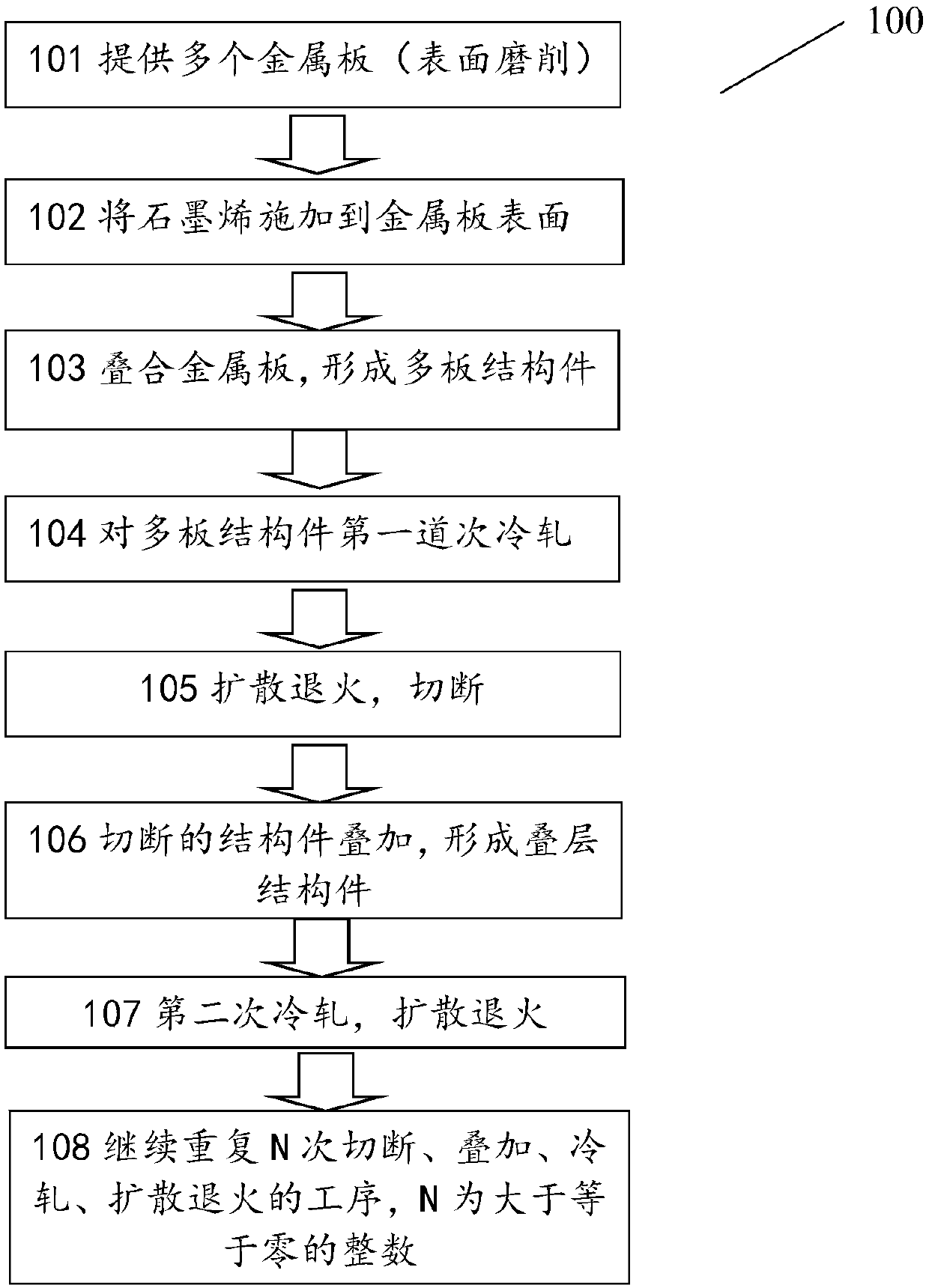

The invention provides a method for preparing an alkene alloy by an accumulative roll bonding technology and the alkene alloy. The method for preparing the alkene alloy by the accumulative roll bonding technology comprises the steps that a plurality of metal plates are provided; graphene is applied to the surfaces of the metal plates; the metal plates are superimposed to form multi-plate structural pieces; first cold rolling is carried out on the multi-plate structural pieces; diffusion annealing is carried out on the multi-plate structural pieces after first cold rolling, and cutting off is carried out; the cut structural pieces are superimposed to form laminated structural pieces; second cold rolling is carried out on the laminated structural pieces, and diffusion annealing is carried out; and the processes of N times of cutting off, superimposing, cold rolling and diffusion annealing are repeated continuously, and N is an integer greater than or equal to zero.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

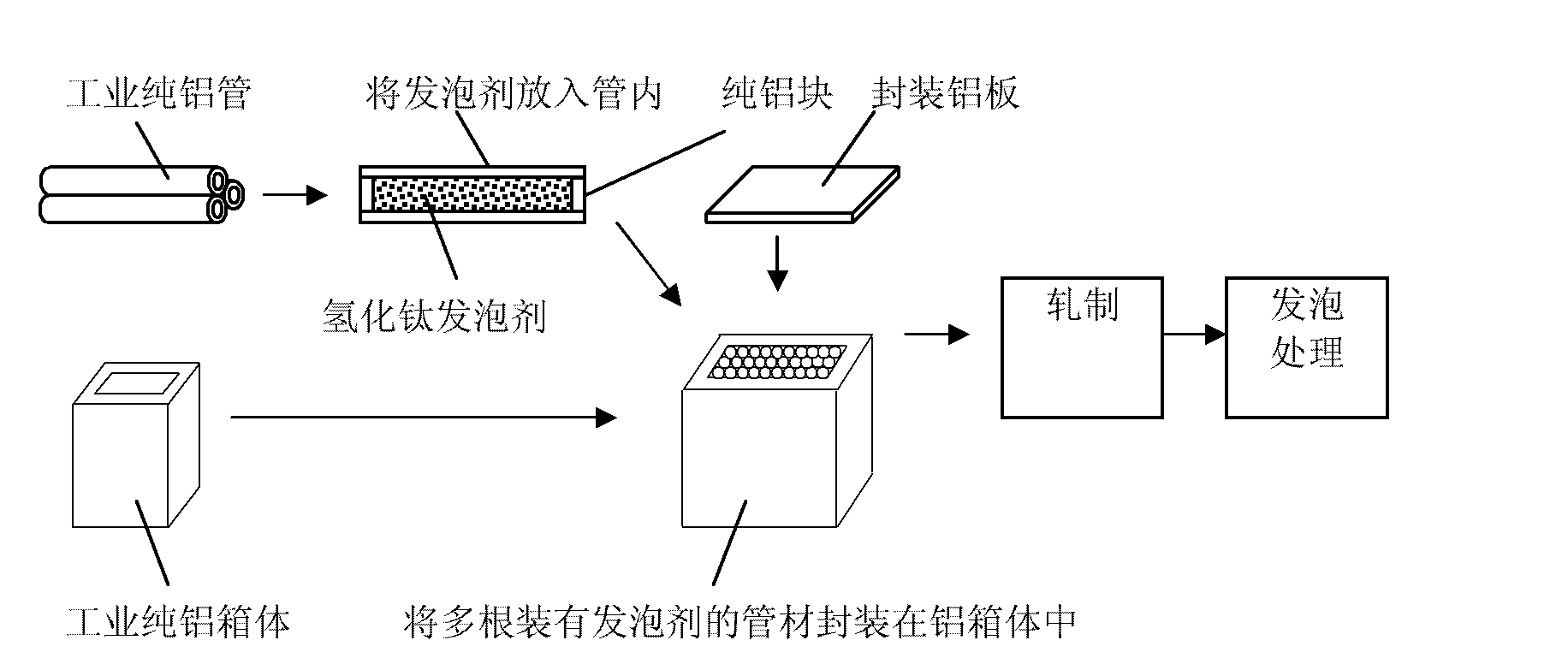

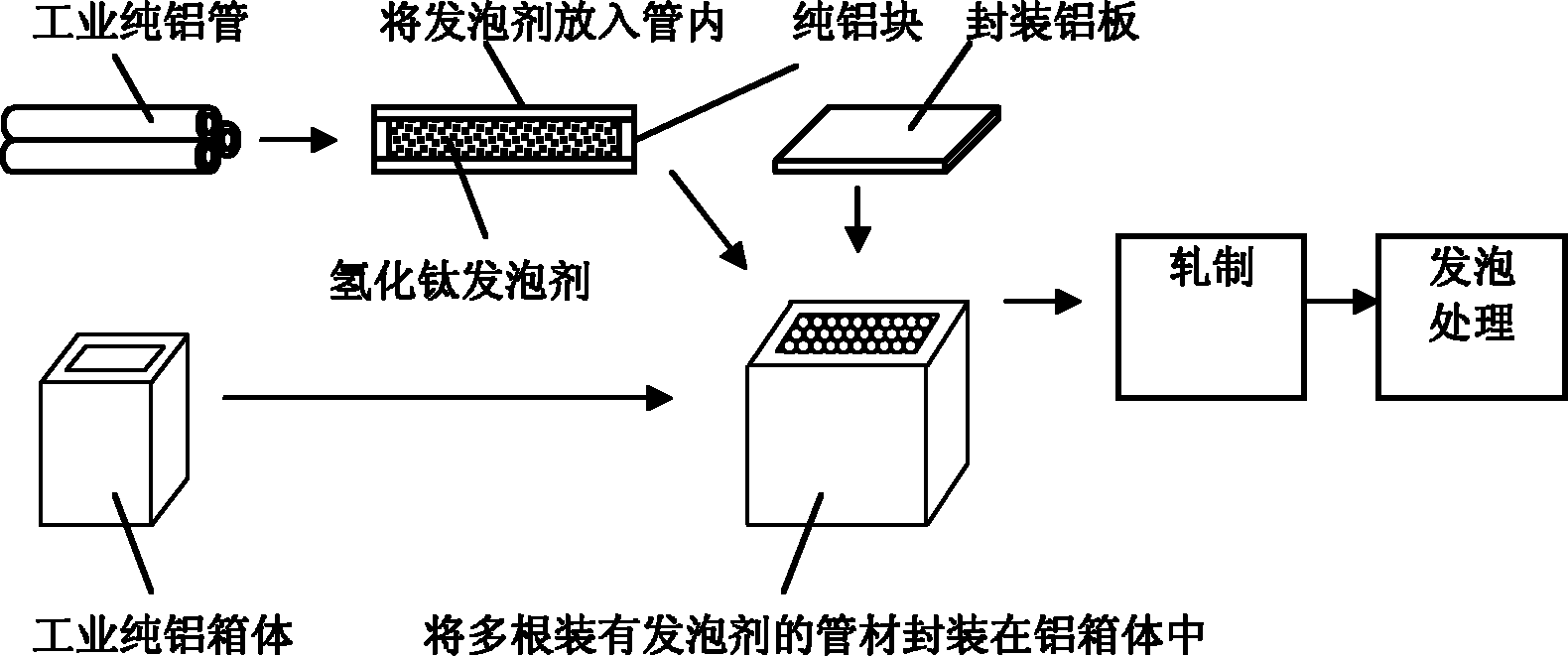

Method for manufacturing foamed aluminum board

The invention provides a method for manufacturing a foamed aluminum board. The method comprises the following steps of: putting titanium hydride powder containing 1 to 3 percent foaming agent into an aluminum or aluminum alloy pipe, sealing a plurality of aluminum or aluminum alloy pipes into which titanium hydride powder is filled in an aluminum or aluminum alloy box, performing mill processing and densifying, and foaming to prepare the foamed aluminum board. By the method, the defects that the pore structure is difficult to control in a casting method and preparation cost is high in a powder metallurgy method are overcome. Compared with an accumulative roll-bonding method, the method has the advantages that the foaming agent can be distributed uniformly, the pore volume can be controlled, the method is not limited by rolling reduction of a critical pass; by the method, the processing can be performed by a compound blank with a large section size, so that a foamed aluminum precursor can be manufactured under a low distortion temperature condition; and the method is convenient to operate and is low in cost.

