Patents

Literature

41results about How to "Avoid edge cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel

InactiveCN102179407AUniform temperatureReduce temperature differenceTemperature control deviceMetal rolling arrangementsTemperature differenceAlloy

The invention relates to a method for preparing hot rolling strip steel capable of preventing edge crack of extremely thin rolled strip steel. The method comprises the following steps of: (1) smelting, namely desulfurizing molten iron, smelting by using a converter, blowing argon at an argon station, and performing continuous casting to form slabs; (2) performing hot rolling, namely heating the slabs to 1,210 to 1260 DEG C, wherein the temperature difference of the same slab is less than or equal to 30 DEG C; performing rough rolling, and finish rolling, wherein the side pressure delta B when the slab with the width B is subjected to rough rolling is controlled according to the following formula: delta B ranges from 35*B / 1,250*(B-1,050) / (1,250-1,050)+35*B / 1,050*(1,250-B) / (1,250-1,050) to 50; and finally reeling to obtain the hot rolling strip steel. The method is simple and practical, is stable in use and high in uniformity, reduces the alloy cost and shortens the production cycle; and the steel plate heat commercial (SPHC) hot rolling strip steel prepared by the method has the obvious effect of preventing the edge crack of extremely thin cold-rolled sheet.

Owner:NINGBO IRON & STEEL

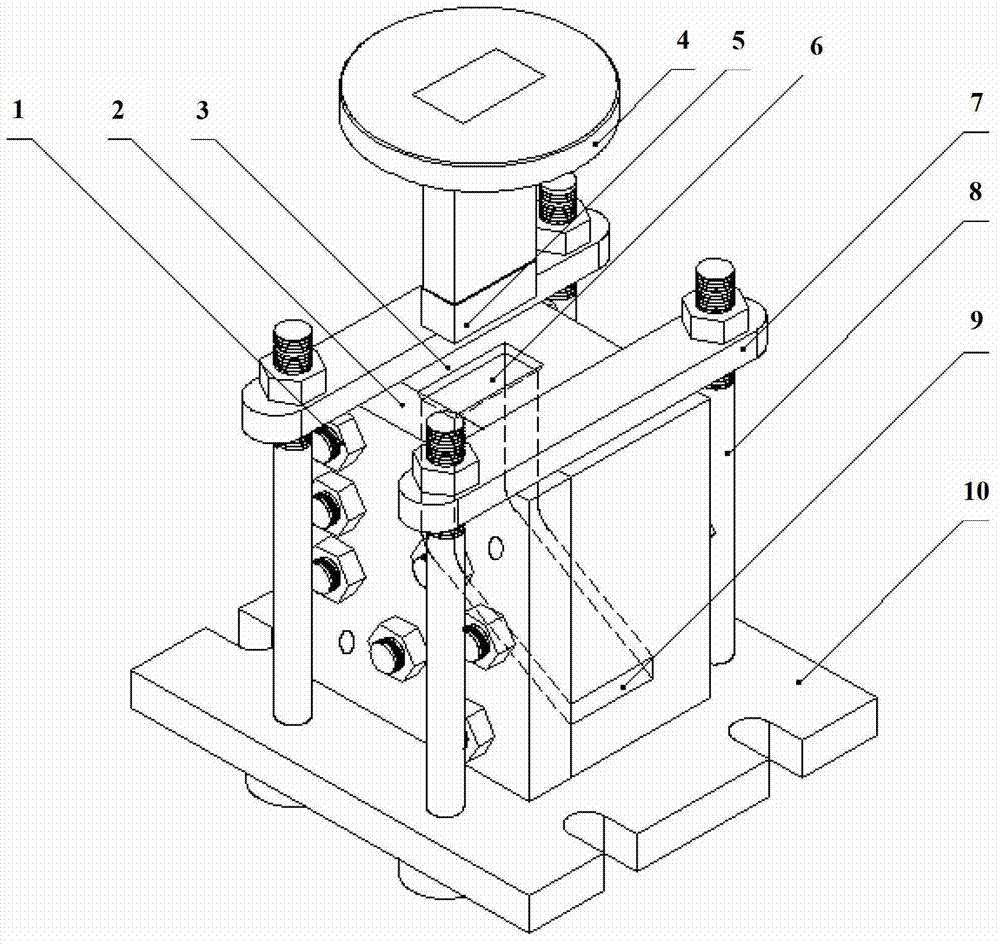

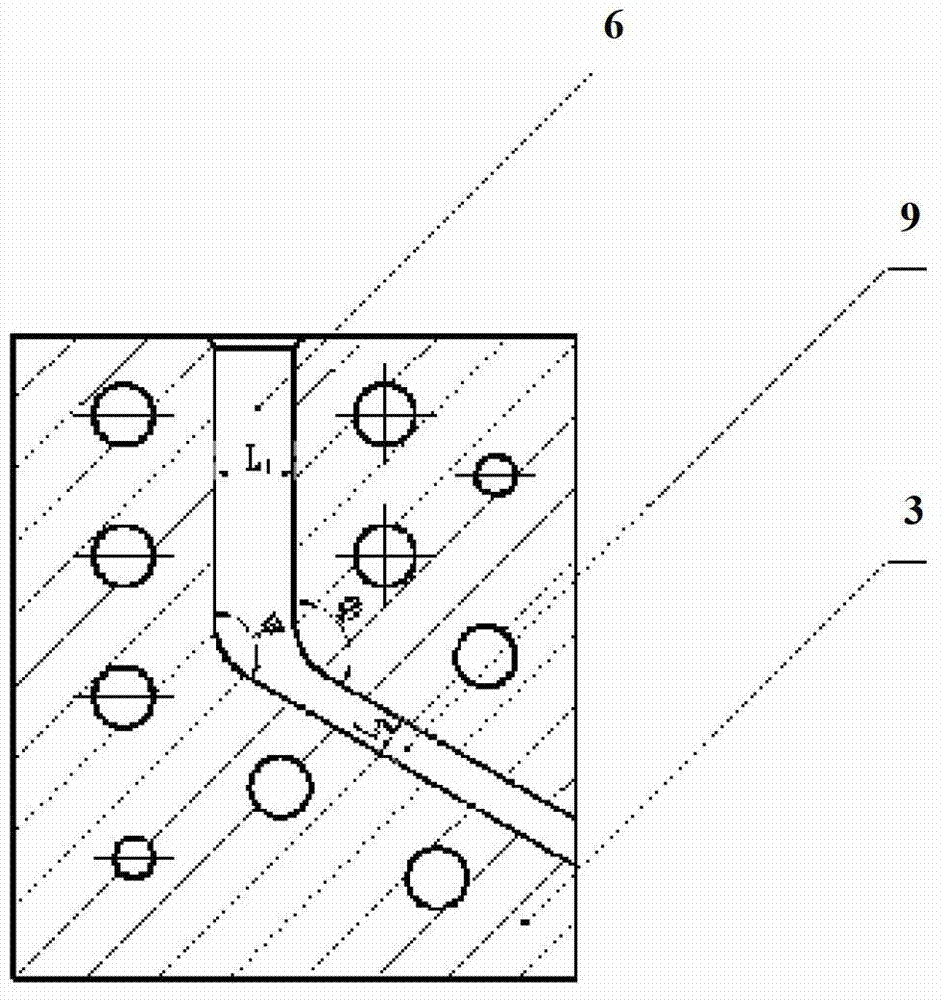

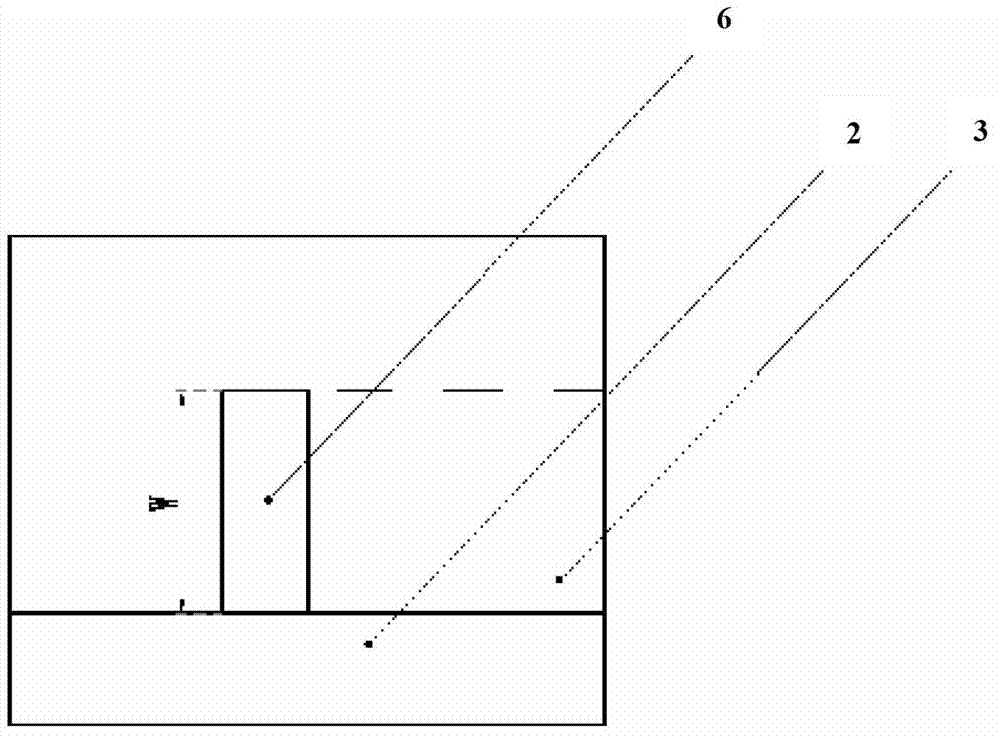

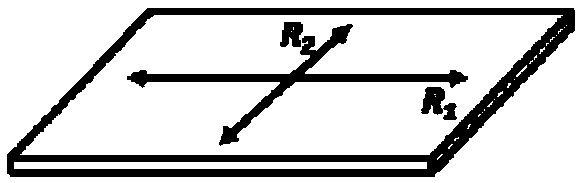

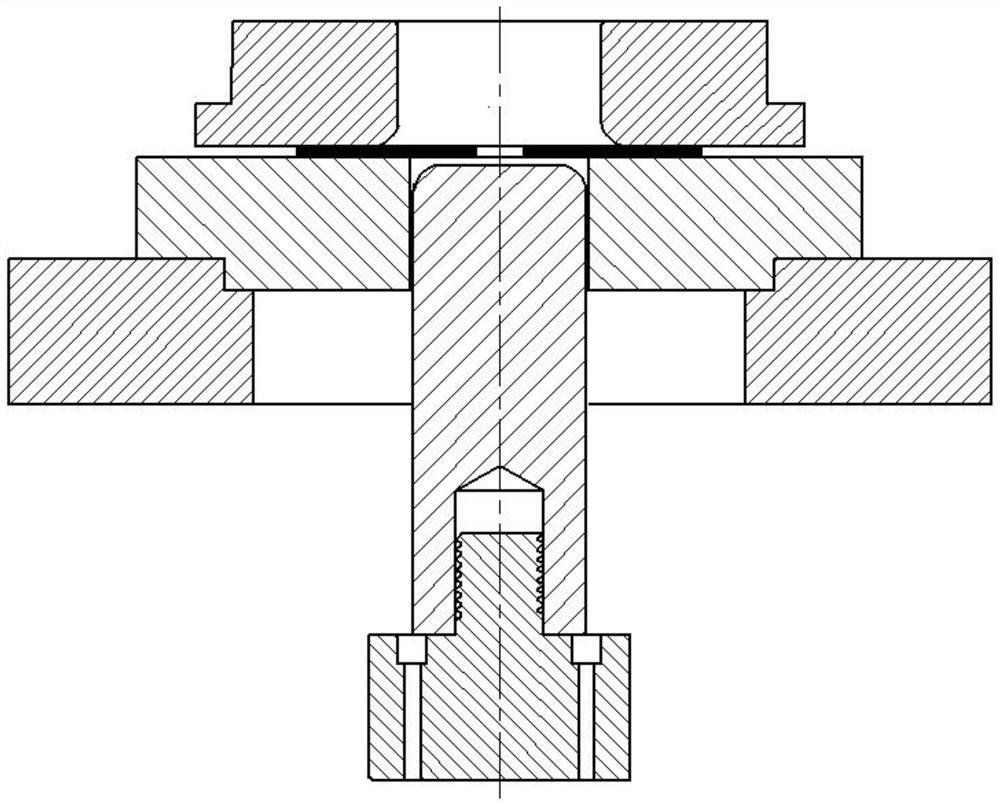

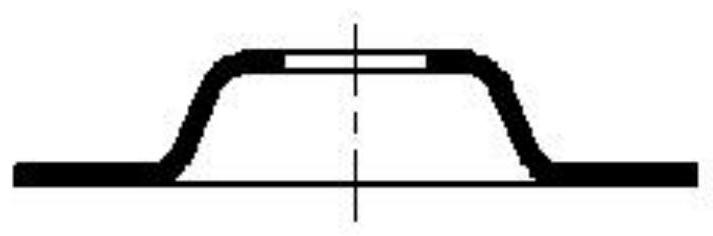

Severe plastic deformation method and severe plastic deformation device for pressing and rolling corner of non-equivalent passage

The invention discloses a severe plastic deformation method and a severe plastic deformation device for pressing and rolling the corner of a non-equal channel. According to the severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel, an equal-channel angular pressing (ECAP) technology and an ARB (Accumulative Roll Bonding) technology are integrated. The concrete process comprises the following steps that pressing force is applied after a test sample, a punching head and a mould are simultaneously preheated to pressing and rolling temperature, so that the test sample passes through the position of the channel corner of the device for pressing and rolling the corner of the non-equal channel completely; compressive deformation is generated when shear deformation is generated by the test sample so as to finish a first pass pressing and rolling process; the test sample is cut into L1 / L2 parts along a length direction, and the L1 / L2 parts are placed in an I channel; and the steps are repeated so as to finish multi-pass pressing and rolling deformation. The mould of the device is provided with the I channel and an II channel which are intersected and also have non-equal sections. The design is reasonable, the structure is simple, and the manufacturing cost is low. According to the method disclosed by the invention, the advantages of the ECAP technology and the ARB technology are integrated, and the mechanical property of a material is effectively enhanced. The process is short in procedure, high in efficiency and low in cost and is simple to operate. The severe plastic deformation method and the severe plastic deformation device for pressing and rolling the corner of the non-equal channel can be widely used for the field of processing metal materials, such as pure metal and alloy.

Owner:SOUTH CHINA UNIV OF TECH

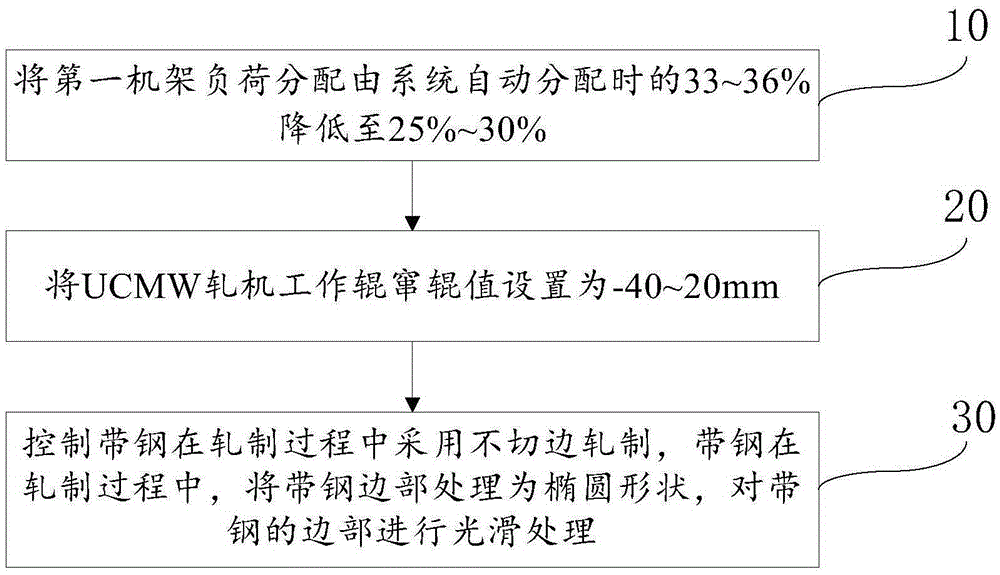

Control method for high-mark non-oriented silicon steel cold continuous rolling edge crack

ActiveCN105396879AAvoid edge crackingIncrease production capacityProfile control deviceWork rollStrip steel

The invention relates to the technical field of rolling technologies, in particular to a control method for the high-mark non-oriented silicon steel cold continuous rolling edge crack. The method comprises the steps that the load allocation of a first rack is reduced to 25%-30% from 33%-36% during automatic system allocation; and the channeling roll value of a UCMW rolling mill work roll is set to be -40-20 mm. According to the control method for the high-mark non-oriented silicon steel cold continuous rolling edge crack in the embodiment, the load allocation of the first rack is reduced to 25%-30% from 33%-36% during automatic system allocation, and the outlet edge crack of the first rack can be reduced; the channeling roll value of the UCMW rolling mill work roll is set to be -40-20 mm, the strip steel edge part stress can be effectively reduced, and the problem of the edge crack of the high-mark non-oriented silicon steel in the cold continuous rolling process is avoided; and the production capacity of the high-mark non-oriented silicon steel cold continuous rolling is improved, and the quality of the high-mark non-oriented silicon steel is guaranteed.

Owner:SHOUGANG ZHIXIN QIAN AN ELECTROMAGNETIC MATERIALS CO LTD

Warm-rolling process method of titanium alloy thin plate

The invention provides a warm-rolling process method of a titanium alloy thin plate and comprises the following steps: firstly, heating a titanium alloy thin plate with a certain thickness up to 300-400 DEG C; secondly, preheating a roller of a rolling mill to 30-60 DEG C; warm-rolling the heated titanium alloy plate for 1-3 turns, and obtaining the rolled slab; and thirdly, orderly performing the finished product annealing, acid washing and fixed-dimensional shearing, obtaining the titanium alloy thin plate with the thickness of 1.2-3 mm. In the invention, the titanium alloy plate is delivered to the preheated rolling mill after being heated within the temperature scale of lower than the recrystallization temperature, in order to perform the warm-rolling; compared with the cold-rolling process technique, the invention can slow down the hardening rate of the titanium alloy, improve the accumulated deformation rate of the rolling turn, reduce the intermediate heat treatment frequency, shorten the production cycle and improve the working efficiency; meanwhile, the method can effectively prevent edge crack, slag at head and tail parts and micro-crack, and improve the surface quality; the invention is easy to control, simple and convenient to operate and applicable to the industrial production on a large scale.

