Titanium-based alloy material spinning forming method based on composite heating

A titanium-based alloy, spinning forming technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of heat source distribution, titanium-based alloy spinning area mold holding, titanium-based alloy material instability and wrinkling, forming temperature Narrow intervals and other issues can be achieved to improve mold life, improve deformation coordination, and achieve the effects of high temperature control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Billet is Ti 2 AlNb alloy cylindrical billet, the initial wall thickness of the billet is 6.0mm.

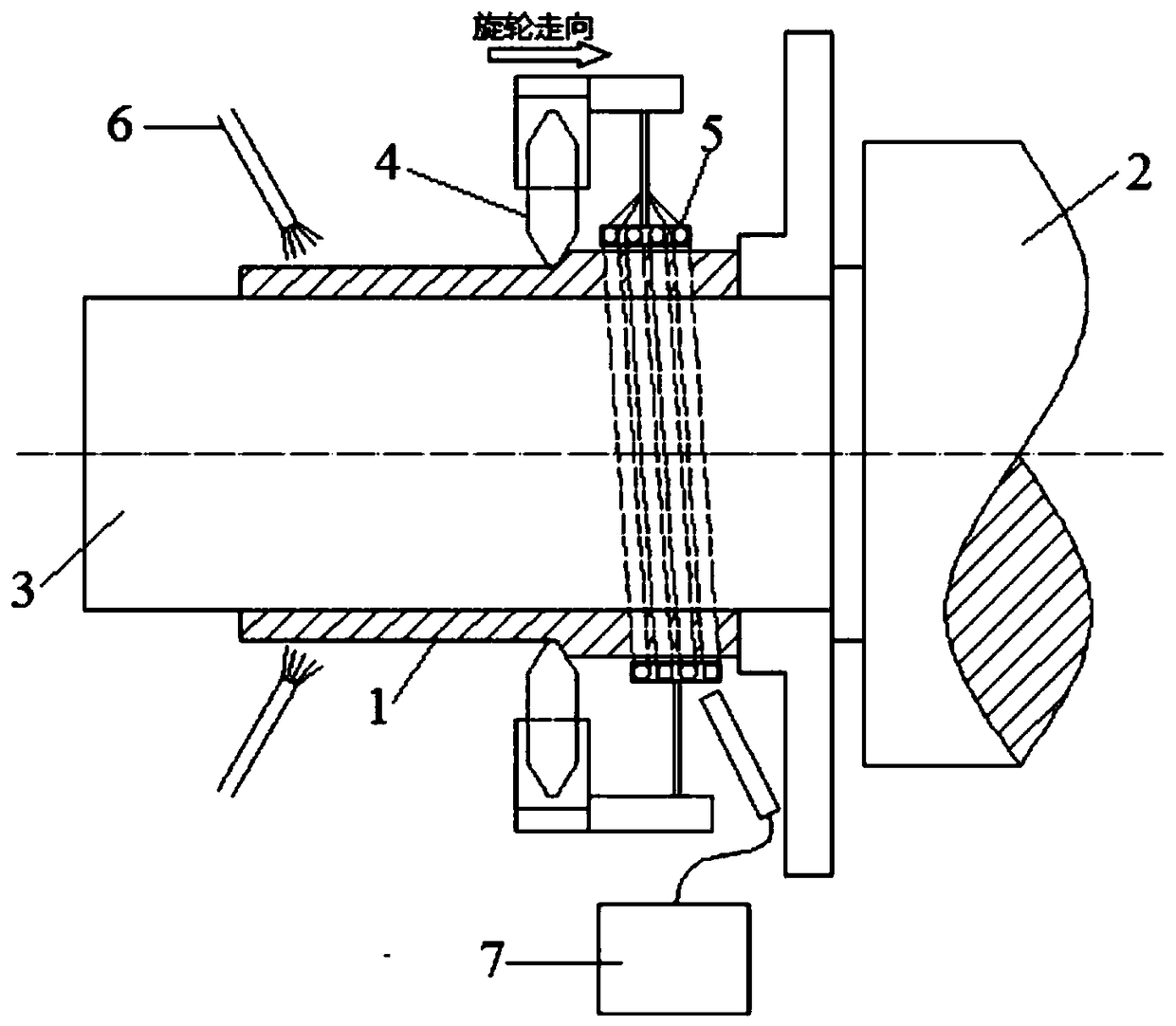

[0052] (1) Put Ti 2 The AlNb alloy cylindrical blank is set on the mandrel of the spinning machine and fixed; the blank, mandrel and rotary wheel of the spinning machine are preheated with a flame gun; the spinning mandrel is heated to 450°C, and the rotary wheel is heated to 200°C. The billet is heated to 500°C;