Owner:UNIV OF SCI & TECH BEIJING

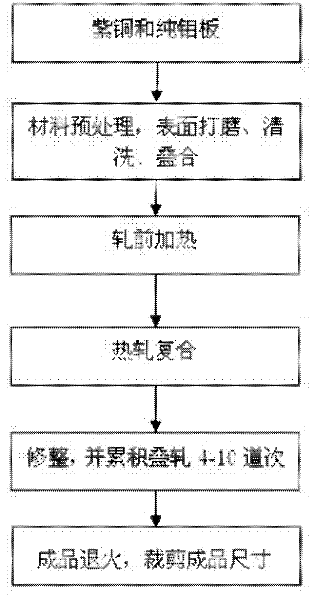

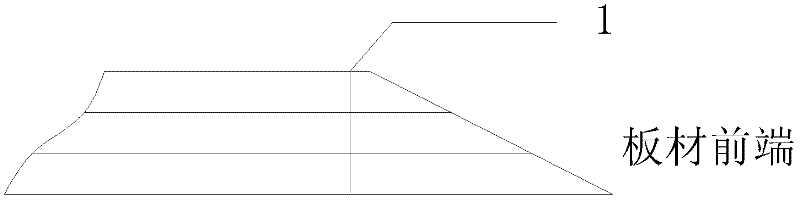

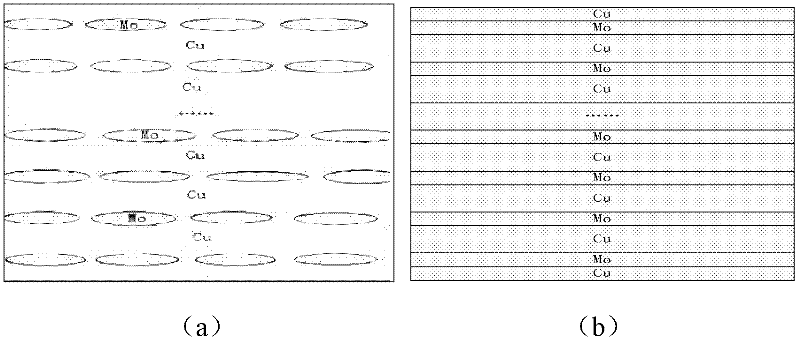

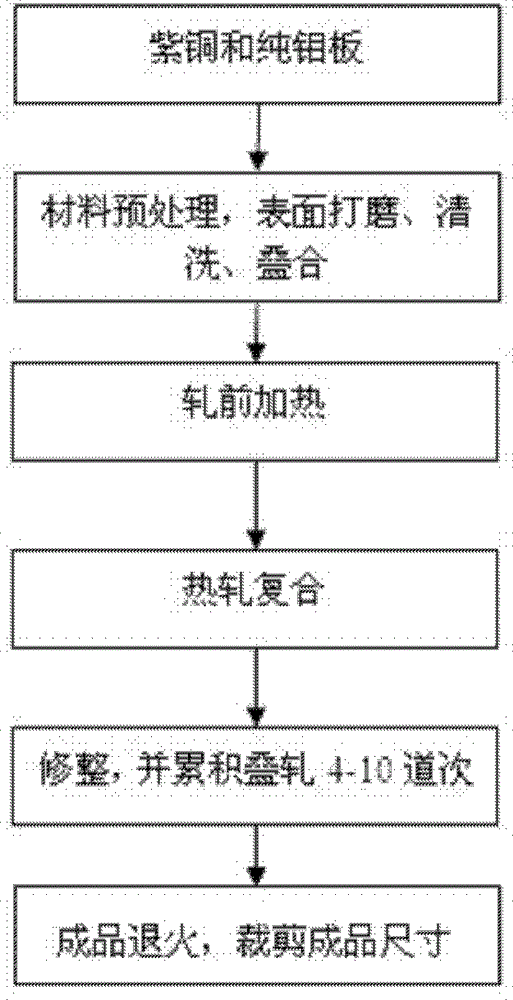

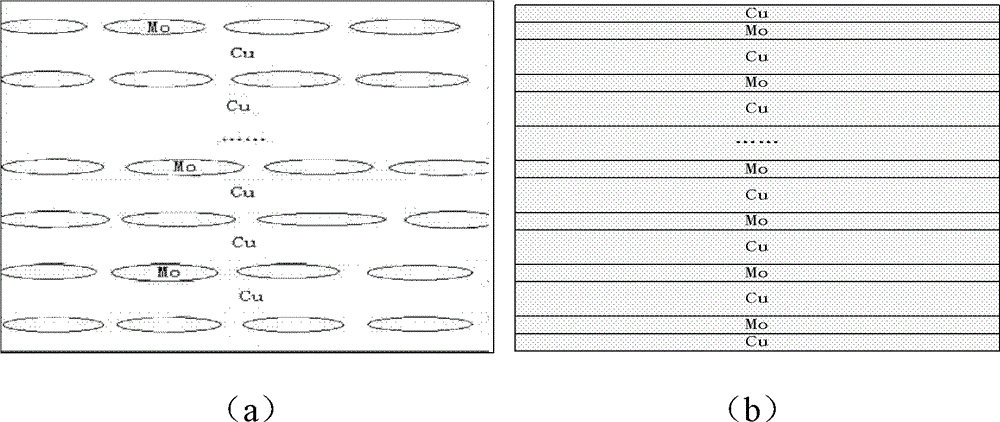

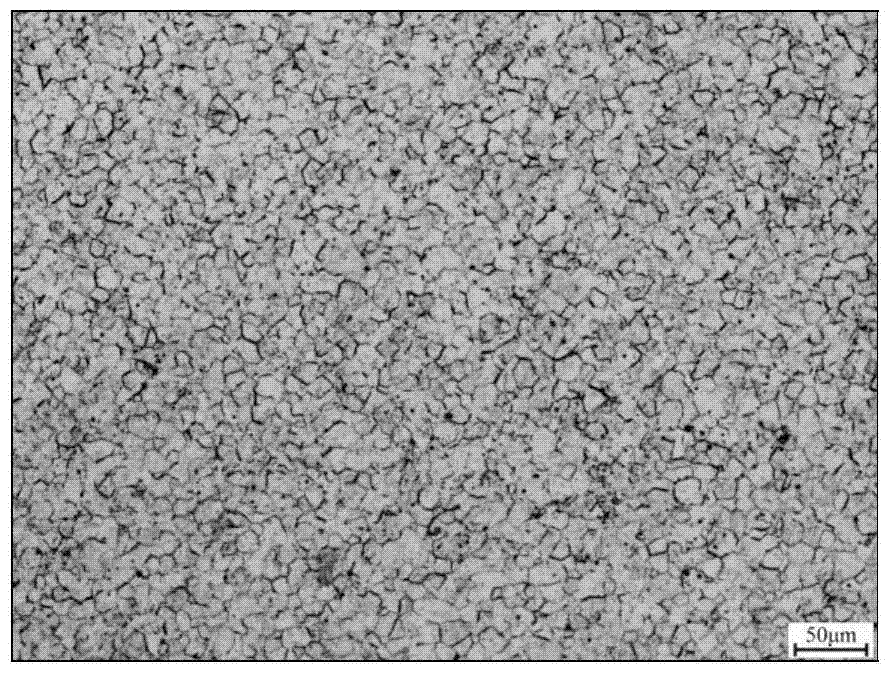

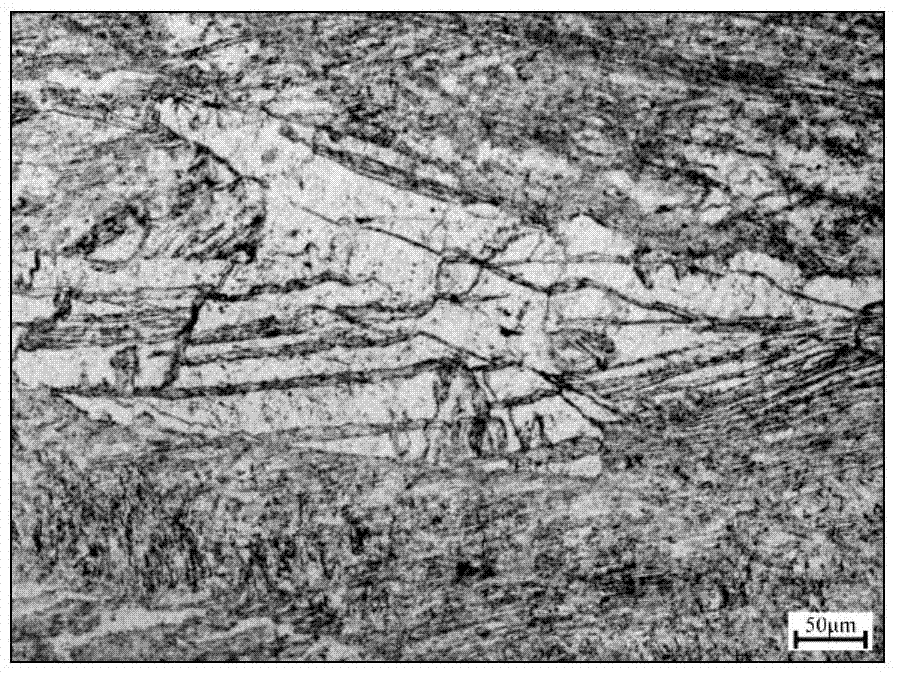

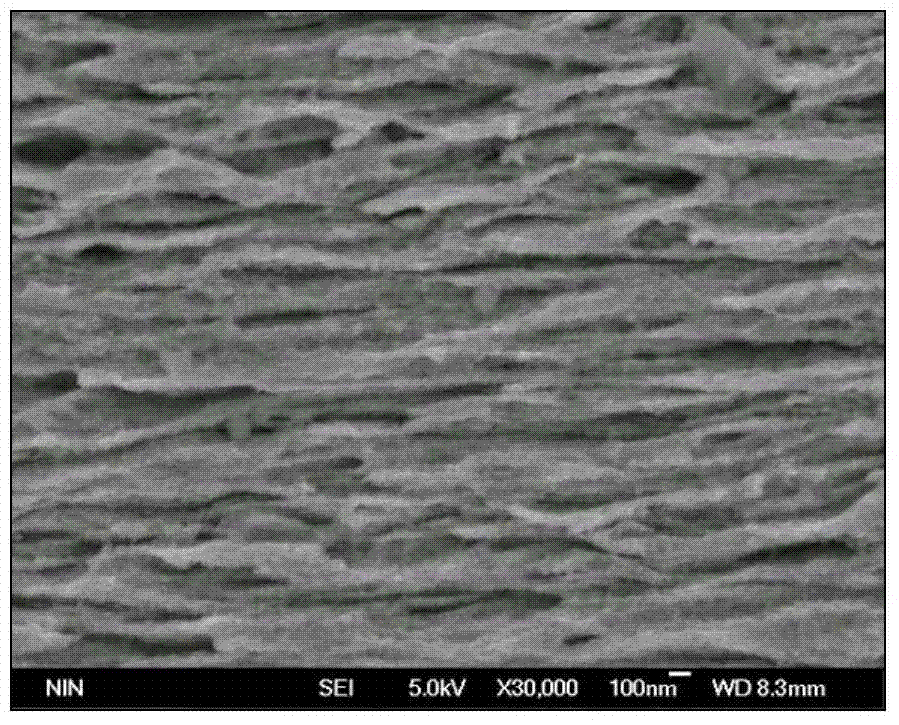

Method for preparing copper/molybdenum composite board with molybdenum fibers by accumulative roll bonding

ActiveCN102529217AImprove conductivityImprove thermal conductivityLaminationLamination apparatusHydrogenCopper

The invention discloses a method for preparing a copper / molybdenum composite board with molybdenum fibers by accumulative roll bonding. In the copper / molybdenum composite board with molybdenum fibers, prepared by the method, molybdenum is fractured to be in a fibrous form by accumulative roll bonding, and then is pinned in a copper plate, and the density of molybdenum fiber can be controlled by accumulative roll bonding passes; and the preparation comprises pretreatment, hot rolling bonding, accumulative roll bonding, finished product annealing and follow-up processing. In the copper / molybdenum composite board with molybdenum fibers, prepared by the method, the copper / molybdenum composite board with different molybdenum fiber densities can be prepared by accumulative roll bonding, and during rolling, a copper-molybdenum interface does not crack, and has no oxidization phenomenon during heat treatment under an argon or hydrogen protective condition, and the prepared composite board has the advantages that the longitudinal tensile strength is 180-360MPa, the transverse tensile strength is 390-620MPa, the elongation rate is 25%-45% and the heat expansion coefficient is controllable. The method has the characteristics of simple preparation process, strong controllability and high yield, and has the most remarkable advantage of being used for large-scale production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