Owner:WESTERN TITANIUM TECH

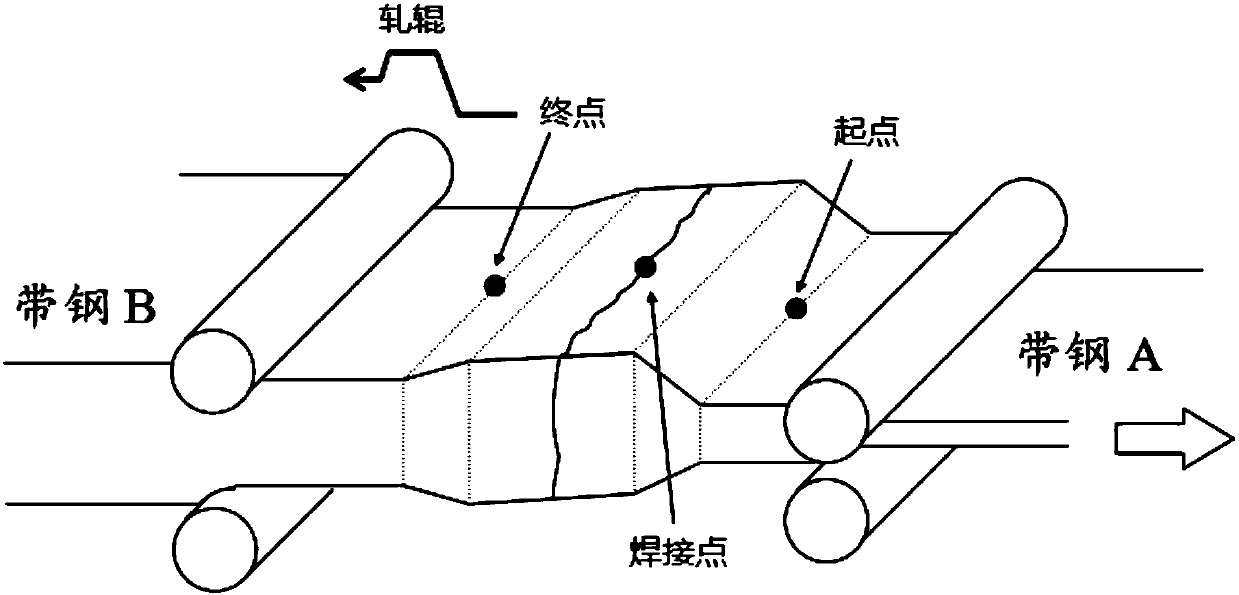

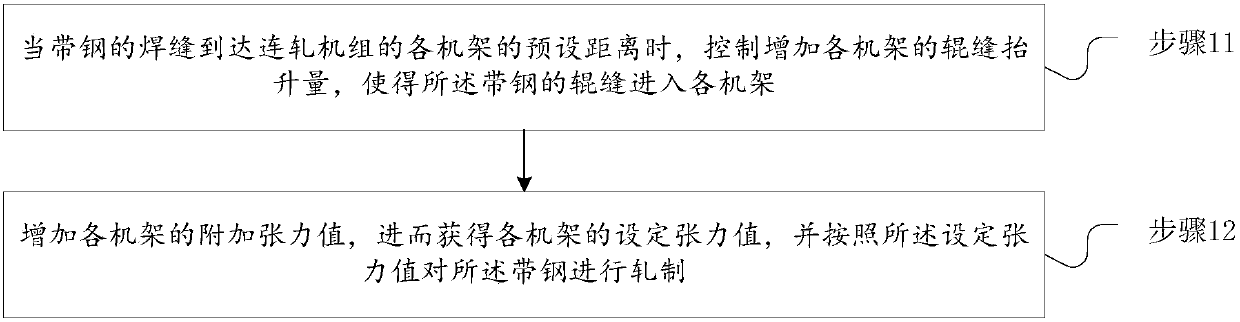

Rolling method for reducing edge cracking of continuous rolling mill

InactiveCN107900101AReduce rolling forceReduce tensile stressRoll force/gap control deviceTension/compression control deviceStrip steelWeld seam

The invention discloses a rolling method for reducing edge cracking of a continuous rolling mill. When a weld joint of a strip steel reaches the preset distance of all the racks of the continuous rolling unit, the lifting amount of a roller gap of each machine frame is controlled and enables the roller gap of the strip steel to enter into each machine frame, so the way of increasing the thicknessof the welding seam and reducing the rolling force of the welding seam area is achieved, edge split and strip breakage accidents caused by ultra-thin strip heads and excessively large rolling force can be avoided, and the smooth rolling is guaranteed. The additional tension value of each machine frame is increased, then the set tension value of each machine frame is obtained, the strip steel is rolled according to the set tension value, so that the tensile stress of the welding seam area is reduced, edge split can be avoided or reduced, so that the phenomenon of strip breakage caused by edge split of the front region and the rear region of the weld joint is avoided, and free rolling of the rolling mill is facilitated.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

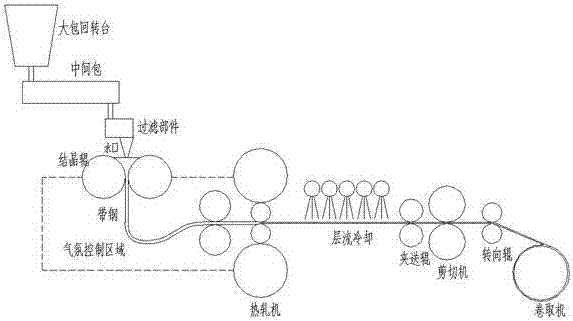

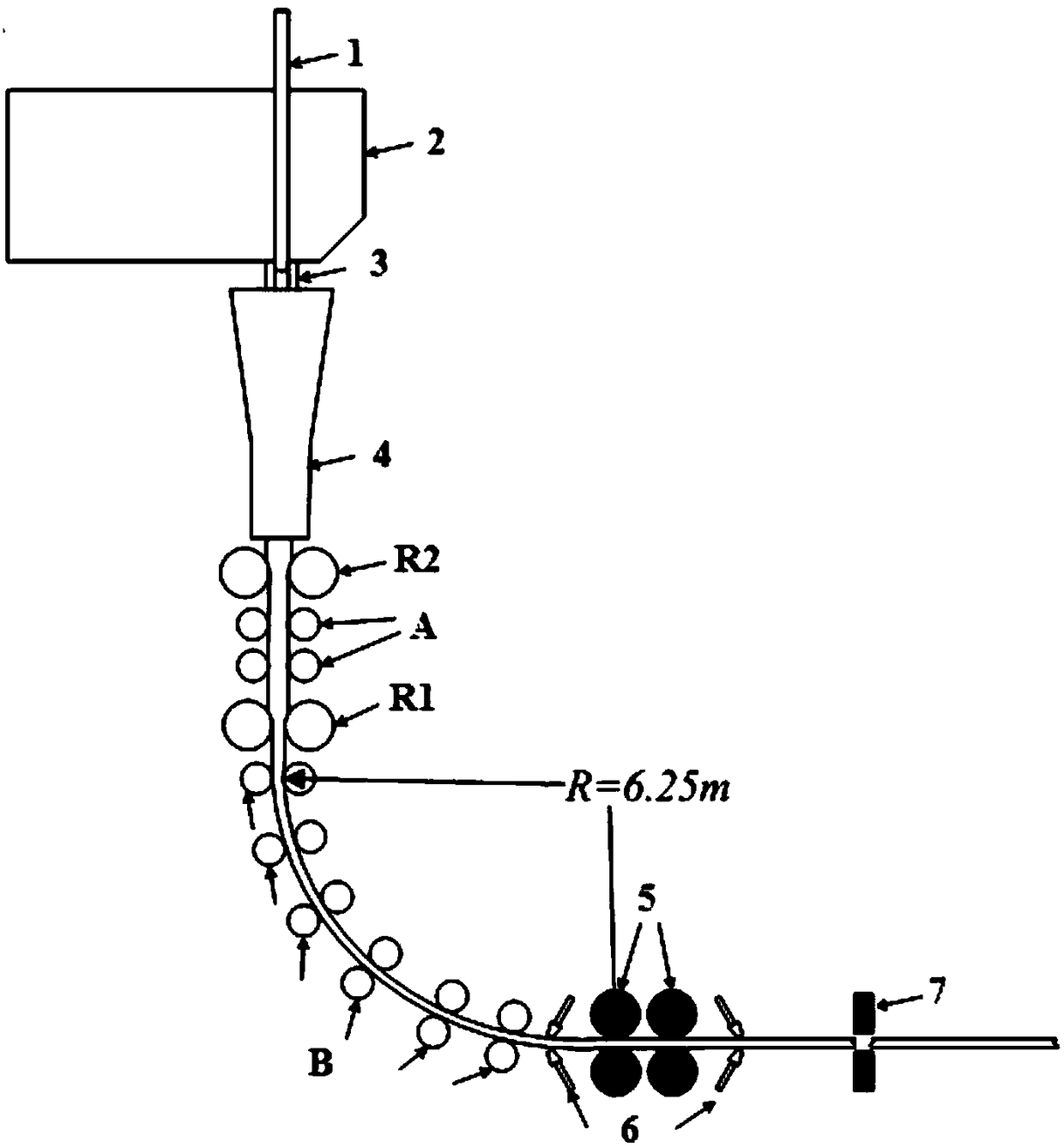

Two-phase stainless steel twin-roll thin strip cast rolling production technology

InactiveCN107186185AReduce consumptionImprove purityMetal rolling arrangementsThermoplasticStrip steel

The invention relates to a duplex stainless steel twin-roller thin strip casting and rolling production process, which includes the following steps: (1) lifting molten steel with qualified composition to a large ladle rotary table; (2) injecting molten steel into the tundish; (3) twin-roller Casting and rolling; (4) Hot rolling of strip; (5) Cooling of strip and cutting off the head and tail; (6) Coiling of strip. The invention directly produces duplex stainless steel thin strips through twin-roll casting and rolling, simplifying the hot rolling process and avoiding edge cracks and peeling defects caused by poor thermoplasticity of duplex stainless steel during hot rolling in traditional processes, as well as difficulties in producing thin-specification products. And other issues. Through the combination of double-roll casting and hot rolling, the product specifications are complete, providing qualified raw materials for the subsequent cold rolling process, shortening the production process and reducing energy consumption.

Owner:JIUQUAN IRON & STEEL GRP

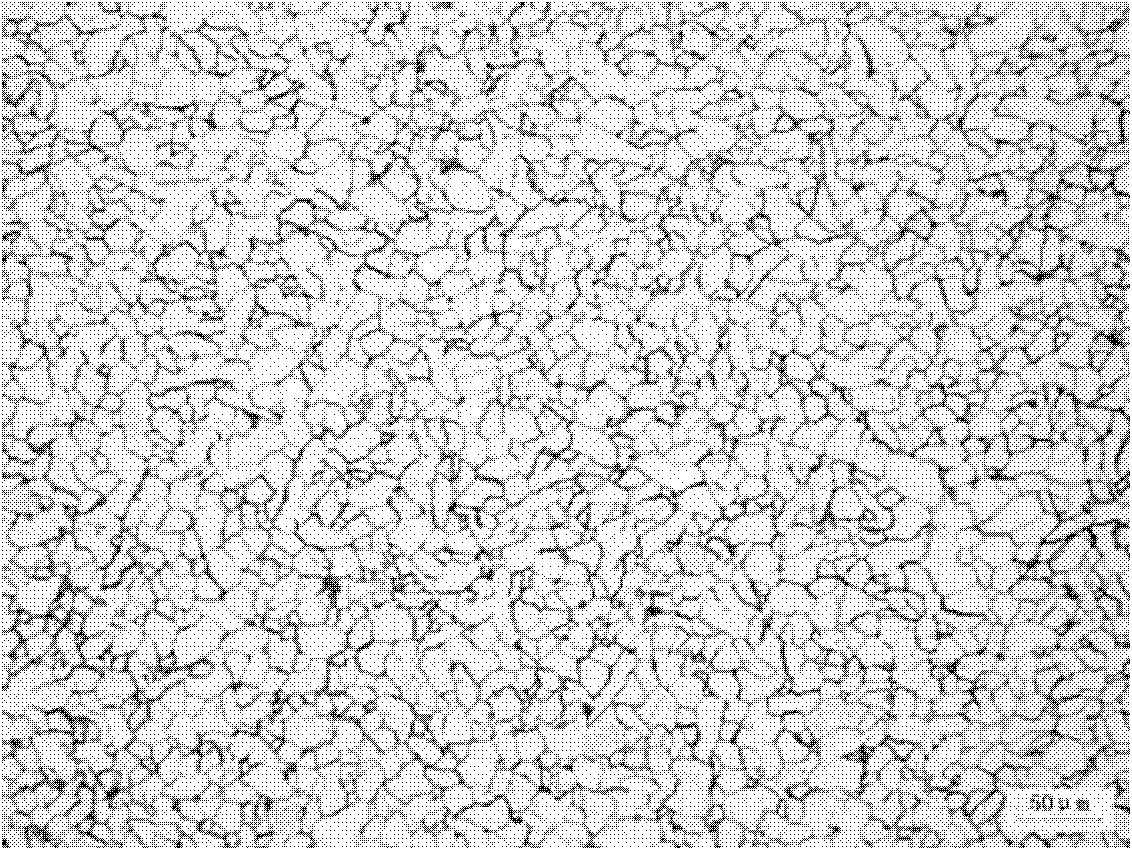

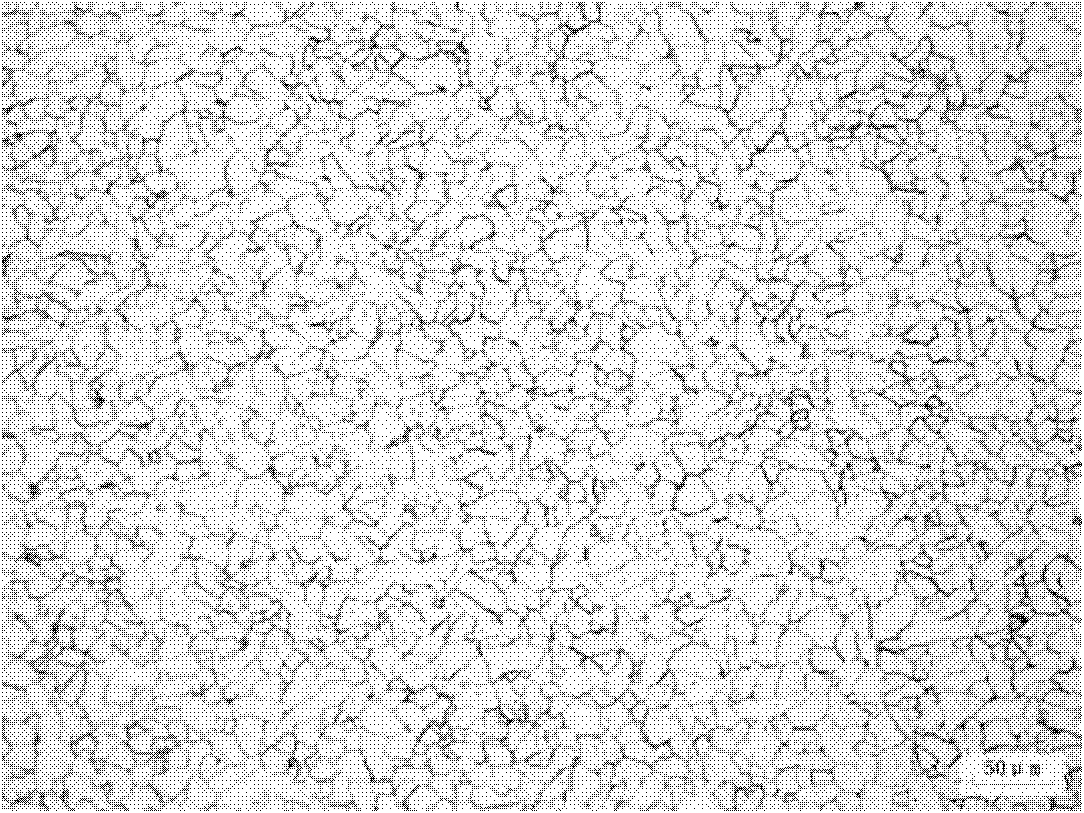

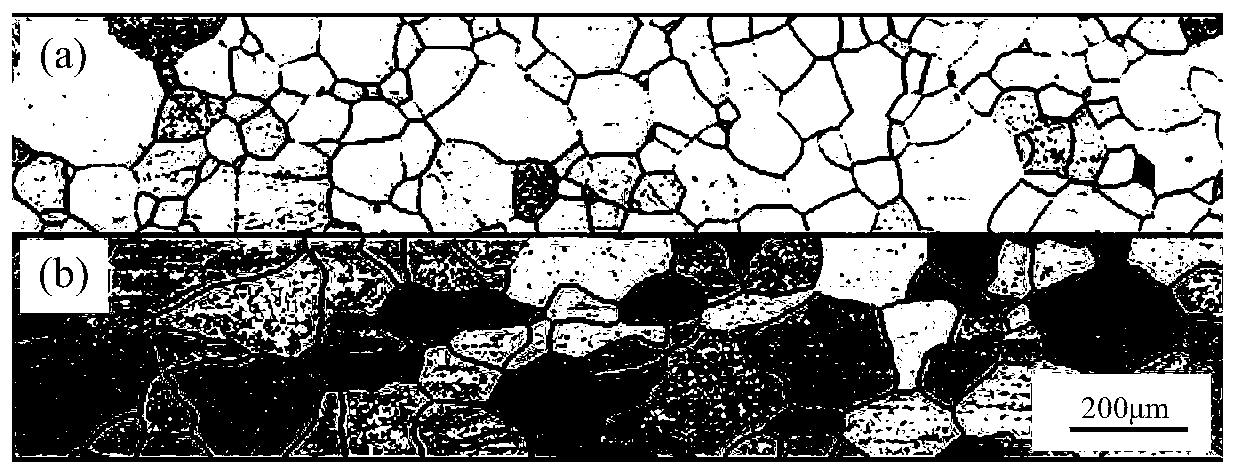

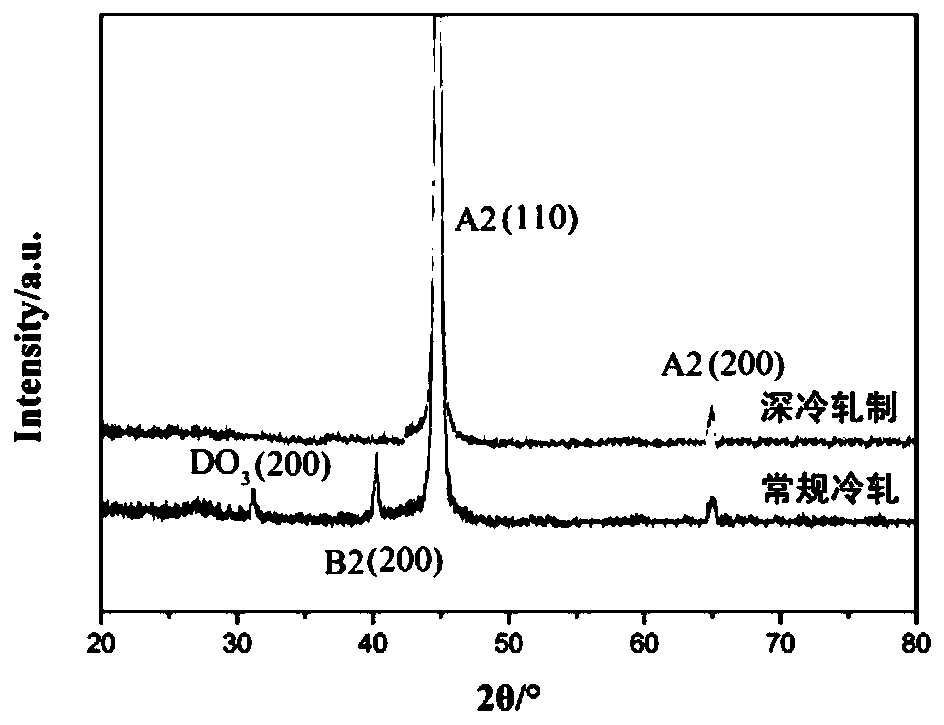

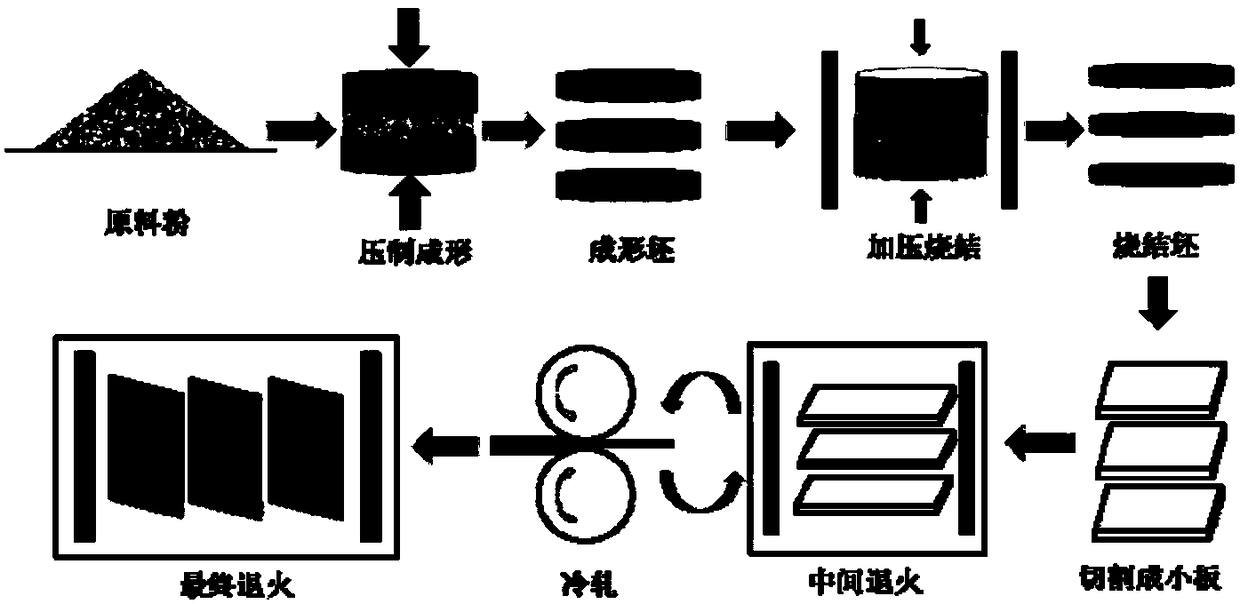

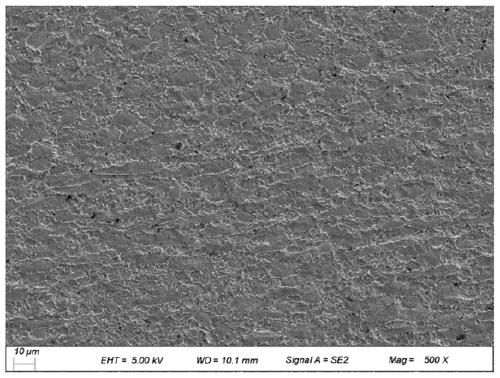

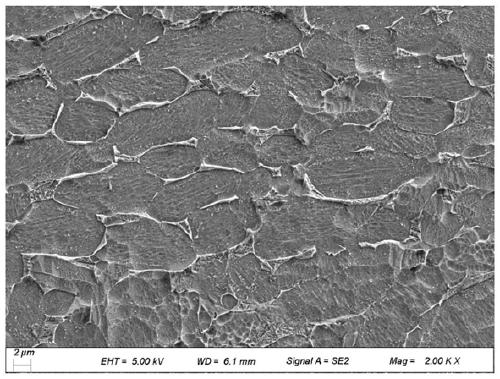

Non-oriented high silicon steel sheet containing boron and zirconium and preparation method thereof