[0053] The flame gun adopts oxygen-propane flame; the steel used for the rotary wheel of the spinning machine is H13 hot work die steel, and the spinning mandrel is made of K403 cast superalloy; Ti 2 There is a transition fit between the AlNb alloy blank and the spinning mandrel.

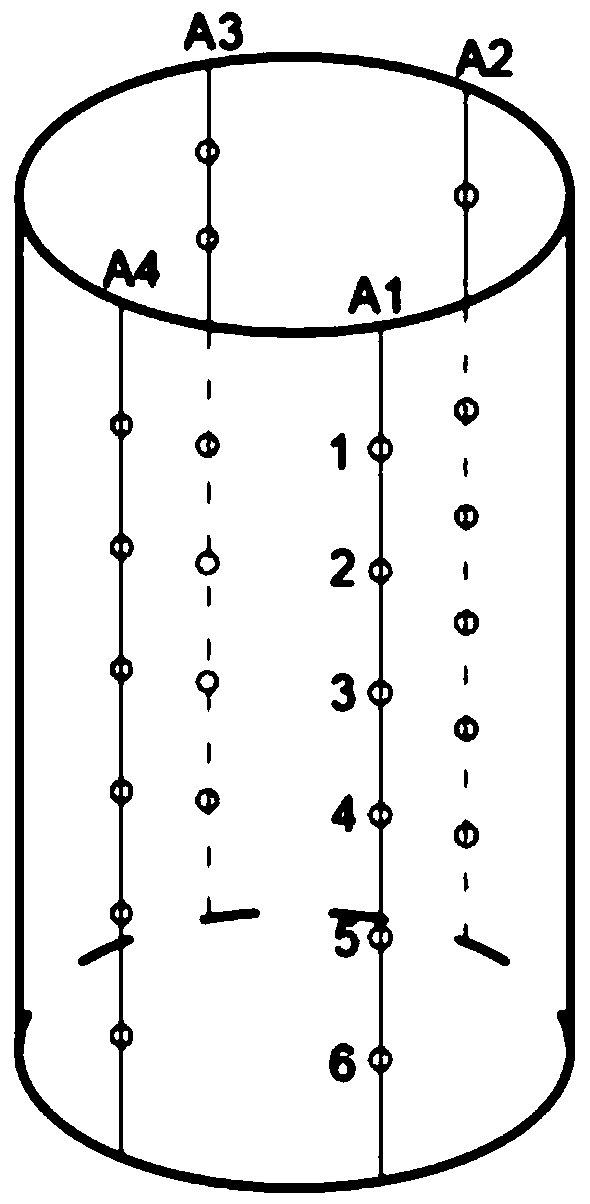

[0054] (2) The follow-up electromagnetic induction coil is fixed on the rotating wheel bracket, and will move along the axial direction with the rotating wheel; the follow-up induction heating coil is sleeved on the Ti 2 Outside the AlNb alloy billet, there is a gap between it and...

Embodiment 2

[0060] Other conditions are the same as in Example 1, and only after step (3) is completed, steps (1) to (3) are repeated again, and the spinning is repeated 2 times, the total pass thinning rate is about 58%, and the wall thickness of the formed part is 2.5mm.

[0061] Observing the formed part, it can be seen that the wall thickness of the formed part is uniform and there is no cracking defect.

Embodiment 3

[0063] The titanium-based alloy billet is a low-plasticity Ti55 high-temperature titanium alloy material, and the billet is a cylindrical billet with an initial wall thickness of 10.0 mm.