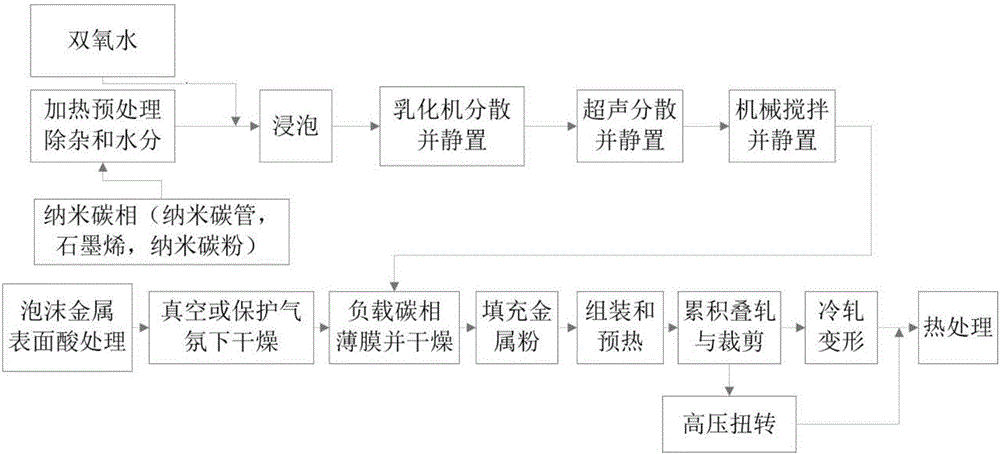

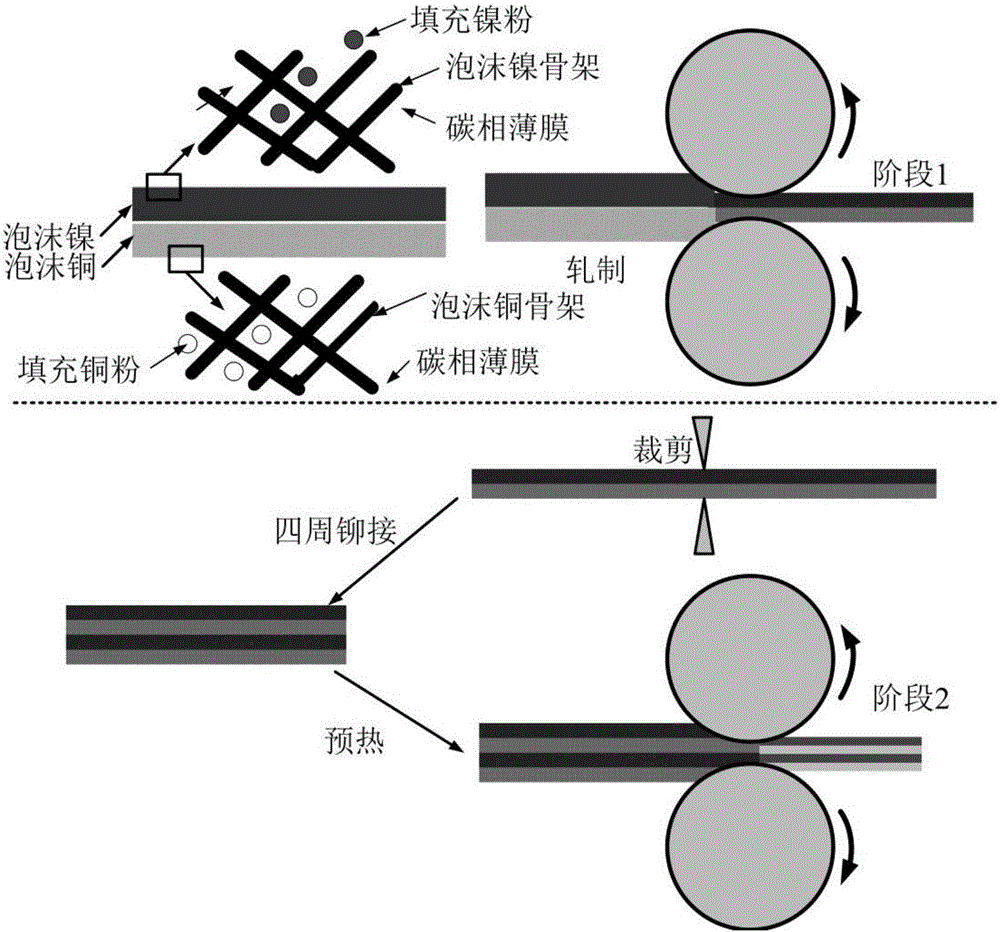

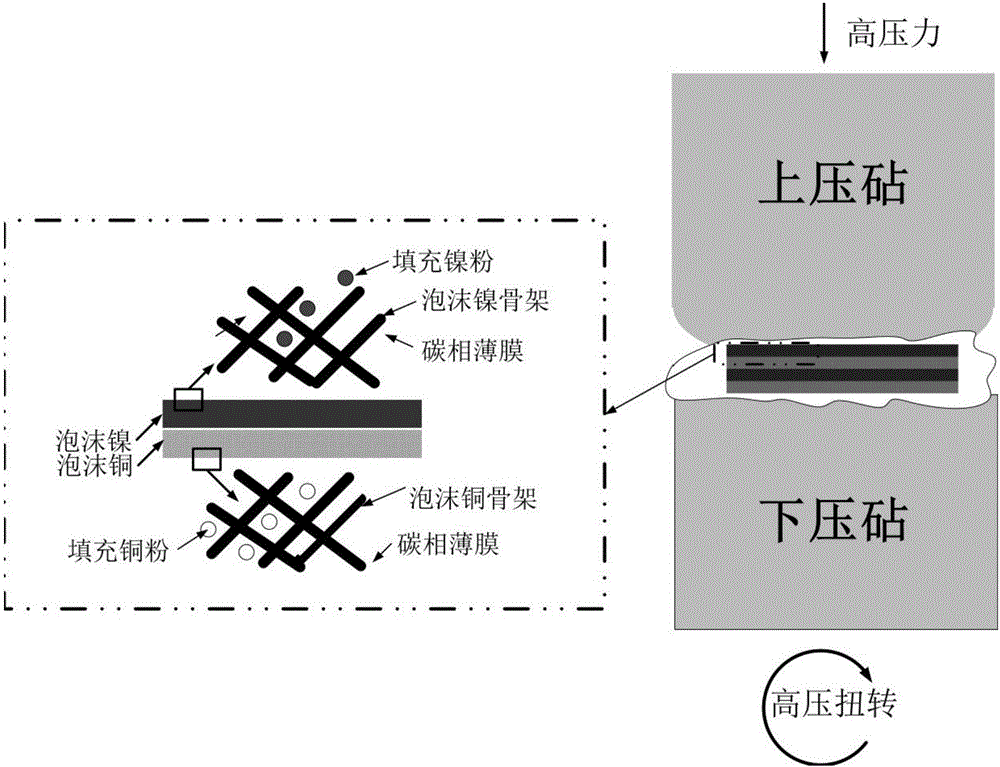

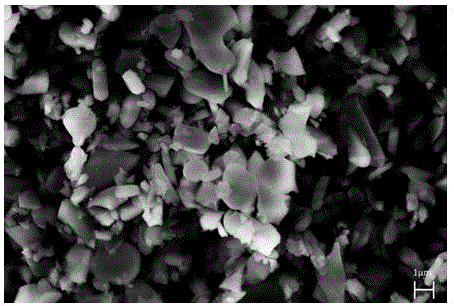

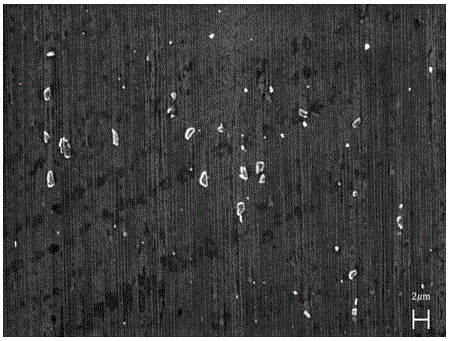

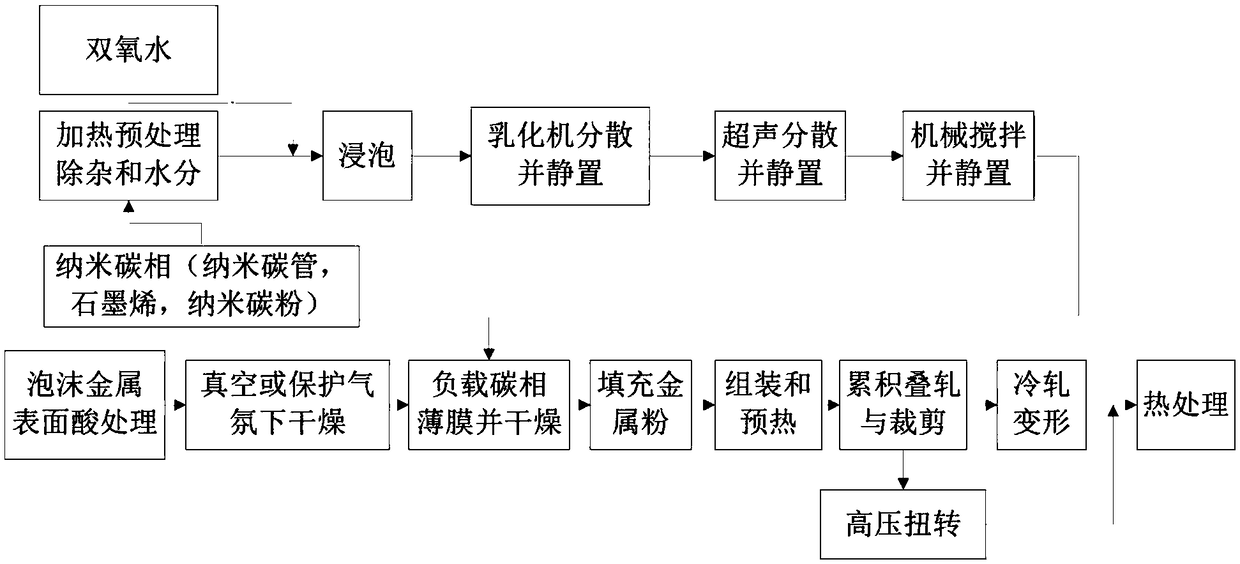

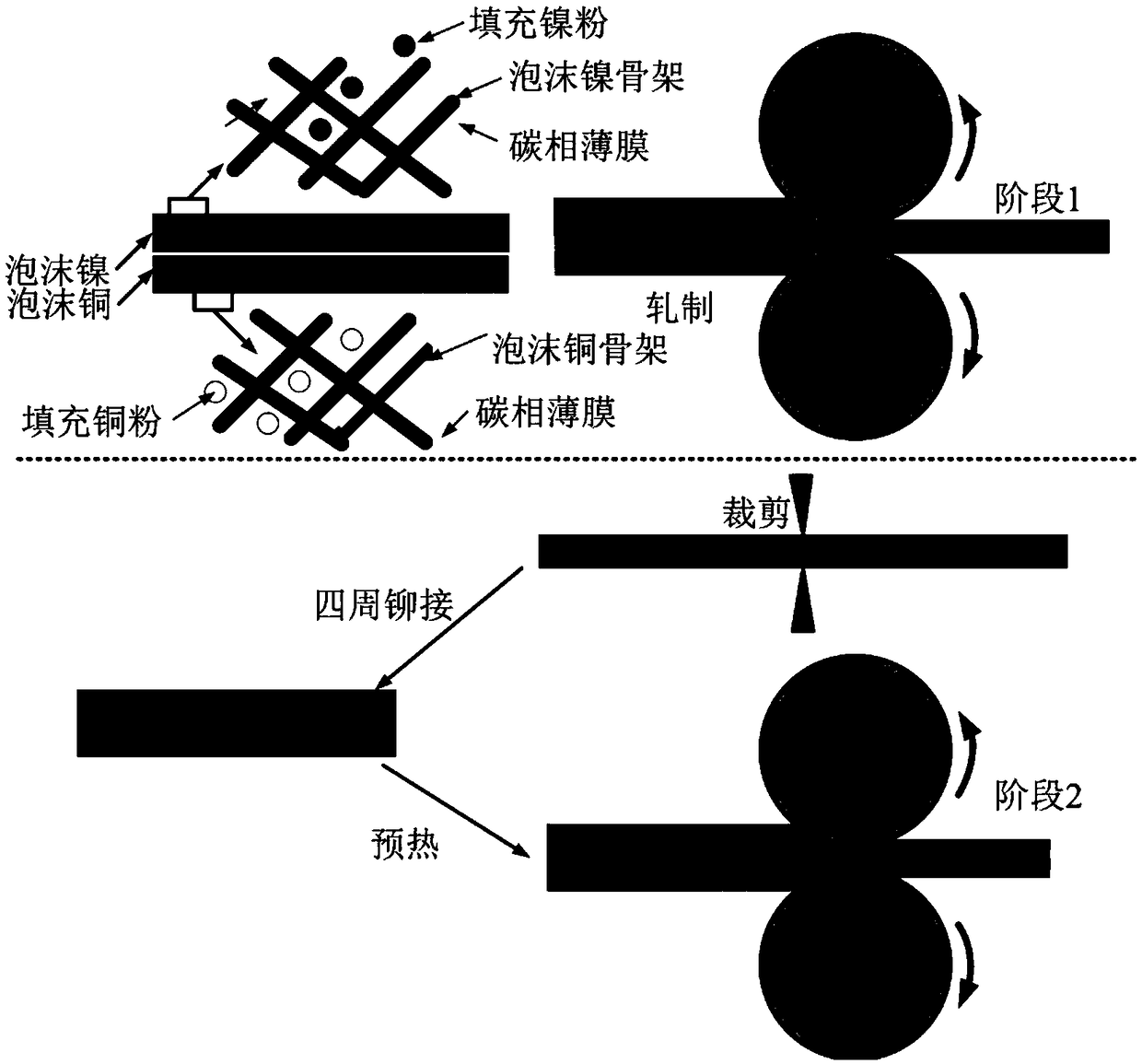

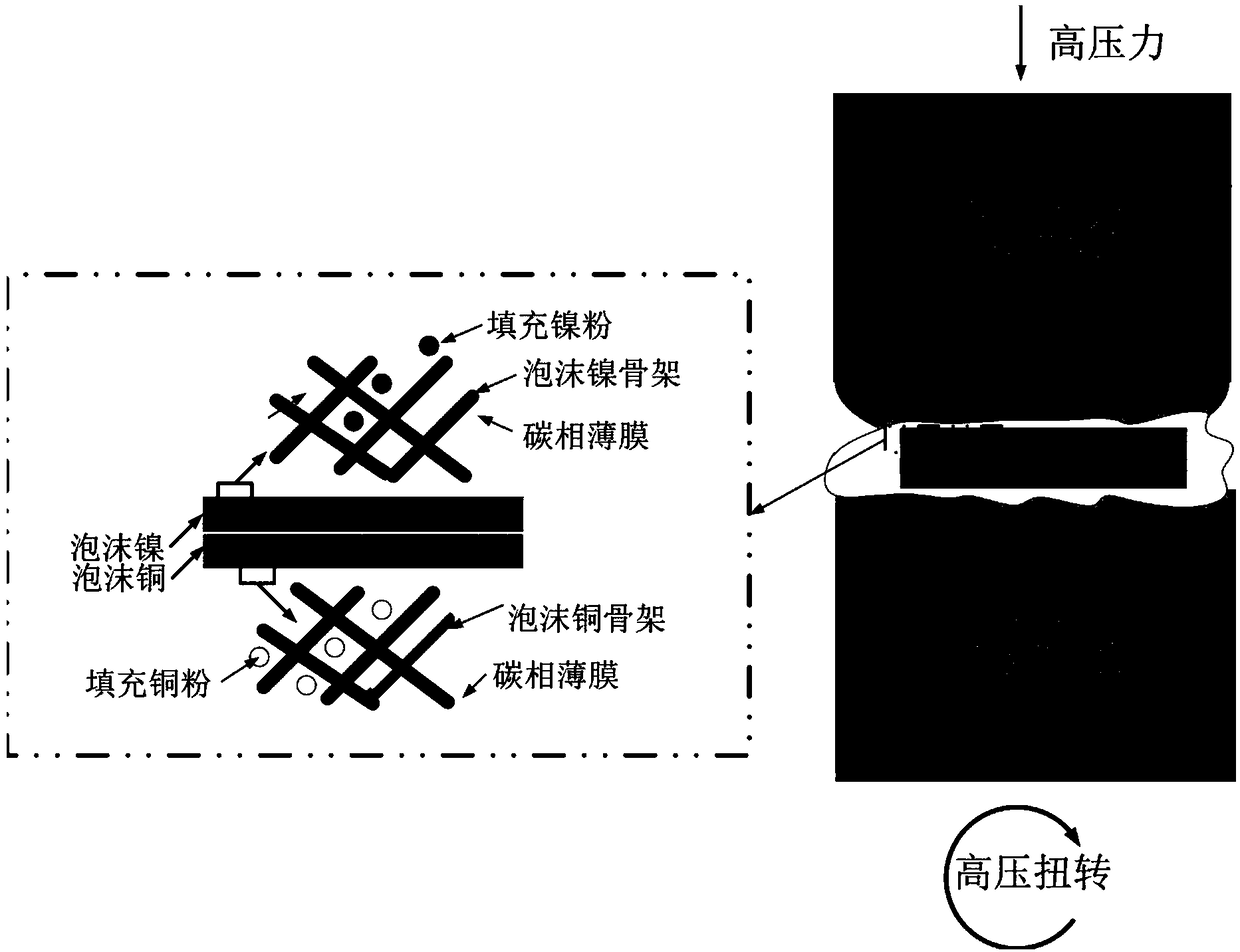

Preparation method of multilayer structural porous metal/nano carbon phase composite material

The invention discloses a preparation method of a multilayer structural porous metal / nano carbon phase composite material. The technical scheme lies in that laminated porous metal with a moderate thickness and a high open-cell rate is taken as the framework; the framework is loaded with a layer of nano carbon phase film with a uniform thickness; the gaps of the porous metal are filled with an appropriate amount of metal powder for assembling; after accumulative roll-bonding or high pressure torsion, the gaps of the porous metal disappear completely, the porous metal framework after transformation and the carbon phase form a compact multilayer nano structure; nano carbon phase with a high volume ratio is uniformly dispersed in the metal matrix during the solid phase preparation process. According to the preparation method, the process is simple, the operation is convenient, the damage to the nano carbon phase is decreased to the lowest, different carbon phase substances can be compounded with different porous metal and metal powder to form a multilayer nano-crystalline and ultra-fine-crystalline composite material; the prepared product has the characteristics of good plasticity, good toughness, fatigue resistance, high tensile strength, excellent electrical conductivity, nontoxicity and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Method for preparing alumina particle reinforced aluminum matrix composite

ActiveCN106216395ASimple structureLow priceAuxillary arrangementsMetal rolling arrangementsBody volumeAccumulative roll bonding

The invention discloses a method for preparing an alumina particle reinforced aluminum matrix composite. The method comprises the steps that aluminum matrix composites of which the roll bonding times are different are obtained through the accumulative roll bonding method at first, and the aluminum matrix composites contain alumina particle reinforcement bodies with different volume fractions; and then, the sample is processed by adopting the follow-up discharge plasma sintering technology, so that the alumina particle reinforced aluminum matrix composite is successfully prepared. The composite obtained through the method is compact and good in bonding condition and contains the reinforcement bodies which have high volume fractions and are dispersed in distribution and small in particle, and the composite has a good comprehensive performance. Alumina particle reinforced aluminum matrix composites with different performances can be obtained by adjusting the accumulative roll bonding times, the reinforcement body volume fractions and other parameters. According to the method adopted by the invention, needed equipment is simple, the cost is low, operation is easy and convenient, and industrialized production is easy.