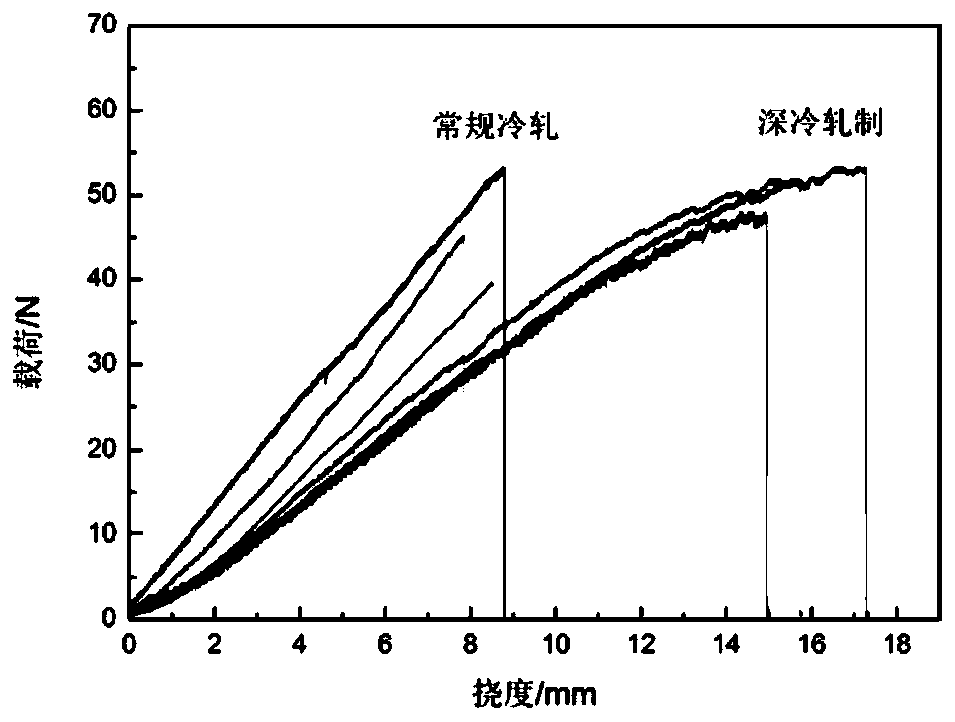

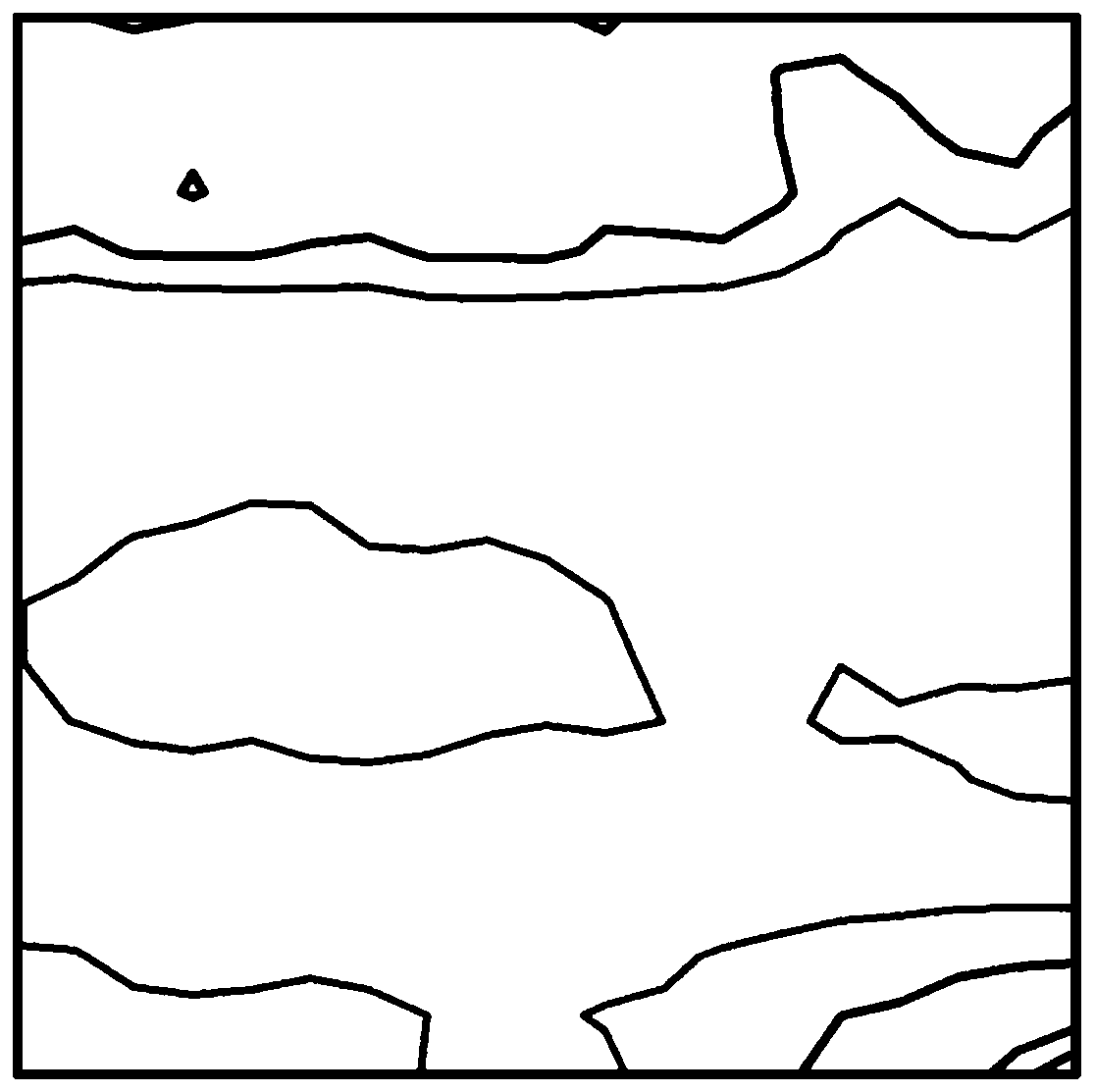

The invention relates to a non-oriented high silicon steel sheet containing boron and zirconium and a preparation method thereof, and belongs to the steel rolling process technology field. The non-oriented high silicon steel sheet containing the boron and the zirconium is characterized by consisting of chemical components by weight percentage: 4.5-6.9% of Si, 0.03-0.05% of B, 0.04-0.06% of Zr, less than 0.01% of C, less than 0.01% of Mn, less than 0.01% of P, less than 0.01% of S, less than 0.003% of N, less than 0.003% of O and the balance Fe, and the non-oriented high silicon steel sheet containing the boron and the zirconium is 0.15-0.2mm in thickness. A microalloying method for improving plasticity of non-oriented high silicon steel by adding the B and Zr elements is provided. Based onthe non-oriented high silicon steel sheet containing the boron and the zirconium and the preparation method thereof, a novel technology which combines warm rolling and deep cold rolling is adopted for preparing the high silicon steel sheet, and by performing microalloying on the B and Zr elements and refining crystal grains through the deep cold rolling, content of an ordered phase is reduced, and the plasticity of the non-oriented high silicon steel sheet is improved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Non-oriented silicon steel and production method thereof

The invention discloses a non-oriented silicon steel and a production method thereof. Molten steel is smelted by adopting a vacuum induction furnace. Molten steel is directly cast into a cast belt with the thickness between 1mm and 3mm through a pair of crystallization rollers rotating in opposite directions. The casting temperature of the molten steel is between 1500 DEG C and 1700 DEG C. The cast belt is subjected to one pass or multiple passes hot rolling and rolled into hot-rolled strip steel with thickness being 0.7mm and 2.5 mm. The hot rolling temperature is between 800 DEG C and 1150 DEG C, and the hot-rolled strip steel is coiled into a roll at the temperature between 500 DEG C and 800 DEG C. Normalizing annealing is conducted on the hot-rolled steel roll after the hot-rolled steel roll is subjected to a levelling or tension levelling working procedure with the elongation rate being 1.0% and 5.0%, and the normalizing annealing temperature is between 700 DEG C and 1000 DEG C. After the steel roll after normalizing annealing is subjected to cold rolling and the final annealing and coating working procedures, low-iron loss and high magnetic induction non-oriented silicon steel products are acquired. The non-oriented silicon steel products manufactured with the production method has high-proportion magnetic induction-favorable <100> and <110> structures, and the product magnetic induction is above 1.80 T.

Owner:SHAGANG GROUP +2

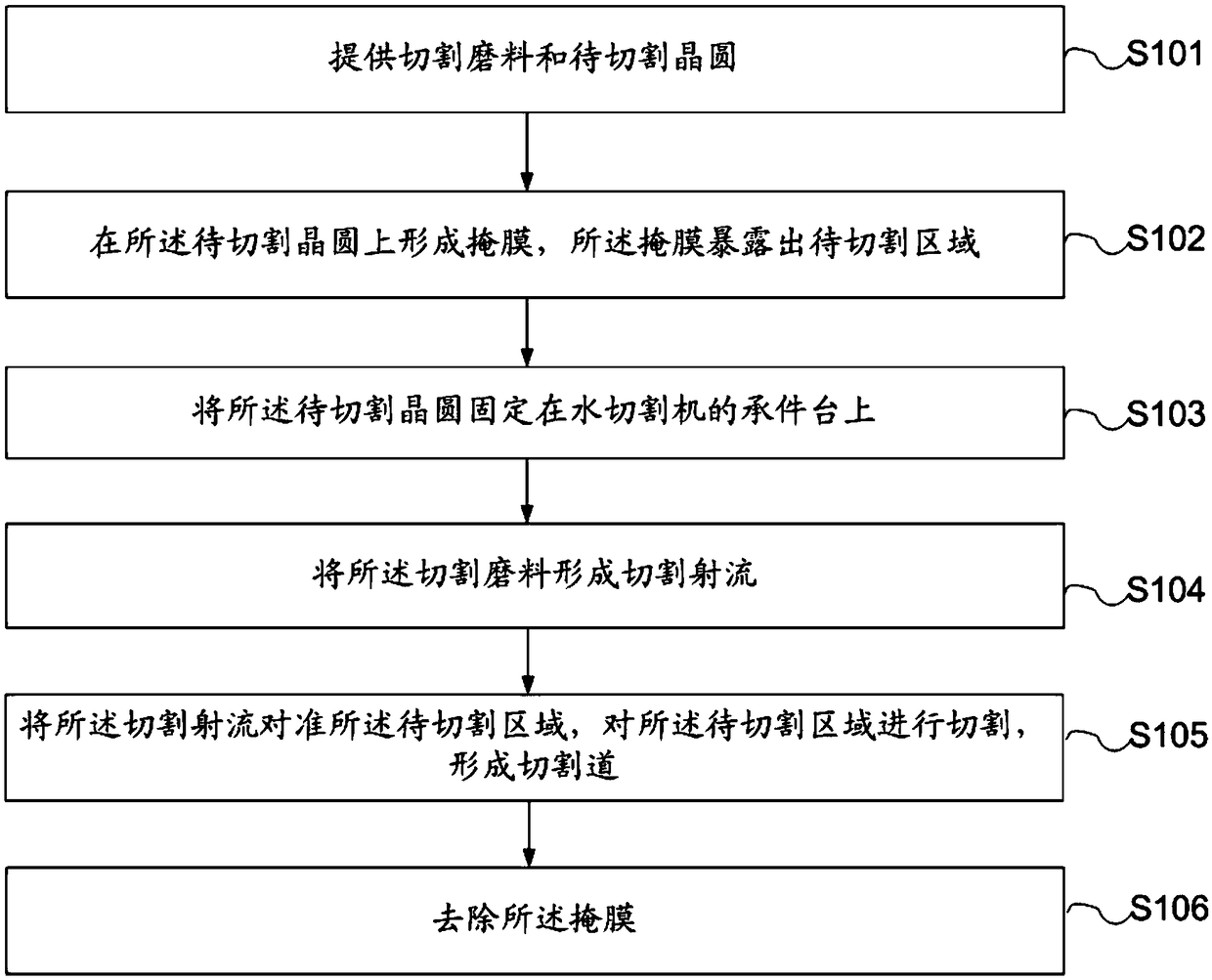

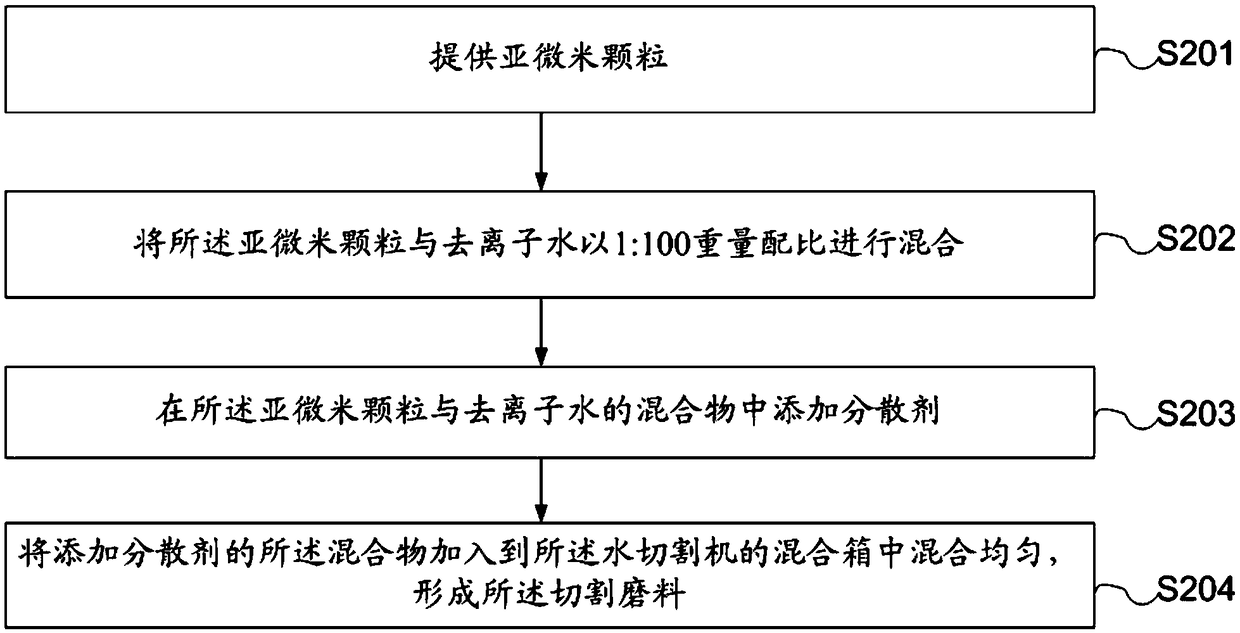

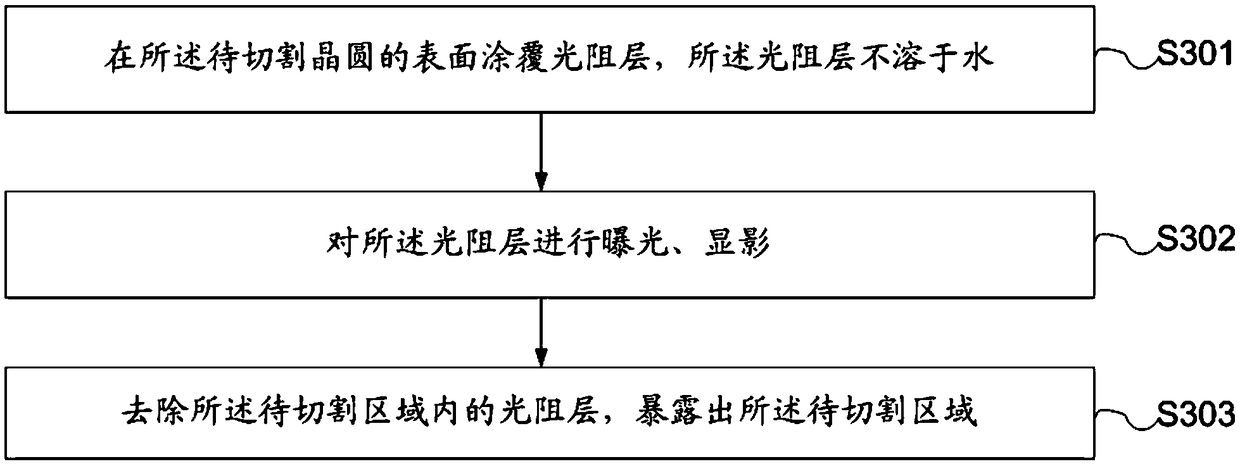

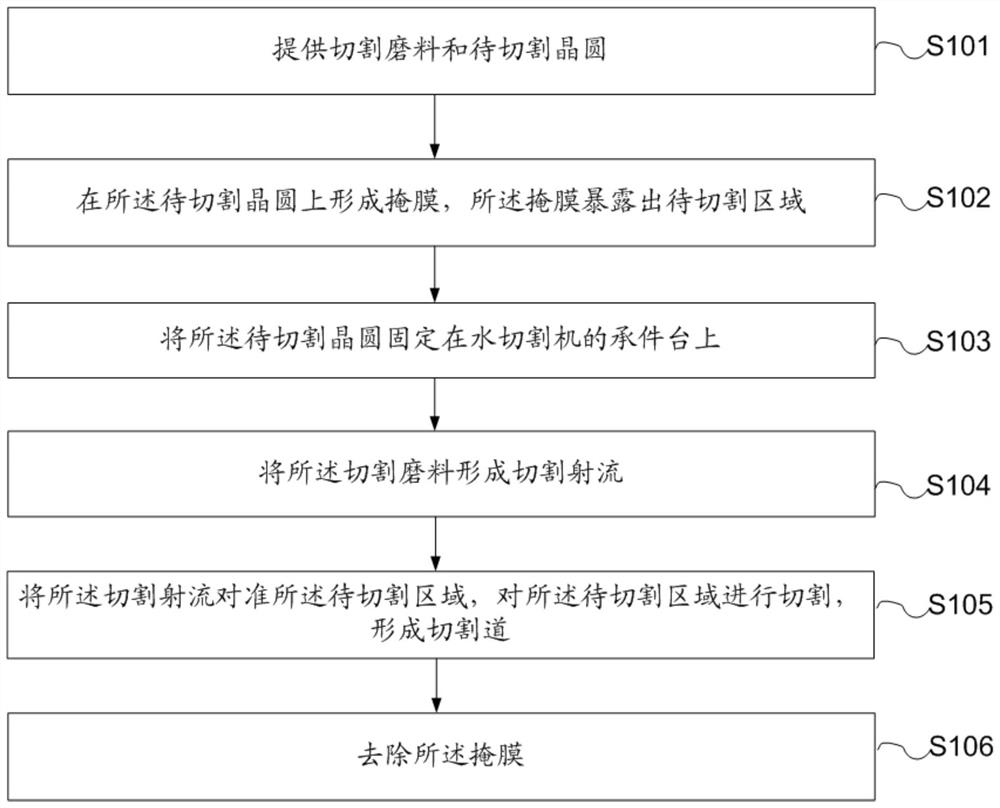

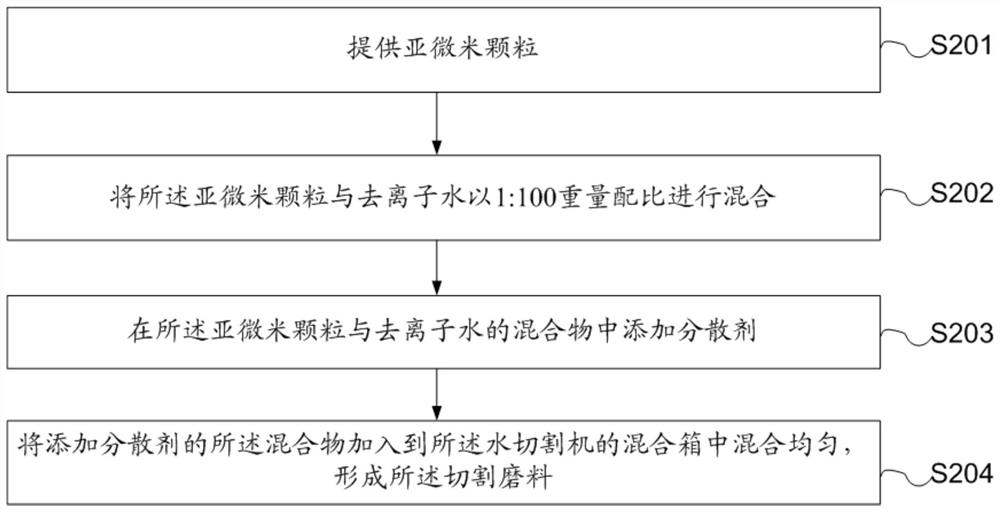

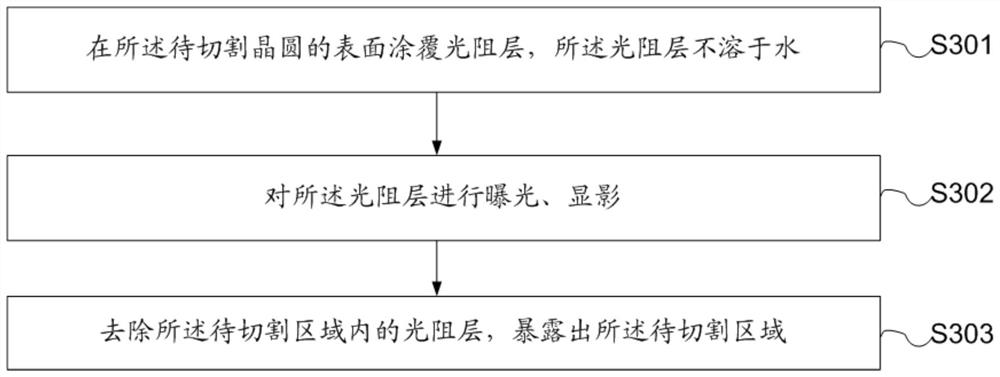

LED chip and cutting method thereof

ActiveCN108899303APrevent leakageAvoid the situationSemiconductor/solid-state device manufacturingAbrasive blasting machinesElectricityEngineering

The invention discloses an LED chip and a cutting method thereof. The cutting method of the LED chip provided by the invention is characterized in that after a cutting grinding material is prepared, the cutting grinding material is pressurized to form high-pressure cutting jet through a pressurization system in a waterjet cutting machine, so that the high-pressure cutting jet acts on the surface of an LED wafer, so that the goal of cutting the LED wafer is achieved. The LED chip cutting method provided by the invention is a cold cutting mode, so that the heat influence cannot be generated in the cutting process; melts similar to that in laser cutting cannot be generated, so that the condition that the LED chip leaks electricity or is shielded by the melts is effectively avoided; the LED lateral wall light outlet is favorably realized; the luminous efficiency of the LED chip is improved. In addition, the high pressure jet effect is fluid stress and is not mechanical stress, so that thephenomenon of edge crack in the chip cutting process is avoided; the qualification rate of the LED chip is improved.

