High-specific-strength magnesium-lithium-based composite material and preparation method thereof

A composite material and high specific strength technology, applied in chemical instruments and methods, electrolytic coatings, manufacturing tools, etc., can solve problems such as low strength and limited application range, and achieve high specific strength, uniform distribution of reinforcements, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

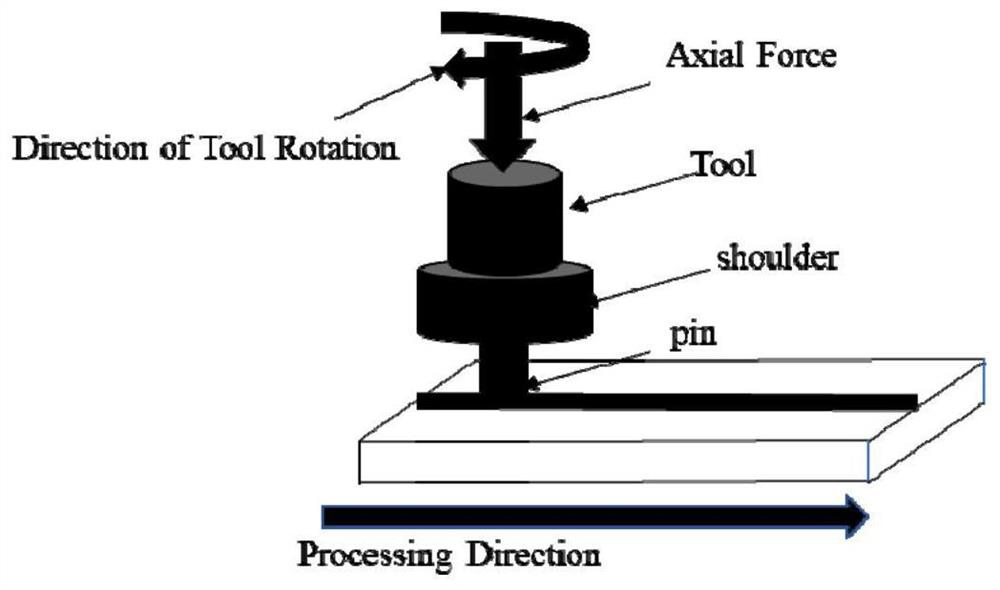

[0029] The invention relates to a magnesium-lithium-based composite material and a preparation method thereof, in particular to a high-specific-strength magnesium-lithium-based composite material and a preparation method thereof. Specific steps are as follows:

[0030] (1) Homogenize the substrate LA141 ingot at 200°C for 12h.

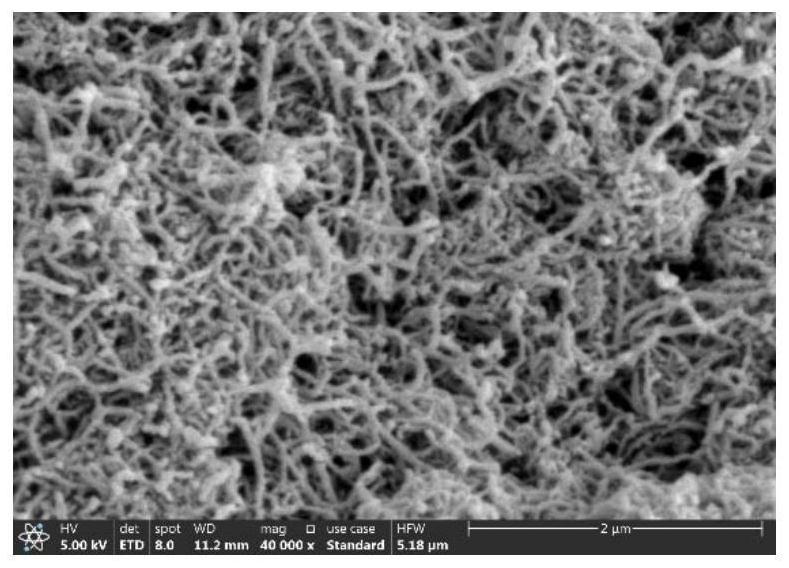

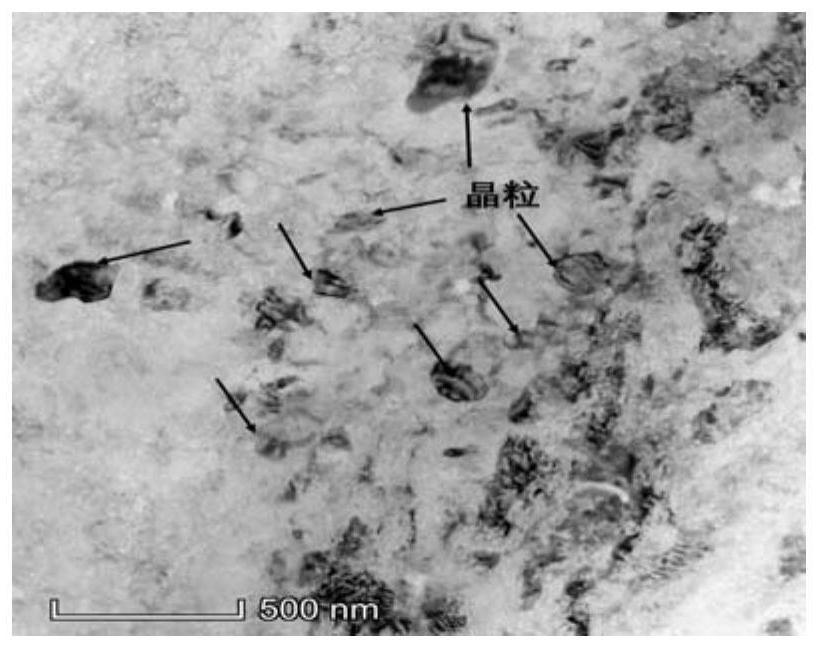

[0031] (2) Cut the homogenized matrix LA141 ingot into a block plate with a size of 110mm×40mm×20mm, sand it until the surface is smooth, and then heat it at 250°C for 30 minutes for pre-rolling, and the amount of pressure per pass is 10% and keep warm for 5 minutes each time until the rolling reaches 2mm. Then the plate obtained by rolling is cut into 150mm × 130mm × 2mm flake plate, and the oxide layer on the surface is removed by sandpaper, cleaned with absolute ethanol, and used for film preparation; 1gM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com