Owner:WUHAN UNIV

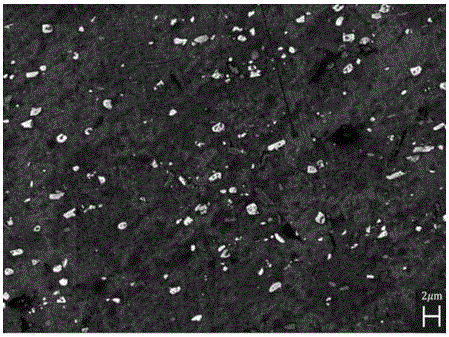

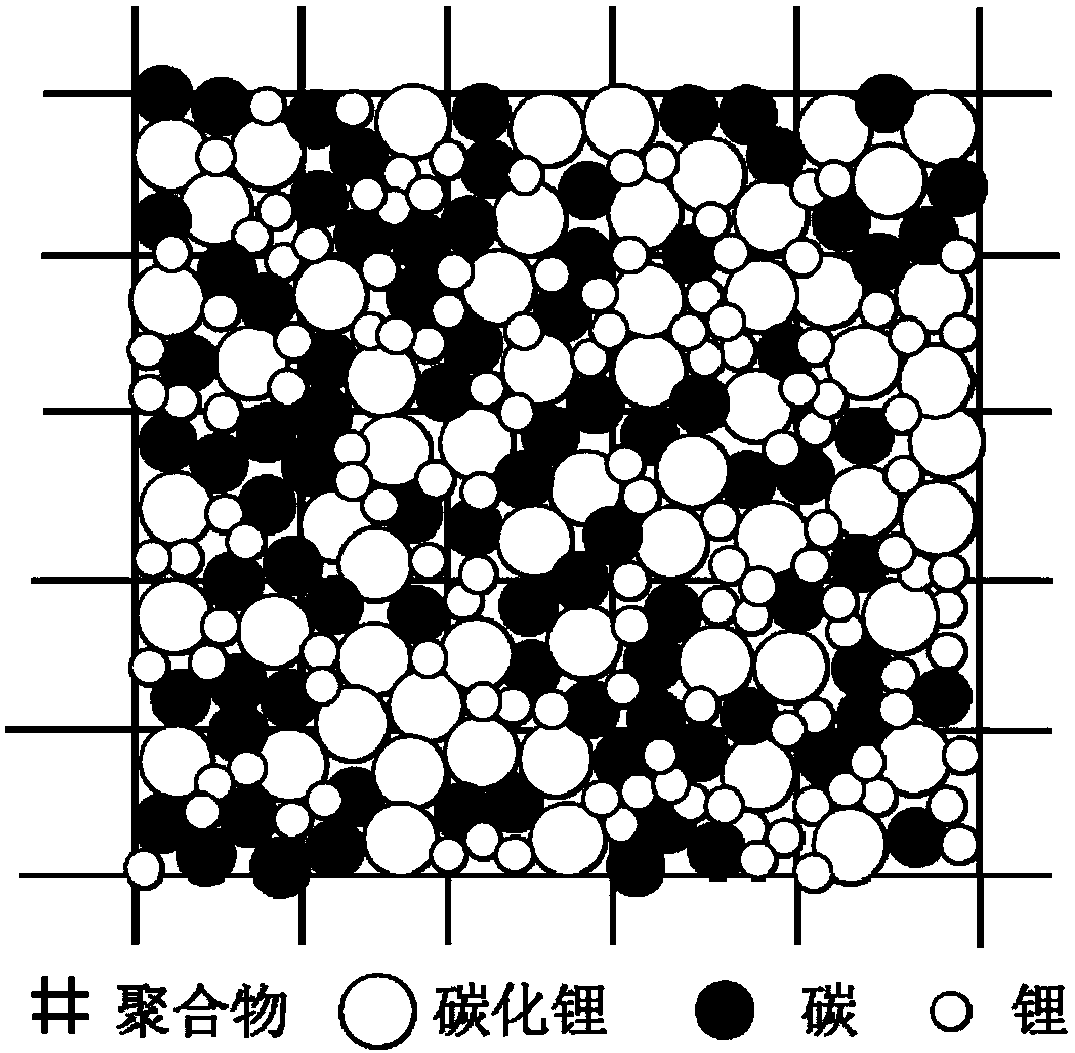

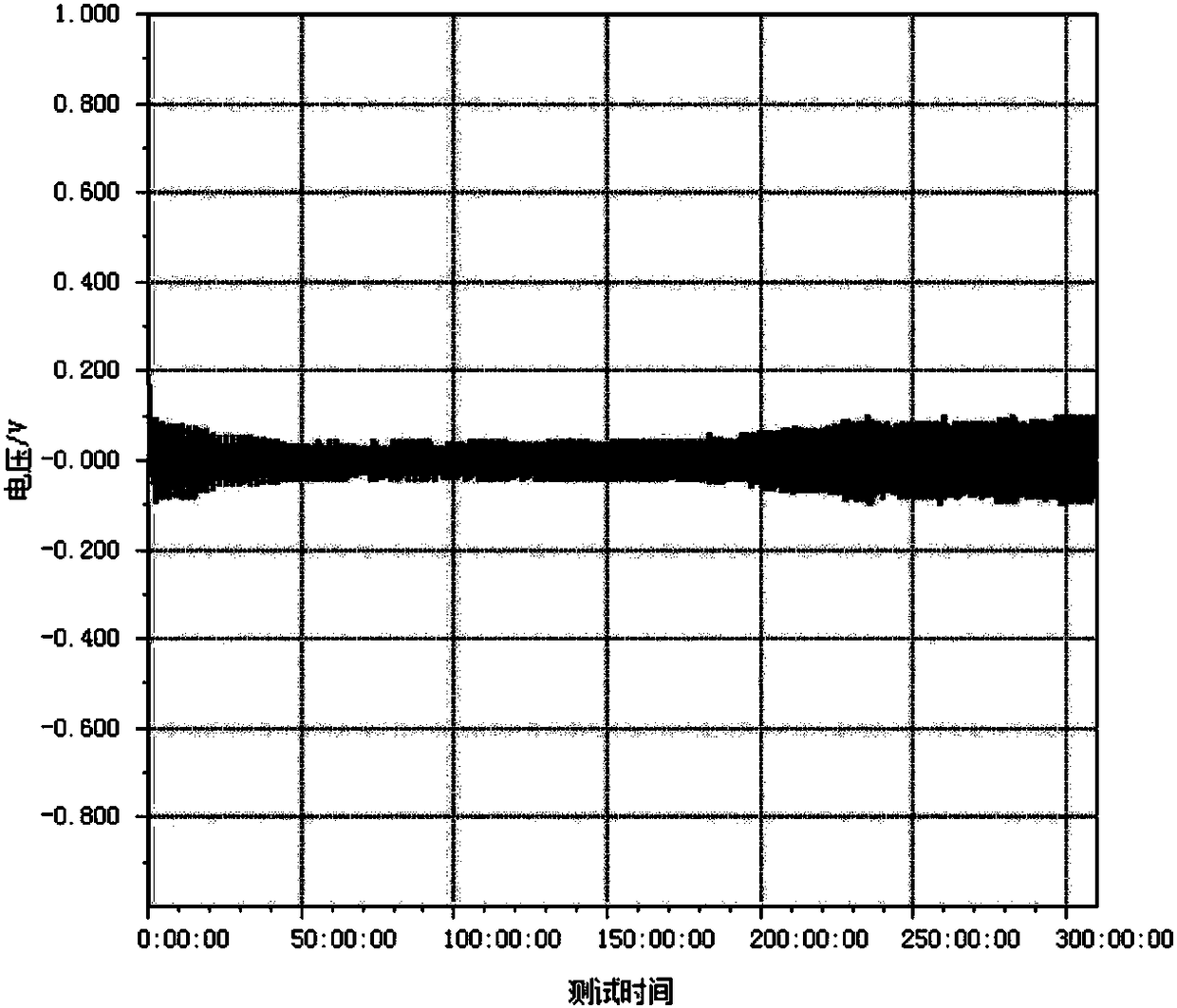

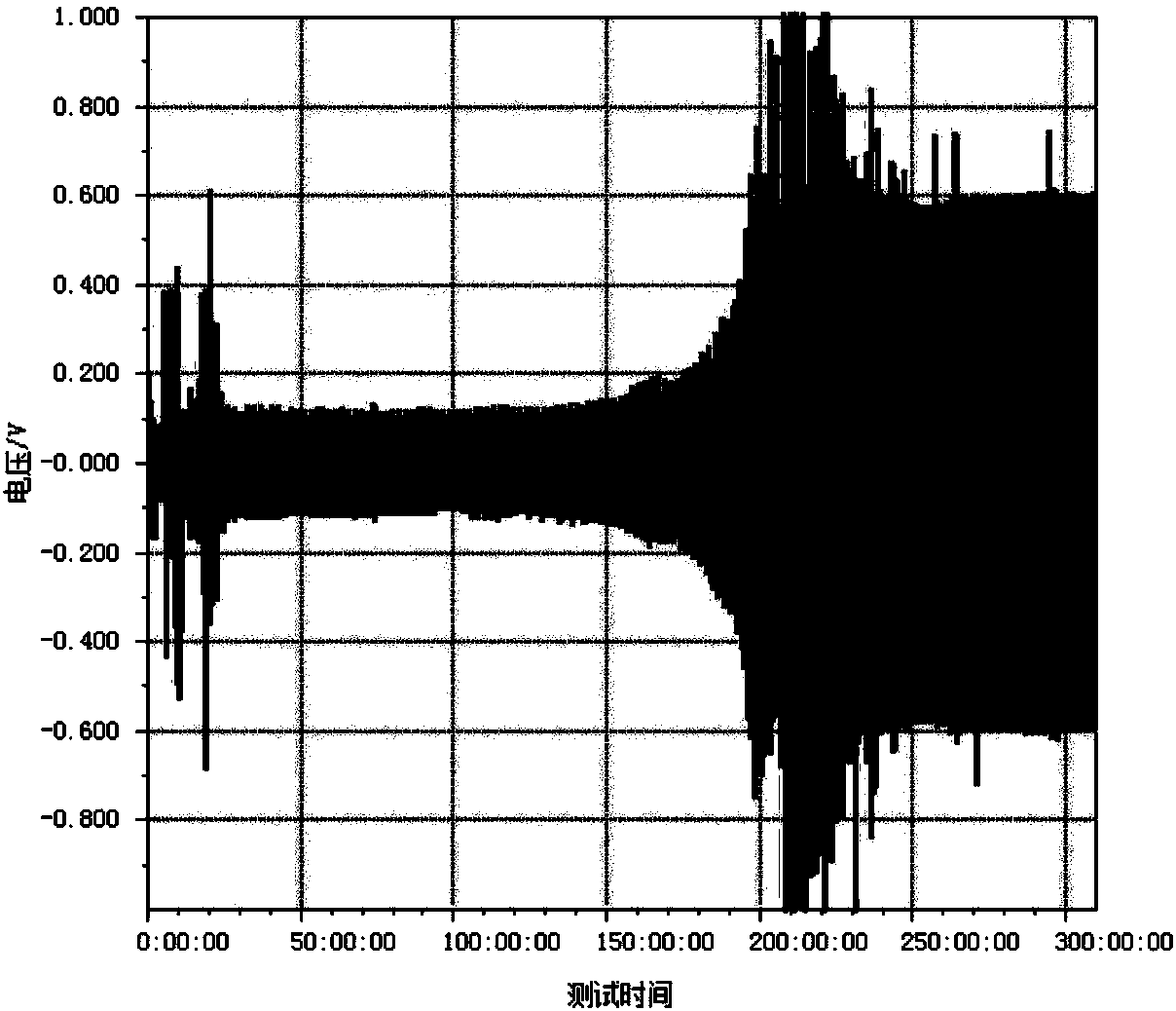

Composite metal lithium negative electrode and preparation method thereof

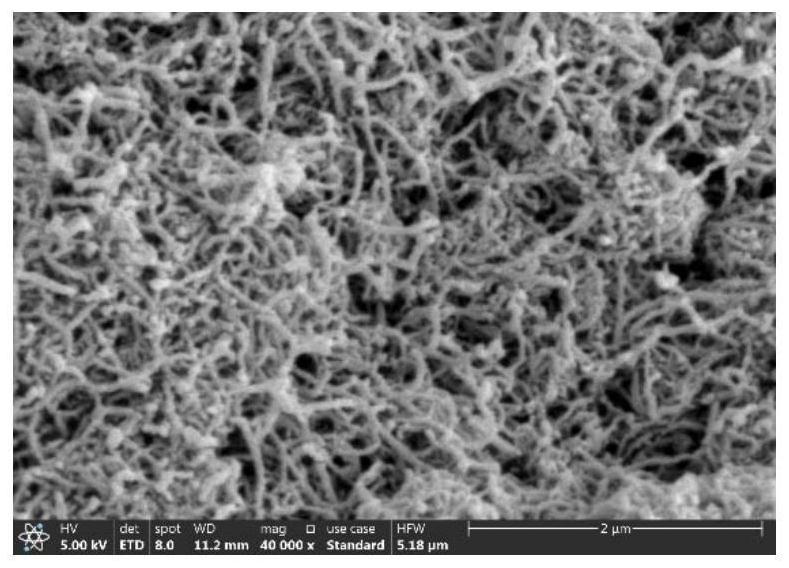

ActiveCN108550808AImprove deposition morphologySolve growth problemsCell electrodesSecondary cellsThree levelNetwork structure

The invention provides a composite metal lithium negative electrode, the composite metal lithium negative electrode comprises a first-level network structure formed by a polymer; a secondary network structure obtained by filing a nano-scale carbon material into the first-level network structure; and a three-level composite structure obtained by filling lithium metal into the secondary network structure. Firstly, the secondary network structure filled with the carbon material is obtained by an accumulative roll bonding method, and then the lithium metal is embedded into the secondary network structure filled with the carbon material by the accumulative roll bonding method, and lithium electrodeposition or evaporative lithium plating to obtain the composite metal lithium negative electrode.The composite metal lithium negative electrode can improve the deposition morphology of the lithium and solve the problem of lithium dendrite growth, thereby improving the cycle performance and safetyof a battery.

Owner:CHINA AVIATION LITHIUM BATTERY RES INST CO LTD +1

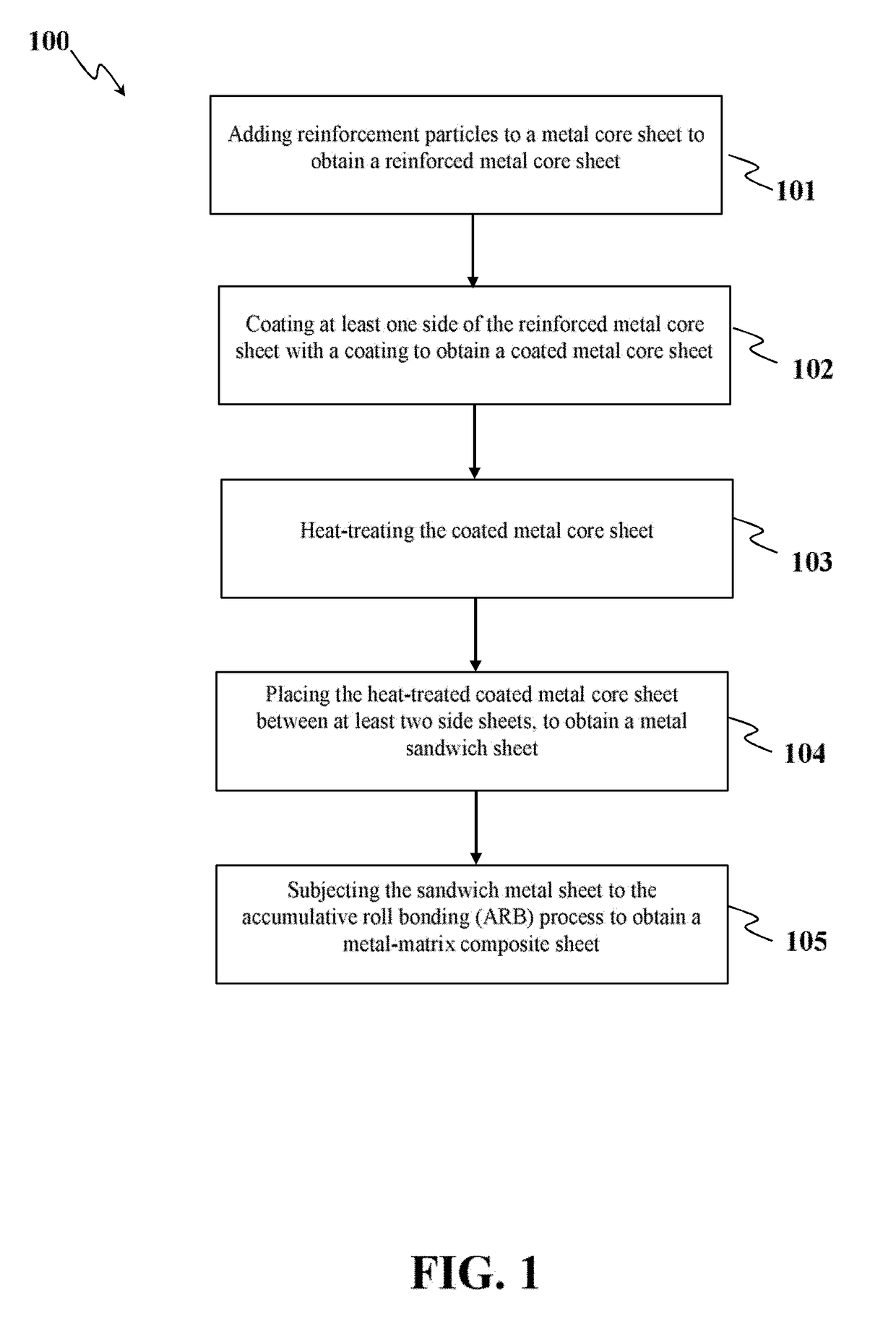

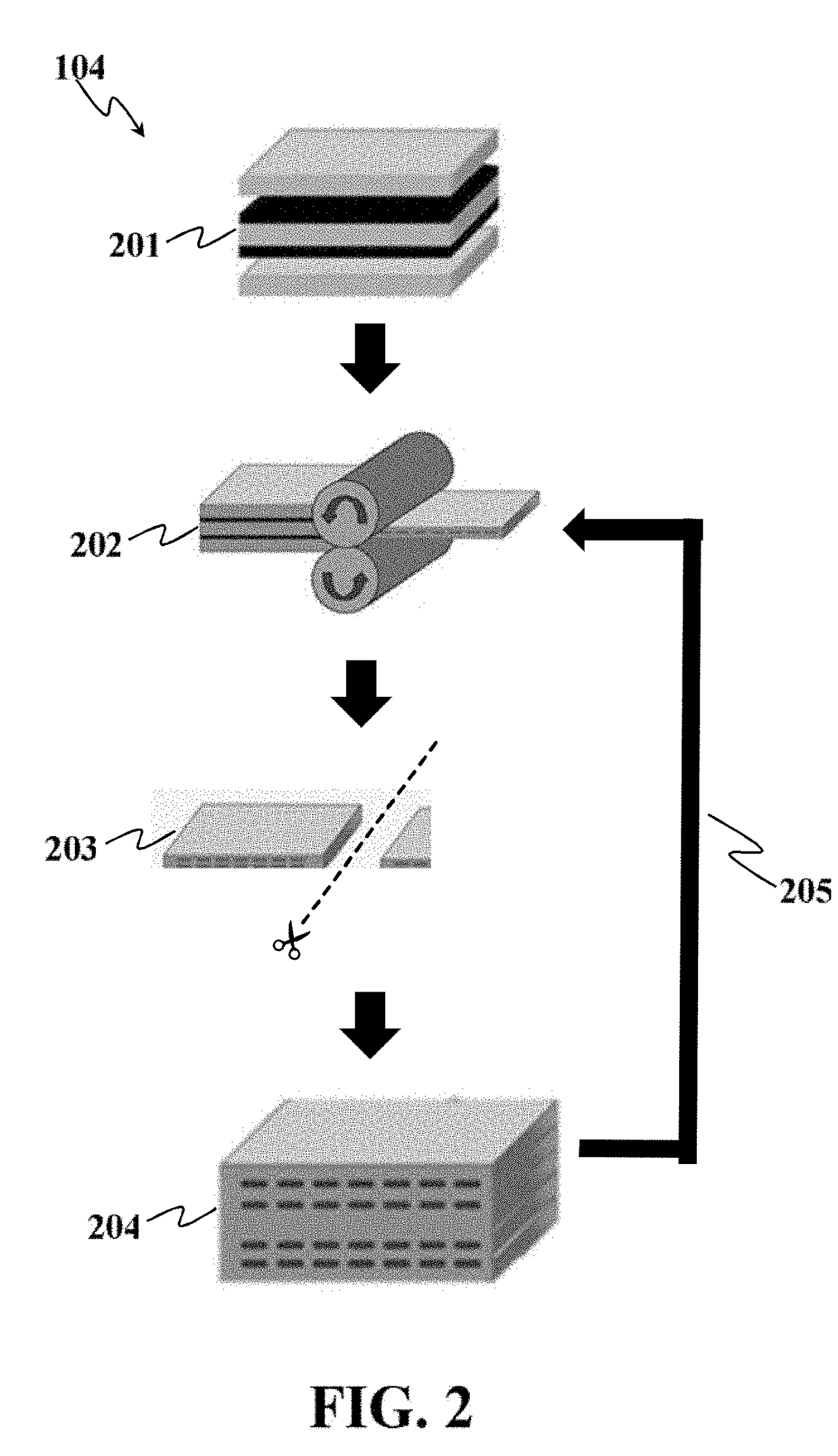

Multilayer metal matrix composite and fabrication thereof

InactiveUS20180057944A1Improve fracture toughnessMolten spray coatingVacuum evaporation coatingMetal matrix compositeAccumulative roll bonding

A multilayer metal-matrix composite that includes a metal core sheet and a plurality of side sheets is disclosed in which the metal core sheet is reinforced with a reinforcement material selected from the group consisting of ceramic reinforcements. The reinforced metal core sheet is coated with an electroless coating. A method of fabricating a multilayer metal-matrix composite with reinforced particles and a coating using a combination of electroless coating method and accumulative roll bonding method is further described in this disclosure with the aim of reducing the number of required accumulative roll bonding cycles to obtain improved or desired properties.