Owner:YANGZHOU CHANGELIGHT

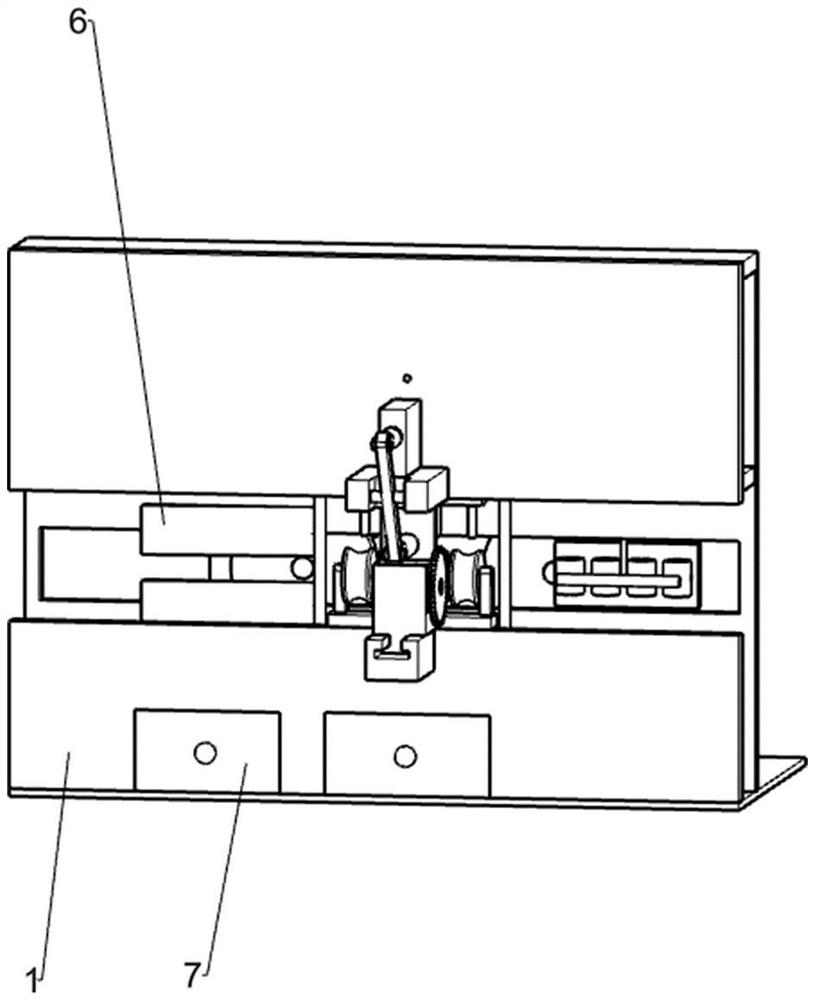

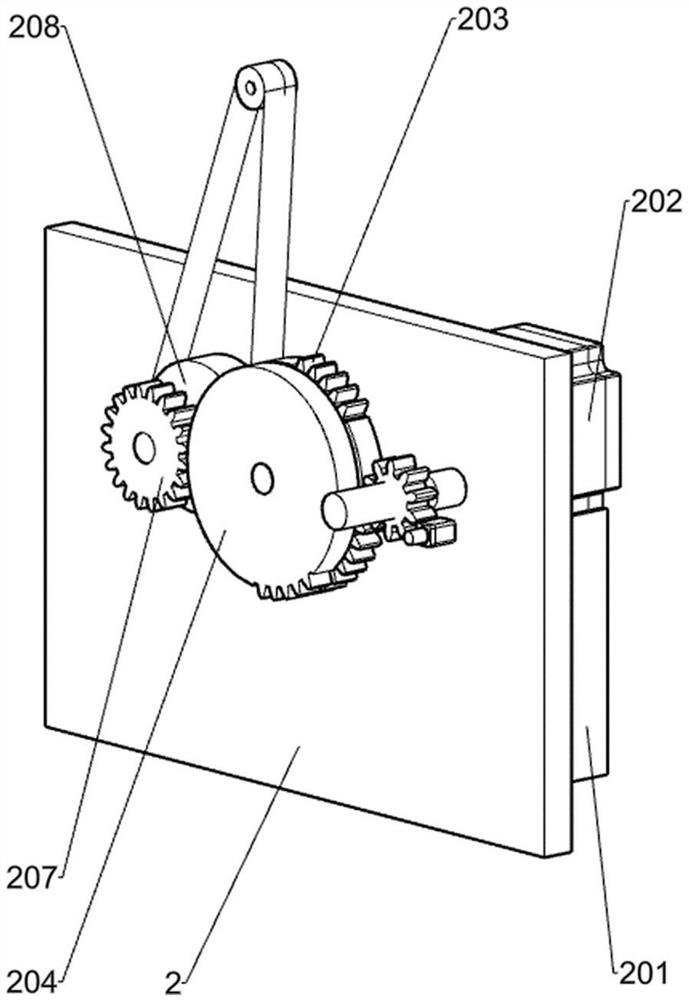

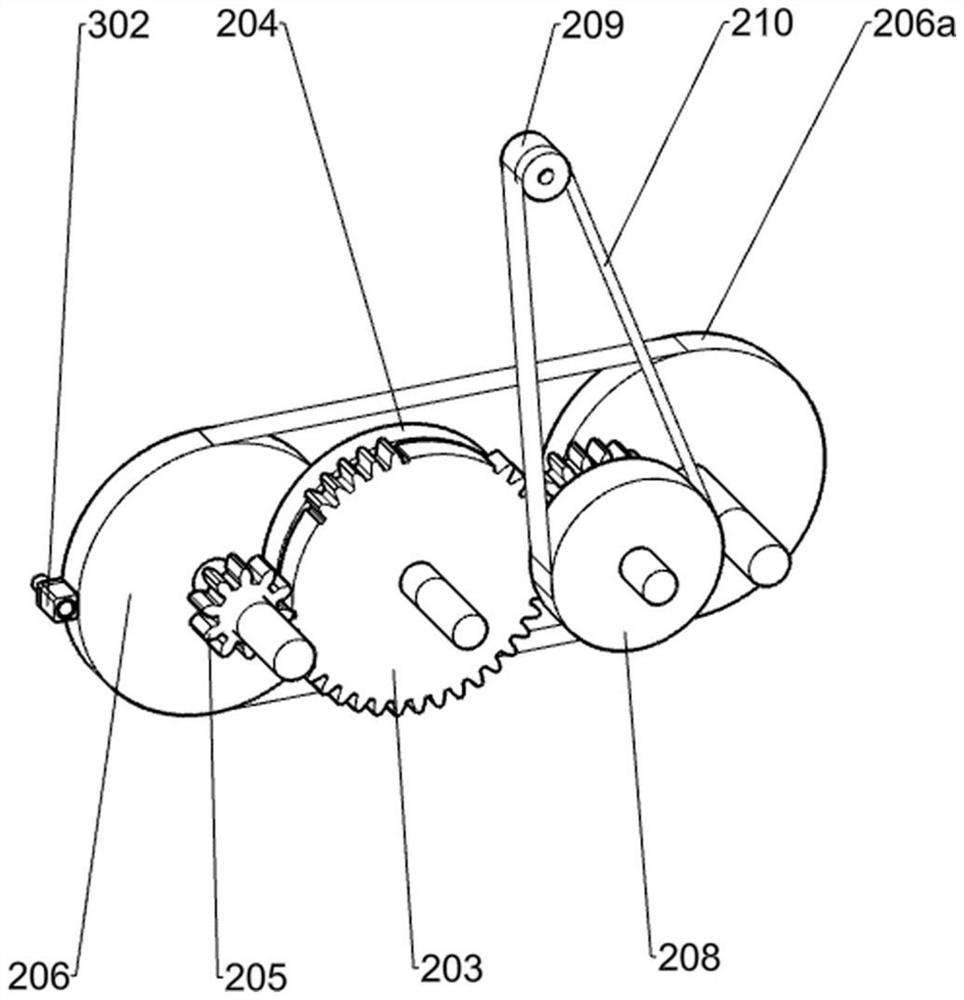

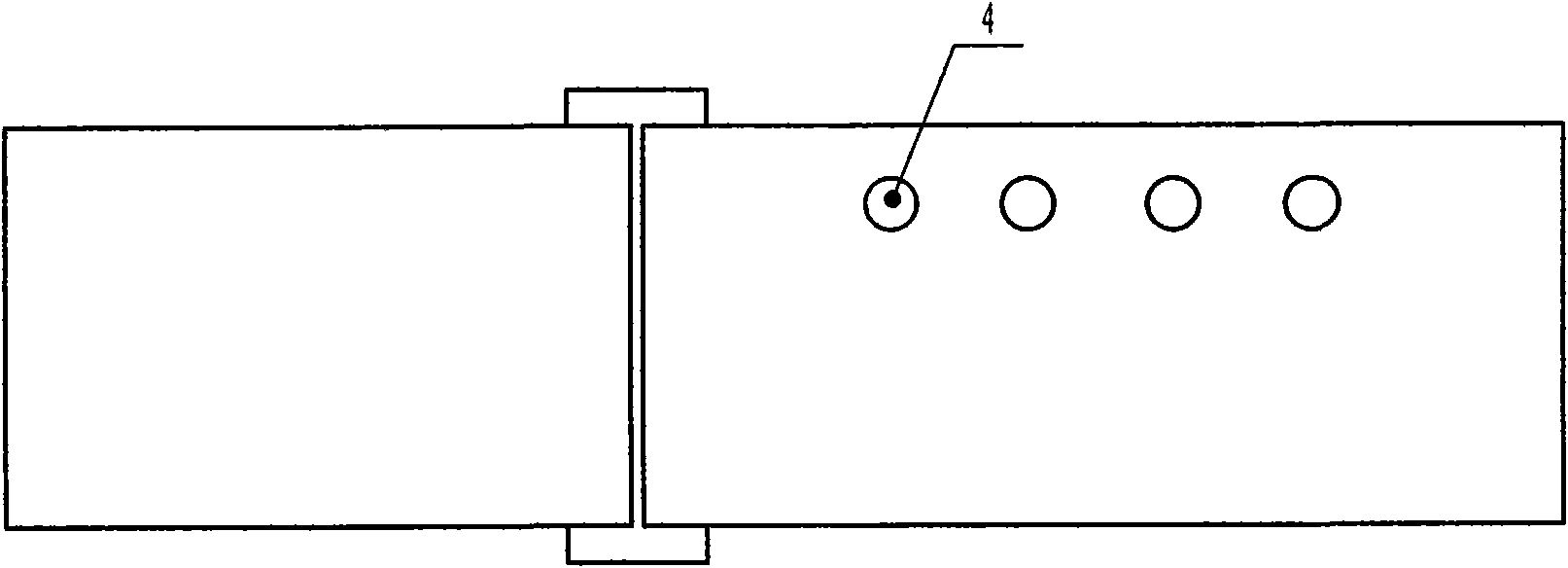

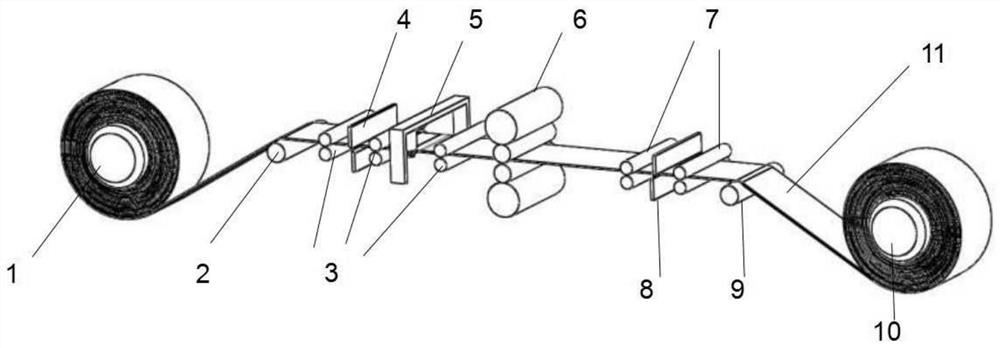

Plastic pipe fitting burr cutting and polishing device with cooperation of opposite cutter shearing and polishing

InactiveCN112192807AAvoid edge crackingImprove the finishEdge grinding machinesPipe fittingPolishing

The invention relates to a cutting and polishing device, in particular to a plastic pipe fitting burr cutting and polishing device with cooperation of opposite cutter shearing and polishing. The plastic pipe fitting burr cutting and polishing device with cooperation of opposite cutter shearing and polishing can be used for cutting edges and corners of plastic parts in batches and has a polishing function. According to the technical scheme, the plastic pipe fitting burr cutting and polishing device with cooperation of opposite cutter shearing and polishing comprises a first support, a power mechanism, a feeding mechanism, a cutting mechanism, a wedge-shaped block and a material box, wherein sliding grooves in the left-right direction are formed in the front side and the rear side of the middle of the first support, the power mechanism is fixedly installed in the middle of the rear side of the first support, and the feeding mechanism is fixedly connected with the power mechanism. The feeding mechanism and the cutting mechanism are additionally arranged, manpower is replaced, the feeding mechanism can transport the whole injection molded plastic pipe fittings at a time, and cutters with the number same to that of the pipe fittings are arranged on the cutting mechanism.

Owner:张跃爽

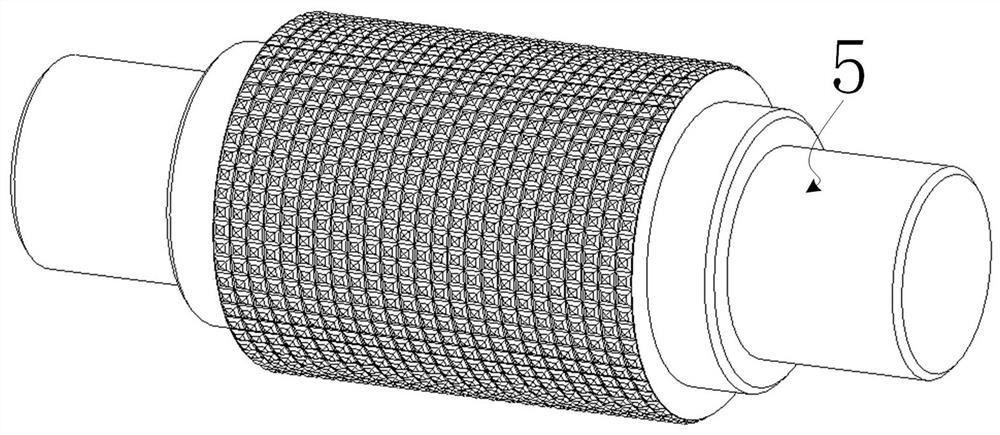

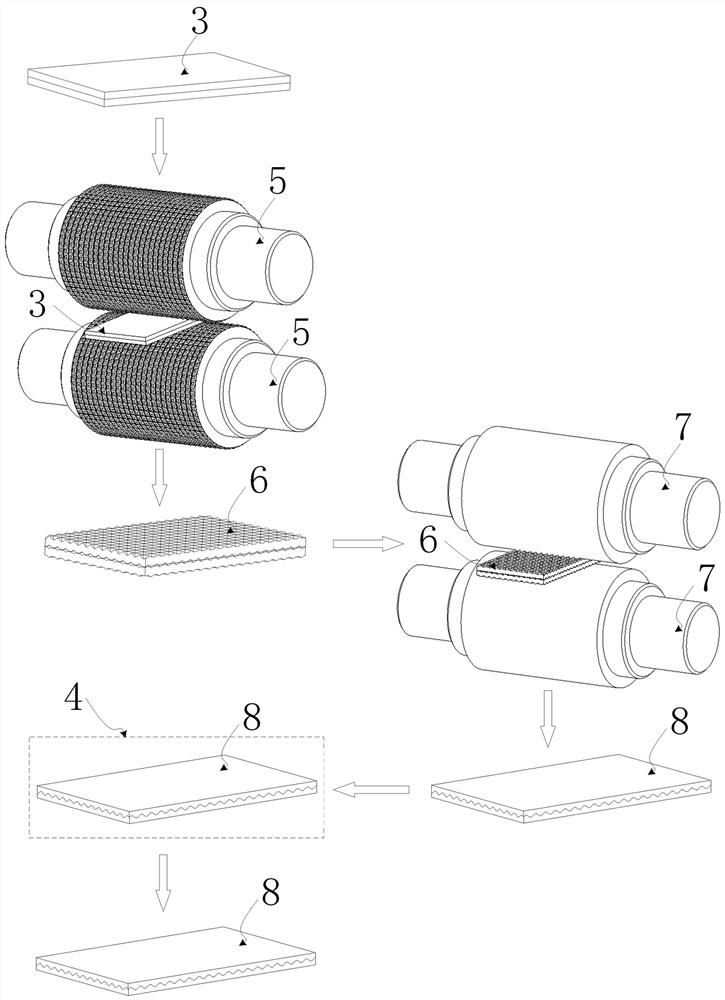

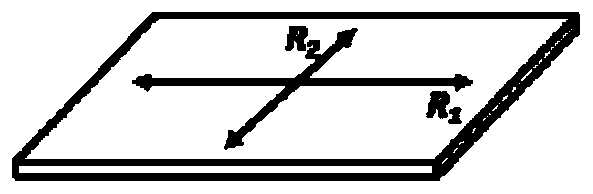

Method for rolling metal clad plate through double crossed corrugated rollers

PendingCN113020263AAvoid serious warping problemsShape ControlWork heating devicesAuxillary arrangementsEngineeringComposite plate

The invention relates to the technical field of metal clad plate preparation, in particular to a method for rolling a metal clad plate through double crossed corrugated rollers, and aims to solve the technical problems that a metal clad plate manufactured by adopting an existing rolling method is low in interface bonding strength, serious in warping and edge crack and the like. According to the technical scheme, a metal clad plate blank prepared through a conventional method is put into a corrugation rolling mill to be rolled, upper and lower rollers of the corrugation rolling mill are crossed corrugated rollers, the selection range of the reduction rate is 30%-50%, a metal clad plate I with the upper and lower surfaces and the bonding interface being corrugated rollers is obtained, then a flat rolling mill is used for conducting two-pass rolling, the selection range of the reduction rate is 20%-40%, and a metal clad plate II with the upper and lower surfaces being planes and the bonding interface being corrugated surface is obtained. The high-quality metal clad plate which is high in bonding strength, small in residual stress, light in bow warping and few in edge crack phenomenon can be obtained.

