Preparing method of memory alloy nano lamination Ni/Ti preformed blank

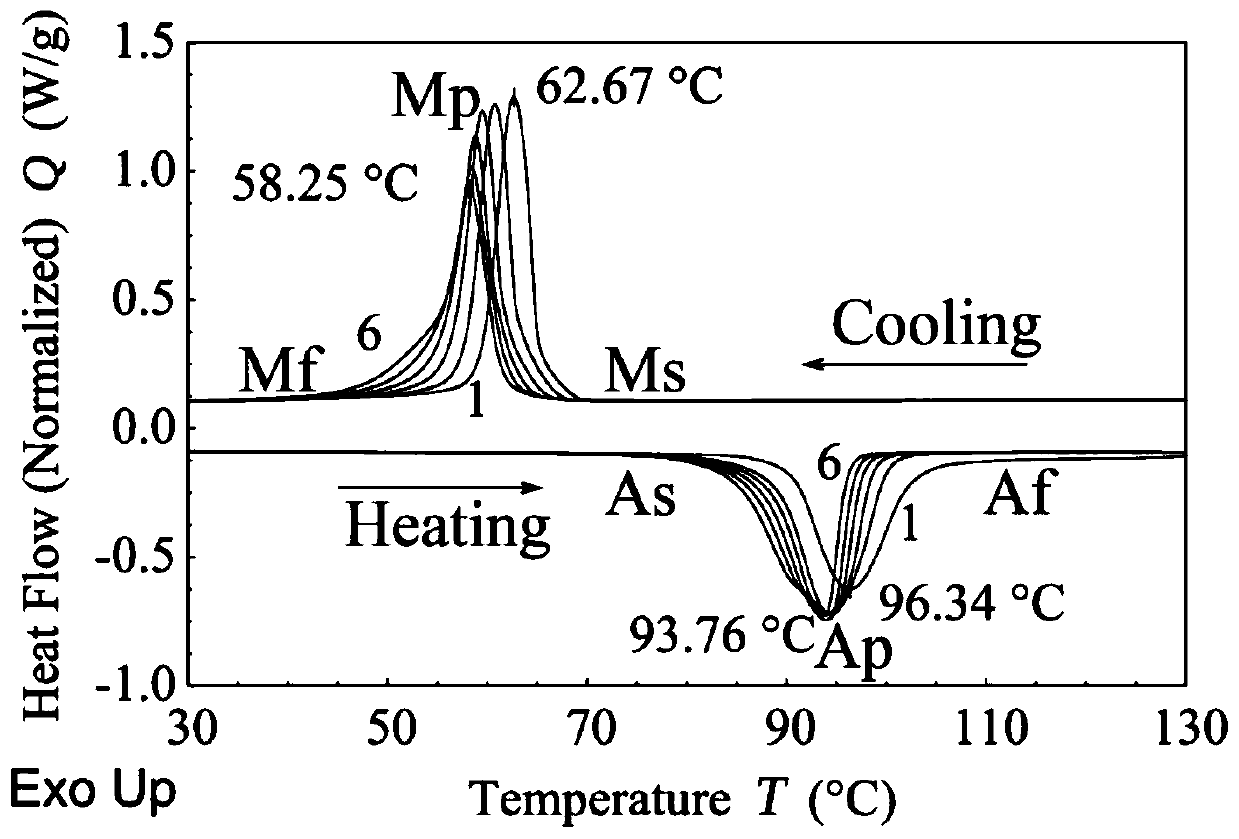

A technology of nano lamination and memory alloy, which is applied in liquid cleaning methods, metal rolling, metal rolling, etc., can solve the problems of NiTi alloy ingot element pollution, small pass deformation, and large deformation resistance. Achieve the effects of large residual stress, high shape memory temperature and stable phase transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