Owner:MOHAMMADIAN NADER +2

TiAl3 particle reinforced aluminum matrix composite material and preparation method and application thereof

The invention discloses a TiAl3 particle reinforced aluminum matrix composite material and a preparation method and application thereof. The preparation method comprises the following steps that nano-titanium powder is uniformly dispersed in an aluminum matrix through room temperature accumulative roll-bonding, then Ti and Al are hot rolled at a temperature lower than the melting point of aluminumto react to generate dispersed TiAl3 particles so as to obtain the TiAl3 particle reinforced aluminum matrix composite material with good compactness, and finally Al in the sample is extruded out through hot extrusion rolling at a temperature higher than the melting point of aluminum, so that the content of TiAl3 in the sample is remarkably improved, the uniformity of the TiAl3 particles is improved, and the density of the sample is further improved in the hot extrusion rolling process. The TiAl3 particle reinforced aluminum matrix composite material has good hardness and strength, the highest hardness can reach 180 Hv, which is more than 6 times as high as pure aluminum, and the highest tensile strength can reach 455 MPa, which is more than 6 times as high as pure aluminum, thus having good application prospect in the field of light and high-strength structural-functional materials.

Owner:WUHAN UNIV

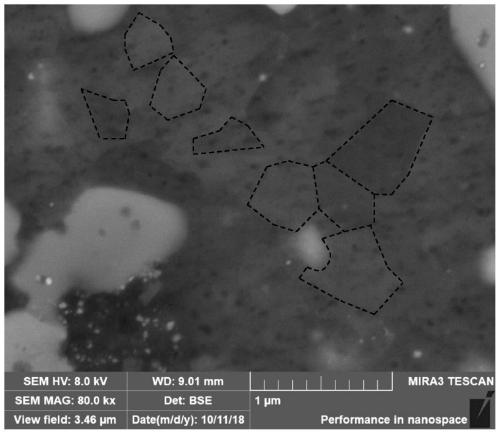

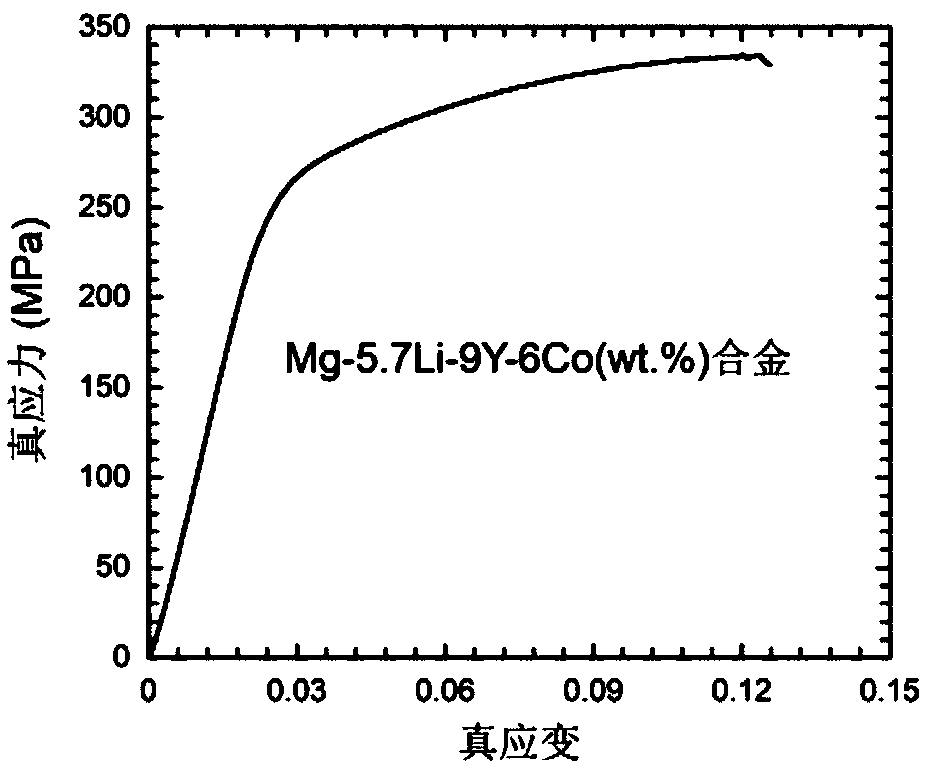

High-strength single-phase (alpha phase) Mg-Li alloy material and preparation method thereof

The invention provides a high-strength single-phase (alpha phase) Mg-Li alloy material and a preparation method thereof, and belongs to the field of metal structural materials. The Mg-Li alloy material is prepared from components in percentage by weight as follows: 0-5.7% of Li, 6.0%-9.0% of rare earth elements, 3.0%-6.0% of Co and the balance of Mg and inevitable impurities. The preparation method of the Mg-Li alloy material comprises the following steps: preheated raw metal is melted in vacuum, an alloy solution is obtained, poured to a mold and cooled, and a cast-state Mg-Li alloy is obtained; the obtained cast-state Mg-Li alloy is subjected to homogenization treatment; the homogenized Mg-Li alloy is rolled at low temperature, wherein low-temperature rolling adopts cross accumulative roll bonding. The Mg-Li alloy material is prepared through steps of vacuum casting, homogenization treatment and low-temperature rolling by reasonably selecting alloy elements and controlling content and proportion of the alloy elements, and has the advantages of high cleanness, high strength and high plasticity.

Owner:ZHEJIANG OCEAN UNIV

High-entropy alloy particle reinforced metal matrix composite material and preparation method thereof

ActiveCN111672906AHigh densityGood phase diffusionFurnace typesAuxillary arrangementsHigh entropy alloysComposite plate

The invention discloses a high-entropy alloy particle reinforced metal matrix composite material and a preparation method thereof. The method comprises the following steps of 1, taking two metal plates with the same size, uniformly coating high-entropy alloy particles on the surface of the metal plates, and then sequentially stacking, riveting and rolling the two metal plates to form a composite plate; 2, carrying out accumulative stitch welding on the composite plate, and cutting, stacking and riveting each time of the accumulative roll bonding until the thickness of a lamination reaches therequired thickness to form a composite material; and 3, carrying out heat treatment on the composite material after accumulative roll bonding, so that a diffusion layer is formed between the high-entropy alloy particles and the metal plates, and the high-entropy alloy particle reinforced metal matrix composite material is obtained. The high-entropy alloy particle reinforced metal matrix compositematerial with improved strength and good plastic toughness is obtained.

Owner:CHANGAN UNIV

High-specific-strength magnesium-lithium-based composite material and preparation method thereof

ActiveCN113249625AAchieve preparationHigh specific strengthLaminationLamination apparatusElectrophoresesCarbon nanotube

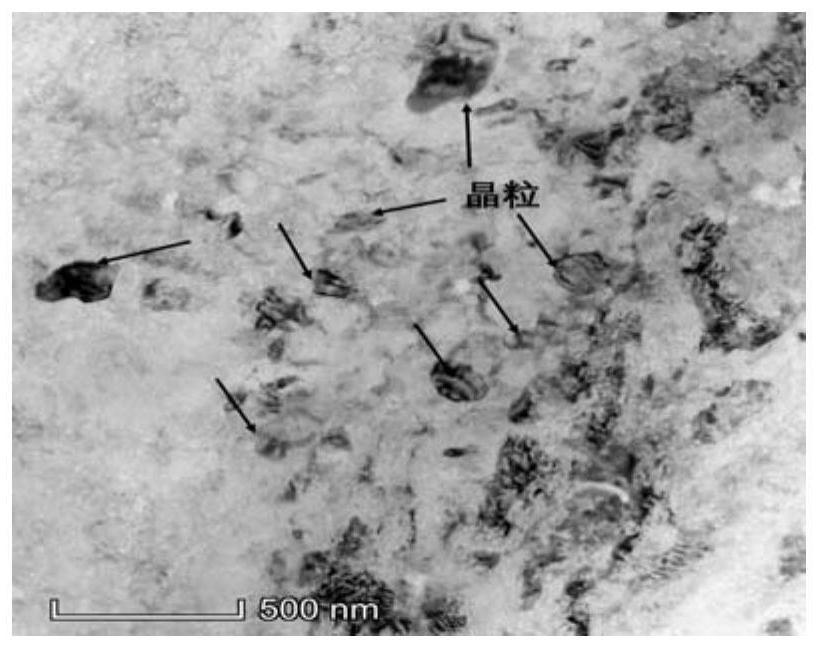

The invention provides a high-specific-strength magnesium-lithium-based composite material and a preparation method thereof. The high-specific-strength magnesium-lithium-based composite material takes an ultra-light magnesium-lithium alloy LA141 as a matrix and multi-walled carbon nano-tubes as a reinforcement, and is prepared through the following steps that (1) an MWCNTs film layer is prepared through an electrophoretic deposition technology; (2) an LA141 / MWCNTs plate is prepared through accumulative roll bonding; and (3) stirring friction processing is carried out to prepare the LA141 / MWCNTs composite material. According to the magnesium-lithium-based composite material and the preparation method thereof disclosed by the invention, the preparation of the magnesium-lithium-based composite material is realized by combining the electrophoretic deposition technology, an accumulative pack rolling technology and stirring friction processing; the method is easy to operate and low in cost, and the composite material which is ultra-fine in grain, uniform in reinforcement distribution and high in specific strength is prepared.

Owner:HARBIN ENG UNIV

Method for preparing fcc-Al reinforced amorphous/aluminum laminar composite material on basis of accumulative roll bonding

InactiveCN110038899AHigh tensile strengthImprove mechanical propertiesMetal rolling arrangementsCrystallization temperatureMechanical property

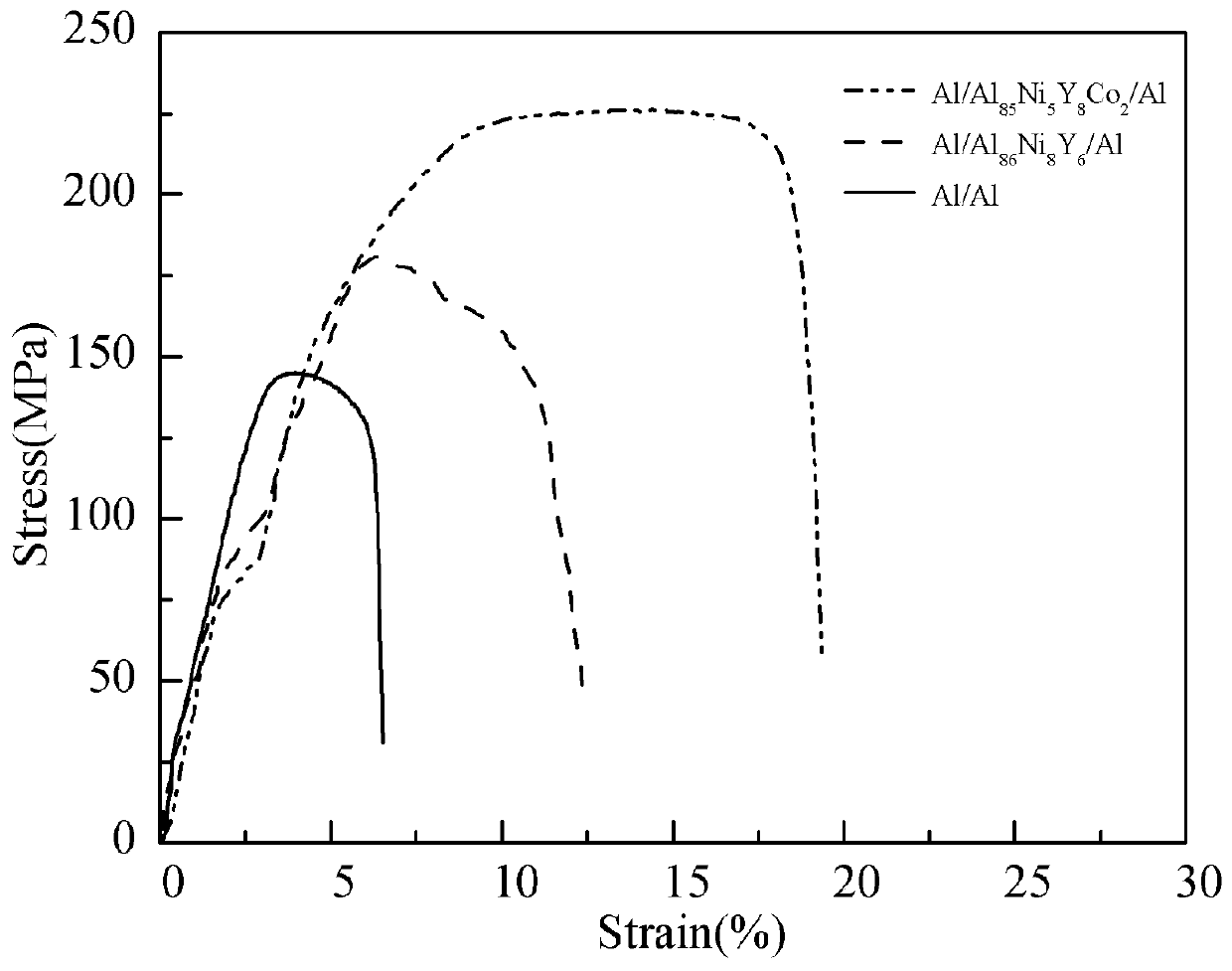

The invention provides a method for preparing a fcc-Al reinforced amorphous / aluminum laminar composite material on the basis of accumulative roll bonding. The method for preparing the fcc-Al reinforced amorphous / aluminum laminar composite material on the basis of accumulative roll bonding is carried out according to the following steps: (1) taking metals Al, Ni, Y and Co as raw materials, and preparing a mother alloy containing different components by virtue of vacuum electric arc melting; (2) choosing a temperature after melt structure transition and preparing amorphous ribbons; (3) cleaningthe amorphous ribbons and the surface of an aluminum alloy, then arranging the amorphous ribbons between two layers of aluminum plates separately and fully laying the amorphous ribbons, and tightly riveting by virtue of rivets and then rolling; and (4) cutting the rolled-compounded plates into two pieces with an equal size in a direction vertical to a rolling direction, stacking the two pieces again, and continuously repeating the process to obtain the laminar composite material. The method for preparing the fcc-Al reinforced amorphous / aluminum laminar composite material on the basis of accumulative roll bonding is started with the amorphous melt structure transition, the mechanical property of the laminar composite material obtained by preparing the amorphous ribbons with the widest crystallization temperature range at first, and then carrying out accumulative roll bonding with 1060 aluminum is greatly improved, and then an application prospect is provided for the aluminum-based amorphous ribbon material.