Owner:TAIYUAN UNIV OF TECH

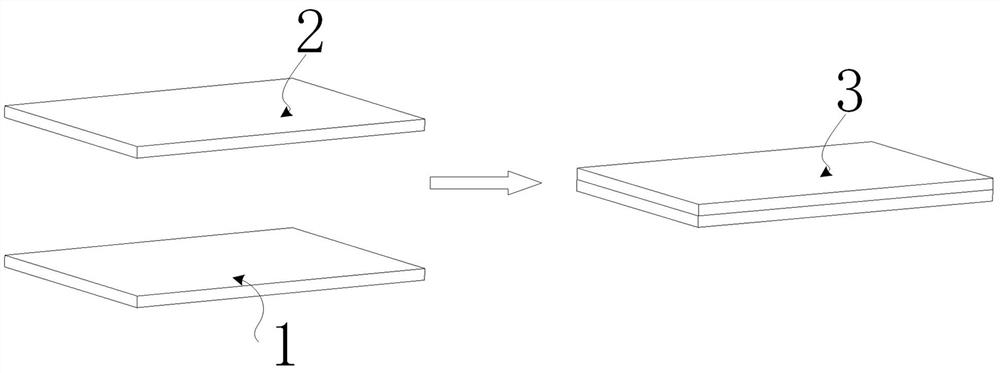

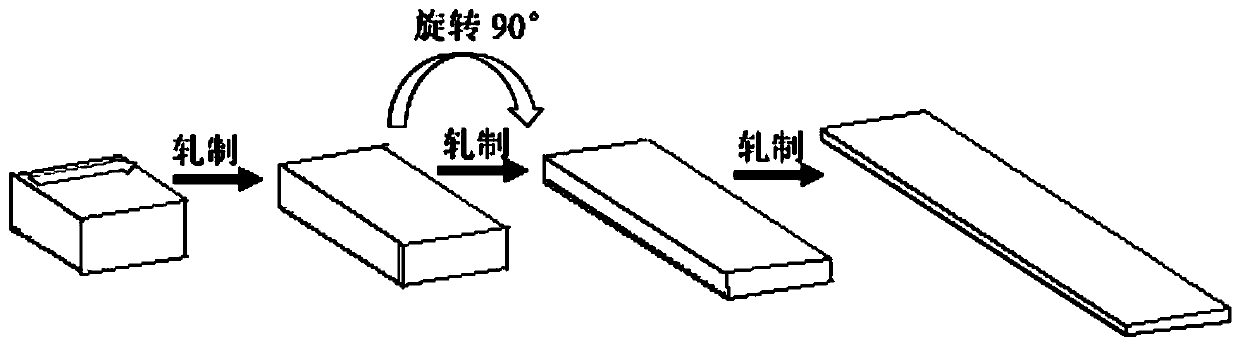

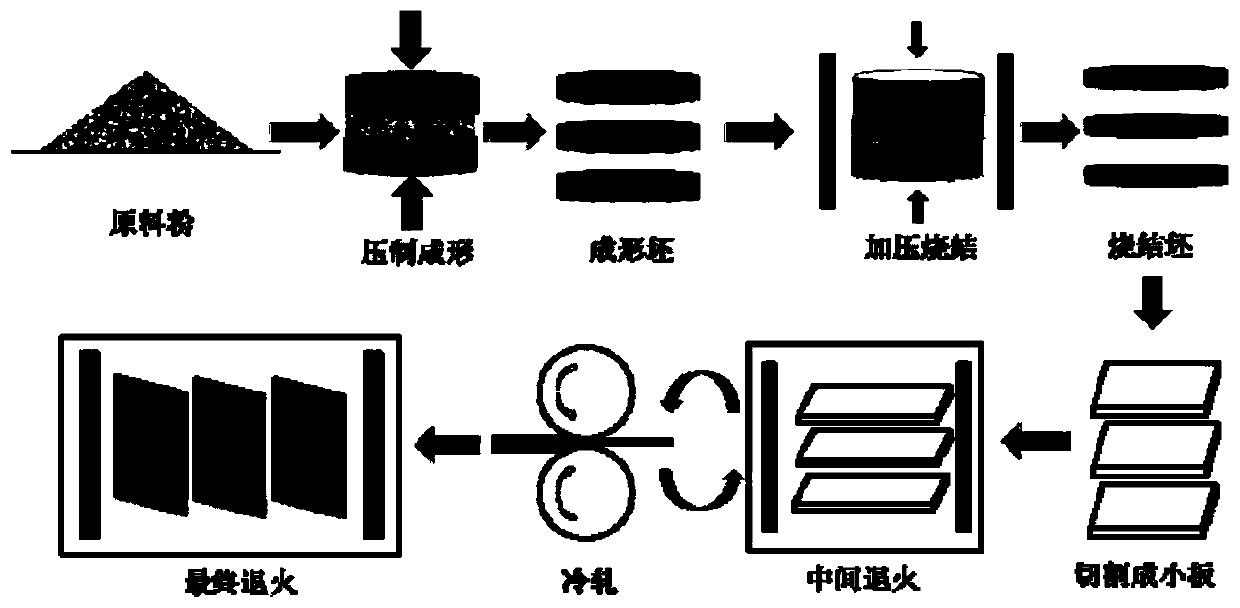

Production method for thin aluminum alloy sheets

The invention provides a production method for aluminum alloy sheets. The production method comprises the steps of compacting aluminum alloy powder, sintering, machining, performing multi-pass cold rolling, finishing and shearing and performing final annealing; blank annealing is performed on sintered blanks before cold rolling; during multi-pass cold rolling, reduction rate of each pass is lessthan 8 percent before total deformation reaches 50 percent, and the reduction rate of each pass is 10 to 30 percent after the total deformation is greater than 50 percent; the total deformation of thealuminum alloy sheets is 50 to 92 percent after multi-pass cold rolling; and cold rolling of any pass is assisted by intermediate annealing. The production method for the aluminum alloy sheets provided by the invention can be used for producing the aluminum alloy sheets in batches; compared with aluminum alloy sheets produced by a cast rolling method, the aluminum alloy sheets produced by the production method provided by the invention are low in cost, uniform in strip microscopic structure and size, free of segregation and high in strength; and compared with a method for producing aluminum alloy sheets by directly rolling powder, the production method provided by the invention has a simple technology, and is more flexible and economic to apply; and the sheets are high in compactness, anddo not have a hole flaw and the like.

Owner:CENT SOUTH UNIV

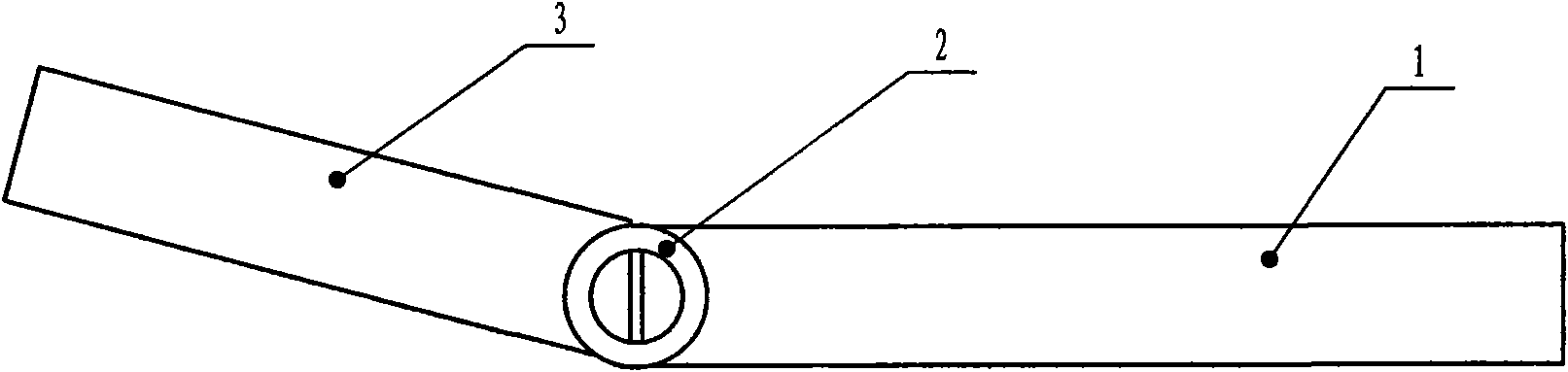

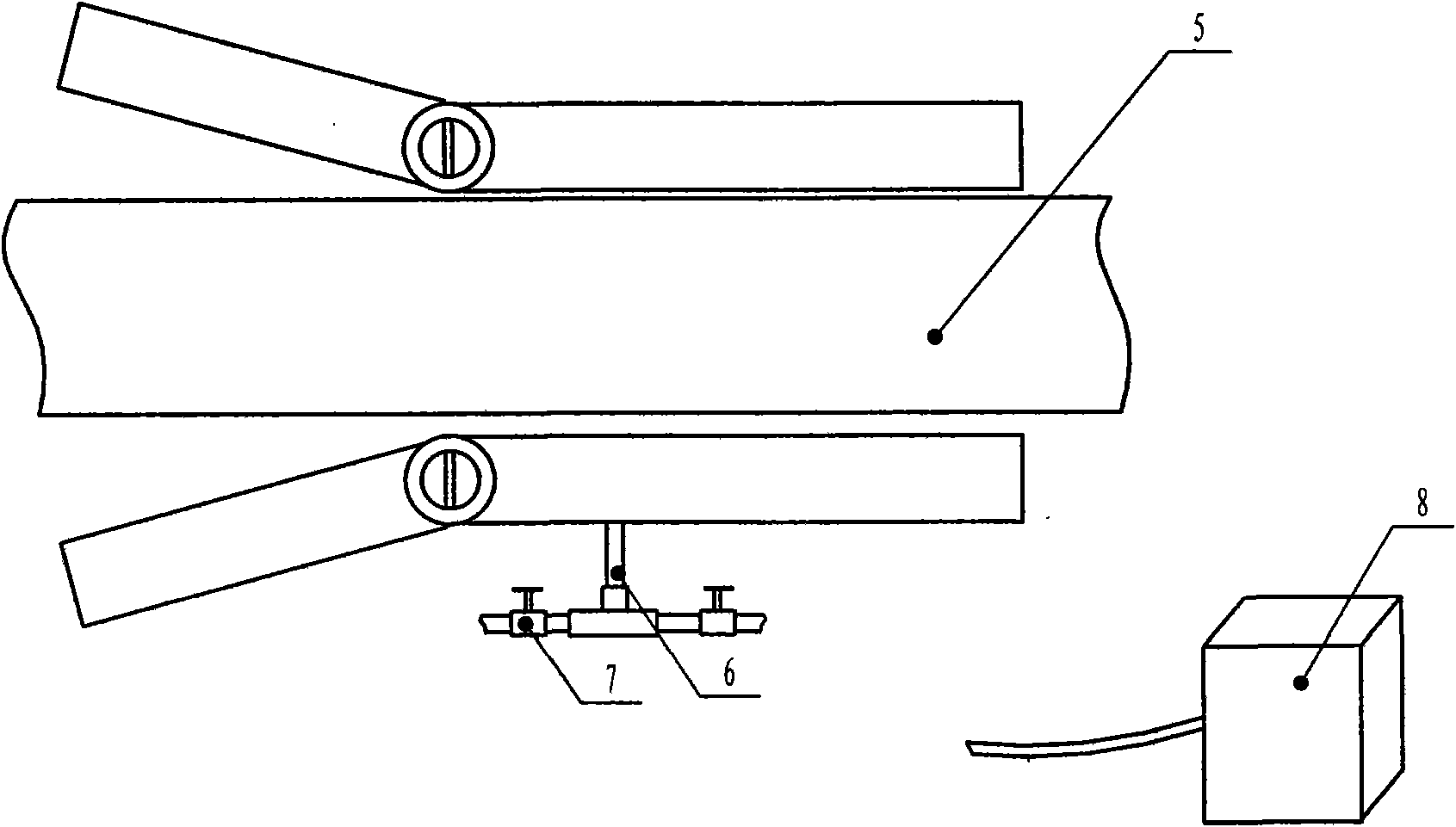

Hot-continuous-rolling strip steel side guide with heating function

InactiveCN101549352APrevent edge crackingGood effectGuiding/positioning/aligning arrangementsMetal rolling arrangementsCombustionControl system

The present invention belongs to an auxiliary means of metallurgy industry production equipment. The invention is used for controlling the position of rolled billet, and especially relates to a hot-continuous-rolling strip side guide with heating function. The hot-continuous-rolling strip side guide comprises two rectangular metal blocks. An angle which is larger than 90 DEG and less than 180 DEC is formed between the two rectangular metal blocks. The two rectangular metal blocks are fixedly connected through a connector. The invention is characterized in that one rectangular metal block wherein is fixedly installed with a plurality of combustion devices which are supplied with gas. The pipe for conveying gas is installed with a valve and a PLC-300 control system for controlling the valve. The hot-continuous-rolling strip side guide of the invention can partially heat an area in about 50-100 millimeters to the edge of rolled middle blank. The temperature at the edge of middle blank can be increased for more than 30 DEG C thereby preventing the generation of edge fracture caused by the overlow temperature of edge in the subsequent rolling. The effect of product quality increase is remarkable through the test of hot-continuous-rolling factory of Shanxi Taigang Stainless Steel Co., Ltd.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

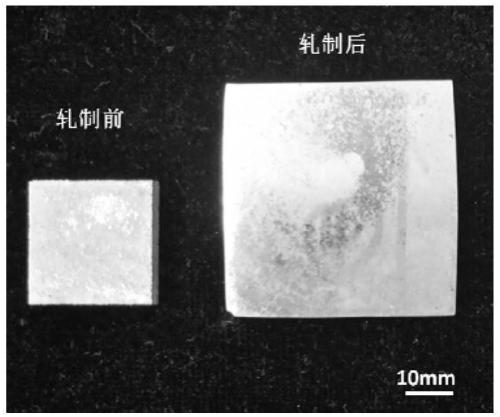

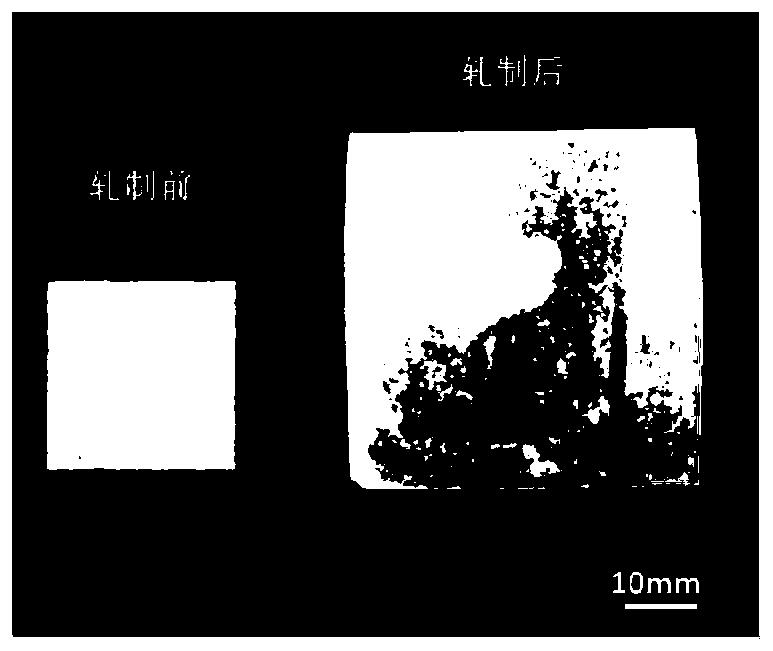

Method for manufacturing difficult-to-deform tin-bismuth alloy pre-formed soldering lug

ActiveCN109513747AImprove deformationGuaranteed normal processingMetal rolling arrangementsLow speedMaterial Crack

The invention discloses a method for manufacturing a difficult-to-deform tin-bismuth alloy pre-formed soldering lug. The method is characterized in that a core process adopts a two-section type temperature-regulating variable-speed and turning calendaring process, namely low-temperature high-speed large-rolling-reduction rough rolling and high-temperature low-speed small-rolling-reduction fine rolling; a temperature, speed and a rolling direction in a calendaring process are controlled, and other processes comprising low-temperature smelting, residual stress relief hot-levelling, rolling, cutting and the like are combined, so that high-efficiency manufacturing for the difficult-to-deform tin-bismuth alloy pre-formed soldering lug is realized. The manufacturing process for the pre-formed soldering lug can effectively solve the problems that a tin-bismuth alloy with intrinsic brittleness and difficult-to-deform characteristic easily generates material crack and the like in a large-deformation-amount processing process, and total deformation amount of the alloy can be 98% or more. The process is simple in flow, can greatly improve production efficiency of a tin-bismuth pre-formed lug,and reduces production energy consumption.