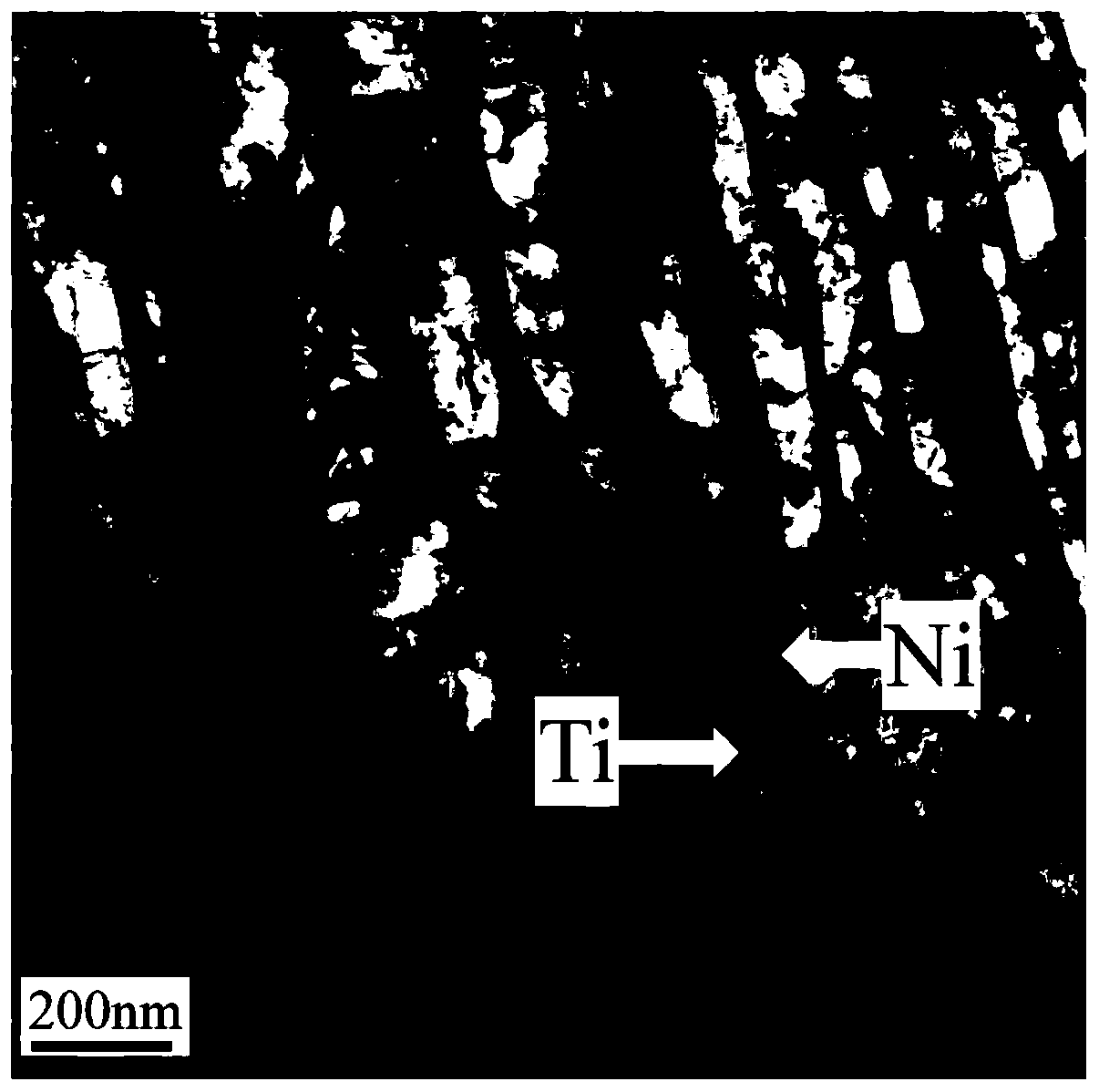

[0027] Preparation of a layered Ni / Ti preform with an average layer thickness of 93.43nm. The total thickness of the composite material is 0.28mm, and its composition design is as follows: the atomic fraction of Ti accounts for 50.8%, and the atomic fraction of Ni accounts for 49.2%.