Owner:CHANGZHOU UNIV

Composite board prepared by accumulative roll bonding of aluminum plates and titanium plates and preparation method of composite board

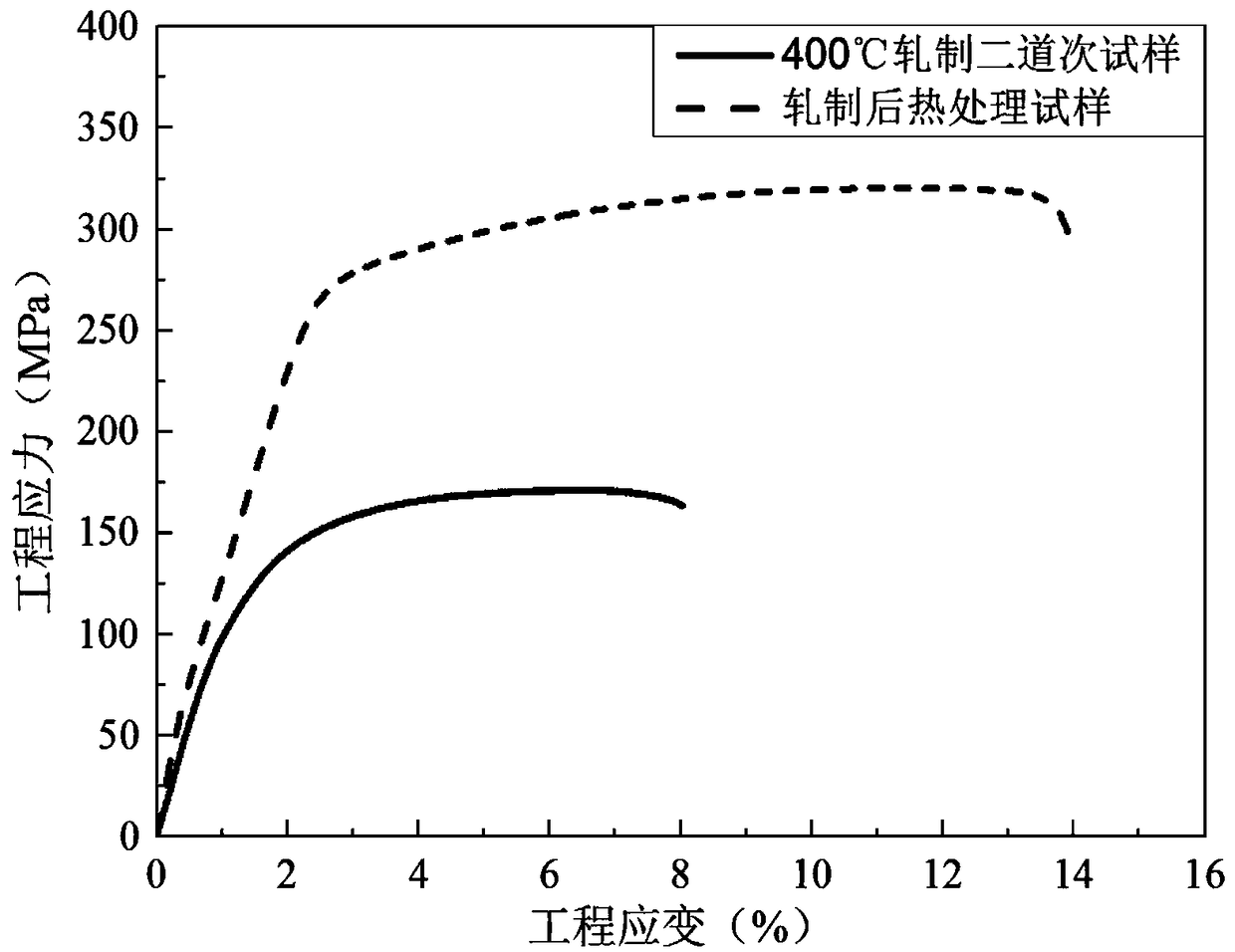

InactiveCN108724847ASimple process requirementsImprove production efficiencyLaminationLamination apparatusBond interfaceTitanium

The invention discloses a composite board prepared by accumulative roll bonding of aluminum plates and titanium plates and a preparation method of the composite board. The preparation method comprisesthe following steps: performing accumulative assembly on two layers of titanium plates and three layers of aluminum plates to obtain accumulated plates, fixedly bundling and uniformly preheating theaccumulated plates, performing accumulative assembling for three times, fixed bundling and rolling so as to obtain three-rolling plates, and finally performing heat treatment on the three-rolling plates, thereby obtaining the composite board. According to the preparation method disclosed by the invention, process requirements are simple, the preparation efficiency is high, the cost is low, and theprepared composite board is excellent in bonding interface and excellent in mechanical property.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

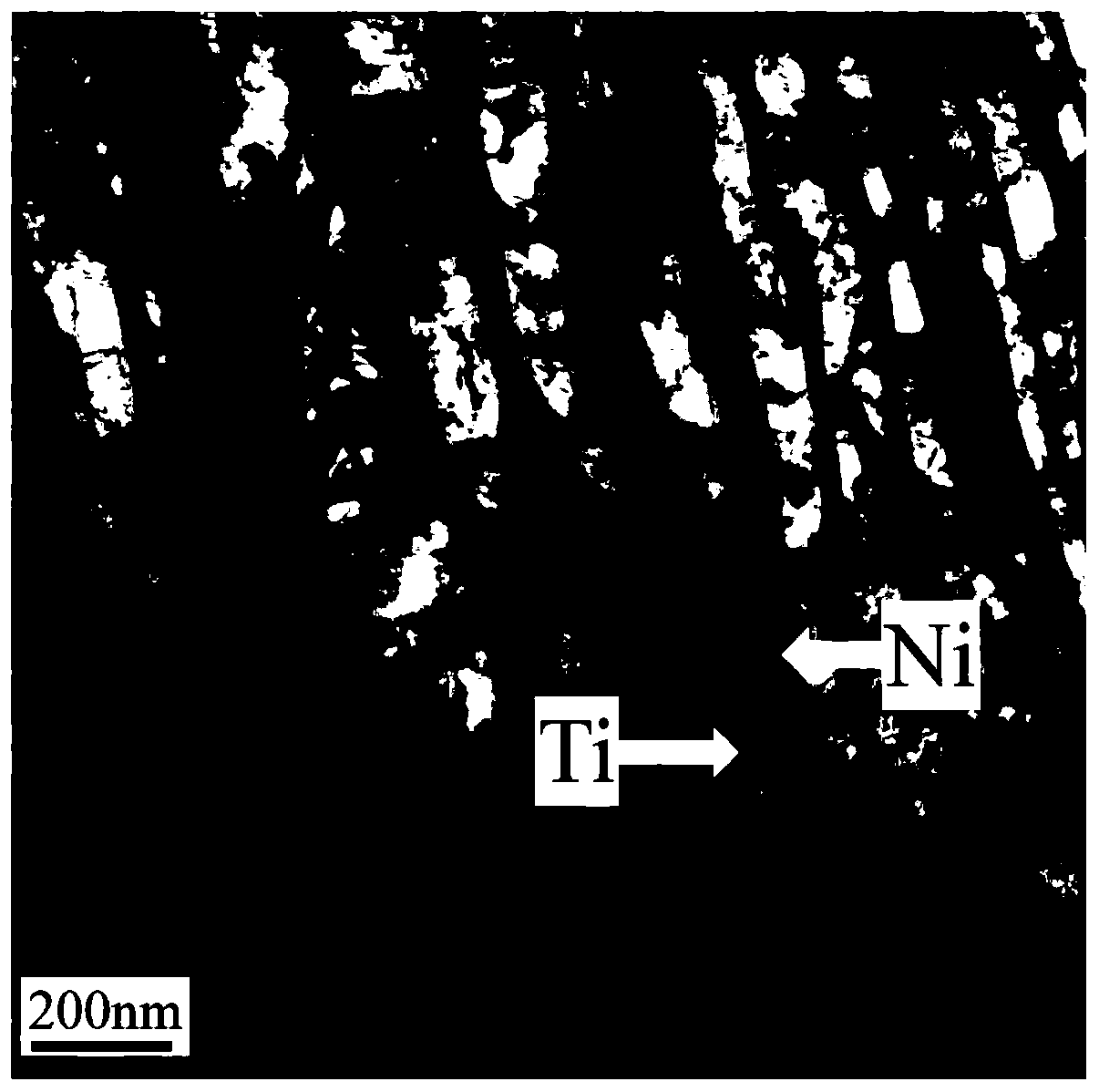

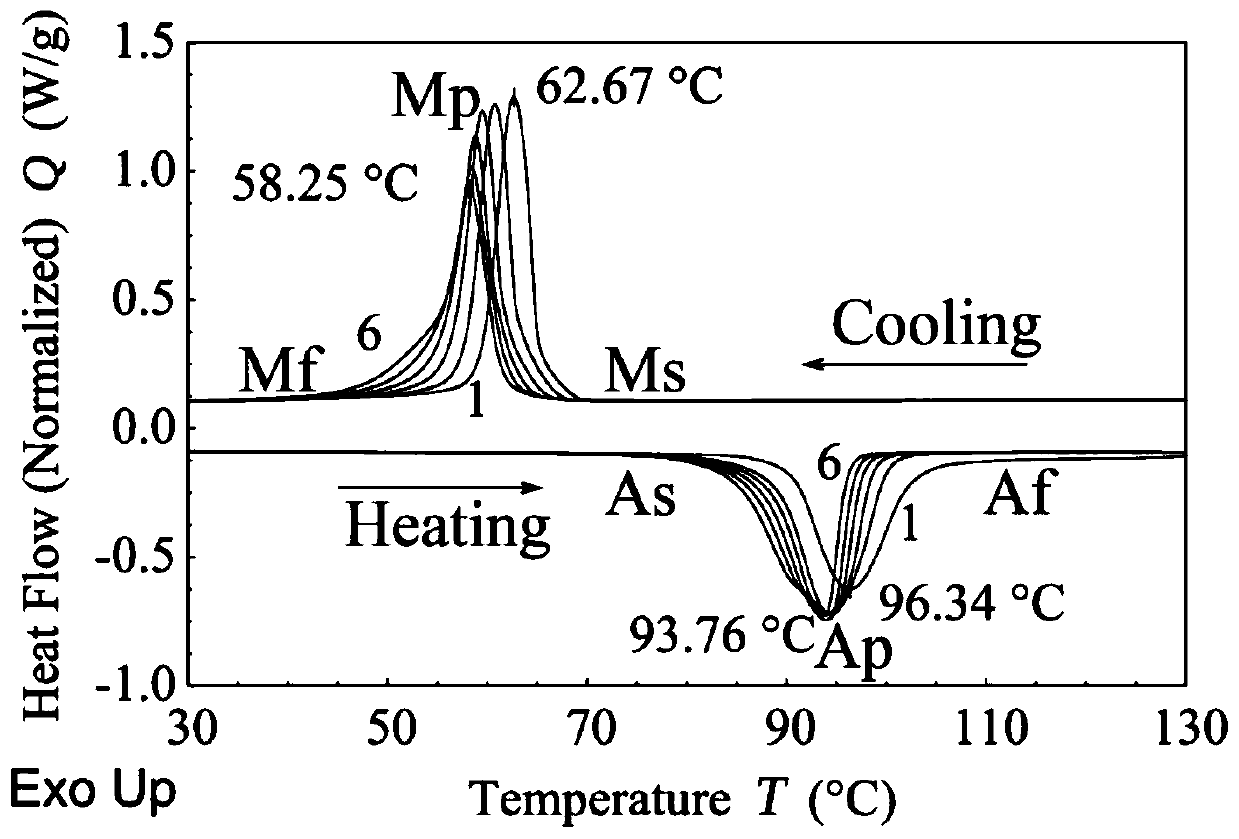

Preparing method of memory alloy nano lamination Ni/Ti preformed blank

ActiveCN110842022AImproved deformation coordinationReduce distanceDrying gas arrangementsArc welding apparatusNiti alloySmelting process

The invention discloses a preparing method of a memory alloy nano lamination Ni / Ti preformed blank, and belongs to the technical field of functional composites. The method comprises the steps of firstly, material preparing, secondly, packaging and thirdly, rolling. Room temperature accumulative roll bonding is adopted, in combination with wrapping of a jacket, the deforming is limited and obstructed, Ni / Ti coordinative deforming is facilitated, and the problems that in the traditional smelting process, NiTi alloy easily introduces impurity elements, the material machining property is poor, inthe cold machining process, deforming resistance is large, and the pass deforming amount is small are solved. Due to the fact that three segments of accumulative roll bonding are carried out at the room temperature, the middle process is not annealed, the residual stress of the finally-composited Ni / Ti layered preformed blank is large, the activity between Ni atom and Ti atom interfaces is high, the layered Ni / Ti preformed blank is high in hardness, and the elastic modulus is high. Time needed by generating of the NiTi shape memory alloy through the certain-temperature reaction diffusion of Niand Ti is shorter, TiNi alloy grains can be generated through refining to a certain degree, the NiTi high-quality shape memory alloy is improved, the grains are thin, the phase change temperature stability can be improved, and the austenitization phase change temperature is slightly increased.

Owner:NORTHEASTERN UNIV +1

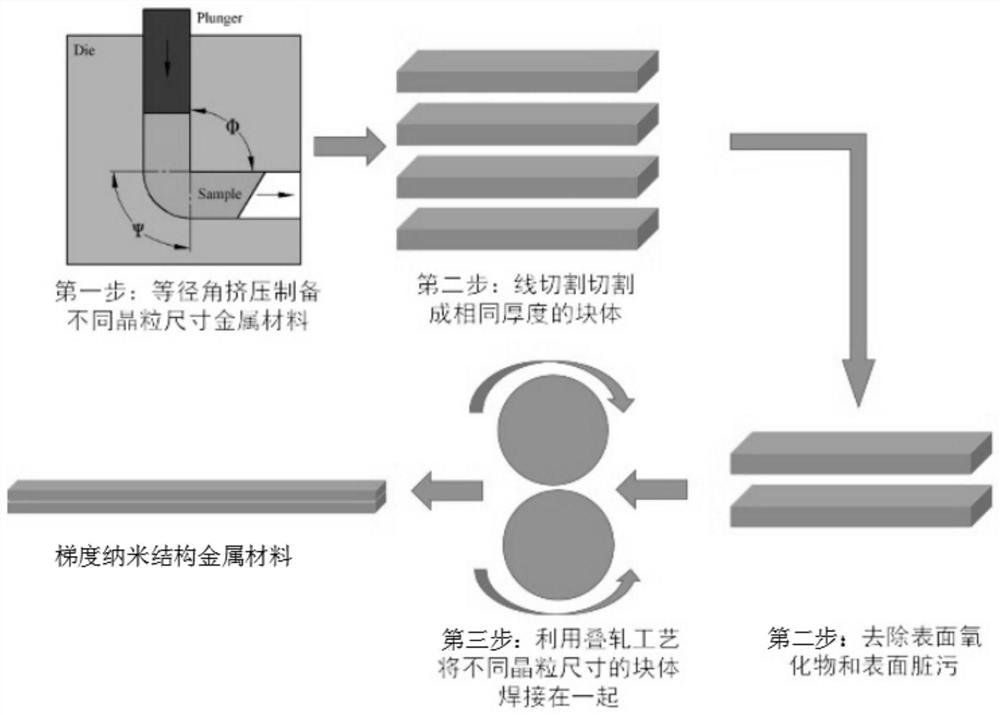

Gradient nano-structure metal material and preparation method thereof

The invention relates to the technical field of precision machining, and provides a preparation method of a gradient nano-structure metal material. The preparation method comprises the following steps: providing n original metal materials, and carrying out extrusion treatment of different passes on the original metal materials respectively through an equal channel angular extrusion process to obtain n metal materials with different grain sizes; cutting the n metal materials through a linear cutting process, and carrying out impurity removal treatment to obtain n metal material sheets with different grain sizes; providing the original metal material sheets and coarse-grain metal material sheets, and sequentially stacking the original metal material sheets, the coarse-grain metal material sheets and the n metal material sheets according to the grain sizes, and sequentially carrying out ply rolling treatment on the original metal material sheets, the coarse-grain metal material sheets and the n metal material sheets through an accumulation ply rolling welding process to prepare the gradient nano-structure metal material. The preparation method is simple and convenient, and flexibility is high, so that the obtained gradient nano-structure metal material can ensure high material strength and material toughness simultaneously.