Owner:SHENZHEN XINGHONGTAI TIN +1

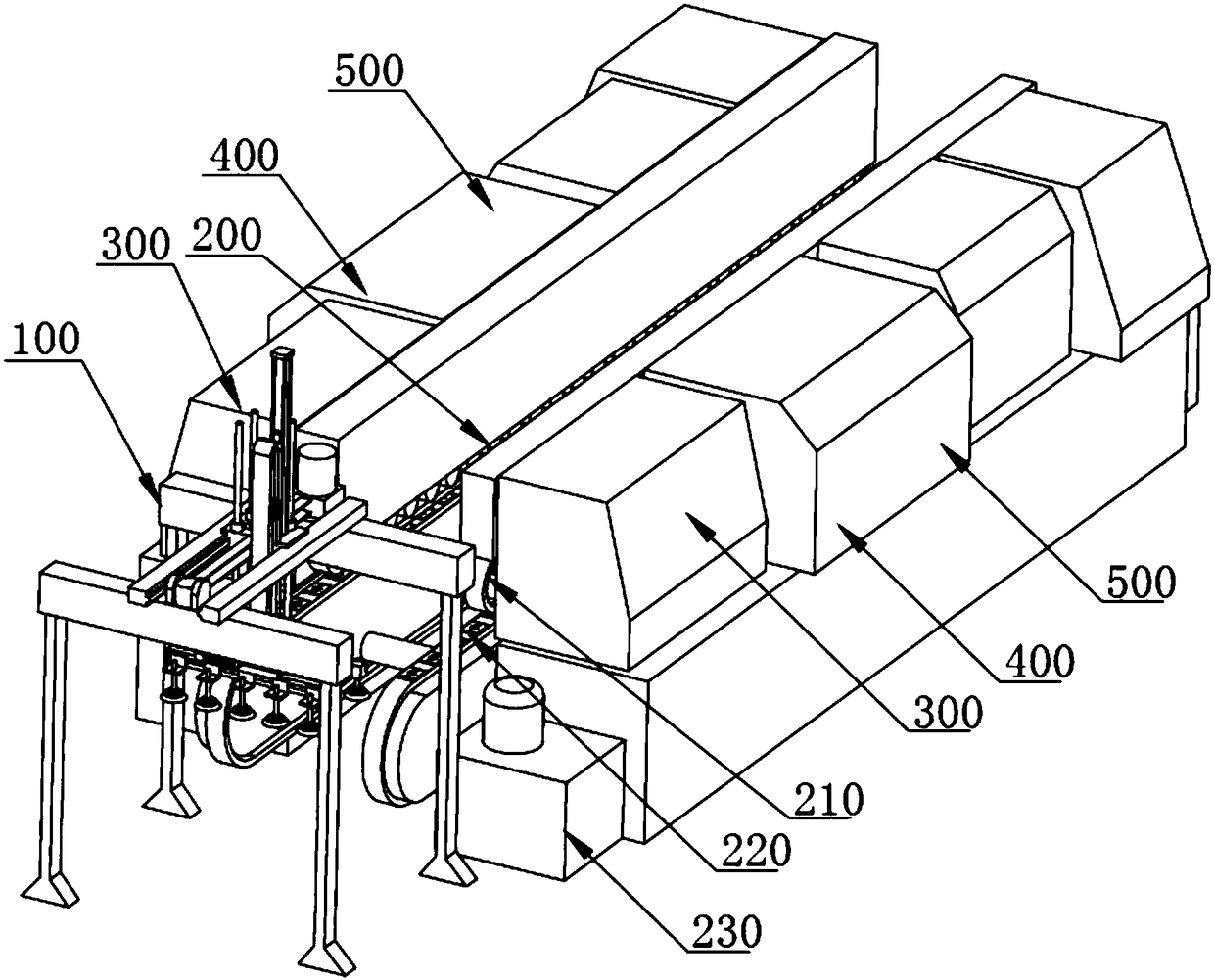

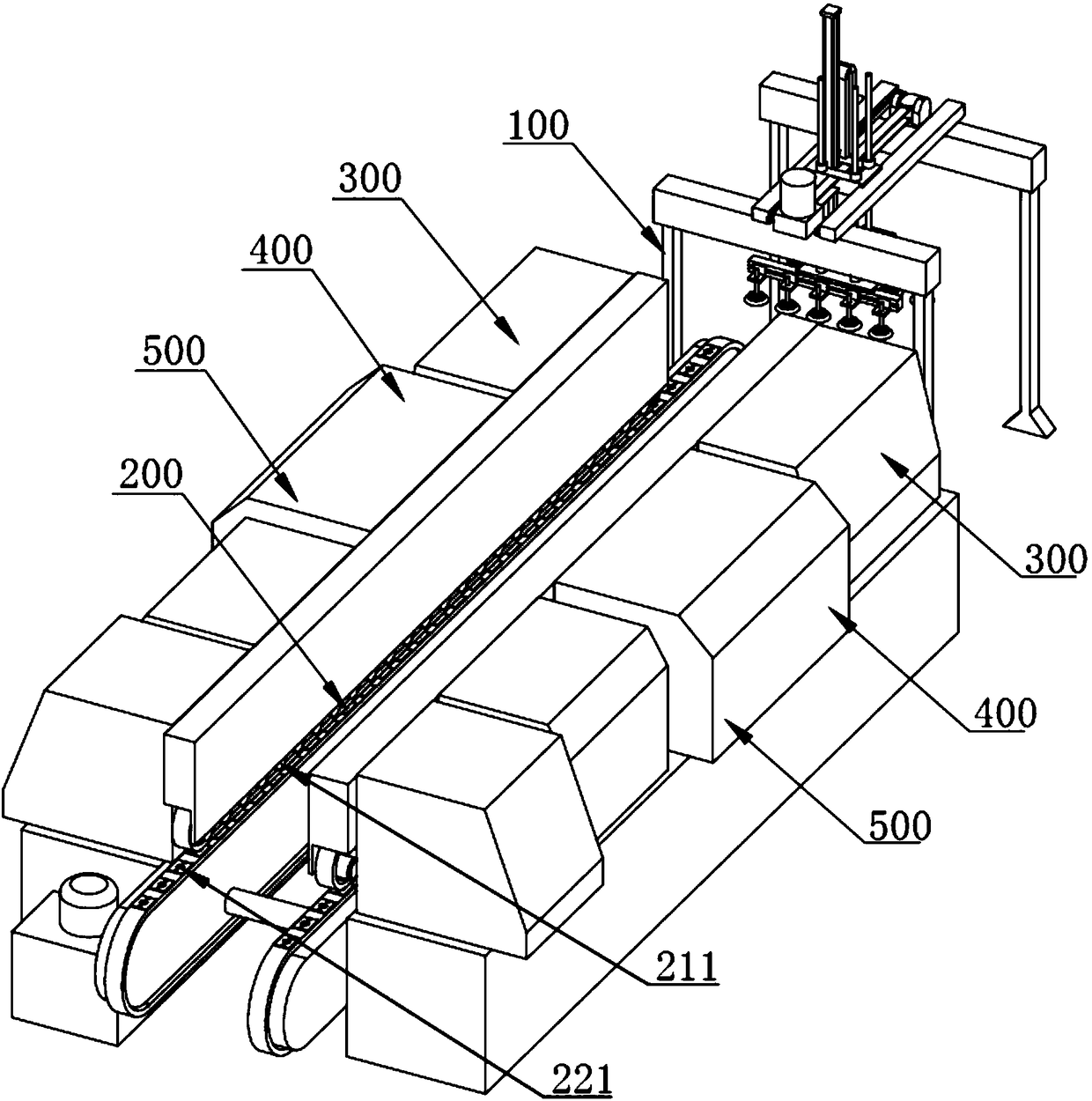

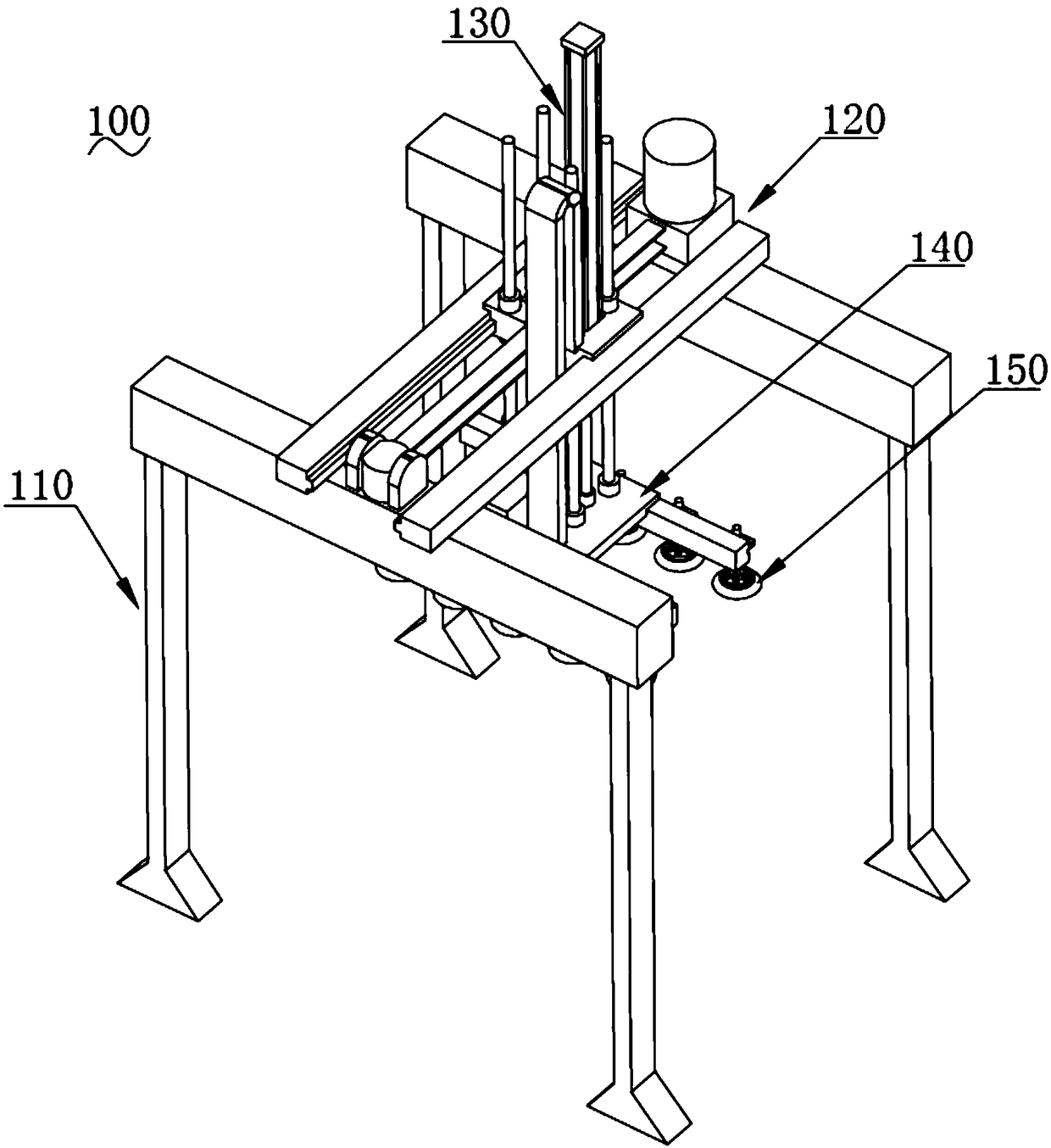

Automatic surface-cutting, edge-sealing, pressing and trimming system for boards and method comprising automatic surface-cutting, edge-sealing, pressing and trimming system

PendingCN109016066AAvoid glitchesPrevent edge crackingEdge grinding machinesWood working apparatusMaterial resourcesEngineering

The invention relates to the technical field of board processing equipment, in particular to an automatic surface-cutting, edge-sealing, pressing and trimming system for boards and a method comprisingthe comprising automatic surface-cutting, edge-sealing, pressing and trimming system. The automatic surface-cutting, edge-sealing, pressing and trimming system for the boards comprises a loading device, a conveying device, a surface-cutting device, an edge-sealing device and a trimming device, wherein the surface-cutting device, the edge-sealing device and the trimming device are sequentially arranged on the conveying device; the loading device is positioned at one side of the conveying device; the surface-cutting device comprises a pedestal, and a first surface-cutting module and a second surface-cutting module which are sequentially arranged; the first surface-cutting module is mounted on the pedestal; and the first surface-cutting module and the second surface-cutting module correspondto the conveying device. The automatic surface-cutting, edge-sealing, pressing and trimming system performs loading, conveying, surface-cutting, gluing, edge-sealing, pressing, cut-off and trimming on the boards in a fully-automatic mode, solves the problem that boards are manually subjected to surface-cutting and edge-sealing or are subjected to surface-cutting and edge-sealing by semi-automaticequipment in the prior art, is high in degree of automation, and saves manpower and material resources.

Owner:东莞市春旭机械科技有限公司

Rolling method for reducing surface cracking of TC4 titanium alloy smelted in an EB furnace

InactiveCN111495970AReduce deformation resistanceLow costFurnace typesWork heating devicesIngotTitanium alloy

The invention discloses a rolling method for reducing the surface cracking of a TC4 titanium alloy smelted in an EB furnace, and belongs to the field of plastic forming. According to the rolling method, a TC4 titanium alloy cast-state slab ingot is directly rolled into a high-quality plate through the method of combination of direct rolling and recrystallization annealing heat , so that on one hand, the production process flow of the TC4 titanium alloy is shortened, and the machining cost is reduced; and on the other hand, the side portion cracking and central surface cracks in the titanium alloy rolling process are reduced, the surface quality of a finished plate is good, and the high-quality TC4 titanium alloy plate is finally obtained.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of aluminum alloy sheet production method

The invention provides a production method for aluminum alloy sheets. The production method comprises the steps of compacting aluminum alloy powder, sintering, machining, performing multi-pass cold rolling, finishing and shearing and performing final annealing; blank annealing is performed on sintered blanks before cold rolling; during multi-pass cold rolling, reduction rate of each pass is lessthan 8 percent before total deformation reaches 50 percent, and the reduction rate of each pass is 10 to 30 percent after the total deformation is greater than 50 percent; the total deformation of thealuminum alloy sheets is 50 to 92 percent after multi-pass cold rolling; and cold rolling of any pass is assisted by intermediate annealing. The production method for the aluminum alloy sheets provided by the invention can be used for producing the aluminum alloy sheets in batches; compared with aluminum alloy sheets produced by a cast rolling method, the aluminum alloy sheets produced by the production method provided by the invention are low in cost, uniform in strip microscopic structure and size, free of segregation and high in strength; and compared with a method for producing aluminum alloy sheets by directly rolling powder, the production method provided by the invention has a simple technology, and is more flexible and economic to apply; and the sheets are high in compactness, anddo not have a hole flaw and the like.

Owner:CENT SOUTH UNIV

Heating method for casting blank corner part

The invention discloses a heating method for a casting blank corner part. The method is completed by using a casting machine. The casting machine is provided with a coal-oxygen burner. The method is specifically performed according to the following steps: (1) in a continuous casting process of the casting machine, using flame of the coal-oxygen burner to directly heat the continuous casting blankcorner part, and warming the corner part and an edge part; (2) in a heating process of the coal-oxygen burner, controlling a flow rate of a coal gas and an oxygen gas to be less than or equal to 800 m<3> / h; (3) in a condition of 5-8 m / min of a pulling rate, and 50-120 mm of a casting blank thickness, within 4-8 s, improving a casting blank temperature to 150-240 DEG C. The method is capable of using the simple coal-oxygen burner to perform direct flame heating in allusion to the edge part of a continuous casting blank, wherein the method is suitable for a heat compensating process of the edgeand corner parts of the current continuous casting blank in a high pulling rate production condition, through improving temperature uniformity, avoiding the edge part from cracking, thereby reducing fracture probability, and reducing crack generation of the edge part and a cracking degree, and in the condition of 5-8 m / min of the pulling rate, and 50-120 mm of the casting blank thickness, rapidlyimproving the casting blank temperature to 150-240 DEG C.

Owner:NORTHEASTERN UNIV

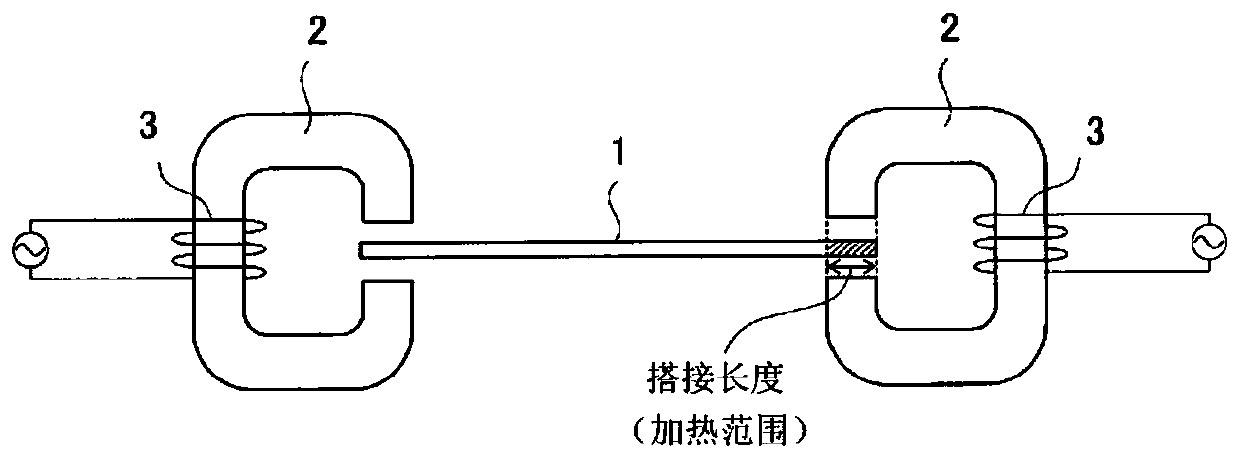

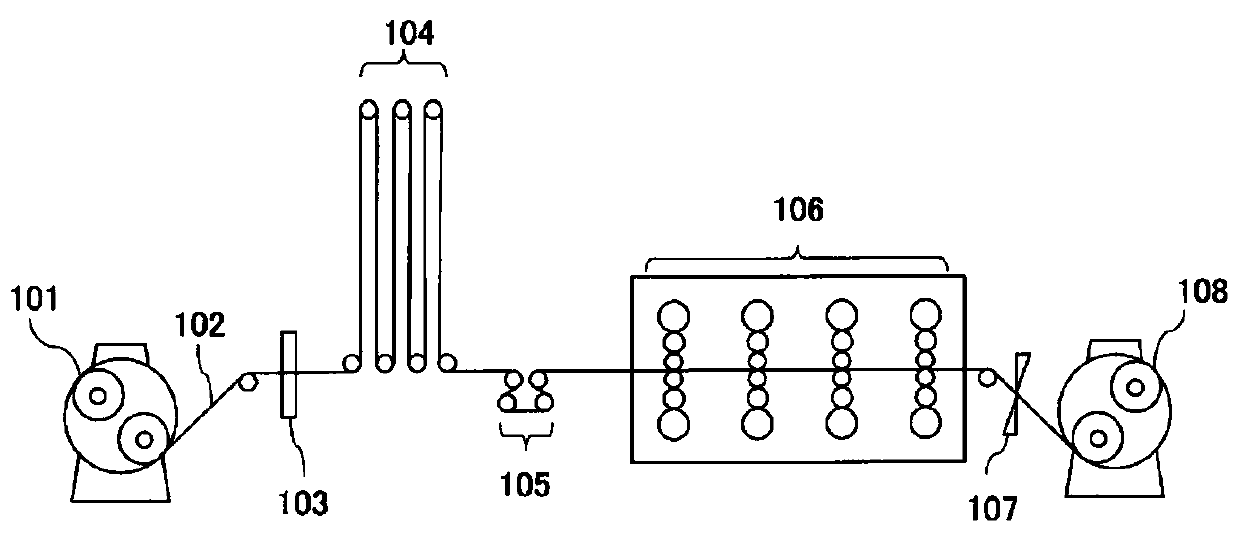

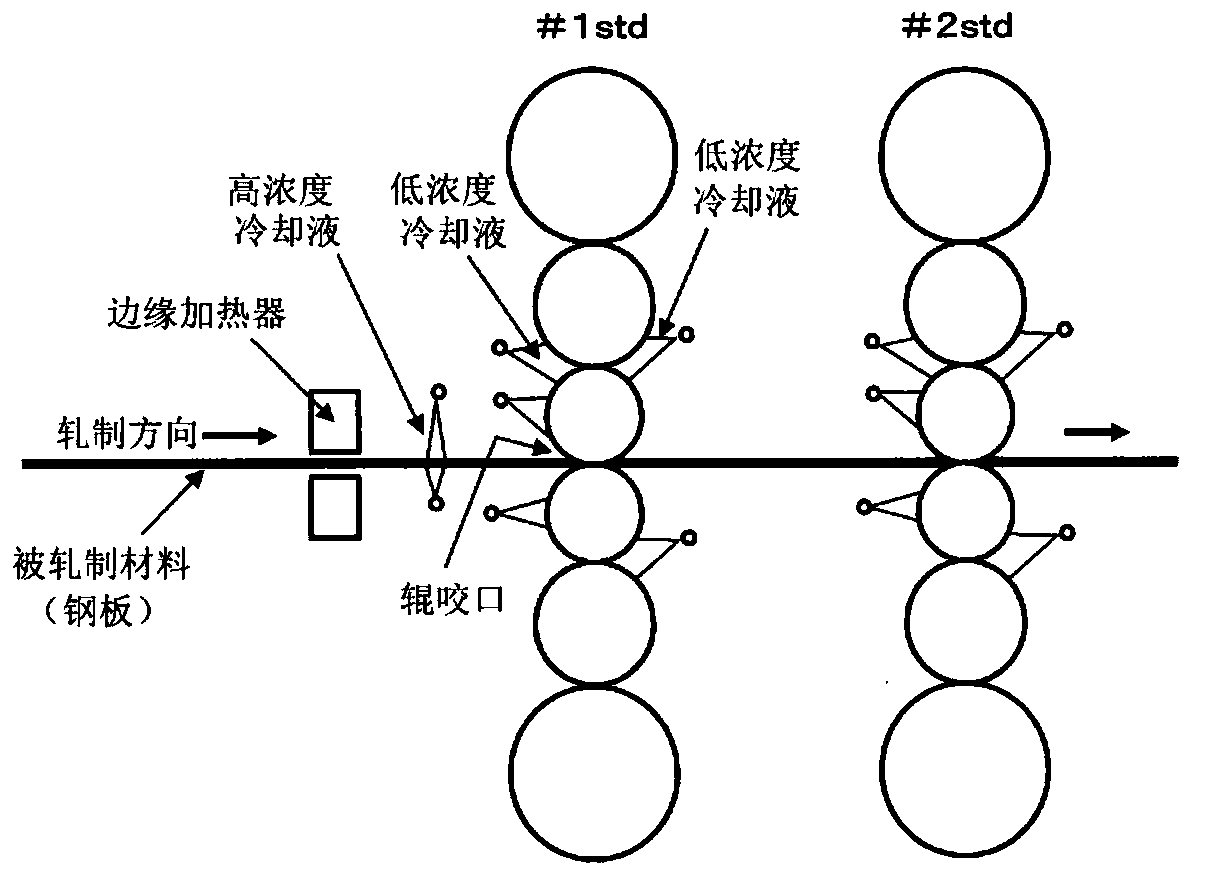

Cold roller and cold rolling method

ActiveCN110300633AImprove water-free spreadingGuaranteed water-free spreadingTemperature control deviceFurnace typesMetallurgyCooling fluid

The invention provides a cold roller and a cold rolling method. It is possible to roll hard-to-roll materials such as silicon steel sheets and stainless steel sheets without cracking the steel sheet edges or fracturing the steel sheet, even during slow rolling, by using a circulating-lubricant tandem cold roller which supplies coolant comprising a rolling oil and cooling water to each stand and continuously rolls a steel sheet, wherein edge heaters for heating both edges of the steel sheet to a temperature of at least 60 DEG C on the roll bite entry side of the steel sheet are provided on theupstream side of the first stand of the cold roller, and equipment for spraying the surfaces of both edges of the steel sheet with a coolant having a higher concentration than the coolant supplied tothe first stand is provided between the edge heater and the first stand.

Owner:JFE STEEL CORP

Method for predicting edge forming limit of high-strength steel plate stamping part

PendingCN113552003AAvoid edge crackingImprove yieldMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesLimit strainEngineering

The invention discloses a method for predicting the edge forming limit of a high-strength steel plate stamping part, and the method comprises the following steps: judging a part deformation element in combination with a part forming process; carrying out deformation element limit strain testing; and obtaining the actual part edge deformation limit according to the actual part stamping deformation condition. According to the method for predicting the edge forming limit of the high-strength steel plate stamping part, the deformation element of the part is judged and tested, and then the deformation limit is obtained according to the actual stamping deformation condition of the part, so that the machining of the part does not exceed the deformation limit, the high-strength steel plate stamping part is prevented from being prone to edge cracking, and the yield of the part is improved.