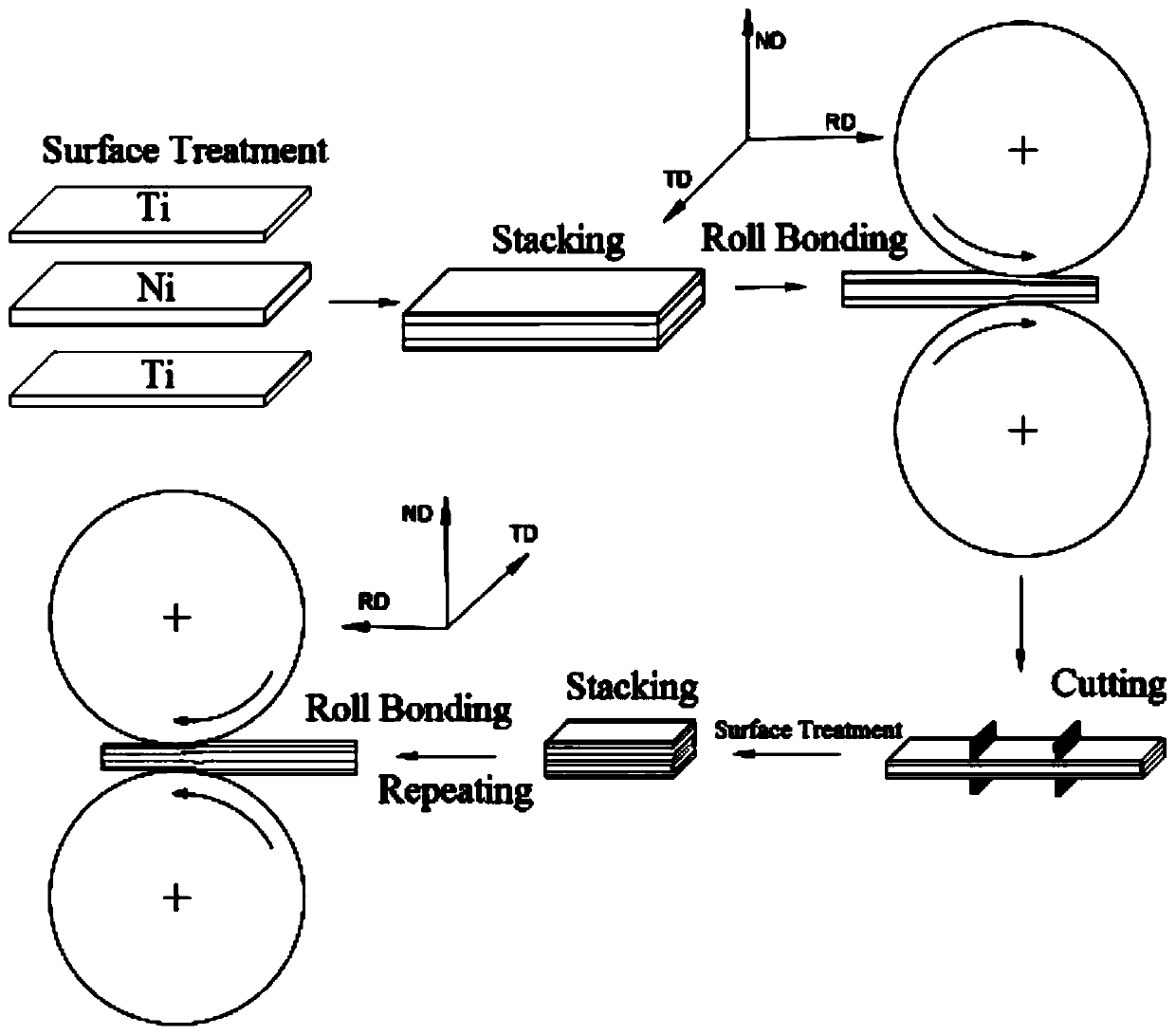

[0028] A method for preparing a memory alloy nano-laminated Ni / Ti preform of this embodiment, the specific steps are:

[0029] Step 1, material preparation:

[0030] Select Ti foil with a thickness of 50 μm, Ti foil with a thickness of 20 μm, and Ni foil with a thickness of 30 μm, and then cut the Ti foil and Ni foil into 35mm×55mm, and use a suitable size bag, and then put the bag, Ti The foil and Ni foil are soaked in acetone for 30 minutes, cleaned by ultrasonic vibration, and finally air-dried with a hair dryer to obtain a clean package, Ti foil, and Ni foil;

[0031] Step 2, encapsulation:

[0032] The Ti foil and Ni foil are stacked alternately according to Ti / Ni / Ti / Ni... / Ti, and 37 lay...

Embodiment 2

[0041] Preparation of a layered Ni / Ti preform with an average layer thickness of 44.49nm. The total thickness of the composite material is 0.28mm, and its composition design is as follows: the atomic fraction of Ti accounts for 50.8%, and the atomic fraction of Ni accounts for 49.2%.

[0042] A method for preparing a memory alloy nano-laminated Ni / Ti preform of this embodiment, the specific steps are:

[0043] Step 1, material preparation:

[0044] Select Ti foil with a thickness of 50 μm, Ti foil with a thickness of 20 μm, and Ni foil with a thickness of 30 μm, and then cut the Ti foil and Ni foil into 35mm×55mm, and use a suitable size bag, and then put the bag, Ti The foil and Ni foil are soaked in acetone for 30 minutes, cleaned by ultrasonic vibration, and finally air-dried with a hair dryer to obtain a clean package, Ti foil, and Ni foil:

[0045] Step 2, encapsulation:

[0046] The Ti foil and Ni foil are stacked alternately according to Ti / Ni / Ti / Ni... / Ti, and 37 lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com