Owner:SHENZHEN TECH UNIV

Method for preparing copper/molybdenum composite board with molybdenum fibers by accumulative roll bonding

ActiveCN102529217BImprove conductivityImprove thermal conductivityLaminationLamination apparatusHydrogenCopper

The invention discloses a method for preparing a copper / molybdenum composite board with molybdenum fibers by accumulative roll bonding. In the copper / molybdenum composite board with molybdenum fibers, prepared by the method, molybdenum is fractured to be in a fibrous form by accumulative roll bonding, and then is pinned in a copper plate, and the density of molybdenum fiber can be controlled by accumulative roll bonding passes; and the preparation comprises pretreatment, hot rolling bonding, accumulative roll bonding, finished product annealing and follow-up processing. In the copper / molybdenum composite board with molybdenum fibers, prepared by the method, the copper / molybdenum composite board with different molybdenum fiber densities can be prepared by accumulative roll bonding, and during rolling, a copper-molybdenum interface does not crack, and has no oxidization phenomenon during heat treatment under an argon or hydrogen protective condition, and the prepared composite board has the advantages that the longitudinal tensile strength is 180-360MPa, the transverse tensile strength is 390-620MPa, the elongation rate is 25%-45% and the heat expansion coefficient is controllable. The method has the characteristics of simple preparation process, strong controllability and high yield, and has the most remarkable advantage of being used for large-scale production.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Preparation method for TLM titanium alloy foil with nanocrystalline structure

InactiveCN104762578AAchieve large deformationIncrease productivityFurnace typesHeat treatment furnacesStress relievingTitanium alloy

The invention provides a preparation method for TLM titanium alloy foil with a nanocrystalline structure. The method includes the following steps of firstly, conducting homogenizing annealing on a TLM titanium alloy plate; secondly, conducting surface processing; thirdly, conducting cold rolling to obtain a foil blank; fourthly, conducting stress relieving; fifthly, sequentially conducting shearing, acid pickling, washing and drying, and then conducting sheath ply rolling till the accumulated deformation amount of rolling reaches 80% to 90%; sixthly, repeatedly executing the fifth step till the average grain size of the foil blank is smaller than 100 nm, and obtaining the TLM titanium alloy foil with the nanocrystalline structure. Production is conducted through an existing conventional device, namely, a two-roller rolling mill or a four-roller rolling mill, the method is particularly suitable for industrially preparing the nanocrystalline foil, production procedures are simple, the limitation on the panel size and materials is small, and grains and the weight of the foil can be easily controlled. Accumulative ply rolling is conducted on the foil of multiple layers, and the nanocrystalline foil with the unique performance can be obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparing method of Ti2AlC particle reinforced copper base composite

The invention discloses a preparing method of a Ti2AlC particle reinforced copper base composite, and belongs to the field of composite preparing. The method comprises the specific steps that Ti2AlC particle suspension is prepared; an oxygen-free pure copper plate in the completely annealed state is subject to surface treatment; the dispersed Ti2AlC particle suspension is evenly sprayed to the surfaces of copper plates, the two copper plates are overlapped, fastened, rolled, and cut in half, the above process is repeated few times, Ti2AlC particles are continuously added, and finally, a boardis continuously subject to accumulative roll-bonding at multiple passes. According to the preparing method, dispersion of reinforced particles in a base body can be obviously improved, through the coordinative effect of particle reinforcing, refined crystalline strengthening and work hardening, the hardness and the strength of the composite can be obviously improved, conductive performance is notobviously reduced, and the preparing method is easy to operate, simple in process, low in cost and capable of being produced in batch.

Owner:YANCHENG INST OF TECH

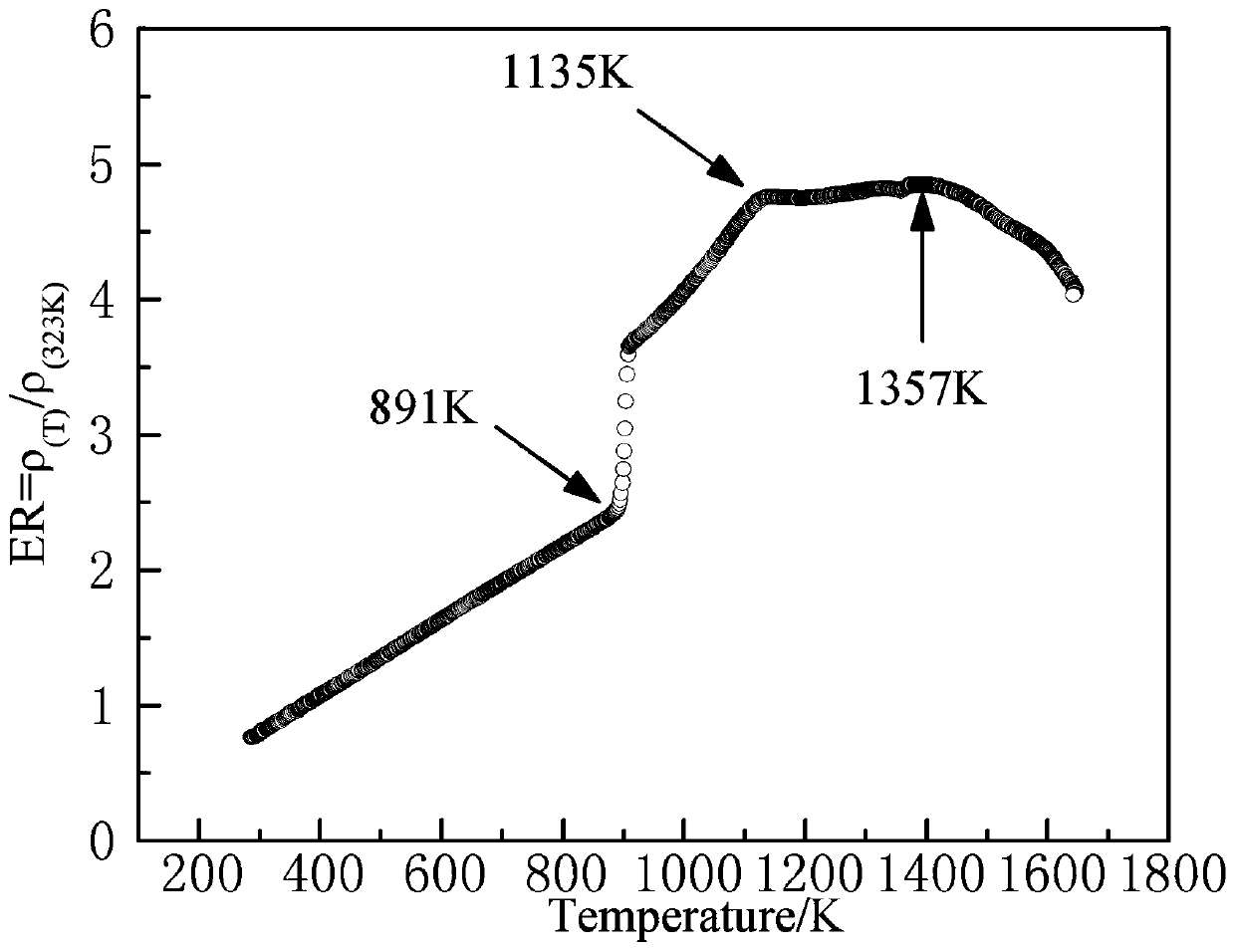

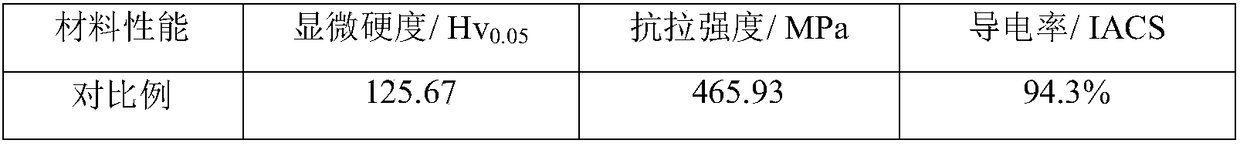

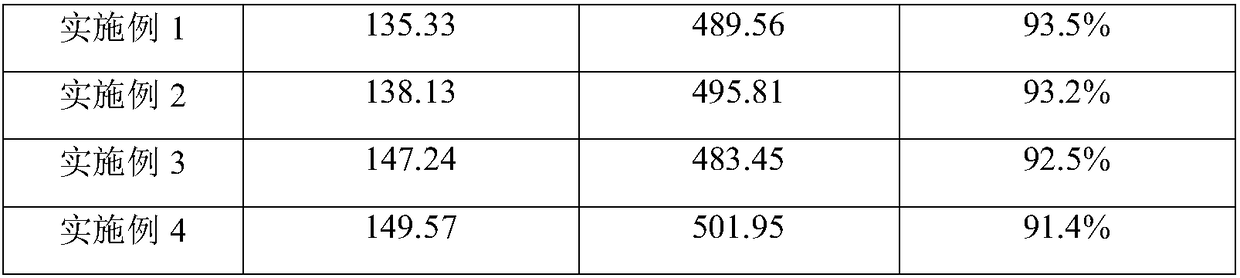

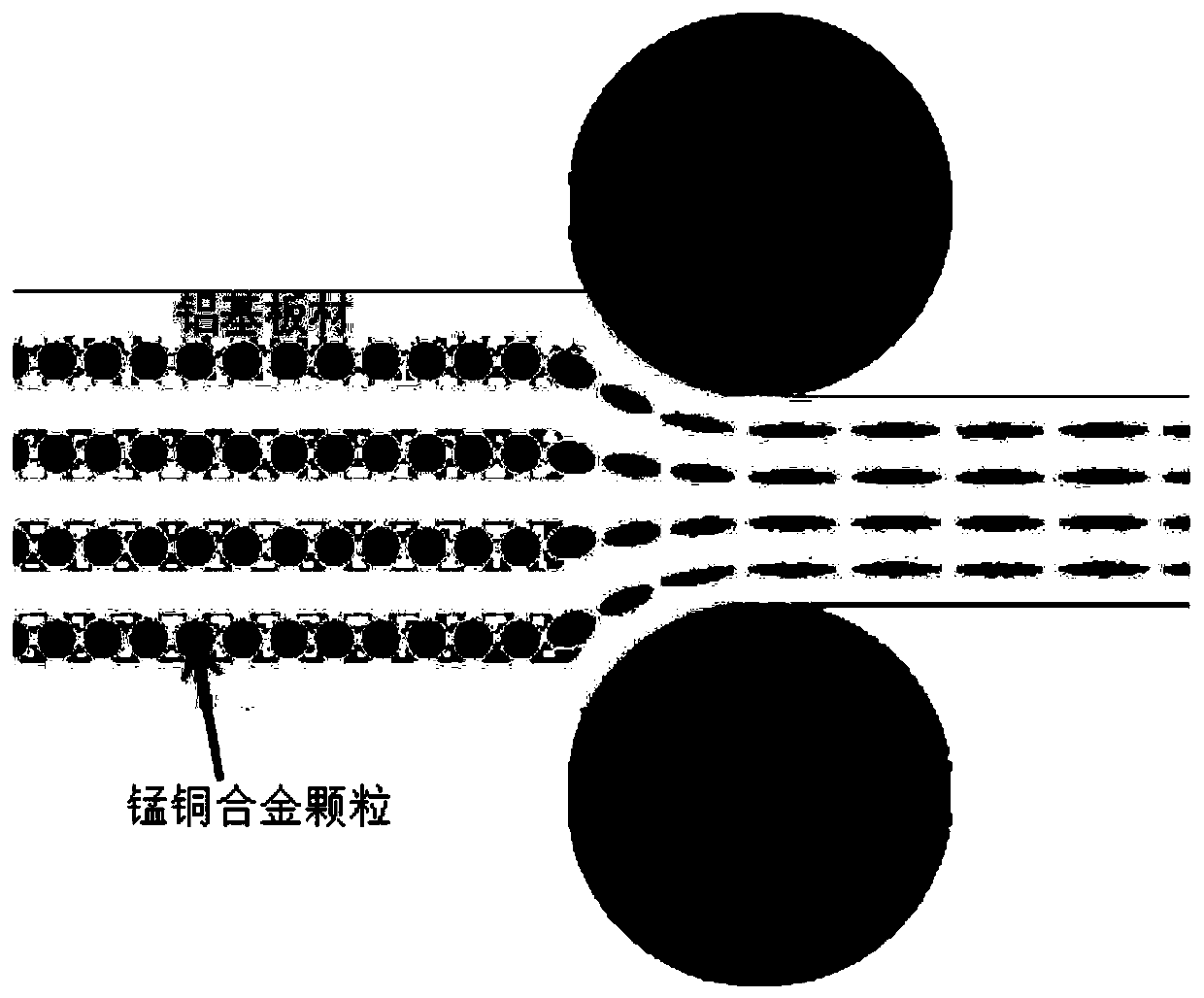

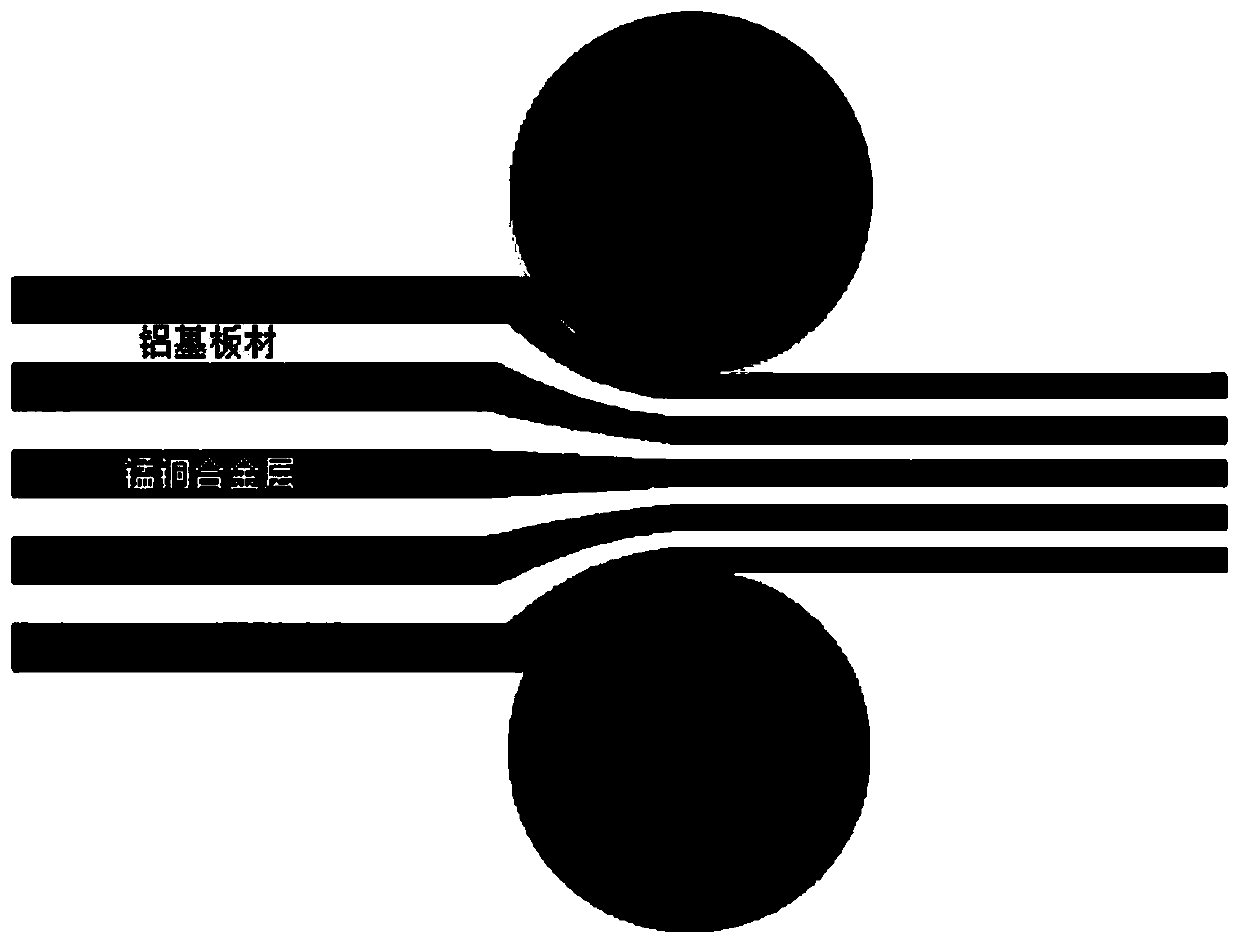

A kind of reinforced lightweight metal matrix composite material based on mn-cu alloy and its preparation method

ActiveCN106583456BOvercome the densityImprove damping performanceMetal rolling arrangementsAviationRoom temperature

The invention discloses an enhanced light metal base composite based on a Mn-Cu alloy and a preparing method of the enhanced light metal base composite. The composite is prepared and obtained in the manner that Mn-Cu alloy particles and a light metal base plate are subjected to interlayer welding through an accumulative roll-bonding method, or a Mn-Cu alloy panel and the light metal base plate are subjected to interlayer welding through the accumulative roll-bonding method. Through a large amount of experiment work, the accumulative roll-bonding method is applied to preparing of the Mn-Cu enhanced light metal base composite for the first time, the damping performance and mechanical performance of the light metal base damping material at the temperature near the room temperature are greatly improved, the requirement for the structural material in the near-room-temperature vibration reducing and noise lowering applying field can be well met, and the enhanced light metal base composite is particularly applicable to the space flight and aviation field and other high technology fields requiring the low density and high performance.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A kind of high-strength toughness magnesium-lithium alloy layered composite material and preparation method thereof

The invention provides a high-strength and toughness magnesium-lithium alloy layered composite material and a preparation method thereof. The preparation method comprises the following steps: 1, cutting an alpha-Mg single phase Mg-Li alloy plate and a beta-Li single phase Mg-Li alloy plate to from two places with same dimensions; 2, fixing the Mg-Li alloy plates obtained in step 1; 3, carrying out composite rolling on the well fixed Mg-Li alloy plates; 5, cutting an Mg-Li alloy plate obtained in step 3 to form two pieces with same dimensions, superposing and fixing the two pieces, and carrying out composite rolling; 5, repeating step 4 5-8 passes to obtain an accumulative roll-bonded composite plate; and 6, annealing the accumulative roll-bonded composite plate obtained in step 5 in a heat treatment furnace. Accumulative roll-bonding is carried out to realize formation of a rub rolling area in order to realize the good interface combination effect of the composite plate. The annealing treatment further improves the interface combination strength, the elongation percentage and other mechanical performances of the composite plate.