Owner:SHOUGANG CORPORATION

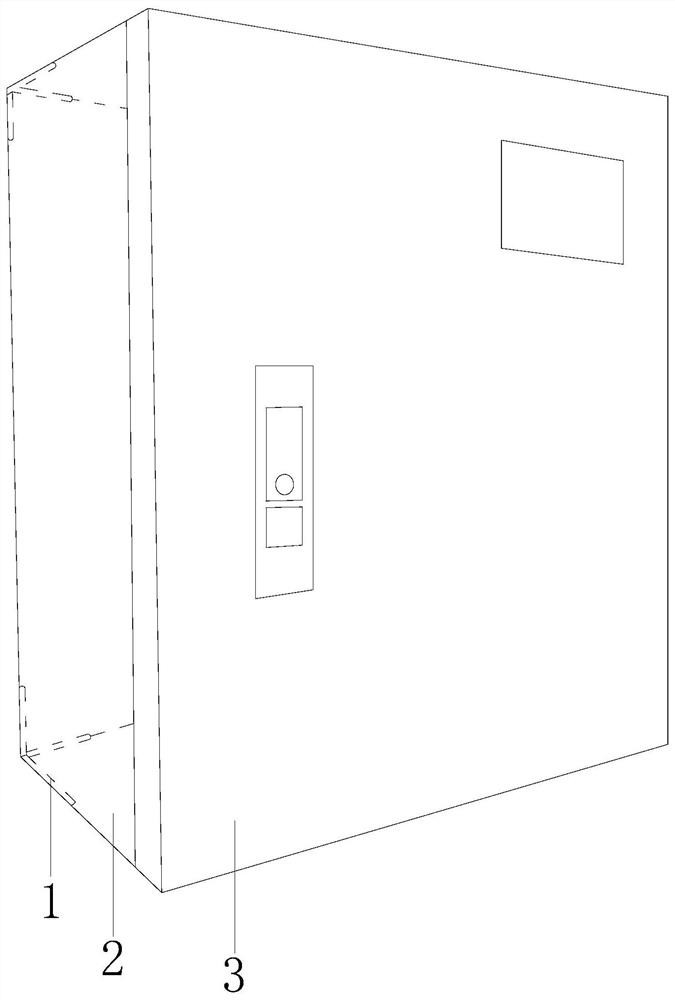

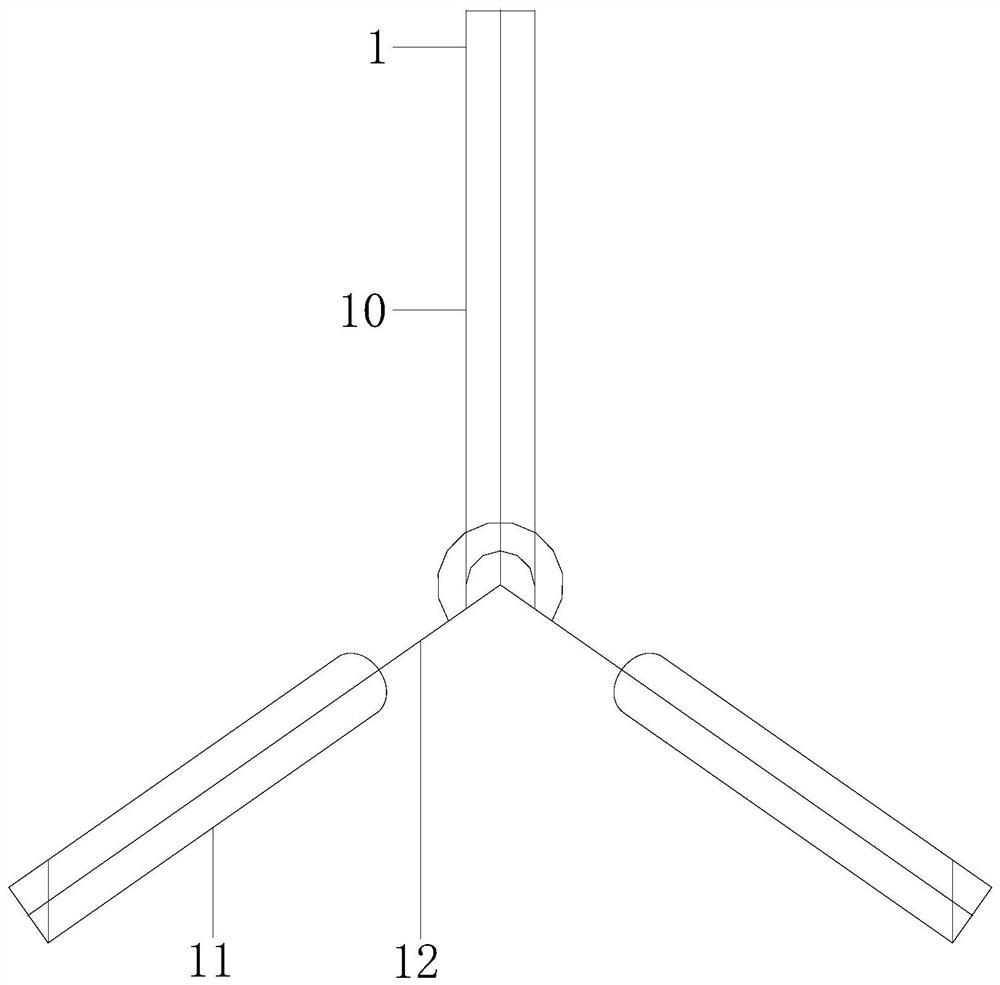

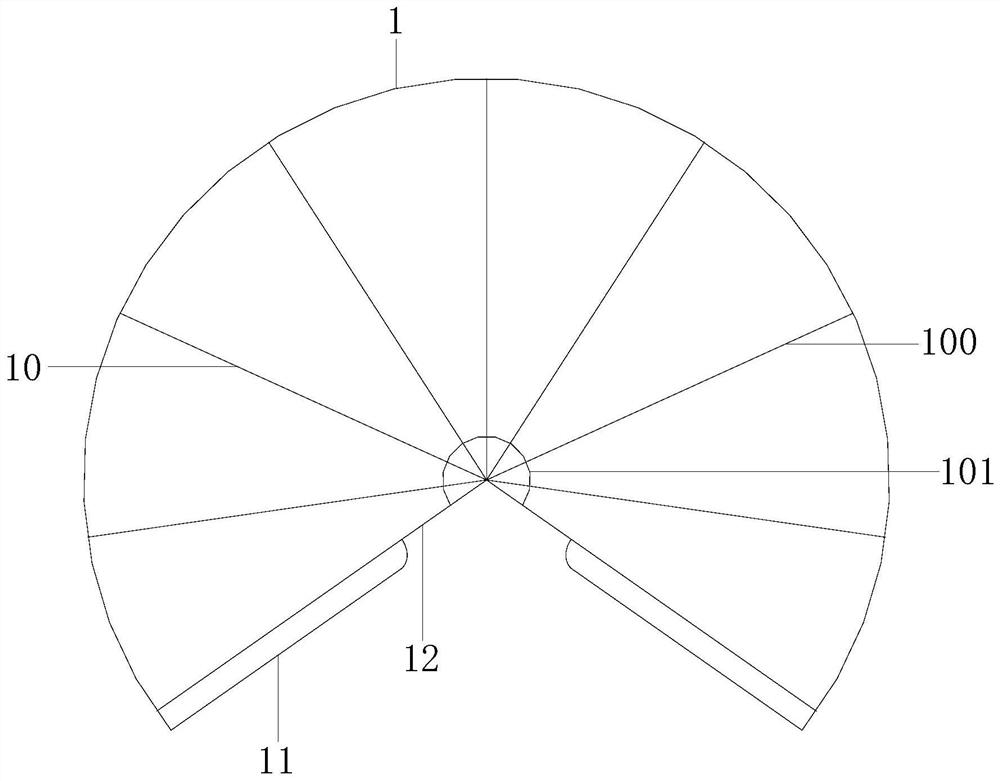

Equipment power distribution control box

InactiveCN112117682APlay a buffer roleIncrease loading capacityAnti-seismic devicesDistribution controlClassical mechanics

The invention discloses an equipment power distribution control box, and the box structurally comprises an inner corner structure, a control box frame and a control box door, wherein the inner cornerstructure is installed in the control box frame, the control box frame is connected with the control box door through a shaft bolt, and the inner corner structure is composed of an upper rod structure, a side supporting structure and a tripod strip, wherein the upper rod structure and the side supporting structure are arranged on the tripod strip; the upper rod structure comprises a movable striprod and a movable rod shaft; the movable strip rod is connected with the movable rod shaft, and the movable strip rod is connected with a bottom supporting strip; the movable rod shaft comprises a rodshaft disc, a reinforcing arc cover, a transverse plate and a welding bottom cover, wherein the rod shaft disc is provided with the transverse plate, the reinforcing arc cover and the transverse plate are locked, and the rod shaft disc is provided with the welding bottom cover. The inner corner structure plays a role in assisting in loading, the loading force at the corner of the box frame of thecontrol box is improved, the side supporting structure plays a role in buffering, the installation impact force is reduced, edge cracking is avoided, and the operation signal is good.

Owner:庄小梅

Low-nickel-content austenitic stainless steel

The invention relates to a low-nickel-content austenitic stainless steel. The low-nickel-content austenitic stainless steel comprises the following components in percentages by weight: 10-13.2% of Cr, less than 1.0% of Ni, 2.3-3.2% of Cu, 5.0-7.2% of Mn, 1.0-1.5% of F, 0.1-0.2% of N, 0.05-0.1% of C, 0.3-0.6% of Si, and the balance of Fe and other inevitable elements. Cheap copper, fluorine and nitrogen replace part of expensive nickel element, the cost can be greatly reduced, and meanwhile, the austenitic stainless steel has good corrosion resistance and hot and cold workabilities; and furthermore, by addition of a certain amount of P and K, the hot and cold workabilities of the stainless steel can be improved, and edge crack and M-shaped defects in a hot rolling process can be avoided. The austenitic stainless steel has excellent corrosion resistance and hot and cold workabilities, particularly has excellent hot workability, and therefore, can replace stainless steel such as 304 steel and 301 L.

Owner:桥运精密部件(苏州)有限公司

A kind of led chip and cutting method thereof

ActiveCN108899303BPrevent leakageImprove luminous efficiencySemiconductor/solid-state device manufacturingAbrasive blasting machinesWaferEngineering

Owner:YANGZHOU CHANGELIGHT

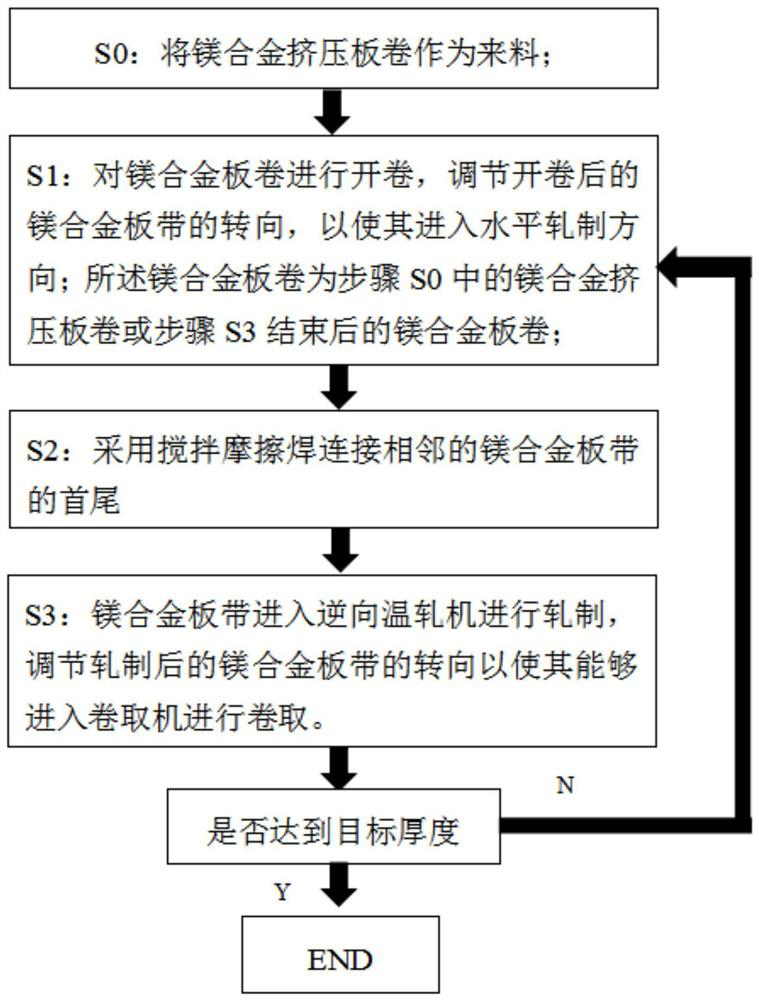

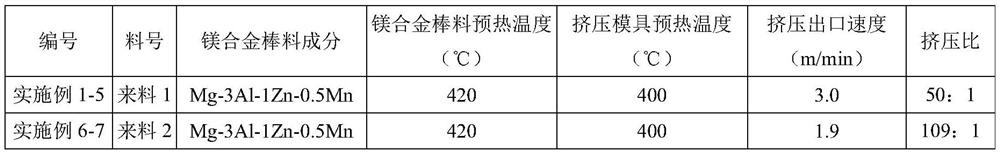

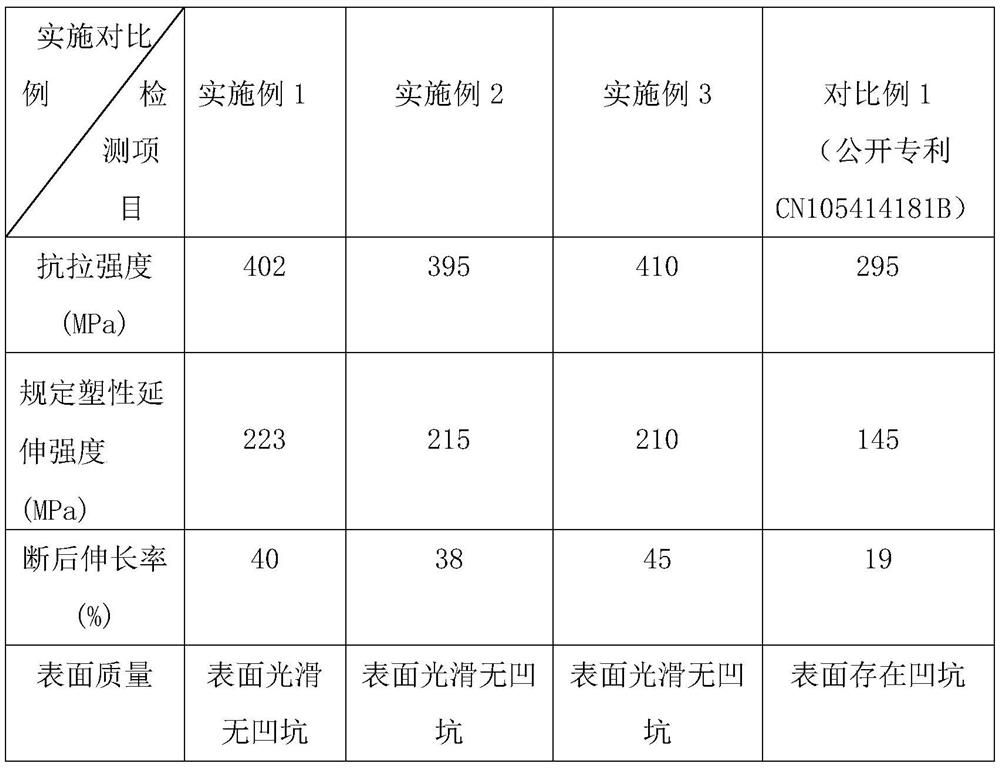

Full-continuous rolling production process for magnesium alloy plate

PendingCN113967663AFully continuous rolling realizedHigh strengthMetal rolling arrangementsContinuous rollingMechanical property

The invention discloses a full-continuous rolling production process for a magnesium alloy plate. The full-continuous rolling production process comprises the following steps that S0, a magnesium alloy extrusion plate coil serves as a supplied material; S1, the magnesium alloy plate coil is uncoiled, and the rotating direction of an uncoiled magnesium alloy plate strip is adjusted so that the magnesium alloy plate strip can enter the horizontal rolling direction; the magnesium alloy plate coil is the magnesium alloy extrusion plate coil in the step S0 or the magnesium alloy plate coil after the step S3; S2, the heads and the tails of the adjacent magnesium alloy plate strips are connected through friction stir welding; and S3, the magnesium alloy plate strip enters a reverse warm rolling machine to be rolled, and the rotating direction of the rolled magnesium alloy plate strip is adjusted so that the magnesium alloy plate strip can enter a winder to be wound; and to the step S1 is turned again to repeat the steps S1-S3 until the target thickness is reached. By the adoption of the full-continuous rolling production process for the magnesium alloy plate, full-continuous rolling of the magnesium alloy plate can be effectively achieved, and the magnesium alloy plate with the mechanical property and the forming property is prepared.

Owner:BAOSHAN IRON & STEEL CO LTD

Rolling and pickling process of wide zirconium plate

PendingCN113385542AFully heatedImprove performanceWork heating devicesWork cleaning devicesHeating furnaceFluorhydric Acid

The invention discloses a rolling and pickling process of a wide zirconium plate. The rolling and pickling process comprises the steps of plate blank heating, rough rolling, hot coil box machining, finish rolling, coiling, welding, pickling annealing, pickling and coiling. According to the process, the temperatures of the first heating section, the second heating section and the soaking section are controlled in a heating furnace, so that a zirconium plate blank is heated more sufficiently, various properties of the plate blank are more stable in the subsequent rolling process, and meanwhile, the heating time in the furnace is shortened; mandrel-free coiling is conducted on a rough-rolled intermediate blank, then uncoiling is conducted to convert the intermediate blank into an upper surface and a lower surface so as to eliminate a head-tail temperature difference, enable the temperature of the plant blank to be more balanced and improve the thin specification and deformation resistance of a zirconium plate, two-stage pickling is adopted in a pickling process, aurous is added into nitric acid and hydrofluoric acid, the temperature change amplitude is reduced, spray-type pickling is changed, and therefore, the pickling process is more sufficient, oxide skin treatment is more thorough, small pits can be prevented from appearing on the surface of the zirconium plate, and the surface quality of the zirconium plate is improved.