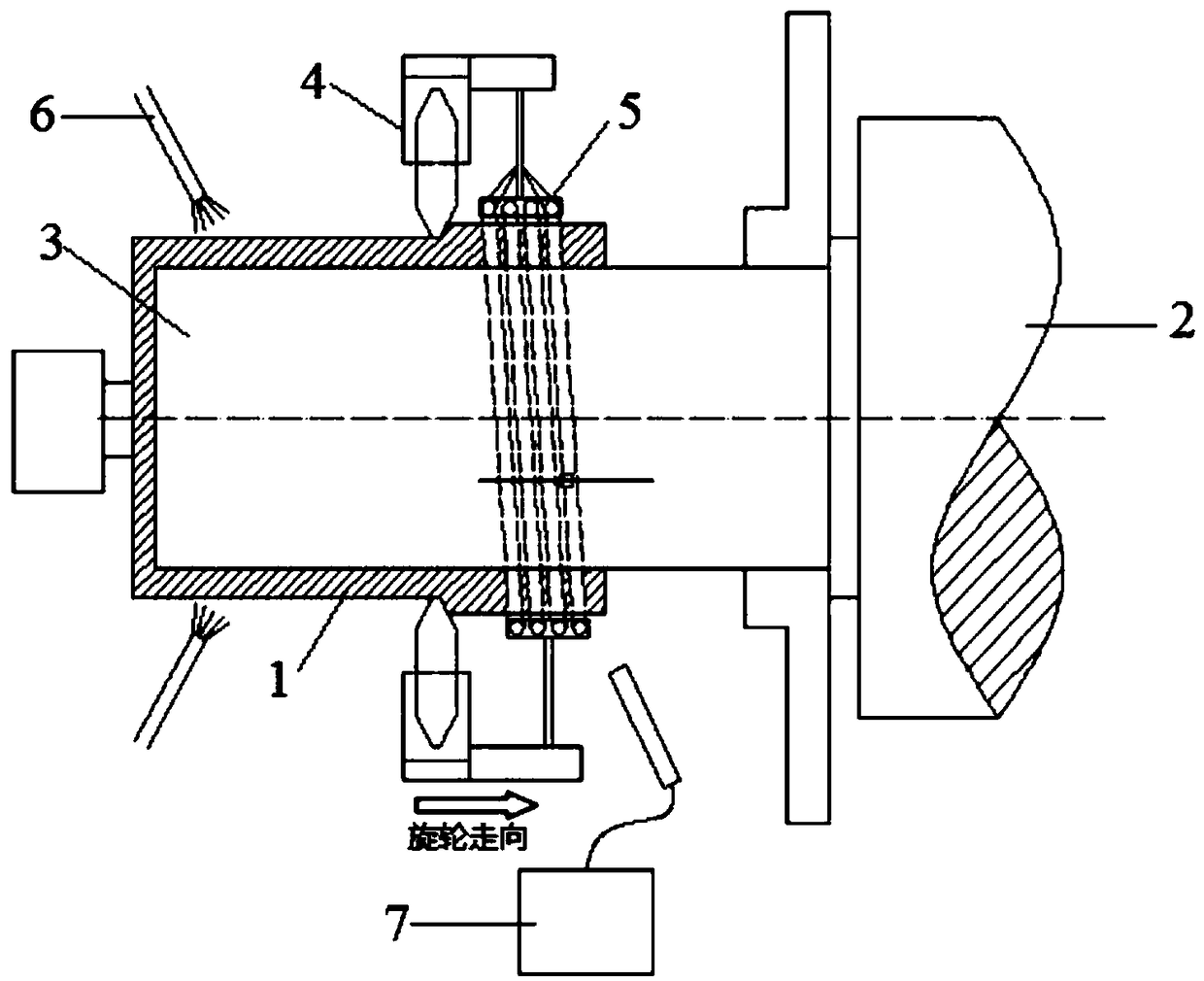

[0064] (1) Put the cylindrical blank of Ti55 alloy material on the mandrel of the spinning machine and fix it; use a flame gun to preheat the mandrel, wheel and blank of the spinning machine, heat the spinning mandrel to 450°C, and turn the wheel Heating to 250°C, the titanium-based alloy blank is preheated to 500°C.

[0065] The flame gun adopts oxygen-acetylene flame; the steel used for the spinning wheel of the spinning machine is W18Cr4V high-speed steel, and the spinning mandrel is made of H13 hot work die steel; the transition fit between the Ti55 alloy billet and the spinning mandrel.

[0066] (2) Start the spinning machine so that the mandrel rotates, and the Ti55 alloy billet rotates together with the spinning mandrel. The follower electromagnetic induction coil is fixed on the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com