Owner:HARBIN ENG UNIV

A kind of preparation method of porous metal/nano-carbon phase composite material with multilayer structure

The invention discloses a preparation method of a multilayer structural porous metal / nano carbon phase composite material. The technical scheme lies in that laminated porous metal with a moderate thickness and a high open-cell rate is taken as the framework; the framework is loaded with a layer of nano carbon phase film with a uniform thickness; the gaps of the porous metal are filled with an appropriate amount of metal powder for assembling; after accumulative roll-bonding or high pressure torsion, the gaps of the porous metal disappear completely, the porous metal framework after transformation and the carbon phase form a compact multilayer nano structure; nano carbon phase with a high volume ratio is uniformly dispersed in the metal matrix during the solid phase preparation process. According to the preparation method, the process is simple, the operation is convenient, the damage to the nano carbon phase is decreased to the lowest, different carbon phase substances can be compounded with different porous metal and metal powder to form a multilayer nano-crystalline and ultra-fine-crystalline composite material; the prepared product has the characteristics of good plasticity, good toughness, fatigue resistance, high tensile strength, excellent electrical conductivity, nontoxicity and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

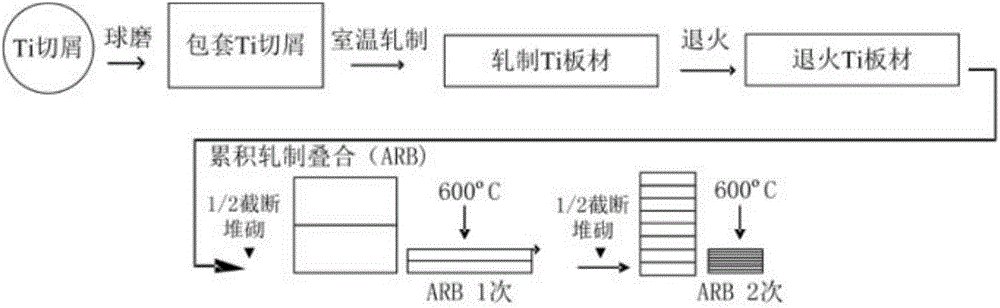

Ball milling-accumulative roll bonding method for circulating solidification of pure titanium machining chips

The invention provides a ball milling-accumulative roll bonding method for circulating solidification of pure titanium machining chips. The ball milling-accumulative roll bonding method for circulating solidification of the pure titanium machining chips comprises the following steps of (1) recovering pretreatment of the Ti machining chips, specifically, the Ti machining chips are cleaned, and thus oil stains and impurities are removed; (2) BM treatment of the Ti machining chips, specifically, ball-milling is conducted on the Ti machining chips pretreated in the step (1); (3) wrapping and packaging of BM-Ti machining chips, specifically, the BM-Ti machining chips are placed into a cavity of a titanium cylinder and then compacted preliminarily through a hand press; (4) indoor-temperature cold-rolling of the wrapped and packaged BM-Ti machining chips, specifically, cold-rolling is conducted on the BM-Ti machining chips wrapped and packaged in the step (3), so that a cold-rolled Ti plate is prepared; (5) annealing treatment of the cold-rolled Ti plate, specifically, the cold-rolled Ti plate is heated to the temperature of 750-850 DEG C, maintained at the temperature for 30-40 minutes and then air-cooled; (6) high-temperature solidification of the Ti machining chips through ARB, specifically, two-pass roll-bonding is conducted on the Ti plate annealed in the step (5), and thus a blocky Ti material is prepared; and (7) quenching, specifically, the blocky Ti material obtained in the step (6) is quenched and cooled to the indoor temperature in a water cooling way.

Owner:SHANGHAI DIANJI UNIV

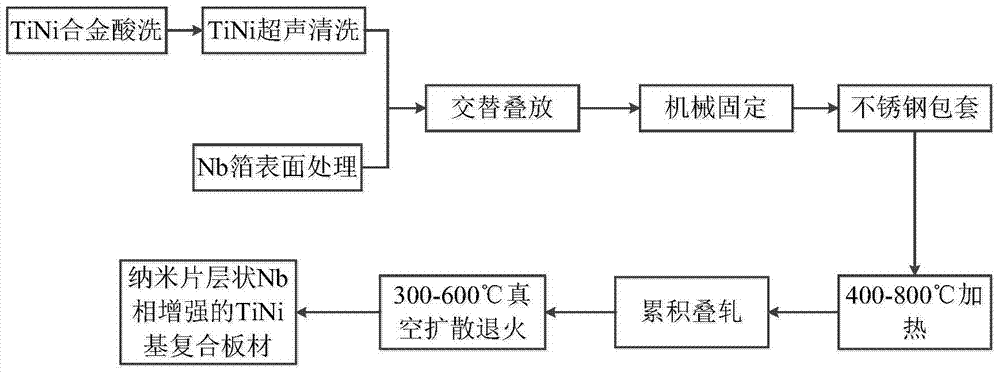

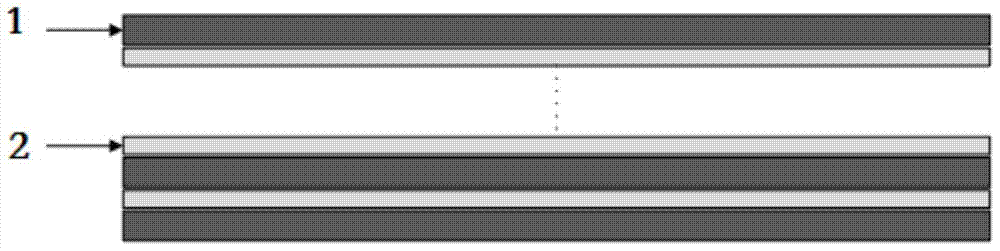

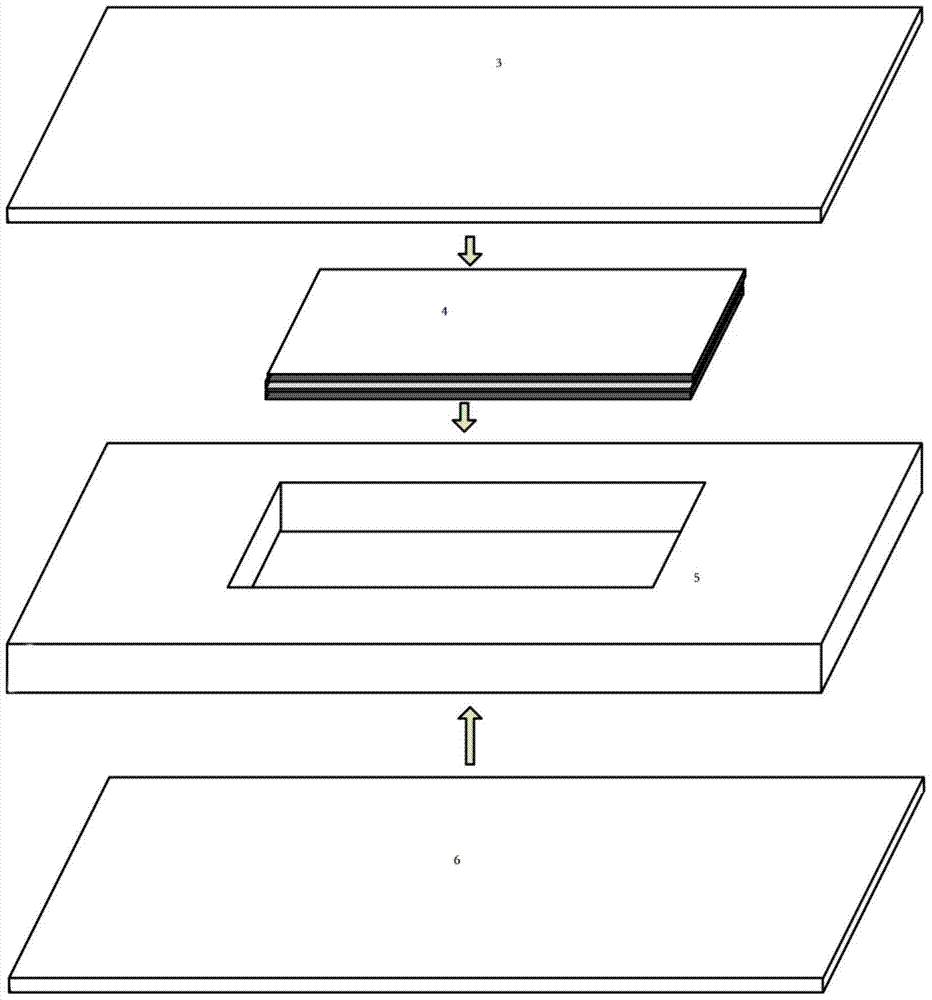

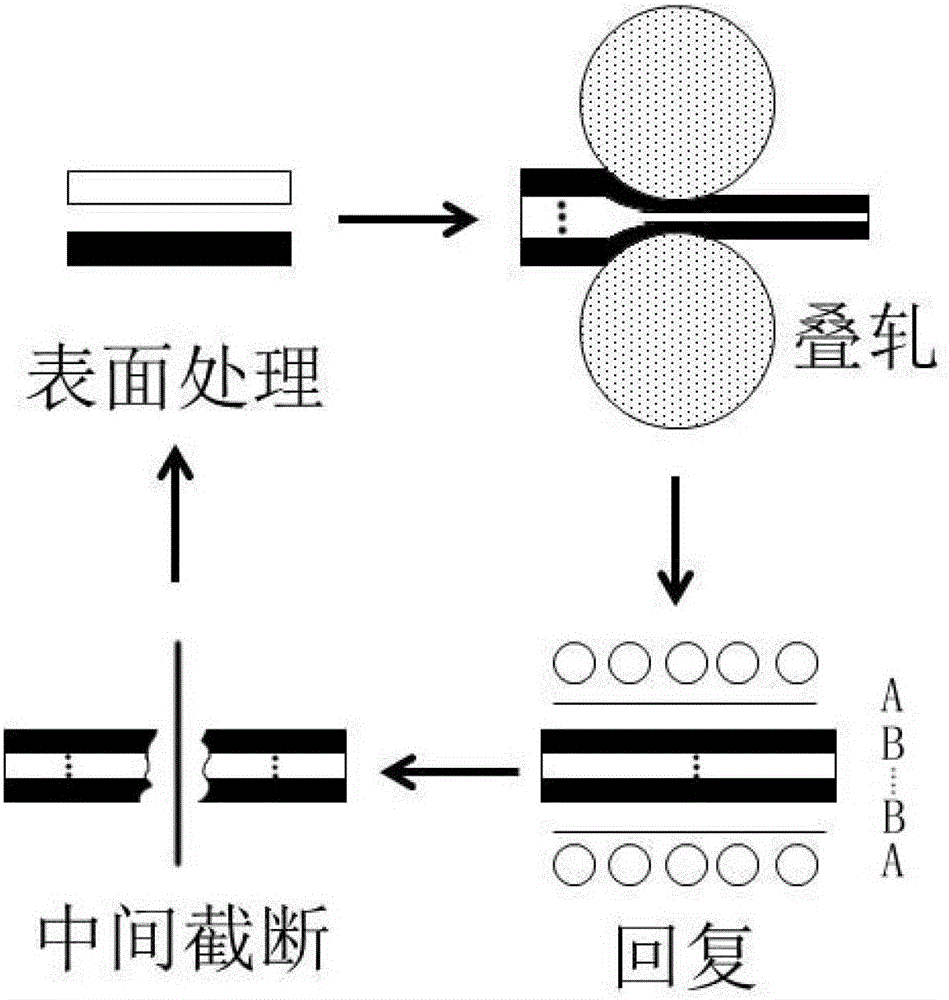

Preparation method of accumulative stack rolling of nano-sheet phase reinforced tini-based alloy composite sheet

ActiveCN105013821BAdjust volume fractionSimple preparation processMetal rolling arrangementsSurface cleaningShape-memory alloy

The invention provides a method for preparing a nanosheet layer phase reinforced TiNi-based alloy composite plate by accumulative roll rolling. (1) pickling and cleaning the surface of the TiNi shape memory alloy foil; (2) mechanically grinding and polishing the reinforced pure metal foil and cleaning the surface; (3) combining the pretreated TiNi alloy foil with the reinforced pure Metal foils are alternately stacked and the outermost layer is TiNi alloy foil; (4) Put the above stacked TiNi alloy foil and reinforced pure metal foil into a stainless steel or pure Ti sheath and vacuumize; (5) ) at 400°C to 800°C for n passes of cumulative rolling; (6) at 300°C to 600°C for vacuum annealing. The invention has the advantages of simple process, convenient regulation, low requirement on equipment, easy realization of batch production and the like. The nanosheet layer phase reinforced TiNi-based alloy plate prepared by the invention can be widely used in medical equipment, damping components, large-strain drivers and the like.

Owner:HARBIN ENG UNIV

A kind of preparation method of non-or low magnetic, cubic texture ni-w alloy composite substrate

The invention provides a preparation method of a Ni-W alloy composite baseband with no or low magnetism and a cubic texture and belongs to the technical field of preparation of high-temperature coating superconducting basebands. The method comprises the following steps: respectively preparing two Ni-W alloy billets with different W contents and the same size; overlaying, welding and fixing the two Ni-W alloy billets together; coldly rolling the two Ni-W alloy billets, wherein the total deformation is 50%; carrying out restorative heat treatment on the two Ni-W alloy billets during rolling; cutting off edge cracks and burrs of the Ni-W alloy billets; dividing the Ni-W alloy billets into twos from the middle parts; carrying out accumulative roll bonding on the Ni-W alloy billets, so that outermost layers of the multi-layer overlaid and rolled billets are all Ni-W alloys with low W contents, wherein the accumulative roll bonding repeats overlaying, welding, rolling and restorative heat treatment for 1-4 times; carrying out restorative annealing on the Ni-W alloy billets between cold rolling and rolling; and recrystallizing and annealing the Ni-W alloy billets in two steps. The preparation method of the Ni-W alloy composite baseband with no or low magnetism and the cubic texture, provided by the invention, can obtain the composite baseband with excellent performance.

Owner:深创超导(深圳)科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com