Owner:山东盛阳金属科技股份有限公司

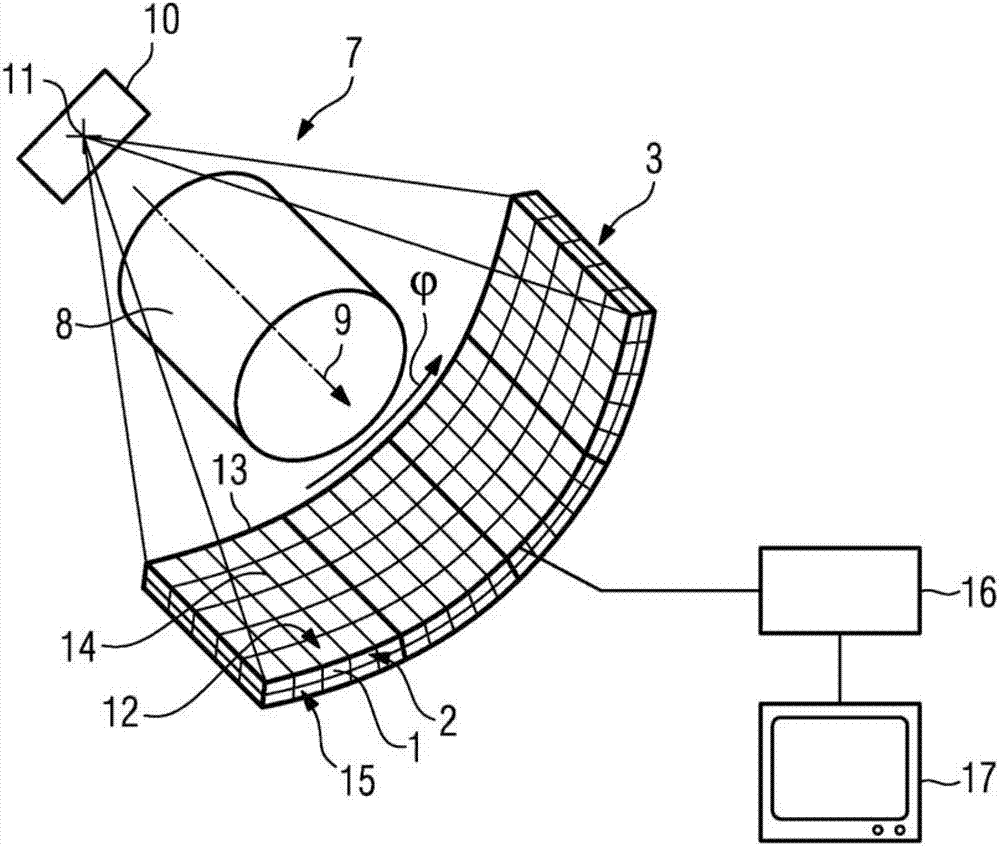

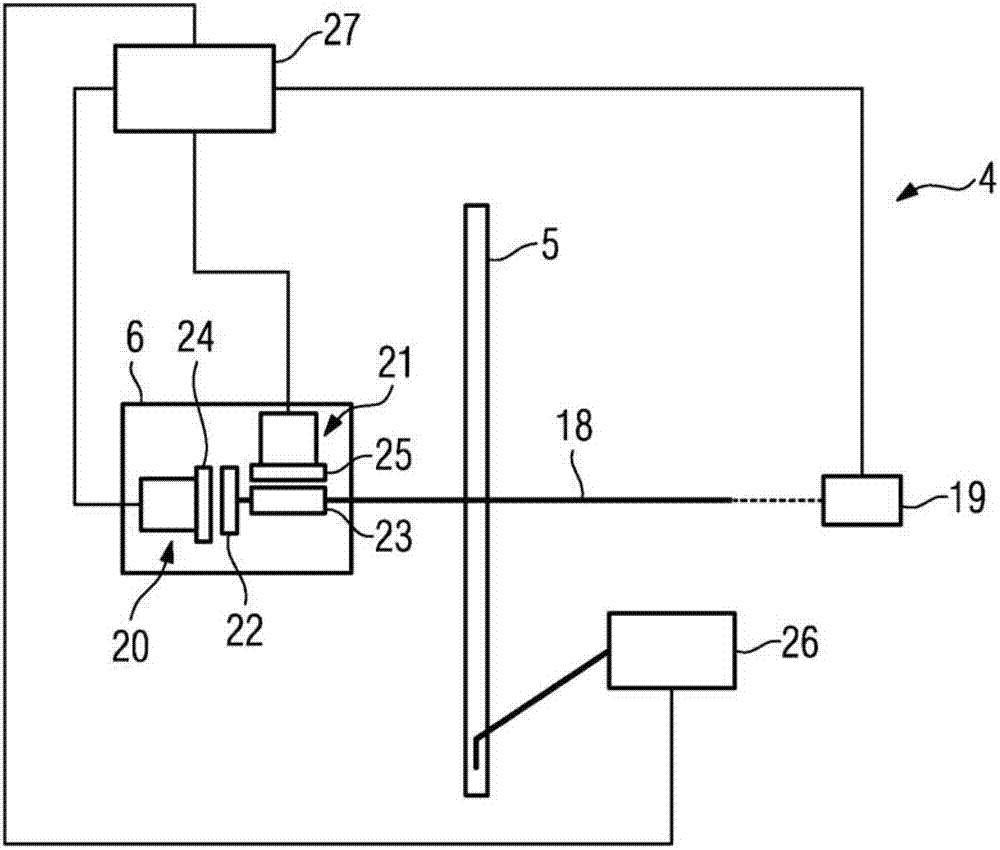

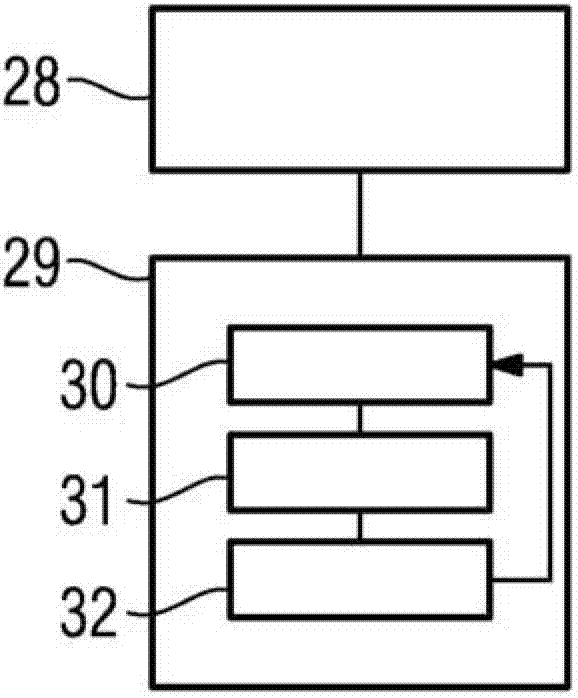

Sawing apparatus and process for producing a scintillator structured into scintillator elements and scintillator having scintillator elements

InactiveCN103097096APromote circulationLow balanceFine working devicesRadiation intensity measurementScintillatorPhysics

The invention relates to a sawing apparatus (4) for producing a scintillator (2), which is structured into scintillator elements (1), for a radiation detector (3). Said sawing apparatus further comprises a rotatably mounted saw blade (5) and an oscillating means (6) for kinematically subjecting the saw blade to oscillation in the ultrasound frequency range. Through the additional oscillation of the saw blade (5), it is possible to achieve better cooling of the saw blade (5) and better removal of sawing waste. This affords the advantage of higher achievable feed rates and longer durability of the saw blade (5). In addition, deep cuts can be made in the scintillator material in a single cutting process, with reduced edge fragmentation and therefore with little scrap. The invention also relates to such a process for producing the scintillator (2) structured into scintillator elements (1), and to a correspondingly structured scintillator (2).

Owner:SIEMENS AG

Warm-rolling process method of titanium alloy thin plate

The invention provides a warm-rolling process method of a titanium alloy thin plate and comprises the following steps: firstly, heating a titanium alloy thin plate with a certain thickness up to 300-400 DEG C; secondly, preheating a roller of a rolling mill to 30-60 DEG C; warm-rolling the heated titanium alloy plate for 1-3 turns, and obtaining the rolled slab; and thirdly, orderly performing the finished product annealing, acid washing and fixed-dimensional shearing, obtaining the titanium alloy thin plate with the thickness of 1.2-3 mm. In the invention, the titanium alloy plate is delivered to the preheated rolling mill after being heated within the temperature scale of lower than the recrystallization temperature, in order to perform the warm-rolling; compared with the cold-rolling process technique, the invention can slow down the hardening rate of the titanium alloy, improve the accumulated deformation rate of the rolling turn, reduce the intermediate heat treatment frequency, shorten the production cycle and improve the working efficiency; meanwhile, the method can effectively prevent edge crack, slag at head and tail parts and micro-crack, and improve the surface quality; the invention is easy to control, simple and convenient to operate and applicable to the industrial production on a large scale.

Owner:WESTERN TITANIUM TECH

Semi-continuous casting process of large-diameter medium-strength heat-resistant magnesium alloy ingot

The invention discloses a semi-continuous casting process of a large-diameter medium-strength heat-resistant magnesium alloy, and the alloy composition (wt.%) aimed at is: Al? 7.5-9.0%, Ag? 0.02-0.80%, Zn? 0.35-0.55%, Mn? 0.05-0.20%, RE? 0.01-0.10%, Ca? 0.001-0.020%, the rest is Mg and non-removable impurity elements. The process includes the steps of melting raw materials at 620-680°C, ventilating and stirring, raising the temperature to 720-740°C for 10-20min, standing at 680-700°C for 1-3h, and casting at low temperature. By adjusting the process parameters of each step, a magnesium alloy ingot with a diameter of Ф330-630mm and a length of ≥1000mm was successfully cast. Large-diameter, high-quality ingots can provide high-quality blanks for the forming of large-scale structural parts, which is of great significance for promoting the wide application of magnesium alloys.

Owner:CENT SOUTH UNIV

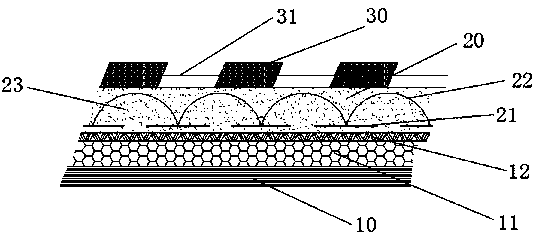

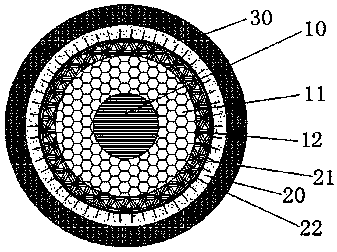

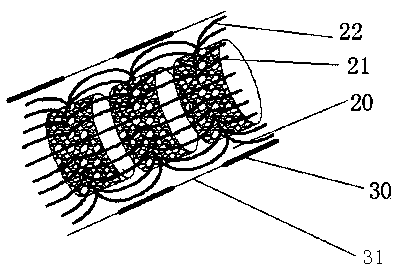

A kind of anti-bending heat dissipation copper-based alloy radio frequency coaxial cable

ActiveCN108336463BAvoid edge crackingImprove distributionWaveguidesCoaxial cableElectrical conductor

The invention discloses a bending-resistant radiating copper-based alloy radio frequency coaxial cable. The structure of the cable from inside to outside is as follows: a center conductor, an electricmedium, an isolation layer, an intermediate layer and an outer jacket; the intermediate layer comprises shielding layers, arc extension structures and a filling layer; the shielding layer is formed by extending and arranging a plurality of hollow cylinders at intervals; the inside of each hollow cylinder is in abut joint the isolation layer, and the adjacent hollow cylinders are connected througha plurality of arc extensions structures; connection points of the arc extension structures and the hollow cylinders are located at the outside of the hollow cylinders, and each extension structure is outward bent in an arc way; and the filling layer is the sliding material. A completely-sealed shielding layer structure is replaced with the intermittent shielding layer structure, and the shielding layers are mutually pulled through elastic extension structures, so that the cable can bend at will when required and can return to an original shape when bending is not required, the cable core canbend by a certain radian, and the edge cracking caused by repeatedly bending the cable edge for a long time is avoided.

Owner:合肥远发信息科技有限责任公司

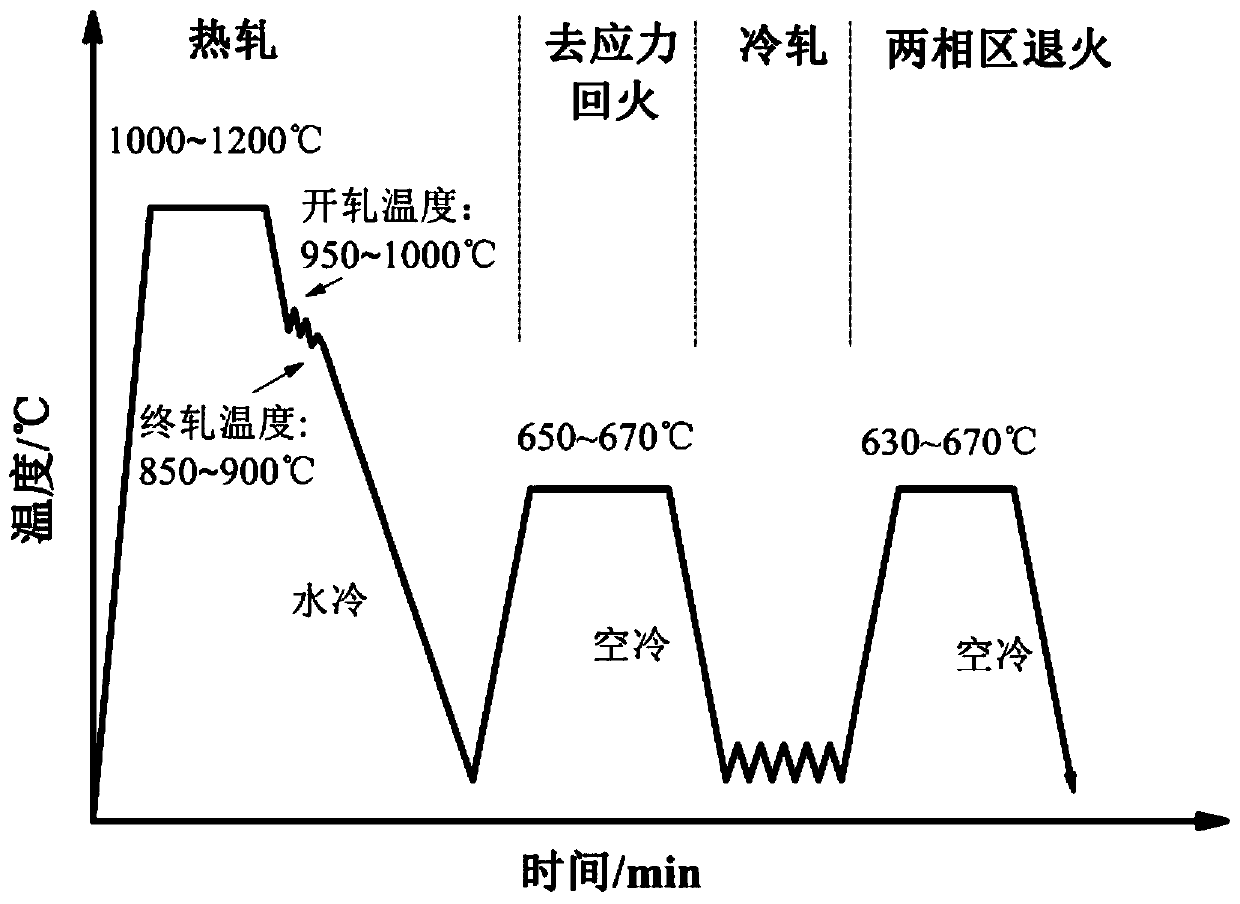

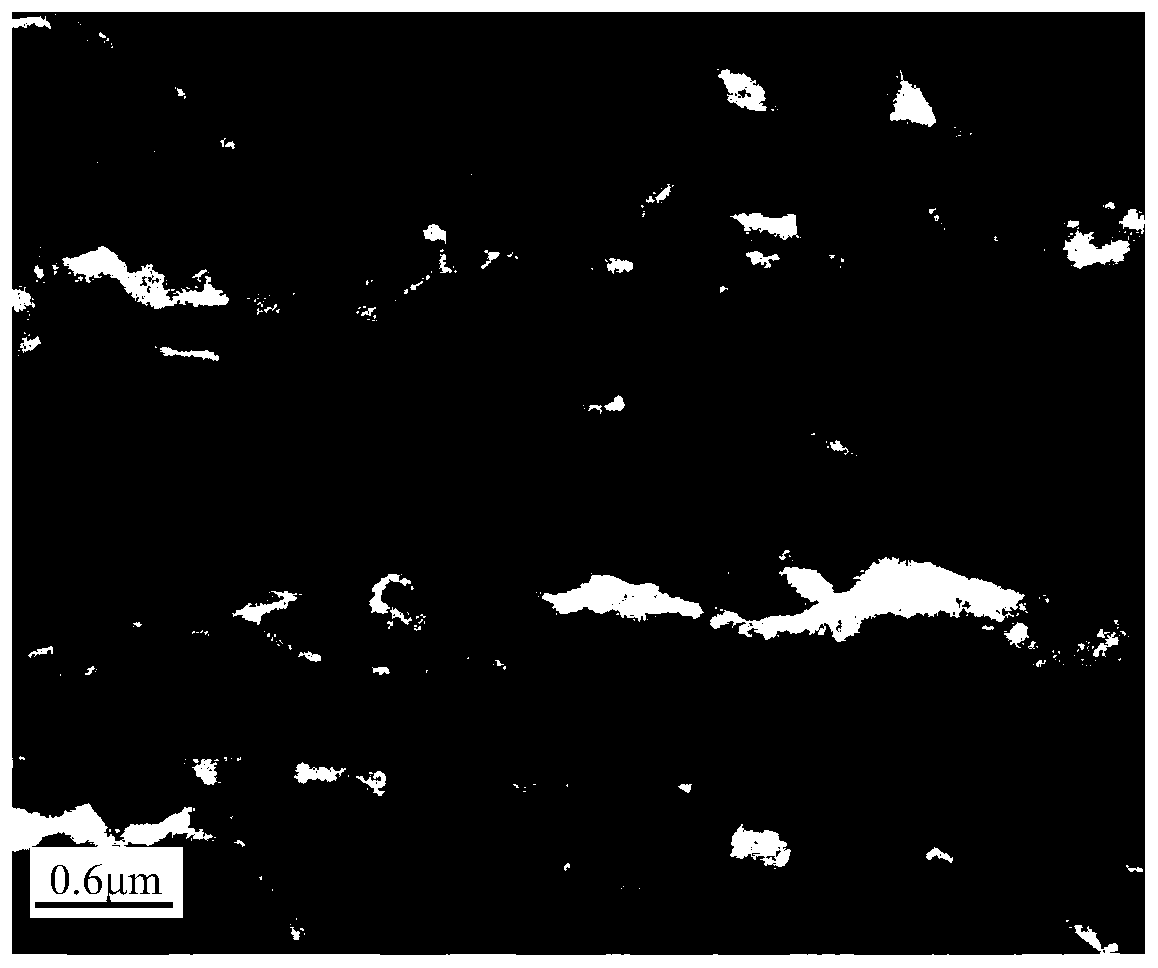

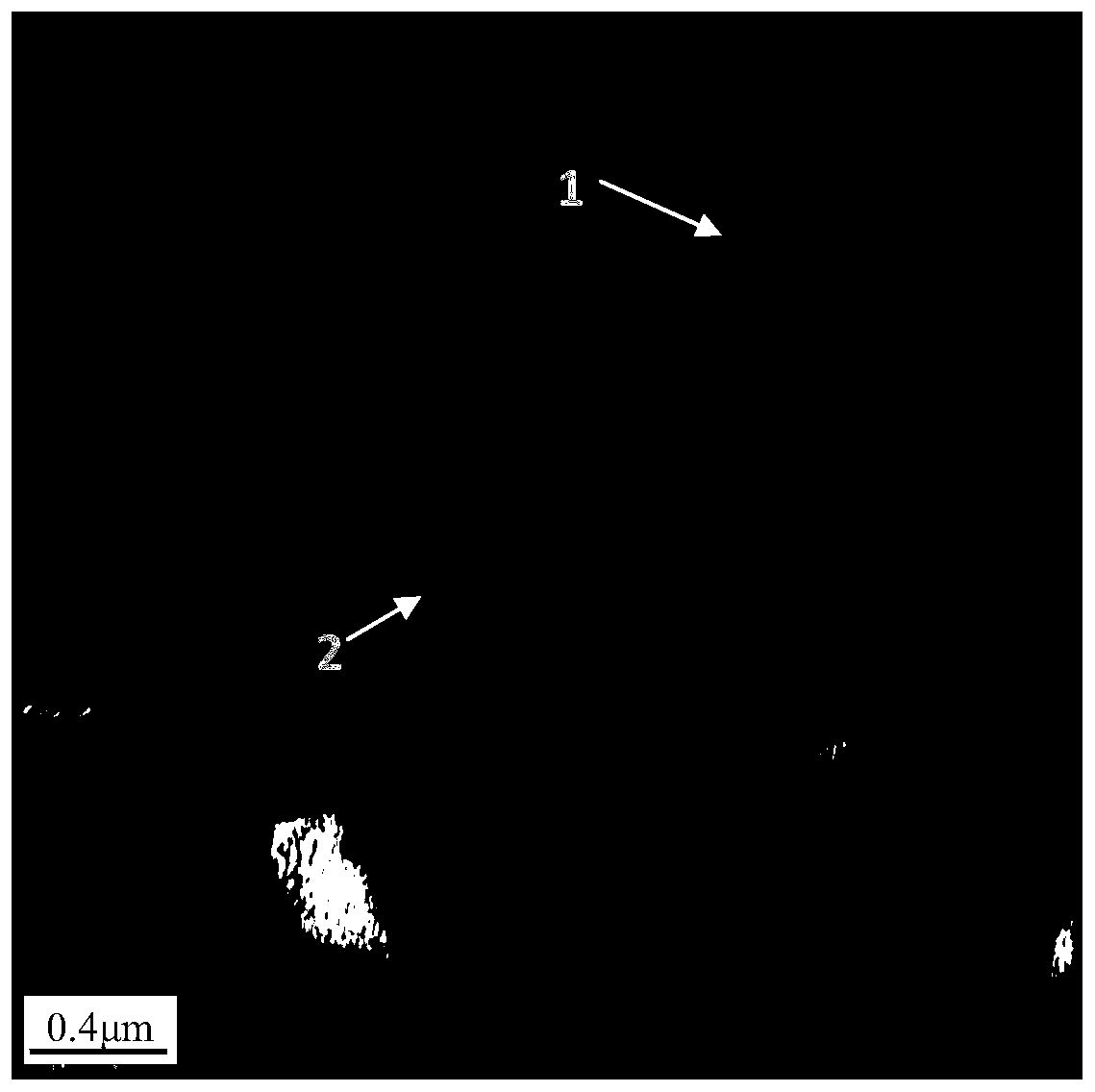

Ultra-low carbon easy-to-weld medium manganese automotive steel with controllable yield ratio and preparation method thereof

ActiveCN107419196BGood welding performanceAvoid hard and brittle phase formationManganeseYield ratio

The invention belongs to the technical field of automobile steel, and specifically relates to an ultra-low carbon, easy-to-weld, medium-manganese automobile steel with a controllable yield-strength ratio and a preparation method thereof. The chemical composition of the steel plate in weight percentage is: C: 0.02~0.06%, Mn: 3.5~8.5%, Si: 0.10~0.50%, S: <0.01%, P: <0.01%, Al: 0.01~0.05%, Cu : 0.02~0.30%, Ni: 0.02~0.35%, Mo: 0.02~0.20%, Cr: 0.02~0.40%, the balance is Fe and other inevitable impurities. Preparation method: After hot rolling, stress relief tempering, cold rolling and two-phase zone annealing, the structure of the steel plate obtained is tempered recrystallized martensite and sub-micron reverse-transformed austenite, with a yield strength of 700 ~850MPa, and the tensile strength is 940~1120MPa.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com